EARTH TUBE HEAT EXCHANGER

Wilson1, Dr. Shobhit Srivastava2

1M.Tech, Production Engineering, Maharishi University of Information Technology, Lucknow, India

2Assistant Professor, Mechanical Engineering Department, Maharishi University of Information Technology, Lucknow, India

Abstract - These days, everyone is worried about the gradually rising cost of power, which is something that we all experience. This is something that we all have in common. Everyone is making a concerted effort, asadirectconsequence of this, to embrace a way of life that is friendlier to the environment. In the context of this hypothetical situation, the Earth Tube Heat Exchanger emerges as the option that offers the greatest number of benefits when compared to the other potential configurations for the installation of the HVAC system. A substantial quantity of electrical power is often required by residential constructions. This is so that the space can be heated and cooled appropriately. We have shifted to using a source of energy that is renewable to reduce the amount of stress that is placed on the active system. TheEarth Tube Heat Exchanger is a system for transferring heat that is powered by geothermal energy and functionsaccordingtothe fundamental principles of how heat should be transferred. Geothermal energy is used to powerthesystem, andthesystem operates following these fundamental principles. The Earth Tube Heat Exchanger was analyzed using theoretical calculations and computer simulations, and this design displays the conclusions derived from those two methods. Because of the technology at our disposal, we can do complete as well as partial installations of HVAC in the living area. These options are both accessible to us. CFD analysis created in Ansys is used in the process of doing the system research so that it may be completed.

Keywords: Geothermal Energy, Heat Exchanger, CFD, Fluent,EffectivenessofETHE.

1. INTRODUCTION

It is predicted that residential and commercial structures, includingplacesofbusinessandretailestablishments,would account for a significant share of the overall quantity of energyandelectricitythatisusedaroundtheglobe.Thecost of heating and cooling buildings that are utilized for residential,commercial,orindustrialpurposesaccountsfor asignificantfractionofthetotalultimatedemandforenergy. The implementation of the most effective combination of insensitivedesigntechniquesistheessentialfirststepinthe processoflighteningtheloadthatisimposedontheactive systems that are responsible for transforming renewable energy into thermal or electrical energy. Solar design methods that do not rely on resistance are now at the forefrontofthiscategoryofdesignstrategiesthatdonotrely

onresistance.Itisconsideredthatgeothermalenergyisone ofthesourcesofenergythatmaybereplenishedthroughout time(noway-endingsourceofenergy).Traditionalheating and cooling systems included components such as compressors,condensers,andevaporators,allofwhichwere essentialtotheiroperation.TheEarthtubeheatexchanger, ontheotherhand,isatypeofsubterraneanheatexchanger that is capable of both drawing heats from the ground to warma roomandreleasingheatintothegroundtocoola room. It does this by absorbing heat from the ground and then releasing heat into the ground. An earth tube heat exchanger is an innovative way of making good use of geothermalenergywithinthelivingarea,bothforthegoalof warmingupthespaceaswellastocoolitdown.Thismaybe done for either purpose. To promote the passage of air throughout the different components of the system, the earth tube heat exchanger needed the employment of a blowerasanecessarycomponent.Itispossibletodrawheat fromthegroundorsenditbackintoitusingapipethatis buriedinthegroundandafluidthatisintroducedintothe system.Thisuncomplicatedarrangementcontributestothe system's total cost savings as well as a reduction in the amount of power that it draws from the wall outlet. This system can eliminate the need for expensive compressor, condenser,andevaporatorcomponentssinceitmakesuseof geothermalenergyinstead.

The concept of using renewable energy sources to power heating and cooling systems is beginning to pique the curiosityofanever-increasingnumberofindividuals.Earthair heat exchangers are an efficient alternative to conventionalheatingandcoolingsystemsthatmayreduce theamountofprimaryenergyneededtokeepabuildingat thetemperaturethatisdesired[1].Asaresultofthefactthat during the colder months the ground may be utilized as a sourceofheat,andduringthewarmermonthsitcanbeused as a source of cooling, the heat pump that is a part of the system can be used to both heat and cool the space. This suggeststhatduringthecoldmonths,theearthitselfmight beusedasasourceofheat.Thetemperatureoftheground hasadirectimpactontheefficiencyoftheheatpumpasan energysource,thusitisimportantto considerthis.Aheat exchanger is used in closed-loop systems to link the heat pumptotheground.Thisheatexchangermayberelatedto the ground in either a vertical or horizontal direction, dependingonthedesignofthesystem.

Whenitcametoconventionalheatingandcoolingsystems,it was essential to position the compressor, condenser, and evaporator in the appropriate areas of the building. The Earth tube heat exchanger, on the other hand, is a type of subterraneanheatexchangerthatiscapableofbothdrawing heatfromthegroundtowarmaroomaswellasreleasing heatintothegroundtocoolaroom.ThisallowstheEarth tubeheatexchangertobeusedforbothheatingandcooling aroom.Thisisaccomplishedbytheplantdrawingheatfrom theground,storingitinitscells,andthenreleasingitback intotheearth.Anearthtubeheatexchangerisaninnovative technique for making excellent use of geothermal energy insidethelivingarea.Thiscanbedonebothtowarmupthe spaceaswellastocoolitdown.Bothofthesegoalsmaybe accomplished with the help of geothermal energy. Either goalmightbeservedbycarryingoutthisaction.Duringthe process of installing the ground loop heat exchanger, it is vital to make use of a blower so that air can be moved throughout the whole system. This ensures that the air is heated and cooled evenly. This is necessary for the earth tubeheatexchangertofunctionproperly.Viatheuseoffluid movement, heat may either be taken from the ground or reintroducedintoitthroughapipethatisburiedunderthe surface.Bothoftheseprocessesareaccomplishedbyplacing thepipeintheground.Thetechniqueinquestionisreferred toasgeo-exchange.Thiseasydesignhelpscontributetothe overallcostsavingsofthesystemandalsoaddstoadecrease intheamountofpowerthatisusedfromthewalloutletby the system. Because it operates off of geothermal energy rather than traditional forms of power, this system can dispense with the pricey compressor, condenser, and evaporatorcomponentsthatarenormallyrequired.

2. METHODOLOGY

In this section of the methodology, we will discuss the method used for the analysis, the software used for the analysis,etc,thesedetailsaregivenbelow:

2.1. Geometrical Parameter of the Tube Pipe

Thetubepipeswhichareusedfor theheatexchanger,the geometrical parameter are given below in the form of the table:

2.2. Description of Numerical Models

The numerical method essentially consists of the fundamentalequationsthatareusedtosolvetheheatflow or exchange. These equations are used to model the heat floworexchange.

Thisisthebasicequationusedfortheheatenergyequation, where,

QrepresentsHeatflow.

Cprepresentsthespecificheatofsubstance,theunitofthisis “J/KgdegreeCelsius”

Mrepresentsthemassofthesubstance(Kg)

T2-T1 representsthetemperaturechange.

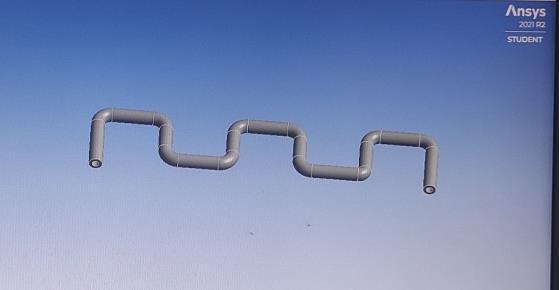

We need to LMTD (Logarithmic mean temperature difference)

Where the COP of the system is calculated by using the followingequation:

COP=Q/W.

WheretheWtermrepresentstheelectricityconsumptionof thesystem.

Ithasbeen shownthat modifying a few elements, such as increasingthediameterofthepipeandtheairspeed,hasthe mostsignificantinfluenceonthecoefficientofperformance (COP)ofthesystem.Thiswasoneofthediscoveriesmadeby scientists.

2.3. Description of CFD Model

Thecomputationalfluiddynamics(CFD)softwareofferedby Fluent is mostly made up of numerical techniques. To analyzetheresults,theCFDcodesofferedbyFluentcontain threecomponents:

1. Apre-processor

2. Asolver

3. Apost-processor

Youwillfirstneedtocreateagrid(ormesh)ofelements(or volumes),thenyouwillneedtodescribethecharacteristics of the fluid, and then you will need to add boundary conditions.Tobegin,youwillneedtocreateagrid(ormesh). During the pre-processing stage, every one of these componentsisregardedasaninput.Thesolverthenapplies a method known as the finite control volume method to solvethegoverningequationsofheatandfluidflow.After that,theresultsofthosesimulationswillbepresentedtothe userinagraphicalformatbyapost-processor,whichmay includegraphs,charts,andanimations.

Duringthisinquiry,itwillbepresumedthattheairitself(the fluidthatismoving)isincapableofbeingcompressedand thatthetemperatureofthegroundwillnotchange.

3. DEVELOPMENT OF AN EARTH-TUBE HEAT EXCHANGER USING COMPUTATIONAL FLUID DYNAMICS

CreatingthemodelontheCFDplatformbymakinguseofthe parametersthathavebeenprovided.

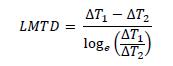

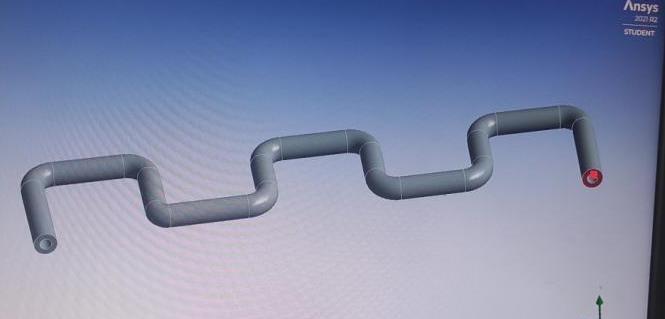

First,theappropriatematerial(i.e.)needstobeselected,and thenthemodelorgeometryneedstobesketchedoutwith theappropriatedimensions.(AsDepictedinFigure1)

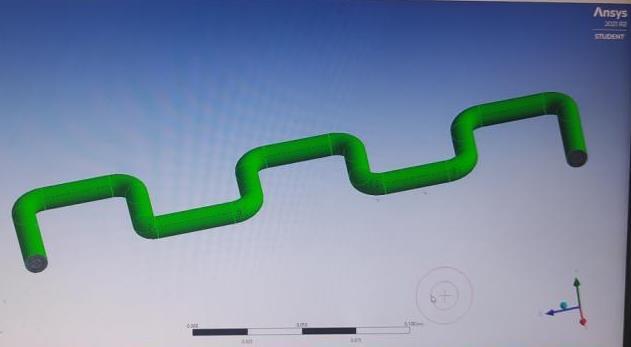

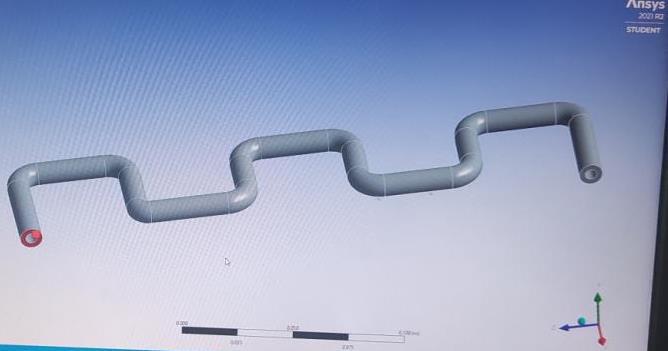

Figure-2: Meshing

Afterthat,tetrahedralvolumesareusedsothatthemodel may mesh. We use something that is termed gridindependent solutions as a method for figuring out the densityofthemesh.(ThiscanbeseeninFigure2)Weare alwaystryingtoenhancethegridratiosothatthegreater accuracyofthemeshingwillresultinimprovementstothe situationasawhole.

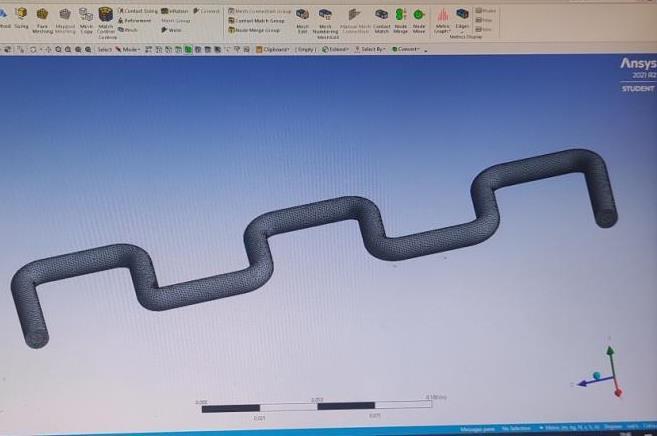

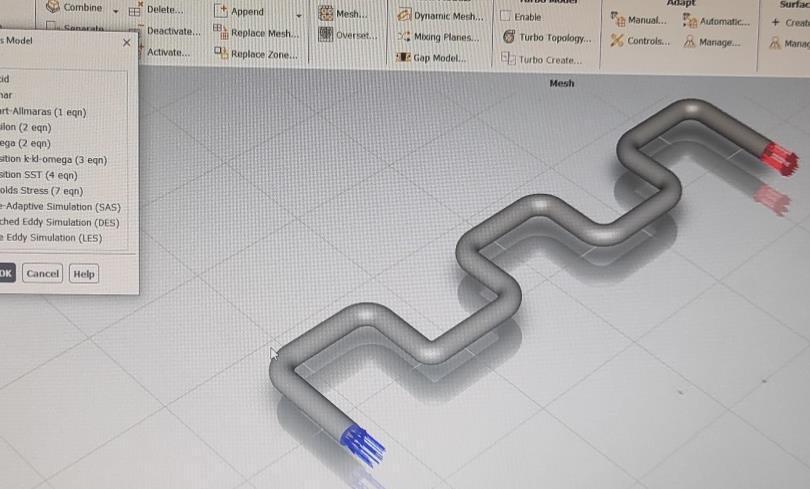

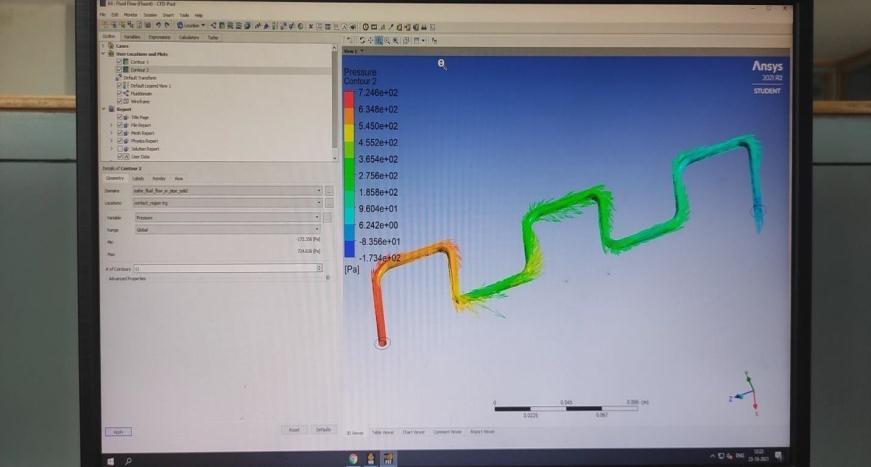

Thenextphase,whichistochoosetheFaces,followsafter that(i.e.InletofthePipe,thewall,theOutletofthePipe,and theFluiddomain).(AsshowninFigure3.)

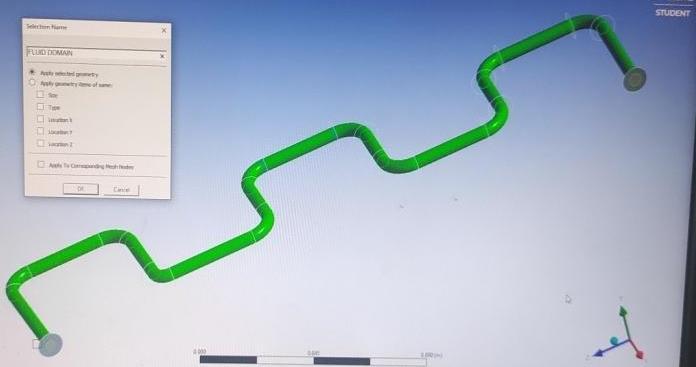

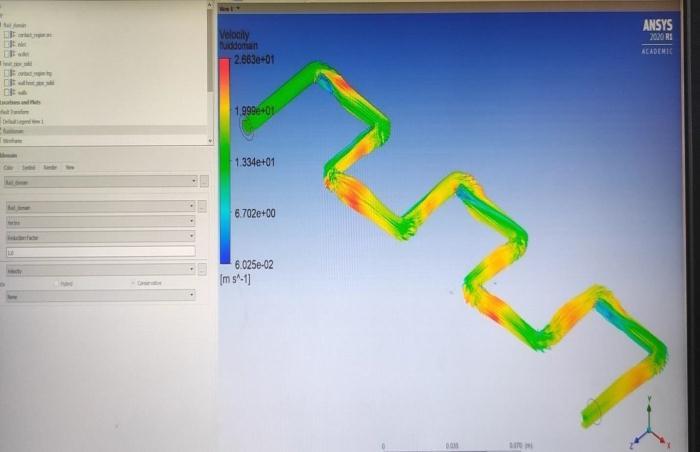

Afterthat,wearrangedthegeometrysuchthatwecouldsee the movement of air (fluid) through the pipe. (As seen in Figure4).

4. RESULT AND

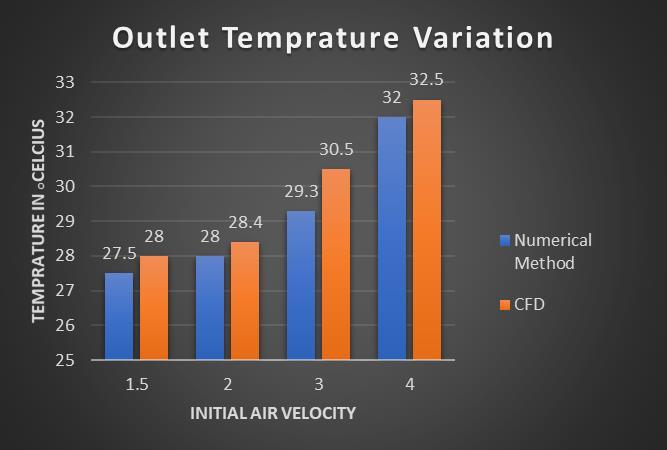

AComparisonoftheResultsObtainedfromtheNumerical MethodandThoseObtainedFromCFDAnalysis

4.1.

Thevarianceisshownratherwellintheformofabargraph inthenextfigure,whichisnumbered5.

Itcanbeseenquiteplainlythattheoutputtemperatureof eitherthenumerical methodortheCFDanalysisdoes not alterorchangeinanyvisiblemanner.Thisissomethingthat can be viewed pretty easily. Both are quite similar to one anotherinmanyways.

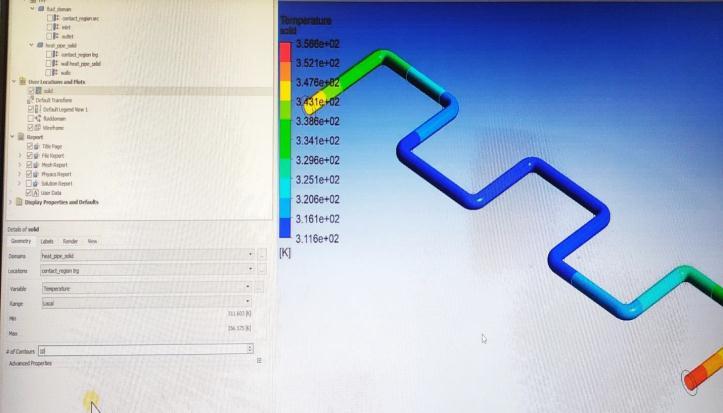

Inthethreeimagesthathavebeenshownsofar(6,7,8),you haveseenhowthetemperature,pressure,andfluiddomain contours vary with time. You have also seen how this fluctuationoccurs.Whencomparedtotheoriginalsituation, itcanbeseenfairlyclearlyinFigure7thatthepressureis muchlowerwheretheexitislocated.Theflowofthefluidor thefluiddomainisalmostthesametheentiretime.Thereis nosuchfluctuation,exceptfortheabruptchangethatoccurs atthecornerpointsofthepipe.Itwhollyreliesonthephase you pick in the 'Solution' portion, how much you want to demonstratetheVariation,andwhetherornotthesethree appearancesaredistinctfromoneanotherorwhetherornot theymaybethesame.

5. CONCLUSION

It has been discovered that the biggest temperature drop occurs when the velocity of the air is at its lowest point. Whenburiedatagreaterdepthinsidetheearth,theEAHE systemoperatesatahigherlevelofefficiency.Atadepthof around 4-5 meters, the circumstances become stable and optimal. Due to an increase in air velocity, the heat convective heat transfer coefficient has increased, but the ground contact factor has decreased. When compared to conductive heat transfer, the contribution that convective heat transfer plays in these EAHE systems is far more significant.Thematerialofthepipedoesnotgenerateanyof thesechanges,exceptfortheinitialcost.

REFERENCE

[1]Duffin,R.J.,&Knowles,G.(1981).Temperaturecontrolof buildings by adobe wall design. Solar Energy, 27(3), 241249.

[2] Coffman, R., Agnew, N., Austin, G., &Doehne, E. (1990, October).Adobemineralogy:characterizationofadobesfrom around the world. In 6th International Conference on the ConservationofEarthenArchitecture:Adobe90preprints: LasCruces,NewMexico,USA,October14-19,1990(pp.424429).

[3] Working document of a project proposal on energyefficient and renewable energy sources project India, Document TA3 –DAARUN – 95001/1PDC, Development Alternatives,NewDelhi,1995.

[4] Lamrani, M., Laaroussi, N., Khabbazi, A., Khalfaoui, M., Garoum,M.,&Feiz,A.(2017).Experimentalstudyofthermal properties of new ecological building material based on peanut shells and plaster. Case studies in construction materials,7,294-304.

[5] Jannot, Y., Remy, B., &Degiovanni, A. (2009). Measurement of thermal conductivity and thermal resistance with a tiny hot plate. High Temperatures-High Pressures,39(1),1-21.

[6] Tarigh, A. D., Tarigh, F. D., &Nikranjbar, A. (2012). A SurveyofEnergy-EfficientPassiveSolarHouses.IPCBEE© IACSITPress,Singapore,27,18-25.

[7] Reddy, B. V., &Jagadish, K. S. (2003). The embodied energy of common and alternative building materials and technologies.EnergyandBuildings,35(2),129-137.

[8]AkshayM.Pudke,KartikS.Shire,YogeshR.Borkar(2017), ComparativeStudyonPassiveSolarBuilding,IARJSETAGNIPANKH16,Vol.4,Specialissue.

[9] Santamouris, M., Argiriou, A., &Vallindras, M. (1994). Designandoperationofalowenergyconsumptionpassive solaragriculturalgreenhouse.Solarenergy,52(5),371-378.