Comparative Study of Conventional and GFRG Building for Affordable Construction

R.Chandru1, R.K.Deva Prakash2, P.Haririthik3, J.Jalal Hussain4, Ms.N.Dhivyasri5

1,2,3,4B.Tech Civil Engineering Student,, Periyar Maniammai Institute of Science and Technology, Vallam, Thanjavur, Tamilnadu, India

Corresponding Author 5Assistant Professor, Periyar Maniammai Institute of Science and Technology, Vallam, Thanjavur, Tamilnadu, India ***

Abstract - In India, Economically Weaker section group of people miss, have no opportunity of owning a home like Stronger section group of people. In this Technology world were using smart building materials for building construction purpose. The cost is reaching sky-high and the current mode of construction adopted Reinforced Cement Concrete (RCC) construction, which is time consuming, costly and not environmentally friendly calls for the use of smart construction materials. One such material Glass Fiber Reinforced Gypsum (GFRG) Panels is adopted. This material is manufactured in a close environment and perform better when compared to RCC in many factors denotes which method is more suitable for today's changing world . The study consisted of comparison of Drawings using AUTO CAD, Exterior design using SKETCH UP, Load analysis using STADD PRO , Estimation using MS EXCEL , Scheduling using MS PROJECT between the conventional RCC construction and GFRG construction. It requires innovative, energy efficient, strong and durable in fast method construction at economical cost.

Key Words: Reinforced Cement Concrete, Glass Fiber Reinforced Gypsum, Drawings, AUTO CAD, Design, SKETCH UP, Analysis,STAADPRO,Estimation,MSExcel,Scheduling,MSProject.

1.INTRODUCTION

Primaryneedofhumanbeingintoday’sworldisfood,clothingandshelter.Houseconstructionisadreamforlow-income peopleinIndia.Whetherheisafarmer,labourorprivateemployee,costofconstructionishighbecauseofhighwagesandhigh materialcost.Apoormanhastospendhisentirelifeinconstructionofahouse.Low-costhousingisreasonableforlow-income owners,iftheycaninvest30%oftheirhouseholdincome.Indiaasadevelopingcountry,has20%ofhigh-incomepopulation thatcanaffordahouseHigh-andmiddle-incomepeopletakeovermostofthelowincomehousing.Thereisanecessityofcostefficientconstructiontechnologyandconstructionmaterials.Alowcosthousingdoesn’tmeantosacrificethestrengthorbuild with operational materials but it means effective use of local materials and techniques that are durable and require less maintenance.Low-costmaterialreducesthecostbyusingalternativetechniques.InIndia,thereisahugerequirementfor buildingmaterialsduetotheexistinghousingshortagemainlyinurbanIndiaandtilldate,ittakesalifetimeworthofsavingsto buyahouse.Toovercomethisproblem,Indianeedsinnovative,highefficientbuildingmaterialsforstronganddurablehousing atanaffordablecost.GFRGPanelprovidesfastconstructionandprovidesenvironmentalprotection.Alotofeffortshadbeen made earlier by the industry experts to find an alternative method to existing construction technology to make it more affordableandinnovative.GlassFibreReinforcedGypsum(GFRG)isoneofthesuchtechnologiesintheconstructionfieldthat couldreducetheconstructioncost.andconstructionperiod.InthisprojectwearecomparingGFRGbuildingwithconventional RCCbuilding.WedesignahouseplanusingAutoCAD,ExteriordesignusingSketchupSoftware,analysethebuildingusingstaad proforbothRCCandGFRGbuilding.ThenwecomparetheresultsofRCCandGFRGBuildingandconcludewhichisbest.

2.LITERATURE REVIEW

Pranay Thergaonkar , Mohit Nagpal et al. (2018) ThereisarapidincreaseintherequirementofbuildingmaterialsinIndia duetotheexistingconditionoftransformationfromtemporaryhousingtoapermanenthousingcausingshortageofhousing material.Constructionindustrywasstillusingtraditionalmethods,techniquesandconventionaltechnologies.Low-costand affordablehousingisabetterwaytoprovidethesheltertothelowermiddleclassandpoorfamilieswhichcanbereached throughtheuseofpropertechniques.Toachieveeffectiveandaffordableconstruction,amaterialknownasGFRG(Glassfiber reinforcedgypsum)hasbeenstudied.Glassfiberreinforcedgypsum(GFRG)wallpanelconsistofgypsuminitsplasterform andglassfibreswhicharebondedtogether.Thispanelshavehollowcavityfrominsideandsocanbeusedasloadbearing walls.Thehollowcavityinsidethewallsisfilledwithreinforcedconcretebasedontheneeds.Thereisvariousothermaterial whichcanbeusedforaffordablehousingbutinthisstudythemainfocusiskeptonGFRG.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1137

Pankaj Kumar (2021) There is a substantial growing demand for housing in India as thepopulation increase rate is skyrocketing. More and more people are shifting from rural to urban areas day by day, making urban areas denser. The MinistryofRuralDevelopmentassessedthatIndia'srustichousinglackremainsat44milliondwellingunits.Toaddressthe difficulties,Indiarequiresinnovative,modernenergy-effectiveconstructionmaterialsforareliable,quick,andtoughhousing strategyfordevelopmentatamoderateexpense.Itislikewisesignificantthathousingstructuresarecatastrophesimpervious tosecureindividuals'livesandproperties.OnestrategytoaccomplishthatistoutilizeGlassFiberReinforcedGypsum(GFRG) panels.Theyservethepurposeoffastconstructionandbecost-efficient,earthquake-resistant,bestsuitableforthefinancially Indianbackwardclassofpeopleandinthecountry'searthquake-proneregionslikeGujarat.Thephosphogypsum'seffective disposalisachievedthroughtheGlassFiberReinforcedGypsum(GFRG)panel,alsoknownasRapidwall.Thesecanbeusedas load-bearingaswellasnon-loadbearingstructures.TouseGFRGinloadbearingbuildings,M20gradeconcreteisusedasa fillingmaterialtoovercomethehurdlesprovidedbygravityandotherfactors.M20gradeconcreteisusedinthesepanelsto satisfytheminimumrequirementsmentionedinIS456:2000.

Salini S, D. Vimal et al. (2020) Eventhoughtheconstructionindustryisoneoftheboomingindustriesintheworldwhichis measuredasasignofgrowthanddevelopment,oneofthemajorsetbacksisthetimeconsumptioninvolvedinoperationand progressofthisindustry.Manytechniquesandmethodologiesareadoptedtoovercomethathindrance,oneofamongthatis GFRGpanels.GFRGpanelsalsoknownasrapidwall.Thistechnologyiswidelyusedinconstructionofwalls,roofandfloorslabs in with or without in combination with concrete. This project is mainly consisted the study of Comparison between the conventionalRCbuildingconstructiontechniqueandGFRGConstruction.TheanalysisofthestructuresarecarriedoutinETabssoftware.Fromtheresultsofanalysisshearforce,storydrift,storydisplacementofthethreestructuresiscompared andresultsarerepresentedgraphicallytostudytheirperformance.

Snehal Ashok Salvi, Janhavi Deshpande, Vishal Jadhav, Nandini Pate, Vaishali Kamade, Aniruddha Chavan et al. (2021) ThisresearchpaperisaboutcostingandrateanalysisofGFRGstructureandconventionalstructure.Beinganengineerisour firstprioritycallingforsolutionsthatworkforourcustomers.Thispaperaneffortmadetogiveanideaofhowwecandothat reducingconstructioncostsandreducingconstructiontimeusespredesigntechnology.GFRGconstructiontechnologyalso calledasRapidwallconstruction technologyinIndia.GlassFiberreinforcedwithgypsumpanels,astheyareready-made gypsumbuildingpanelshavecavities Itisusedincommercialbuildings,institutionsandresidentialbuildings.GFRGwallscan beusedaspartofthestructuresuchaswallsandslabs,withoutoutercolumnsandbeamsarerequired.

3.METHODOLOGY

Withreferencetotheliteratures,theplananddesignparametersareidentifiedfromtheliteraturesandexperts’opinion.With thisidentifiedfactorthedataarecollectedforanalyzinganddesignofG+1RCCandGFRGpanelbuildingusingStaddpro, planningusingAutoCADand3-DimensionalviewusingSketchup.FinallycomparingtheresultsofbothGlassFiberReinforced GypsumandReinforcedcementconcrete.Theriskfactorsidentifiedaretobeanalyzedbysuitablequalitativeriskanalysisand aproperframeworkwillbeprovided

Data Collection

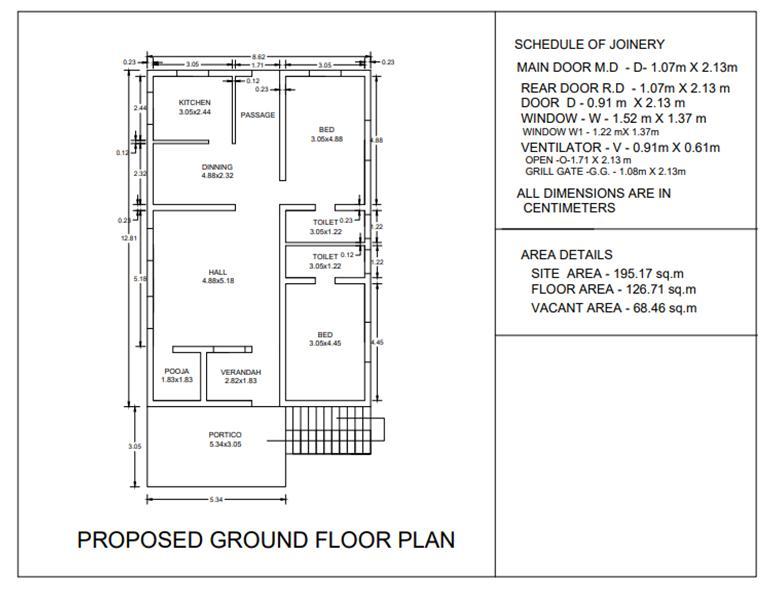

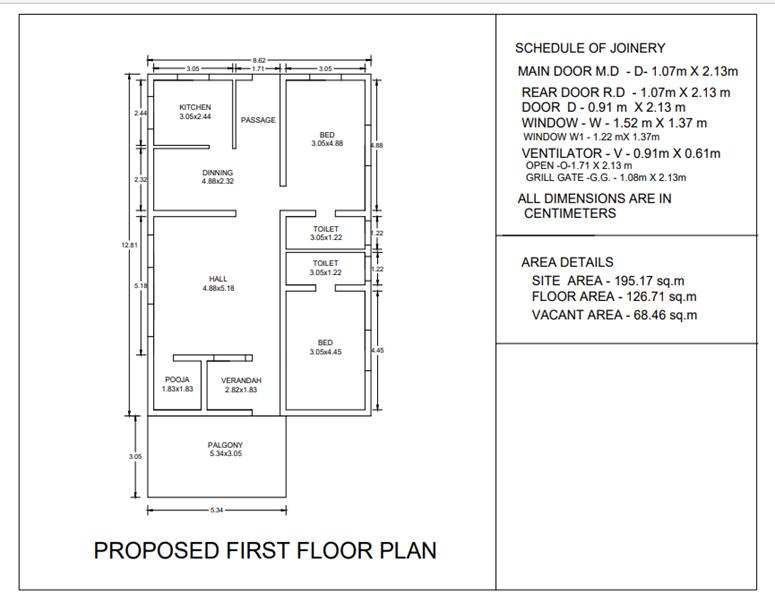

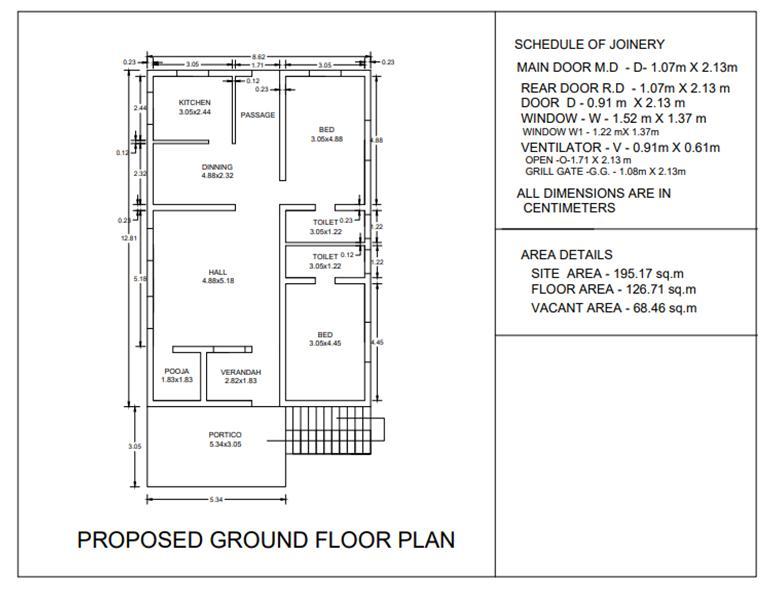

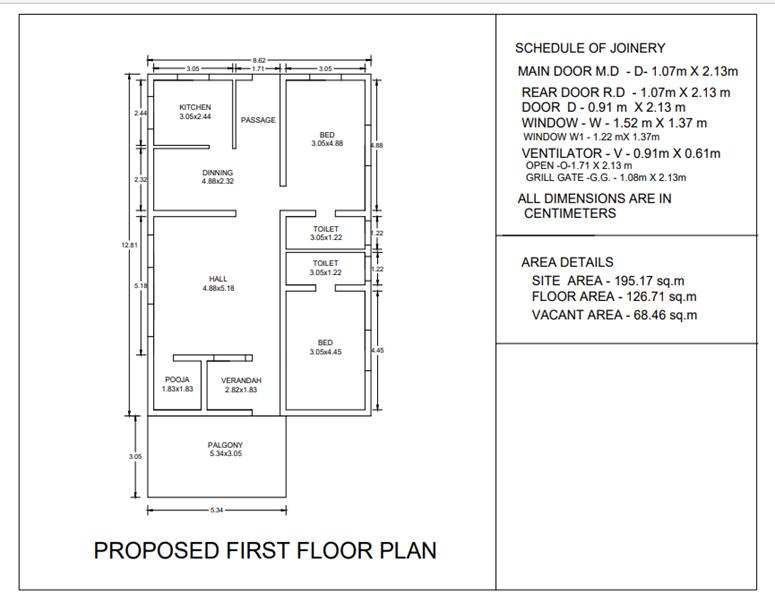

Building plan for both RCC and GFRG Building using AUTO CAD

3D Model using Sketch up

Designing and Analysing for both RCC and GFRG Building using Staad Pro

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1138

Estimation for both RCC and GFRG Building using MS Excel Scheduling For both RCC and GFRG Building using MS Project Conclusion

4.DATA COLLECTION

DatarequiredforConstructionofG+1ResidentialBuildingTheSiteareais195.17sq.m.The

is126.71 sq.m.TheVacantAreais68.46sq.m.ThebuildingisfacingSouthdirection.ThesoiltypeisLoam

5.BUILDING PLAN FOR RCC AND GFRG BUILDING USING AUTOCAD

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1139

ProGroundFloorarea

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1140

6.EXTERIOR DESIGN OF RCC AND GFRG BUILDING USING SKETCH UP

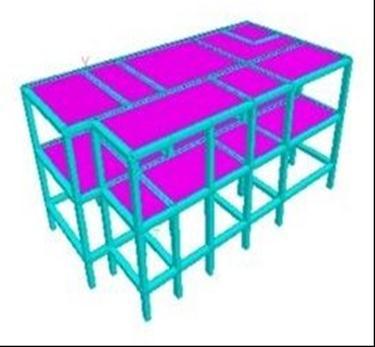

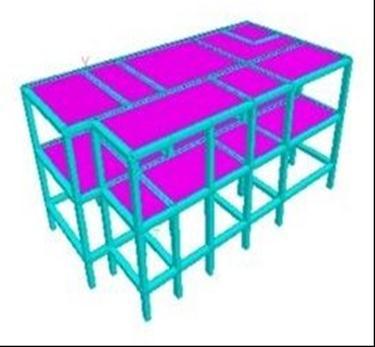

7.ANALYSIS OF RCC AND GFRG BUILDING USING STAAD PRO

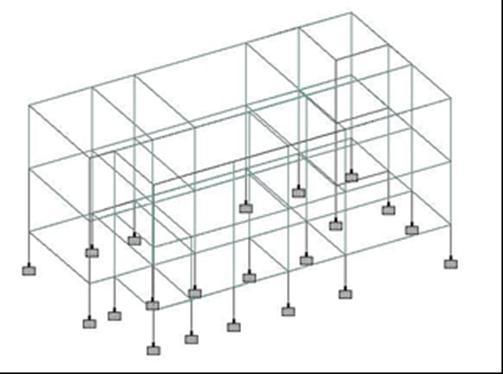

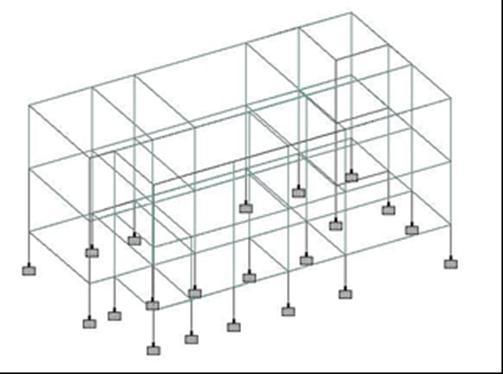

7.1 Analysis of RCC Building using Staad Pro

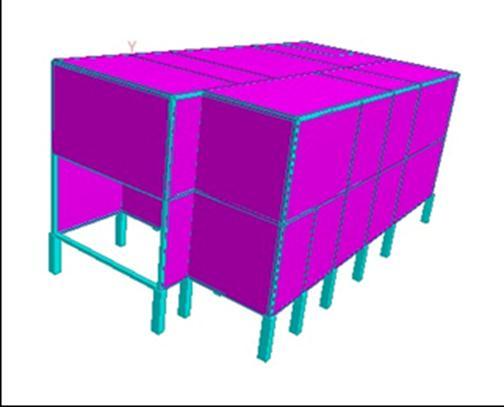

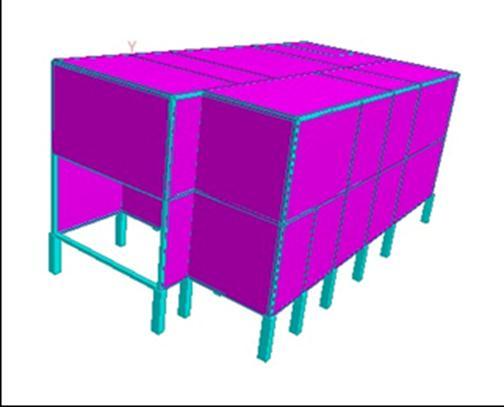

TheaboveAutoCADplanisdrawninstaadProforbothRCCstructureandtheResultsarenotedandcompared.TheModelis createdfirstandloadssuchasDeadload,Liveload,andwindloadisapplied.Thestructureischeckedforerrorandthereportis generated.Bendingmomentdiagram,bendingmoment,shearforceetc.aregenerated.Beamcrosssection,Beamelevation, Columncrosssection,Columnlayout,GroundfloorRoofslabbottomreinforcement,Groundfloorslabgeneralarrangement plan,GroundFloorslabtopreinforcement,Groundfloorslabbottomreinforcement,Topfloorslabgeneralarrangementplan, Topfloorroofslabtopreinforcementdrawingsandtheirdetailscanbedownloaded.

Themodeliscreatedandsupports,columns,beamsandslabsareassigned.

7.2 Assigning Wind Load, Dead Load and Live Load

1) Wind Load

Intheloadsanddefinitions,weshoulddefineandassignwindloads.ClickoncalculateasperASCE-7andenterthevalues asperIS875part-3.Thenassignthevaluesinthebuilding.

Wallload=LengthxHeightxThicknessofwallxUnitweightofGFRGPanel

=1mx3.05mx0.124mx0.433

Floorload=LengthxWidthxThicknessofslabxUnitweightofconcrete

=1mx1mx0.15x25kN/M3

2) Dead Load

Wallload=LengthxHeightxThicknessofwallxUnitweightofbrick

=1mx3mx0.23mx20kN/m3

Floorload=LengthxWidthxThicknessofslabxUnitweightofconcrete

=1mx1mx0.15x25kN/M3

3) Live load

LiveloadsarealsocalledimposedloadsarecalculatesasperIS-875Part-2.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1141

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1142

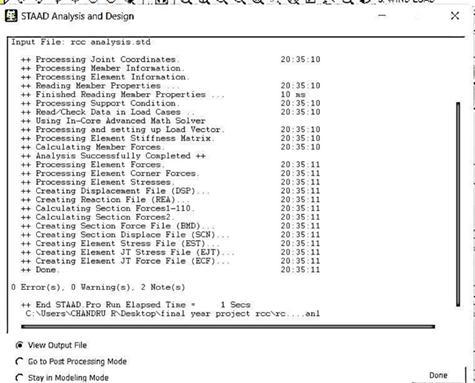

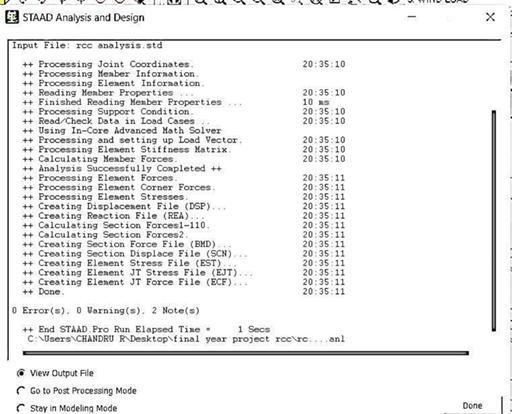

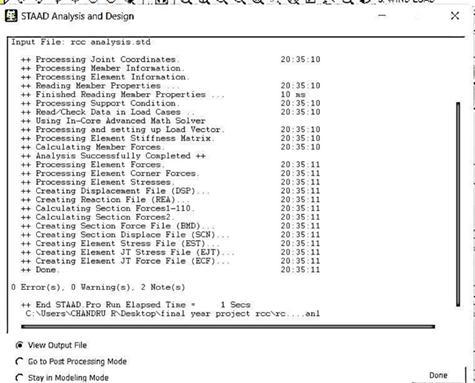

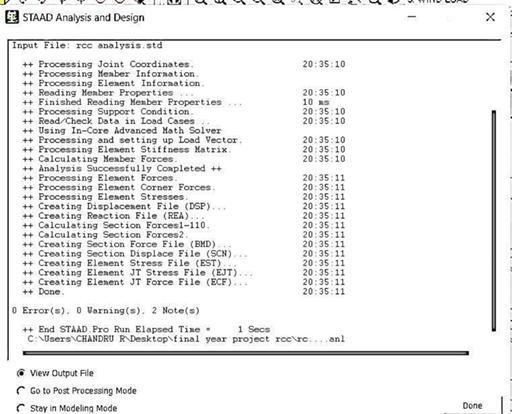

7.3 Run Analysis

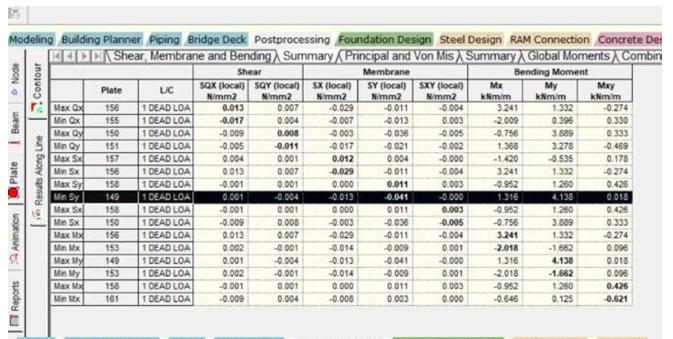

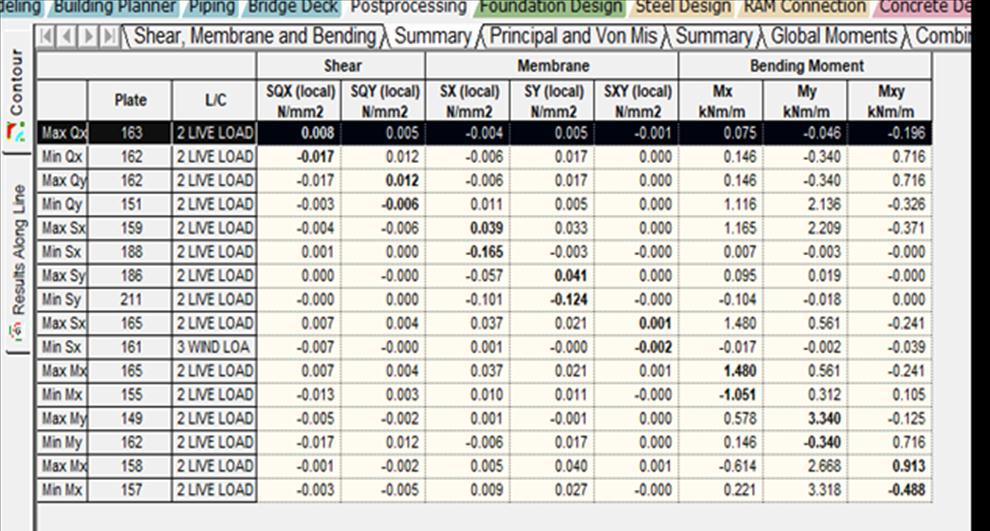

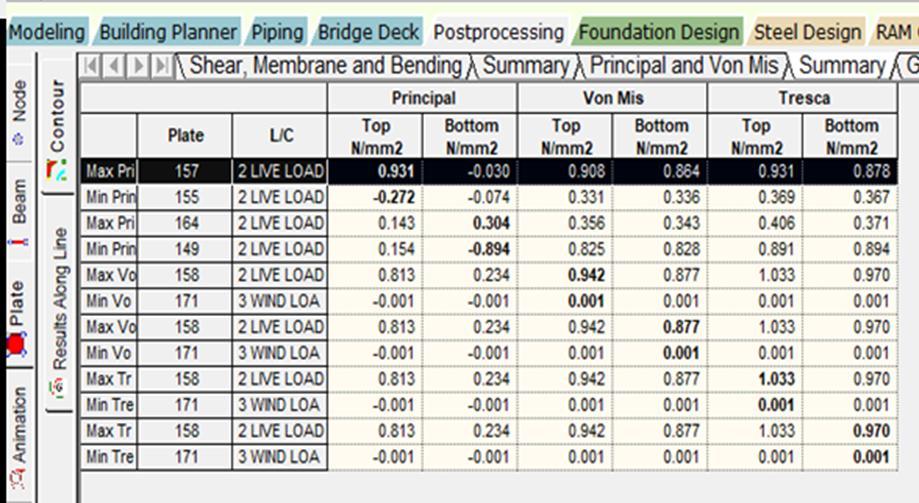

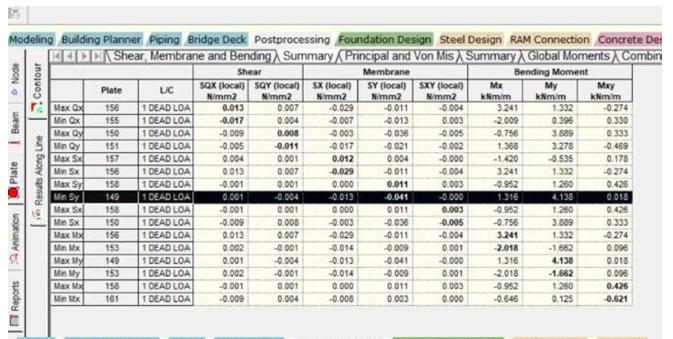

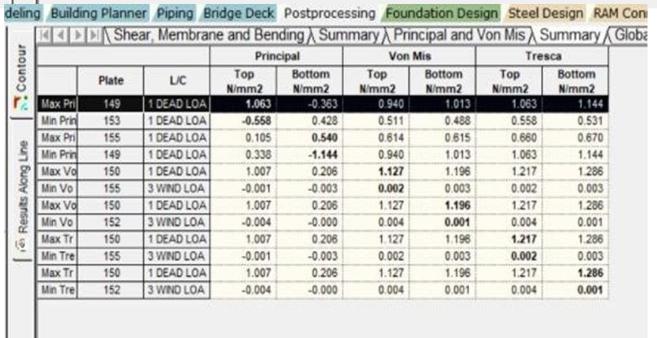

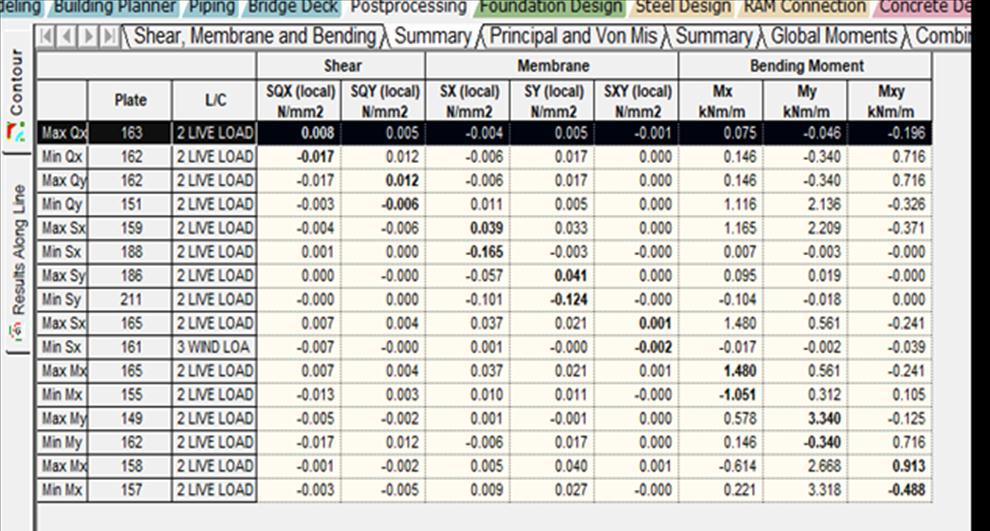

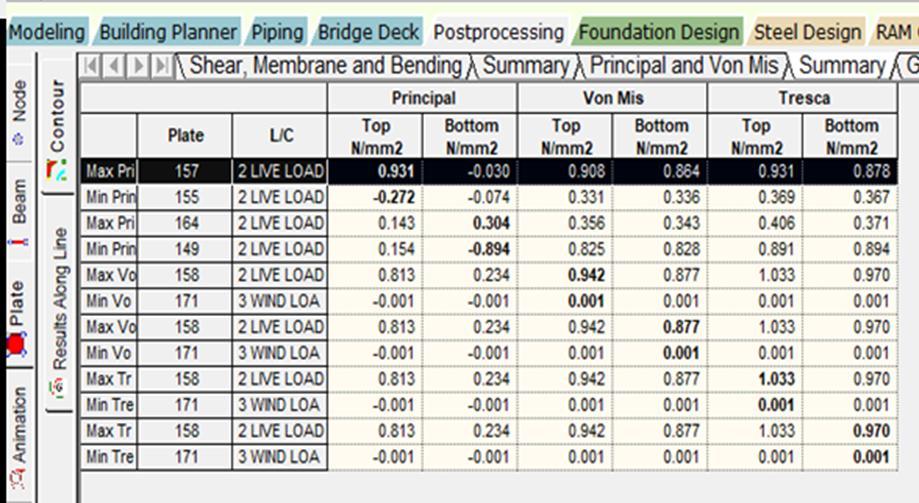

7.4 Shear, Membrane and Bending Summary for RCC

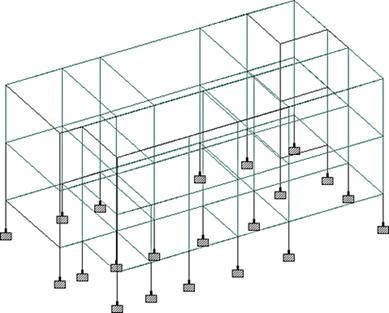

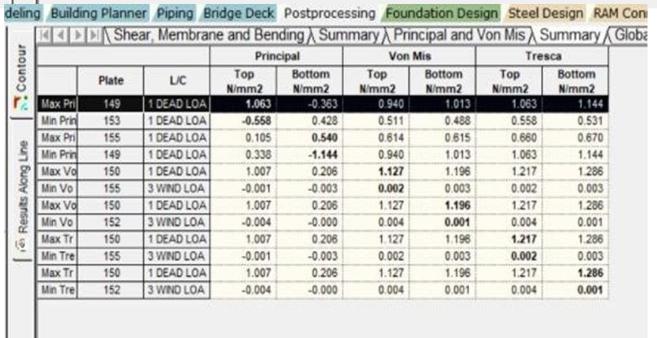

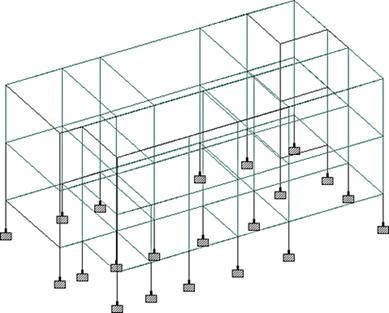

7.5 Analysis of GFRG Building using STAAD PRO

TheaboveAutoCADplanisdrawninstaadProforbothRCCGFRGstructureandtheResultsarenotedandcompared.The ModeliscreatedfirstandloadssuchasDeadload,Liveload,andwindloadisapplied.Thestructureischeckedforerrorand thereportisgenerated.Bendingmomentdiagram,Bendingmoment,shearforceetcaregenerated.Beamcrosssection,Beam elevation,Columncrosssection,Columnlayout,GroundfloorRoofslabbottomreinforcement,Groundfloorslabgeneral arrangementplan,GroundFloorslabtopreinforcement,Groundfloor slabbottomreinforcement,Topfloorslabgeneral arrangementplan,Topfloorroofslabtopreinforcementdrawingsandtheirdetailscanbedownloaded

Themodeliscreatedandsupports,columns,beamsandslabsareassigned.

7.6 Assigning Wind Load, Dead Load and Live Load

1) Wind Load

Intheloadsanddefinitions,weshoulddefineandassignwindloads.ClickoncalculateasperASCE-7andenterthevaluesas perIS875part-3.Thenassignthevaluesinthebuilding.

2) Dead Load

3) Live Load

LiveloadsarealsocalledimposedloadsarecalculatesasperIS-875Part-2.

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1143

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1144

7.7 Run Analysis

7.8 Shear, Membrane and Bending Summary for GFRG

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1145

RESIDENTIAL CONVENTIONAL BUILDING Sl.No Description of Item Of Work Nos L B D Counts Unit Unit Rate Amount (Rs) 1 SUB-STRUCTURE A SiteClearance 125.00 m2 4000 B Excavation 29 2.00 2.00 3.20 371.20 m3 245 90944.00 C Filling&CompactingArea 29 2.00 2.00 2.60 301.60 m3 153 46144.80 D CrushedStoneForPCC 29 2.00 2.00 0.05 5.80 m3 315 1827.00 E C.CBed1:4:8mix 29 2.00 1.60 0.10 9.28 m3 980 9094.40 F PEFilm (0.05THK) 29 2.00 2.00 - 116.00 m2 660 76560.00 G Anti-termite 29 2.00 2.00 - 116.00 m2 425 49300.00 H FormworkforFooting 29 2.00 0.36 - 20.88 m2 180 3758.40 CONCRETE QUANTITY - Upto Plinth Level 2 CONCRETE A FoundationForFooting 29 1.80 1.80 0.36 33.83 m3 6500 219866.40 B Column-ConcreteM25 29 0.23 0.30 4.00 8.00 m3 6500 52026.00 C PlinthBeam -ConcreteM25 52 0.23 0.38 6.00 27.27 m3 6500 177247.20

8.ESTIMATION FOR RCC AND GFRG BUILDING USING MS EXCEL 8.1 Estimation for RCC Building

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1146 D PlinthBeam-ConcreteM25 39 0.23 0.38 5.00 17.04 m3 6500 110779.50 E FlooringP.C.Cin1:4:8mix 1 12.81 8.62 0.15 16.56 m3 6500 107661.65 3 CONCRETE QUANTITY - Plinth Level to Roof Level A Column-ConcreteM25 2 0.23 0.30 15.00 2.07 m3 6500 13455.00 B FloorBeam -ConcreteM25 2 0.23 0.38 26.00 4.54 m3 6500 29541.20 C FloorBeam -ConcreteM25 2 0.23 0.38 20.00 3.50 m3 6500 22724.00 D FloorSlab-ConcreteM25 2 12.81 8.62 0.15 33.13 m3 6500 215323.29 E LintelConcrete 2 0.23 0.23 43.00 4.55 m3 6500 29571.10 F SunShadeConcrete 16 0.75 1.50 0.13 2.25 m3 6500 14625.00 4 BRICK WALL ShortWall 43 0.23 3.50 1.00 34.62 m3 Long Wall 43 0.23 3.50 1.00 34.62 m3 DeductionDoor 12 2.30 1.07 0.23 6.79 m3 DeductionWindow 16 1.52 1.37 0.23 7.66 m3 A TotalVolumeofBrick 54.77 m3 1600 87639.05 B PlasteringAreaInside 193.54/0.23 238.15 m2 500 119074.80 C PlasteringAreaOutside 193.54/0.23 238.15 m2 500 119074.80 D MainDoors 12 1.52 1.37 24.99 m2 1600 39982.08 E AccessDoors 2 0.93 1.33 2.47 m2 1600 3958.08 F Windows 16 1.52 1.37 33.32 m3 1600 53309.44 5 FLOORING A Marbles 2 12.81 8.62 - 220.84 m2 550 121464.42 B WATER PROOF : SSAP Waterproof System 2 12.81 8.62 - 220.84 m2 60 13250.66 C Ceilingplastering 2 12.81 8.62 - 220.84 m2 500 110422.20 6 STAIR CASE A Waistslab 2 3.00 4.00 0.13 24.00 m3 B Landing1 2 3.00 4.00 0.13 24.00 m3 C Landing2 2 3.00 2.00 0.13 12.00 m3 D Total 60.00 m3 6500 390000.00

REINFORCEMENT A SlabReinforement10Dia - - - - 4420.00 kg 70 309400.00

7

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1147 B Beam ,waist ,Sunshade & Lintel Reinforement6,12&20Dia - - - - 2140.00 kg 70 149800.00 C ColumnReinforement6&20Dia - - - - 4500.00 kg 70 315000.00 D FootingReinforement16Dia - - - - 2100.00 kg 70 147000.00 8 Painting A Innerwall-painting 193.54/0.23 238.15 m2 60 14288.98 B Outerwall-painting 841.47/0.23 1035.43 m2 60 62125.98 C Painting forJoineries 8 2.50 1.00 20.00 m2 60 1200.00 D Painting forGrillwork 3 1.20 0.90 3.24 m3 60 194.40 TOTAL COST 3331633.83 9 Elevationwork& GrillWork 2% 66632.68 10 Electricalwork 10% 333163.38 11 Plumbingwork 15% 499745.07 12 Supervisorcharge 1% 33316.34 13 Landscaping 4% 133265.35 4397756.66 SUPERVISIONSCHARGE 15%. 659663.50 TOTAL COST FOR CONSTRUCTION Rs. 5057420.15 8.2 Estimation for GFRG Building RESIDENTIAL GFRG PANEL BUILDING Sl.No Description of Item Of Work Nos L B D Counts Unit Unit Rate Amount (Rs) 1 SUB-STRUCTURE A SiteClearance 125.00 m2 4000 B Excavation 29 1.80 1.80 3.20 300.67 m3 245 73664.64 C Filling&CompactingArea 29 1.80 1.80 2.60 244.30 m3 153 37377.29 D CrushedStoneForPCC 29 1.80 1.80 0.05 4.70 m3 315 1479.87 E C.CBed1:4:8mix 29 1.80 1.80 0.10 9.40 m3 980 9208.08 F PEFilm (0.05THK) 29 1.80 1.80 - 93.96 m2 660 62013.60

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1148 G Anti-termite 29 1.80 1.80 - 93.96 m2 425 39933.00 H FormworkforFooting 29 1.80 0.36 - 18.79 m2 180 3382.56 CONCRETE QUANTITY - Upto Plinth Level 2 CONCRETE A FoundationForFooting 29 1.60 1.60 0.36 26.73 m3 6500 173721.60 B Column-ConcreteM25 29 0.23 0.30 4.00 8.00 m3 6500 52026.00 C PlinthBeam -ConcreteM25 52 0.23 0.38 6.00 27.27 m3 6500 177247.20 D PlinthBeam-ConcreteM25 39 0.23 0.38 5.00 17.04 m3 6500 110779.50 E FlooringP.C.Cin1:4:8mix 1 12.81 8.62 0.15 16.56 m3 6500 107661.65 3 CONCRETE QUANTITY - Plinth Level to Roof Level A Column-ConcreteM25 2 0.23 0.30 15.00 2.07 m3 6500 13455.00 B GFRGPanelSlab 2 12.81 8.62 - 220.84 m2 800 176675.52 C LintelConcrete 2 0.23 0.23 43.00 4.55 m3 6500 29571.10 D SunShadeConcrete 16 0.75 1.50 0.13 2.25 m3 6500 14625.00 4 GFRG PANEL WALLS GFRGPanelWalls 18 12.00 0.12 3.00 77.76 m2 DeductionDoor 12 2.30 1.07 0.23 29.53 m2 DeductionWindow 16 1.52 1.37 0.23 33.32 m2 A Totalarea ofGFRGPanel 14.91 m2 1120 16698.75 B MainDoors 12 1.52 1.37 24.99 m2 1600 39982.08 C AccessDoors 2 0.93 1.33 2.47 m2 1600 3958.08 D Windows 16 1.52 1.37 33.32 m3 1600 53309.44 5 FLOORING A Marbles 2 12.81 8.62 - 220.84 m2 550 121464.42 B WATER PROOF : SSAP Waterproof System 2 12.81 8.62 - 220.84 m2 60 13250.66 C Ceilingplastering 2 12.81 8.62 - 220.84 m2 250 55211.10 6 STAIR CASE A Waistslab 2 3.00 4.00 0.13 24.00 m3 B Landing1 2 3.00 4.00 0.13 24.00 m3 C Landing2 2 3.00 2.00 0.13 12.00 m3 D Total 60.00 m3 6500 390000.00 7 REINFORCEMENT

9.SCHEDULING FOR RCC AND GFRG BUILDING USING MS PROJECT

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1149 A waist,Sunshade&LintelReinforement 6,12&20Dia - - - - 640.00 kg 70 44800.00 B ColumnReinforement6&20Dia - - - - 2640.00 kg 70 184800.00 C FootingReinforement16Dia - - - - 1800.00 kg 70 126000.00 8 Painting A Painting forJoineries 8 2.50 1.00 20.00 m2 60 1200.00 B Painting forGrillwork 3 1.20 0.90 3.24 m3 60 194.40 TOTAL COST 2137690.54 9 Elevationwork& GrillWork 2% 42753.81 10 Electricalwork 10% 213769.05 11 Plumbingwork 15% 320653.58 12 Supervisorcharge 1% 21376.91 13 Landscaping 4% 85507.62 2821751.51 SUPERVISIONSCHARGE 15%. 423262.73 TOTAL COST FOR CONSTRUCTION Rs. 3245014.24

9.1 Scheduling for RCC Building TaskName Duration Start Finish RCC Scheduling 150.56 days September 1, 2022 8:00 AM March 17, 2023 11:00 AM SiteClearance 1day September1,20228:00AMSeptember2,20229:00AM Marking 1day September2,20229:00AMSeptember 3, 2022 10:00 AM Excavation 1day September 3, 2022 10:00 AM September 5, 2022 11:00 AM PCC1:5:10 1day September 5, 2022 11:00 AM September 6, 2022 12:00 PM MatFixing 2days September6,20228:00AMSeptember 8, 2022 10:00 AM ColumnStartup 2days September 8, 2022 10:00 AM September 10, 2022 12:00 PM

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1150 Shutteringforfooting 1day September 10, 2022 1:00 PM September 12, 2022 2:00 PM Concretingforfooting 1day September 12, 2022 2:00 PM September 13, 2022 3:00 PM Curing 15days September 13, 2022 3:00 PM October3,20222:00PM Backfilling 1day September 13, 2022 3:00 PM September 14, 2022 4:00 PM CentringworkinPlinthbeam 3days September 14, 2022 4:00 PM September 19, 2022 10:00 AM ShutteringworkinPlinthbeam 8days September 19, 2022 10:00 AM September 29, 2022 10:00 AM ConcretinginPlinthBeam 1day September 29, 2022 10:00 AM September 30, 2022 11:00 AM Curing 15days September 30, 2022 11:00 AM October20,202210:00AM FlooringP.C.Cin1:4:8mix 4days September 30, 2022 11:00 AM October5,20224:00PM CentringworkincolumnuptoFirstfloorroof 2days December20,20228:00AMDecember 22, 2022 10:00 AM ColumnCastinguptoFirstfloorRoof 1day December 22, 2022 10:00 AM December 23, 2022 11:00 AM Curing 15days December 23, 2022 11:00 AM January12,202310:00AM BrickworkuptoFFRoof 10days December 23, 2022 11:00 AM January5,20232:00PM Curing 15days January5,20232:00PM January25,202312:00PM CentringworkinColumnuptoGFRoof 4days October5,20224:00PM October11,202211:00AM ColumnCastinguptoGFRoof 12days October11,202211:00AMOctober26,20224:00PM Curing 15days October26,20224:00PM November15,20223:00PM BrickworkuptoGFRoof 10days October26,20224:00PM November9,20229:00AM Curing 15days November9,20229:00AMNovember28,20225:00PM GroundFloorBeam,SlabFormworkandCasting 20days November9,20229:00AMDecember5,20222:00PM LintelandSunshadeSlabformworkCasting 1day December5,20222:00PM December6,20223:00PM Curing 15days December6,20223:00PM December26,20222:00PM CentringworkinFirstfloorroof 2days December6,20223:00PM December8,20225:00PM CastingandfillingofconcreteinGFRoof 1day December9,20228:00AM December10,20229:00AM Curing 15days December10,20229:00AMDecember29,20225:00PM ElectricalandPlumbingworkforFirstFloor 7days December10,20229:00AMDecember19,20225:00PM

9.2 Scheduling for GFRG Building

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 FirstFloorLintelandSunshadeSlabFormworkand Casting 1day January5,20232:00PM January6,20233:00PM Curing 15days January6,20233:00PM January26,20232:00PM CentringworkinFirstfloorroof 2days January6,20233:00PM January9,20235:00PM CastingandfillingofconcreteinFirstFloorRoof 1day January10,20238:00AM January11,20239:00AM Curing 15days January11,20239:00AM January30,20235:00PM FlooringP.C.Cin1:4:8mix 4days January11,20239:00AM January16,20232:00PM JoineryFixing&GrillworkforGF&FF 10days January16,20232:00PM January28,20234:00PM Plastering 7days January28,20234:00PM February7,20233:00PM Painting 15days February7,20233:00PM February27,20232:00PM Elevation 7days February27,20232:00PM March8,202312:00PM Handingoverofsite 7days March8,20231:00PM March17,202311:00AM

© 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1151 TaskName Duration Start Finish GFRG SCHEDULING 101 days September 1, 2022 8:00 AM December 27, 2022 5:00 PM SiteClearance 1day September1,20228:00AM September1,20225:00PM Marking 1day September2,20228:00AM September2,20225:00PM Excavation 4days September3,20228:00AM September7,20225:00PM PCC1:5:10 1day September8,20228:00AM September8,20225:00PM MatFixing 2days September9,20228:00AM September10,20225:00PM ColumnStartup 2days September12,20228:00AM September13,20225:00PM ShutteringforFooting 1day September14,20228:00AM September14,20225:00PM ConcretingforFooting 1day September15,20228:00AM September15,20225:00PM Curing 15days September16,20228:00AM October3,20225:00PM Backfilling 1day September16,20228:00AM September16,20225:00PM CentringworkinPlinthbeam 3days September17,20228:00AM September20,20225:00PM ShutteringworkinPlinthBeam 8days September21,20228:00AM September29,20225:00PM ConcretinginPlinthBeam 1day September30,20228:00AM September30,20225:00PM Curing 15days September30,20228:00AM October17,20225:00PM FillingofConcreteinGFRGPanel 2days October18,20228:00AM October19,20225:00PM LintelandSunshadeSlabformworkCasting 1day October20,20228:00AM October20,20225:00PM FlooringP.C.Cin1:4:8mix 4days October21,20228:00AM October25,20225:00PM GFRGPanelFixinginGroundFloorRoof 2days October26,20228:00AM October27,20225:00PM

10.CONCLUSION

ThisstudyinvestigatedtheimportanceofGlassFiberReinforcedGypsum(GFRG)structurehasmuchbetterthanReinforced CementConcrete(RCC)structures.Thepanelshavegoodlifespanassameasconcretestructure.Nowadaystheuseofpanelsfor constructioninvolvesgradually,butstillmostofthepeoplearenotawareinthistypeofconstructionpracticeforresidential buildingfromthisprojectwehavecreatedsomeawarenessabouttheconstructionofpanelsystems.Initialstageofprojectis Datahascollectedinthevariousaspectsofplanning,designingandanalyzingparameterthesecondstageofthestudyispreparing ofG+1buildingplanusingAUTOCADD,DesignandanalysisusingSTADDPROand3DmodellingusingSKETCHUP,Estimation using MS EXCEL, Scheduling using MS PROJECT, resourceallocationandsoon.Themainmottoofthis projectistocreate awarenessamongpeopleabouttheconstructionataffordableprice.

REFERENCES

[1]. SaliniS,D.Vimal.,May-2020,“AComparativeanalysisontheperformanceofGFRG(Framed&Non-Framed)building overRCbuilding,”InternationalJournalofScientific&EngineeringResearch,Volume11,Issue5,May-2020

[2]. AnnaRebeccaPrasad,AnueMarryMathew,2015,“SeismicAnalysisandCostEstimationofGFRPandRCCAuditorium BuildingusingETABS,”InternationalJournalofScienceandResearch(IJSR)ISSN(Online):2319-7064IndexCopernicus Value(2015):78.96|ImpactFactor(2015):6.391

[3]. Pranay Thergaonkar, Mohit Nagpal, February – 2018, “Towards Achieving Economical, Efficient and Environment FriendlyHousingbyGFRG,”InternationalJournalofInnovativeScienceandResearchTechnologyISSNNo:-2456–2165. Volume3,Issue2,February–2018

[4]. ShivprasadR.,DeepakS.Vyavhare,VaibhavA.Karande,ShivramA.Shinde,RahulB.Kesarkar,Apr2022,“AnAttemptof GreenBuildingConstructionUsingGFRGPanels,”InternationalResearchJournalofEngineeringandTechnology(IRJET) e-ISSN:2395-0056Volume:09Issue:04

[5]. PhilipCherian,ShintoPaul,S.R.GouriKrishna,DevdasMenon,AMeherPrasad,June2017,“MassHousingUsingGFRG Panels: A Sustainable, Rapid and Affordable Solution,” J. Inst. Eng. India Ser. A (June 2017) 98(1-2):95–100 DOI 10.1007/s40030-017-0200-8

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1152 CentringworkinGroundFloorRoof 2days October28,20228:00AM October29,20225:00PM FillingofConcreteinGroundFloorRoof 1day October31,20228:00AM October31,20225:00PM FixingofGFRGPanelsinFirstFloor 2days November1,20228:00AM November2,20225:00PM FillingofConcreteinGFRGPanel 2days November3,20228:00AM November4,20225:00PM FlooringP.C.Cin1:4:8mix 4days November5,20228:00AM November9,20225:00PM LintelandSunshadeSlabformworkCasting 1day November5,20228:00AM November5,20225:00PM GFRGPanelFixinginFirstFloorRoof 2days November7,20228:00AM November8,20225:00PM CentringworkinFirstFloorRoof 2days November9,20228:00AM November10,20225:00PM FillingofConcreteinFirstFloorRoof 1day November11,20228:00AM November11,20225:00PM ElectricalandPlumbingWorkforGFandFF7days November12,20228:00AM November19,20225:00PM JoineryFixingandGrillworkforGFandFF 10days November12,20228:00AM November23,20225:00PM Painting 15days November24,20228:00AM December10,20225:00PM Elevation 7days December12,20228:00AM December19,20225:00PM HandingoverofSite 7days December20,20228:00AM December27,20225:00PM

[6]. Pankaj Kumar, 2021, “Experimental Study of Glass Fiber Reinforced Gypsum (GFRG) Panels filled with alternate ConcreteMixusingFlyAsh,”InternationalJournalofEngineeringAppliedSciencesandTechnology,2021,Vol.5,Issue 11,ISSNNo.2455-2143

[7]. ArunDeshwali,Dr.RaghvendraSingh,2017,“SeismicEvaluationofGFRGPanelandBrickInfillStep-BackSet-Backand Step-BackBuilding,”IJSRSET,Volume3, Issue8,PrintISSN:2395-1990.OnlineISSN:2394-4099

[8]. ZhengyongLiu,HuiqingYing,2010,“ElasticLateralFeaturesofaNewGlassFiberReinforcedGypsumWall,” World AcademyofScience,EngineeringandTechnologyInternationalJournalofCivilandEnvironmentalEngineeringVol:4, No:3,2010

[9]. HaiderAbdalsadaAbdallah,MohammedIssaAli,PatilLaxmikantDiliprao,2021,“RapidConstructionofHouseUsing Shipping Container and GFRG Panels,” International Journal of Research in Engineering and Science (IJRES) ISSN (Online):2320-9364,ISSN(Print):2320-9356

[10]. IS–456:2000Codeofpracticeforplainandreinforcedconcrete

[11]. GFRG / RAPIDWALL CONSTRUCTION MANUAL Prepared by Structural Engineering Division Department of Civil EngineeringIITMadrasandPublishedbyBuildingMaterials&TechnologyPromotionCouncilMinistryofHousing& UrbanAffairsGovernmentofIndia

[12]. AliHaiderJasvi,D.K.Bera,2015,“SUSTAINABLEUSEOFLOWCOSTBUILDINGMATERIALSINTHERURALINDIA,”

IJRET:InternationalJournalofResearchinEngineeringandTechnologyeISSN:2319-1163,pISSN:2321-7308

[13]. SiddharthVyas,Dr.G.P.Khare,Mr.DushyantKumarSahu,May2018,“Comparative studyandanalysisofGFRGand conventional multistoried building using E-TABS,” International Research Journal of Engineering and Technology (IRJET)e-ISSN:2395-0056,Volume:05,Issue:05,May2018

[14]. DharmasasthaK1,MaiyaMP2,ShivaNagendraSM3,July2018,“PerformanceStudyofThermallyActivatedGlassFibre ReinforcedGypsumRoof,”InternationalHighPerformanceBuildings,Conference,SchoolofMechanicalEngineering,July 2018

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056 Volume: 10 Issue: 04 | Apr 2023 www.irjet.net p-ISSN:2395-0072 © 2023, IRJET | Impact Factor value: 8.226 | ISO 9001:2008 Certified Journal | Page1153