Design a Corrugated Tube for Energy Absorption

Narendra Kumar Saini1 , Balendra Bhaskar 21 M.Tech Scholar, Department of Mechanical and Aerospace Engineering, Nims University, Jaipur, Rajasthan, India

2 Asst. Professor, Department of Mechanical and Aerospace Engineering, Nims University, Jaipur, Rajasthan, India ***

Abstract - The focus of studying energy-absorbing structures is to analyze their behavior under impact and compression. Impact characteristics are influenced by geometric factors, which also apply to dynamic loading scenarios. Peak crush load, denoted by Pmax, represents the maximum axial load experienced during compression, usually at the beginning. The magnitude and occurrence of Pmax can be altered by adding holes. The objective of the finite element analysis performed using ANSYS 15.0 with the tool EXPLICIT DYNAMICS is to determine the energy absorption of two types of tubes and compare their effectiveness in absorbing energy smoothly and efficiently. By analysing the impact loading, the solution obtained from the ANSYS test can provide insights into the energy-absorbing capabilities of the structures being tested. Key word energy-absorbingstructures,impactanalysis, compression, geometric factors, dynamic loading, peak crush load, Pmax, finite element analysis, ANSYS , EXPLICIT DYNAMICS, energy absorption, tubes, smooth deformation.

Key Words: energy-absorbingstructures,impactanalysis, compression,geometricfactors,dynamicloading,peakcrush load, Pmax, finite element analysis, ANSYS , EXPLICIT DYNAMICS,energyabsorption,tubes,smoothdeformation.

1. INTRODUCTION

As the world population grows, the demand for new cars increasesfromyeartoyear.AccordingtotheInternational EnergyAgency,by2035thenumberofcarswillreach1.7 billion. As the number of vehicles in traffic increases, the numberofaccidentsalsoincreases.

AccordingtotheWorldHealthOrganization(WHO),thetotal numberofdeathsinrailroadsisstillincrediblyhighat1.2 millionperyear.Peoplelivingincarsmakeupabout50%of thisfigure.Automotiveengineersplayanimportantrolein the design of cars to solve this problem by providing maximumsafetyforpassengers.Thiscanbedonethrough safetymeasures,inwhichthestructureofthecarisdesigned toprovidegreaterprotectionandsafetyintheeventofan accident.

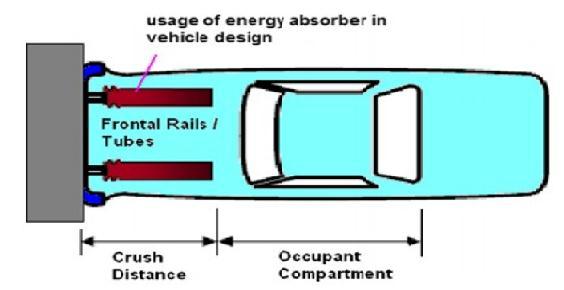

Thefirstcarstructureresponsibleforabsorbingthecollision energyinafrontalcollisionarethefrontrails,alsocalledthe side rails (see Figure 1). Side members are thin-walled hollow tubular structures of rectangular or square crosssectionthatdissipateenergylossfromplasticdeformation. Thin-walled systems are frequently used in collision avoidanceandenergyabsorptionapplicationsduetotheir

light weight and high energy absorption efficiency. Strict vehicle safety standards force engineers to have strong suction power to avoid affecting the entire weight of the vehicle.Manystudieshavebeenpublishedonthestudyof energyabsorptioninmetallictubularthin-walledstructures. Thesestudiescanbeclassifiedasfollows:

(1) investigates the effect of different geometries and configurations.

(2)investigatestheeffectoffoam.

Extensive work has been done to investigate different geometric modifications and configurations of thick tubes designedtoimproveenergyabsorptioninthintubes.Mostof the work published in thisarea focusesonsimple tubular structuresvisiblefromthefabricationprocess.Oneofthese modifications is the splitting of thin walls into simple extruded multicellular profiles that can be partially or completely tubular. Tang et al. investigated the energy absorptionpropertiesofmulticellularcylindricaltubesand found that different cell geometries improve energy absorption.

Otherstudiesonvariouscellgeometrieshaveinvestigated theeffectofthin-walledtubeswithdifferentcrosssections onenergyabsorption.Changingthethicknessofthetubular structure is another geometric change researchers are investigating to improve energy absorption and reduce weight. Similarly, the effect of varying the thickness of varioustubularstructureswasinvestigated.Custom-made tubularstructureshavealsobeenstudiedaspotentialenergy absorberswithdifferentthicknesses.Expandedmetaltubing is another method researchers use to improve energy absorptionandreduceweightinthinlayers.

Other researchers investigated the effect of polygonal tubular structures on energy absorption, while others investigatedtheenergyofdoublepipesandnested.

Figure 1 Longitudinalthin-walledcabinetfrontstructure

Otherresearchershavestudiedthe effectofsteel foam on thepipe.Foamisconsideredanattractiveenergyabsorber duetoitslowloadresistanceandsustainedloadplateau.

Togetthebestcombinationoffoamandtubularstructures, youmustconsiderthefoamdensity,linewidth,thickness, and cross-section profile, as well as the material. Some researchers have studied non-porous foams, while others have studied foams. He found on the principle that if designed correctly,foamscanimproveshock,functionally gradedfoams.Solutionsareoftenlimitedtothefabrication methodsusedtocreatethinwalls.Evenrecentresearchin crash-resistance applications has focused on simple geometry.

With advances in additive manufacturing (AM), it is now possibletocreatecomplexgeometriesthatcanbeintegrated into thin layers. The main purpose of this study is to numericallyinvestigatetheenergyabsorptionpropertiesof thin walled geometries. This numerical study is a preliminarystudytoevaluatetheenergyabsorptioncapacity ofcomplexgeometries.Thenextstepinthisresearchisto performdynamic extrusion teststonumericallyselectthe bestdesignforfurtherproductionandevaluatethepotential forenergyuseofthethinfilmprocess.

2. Literature Review

K. Yamazaki and J. Han This article is about the developmentofmethodsformaximizingtheimpactstrength oftubularstructuresandtheirapplicationtotheproblemof axial extrusion of cylindrical and square tubes. In the program proposed in this study, the latest finite element code DYNA3D is used to simulate the complex damage behavior of tubular structures. Use response surface approximationtechniquestoconstructadesignproblemina predesignedenvironmentusingatestmodel.

Approximation problems are solved by traditional mathematical methods. This optimization process is repeateduntilconvergenceisachieved.Also,thecomparison of crushing energy absorption of cylindrical and square pipesisdiscussed

Upkar Mane, Prof. SS Mashyal Thinwallenergyabsorber tubing is widely used as energy absorber in many automotiveandaerospaceapplicationsduetotheirhigher energyabsorption.Theexhaustpipeisconnectedbetween thefrontbumperandthedashboard.

It is one of the members of the structure that absorbs the highenergyinafrontalcollisionsothattheimpactforceis nottransferredtothedriver/passenger.

Considertheabsorptionofelectricitybythedynamicpulse, pulse velocity and pulse energy are interrelated factors. Tests are done semi-statically, while some are done dynamically. The energy absorption pipe length and pipe crosssectionratio,withthegreatinfluenceoffriction,such astheeffectoffrictionandspecificenergyabsorbingcontact time,maximumenergyandcollisiondistance.Supposethe pulseisconstantat15m/s.

Aluminumpipeswithvariouscross-sectionsaredefinedby preciseanalysis.Afterprovidingthenecessaryinteraction and meshing functions, all models are run with dynamic opencodeusingLSDYNA.

Arameh Eyvaziana, Meisam K. Habibia, Abdel MagidHamoudaa and Reza Hedayatib, This study, conducted explores the effect of fluctuations on energy absorption,fracturebehaviorandfailureofaluminumpipes under axial compression load. The researchers tested five different tubetypesandsimpletubesofvarioussizesand orientations.Theyalsointroducednewsolutionsformusic production.Thestudyfoundthatthedirectionofthegrooves improves performance and control performance, which is importantforthereliabledesignoftheshockabsorber.The test results provide recommendations for improving how thebikebumps,controlsandcrashesunderaxialloads.

Javad Marzbanrad1,Mehdi Mehdikhanlo,AshkanSaeedi Pour The energy absorption values of thin pipes with different geometries were investigated with detailed simulations. Square, round and oval steel and aluminum tubesareusedtocomparetheabsorptionpower.Theresults oftheload-bearingtestusedfortheanalysisofsquaresteel pipesarerecommended.The3Dsimulationwasdoneusing thefiniteelementmethod,whentheimpactorcollidedwith onesideofthetubewhiletheotherremainedrigid.Square pipes of 2 different thicknesses and 2 widths were also compared.

Inaddition, 2cross-sections suchascircularandelliptical withthesameareawerestudiedforcomparisonatthebeam transition.Theresultsshowthattheellipticalcrosssection hasmoreabsorbingpowerthantheothertwo.Inaddition,as thethicknessincreasesinpipeswithsmall cross-sections, theamountofenergyabsorbedwillalsoincrease.

F Tarlochan*, Sami AlKhatib Thin-walledstructureswere usedintheenergyabsorbingareaatthetimeoftheaccident.

Numerous studies have been carried out on tubular structures.Complexgeometriesareexcludedfromsolutions duetomanufacturinglimitations.Complexgeometriescan be achieved with advances in additive manufacturing. As motivation,theaimofthisstudyistoanalyzethecollision behaviorofcomplextubularstructures.

Five models were evaluated. The complex geometry was foundtobemoreeffectivethanthecurrentlyusedtubular structure.

J. Han and K. Yamazaki conductedastudyusingthefinite elementmethodtoinvestigatetheaxialcrushingbehaviorof groovedandsmoothsquarepipes.Theycomparethemean axial extrusion force between numerical and theoretical predictionsandalsocompareanddiscussfoldingpatterns derived from numerical simulations and experimental observations.Throughnumericalanalysis,theyobtaineda methodtomaximizetheeffectoftubularstructure,andused thesurface methodandvarious mathematical conceptsto solvetheproblemofmaximumenergyabsorptionofribbed andnon-ribbedsquaretubes.

In addition, the crushing energy absorption capacities of cylindrical pipes and ribbed and non-ribbed square pipes werecompared.

2.1. Objective of Project

❖ UseAutoCADsoftwaretocreatethinwalls.

❖Performfiniteelementanalysisusingboundaryconditions andspecificloads.

2.2 Project Scope

❖EnergyAbsorberTubeStudy.

❖ EnergyAbsorberTubeDesign.

❖ FiniteElementNetworks,Loading,BoundaryConditions, etc.

❖ FiniteElementAnalysis.

3 METHODOLOGY

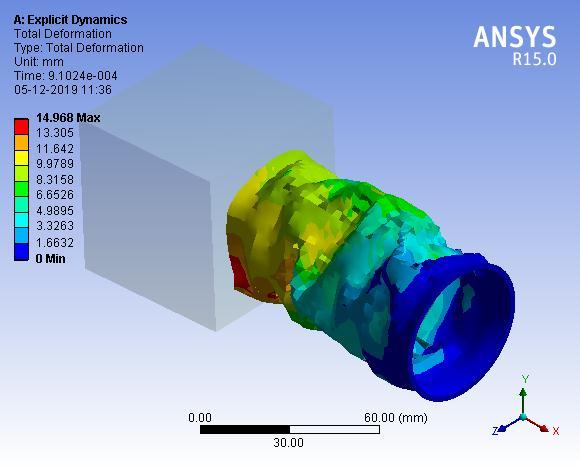

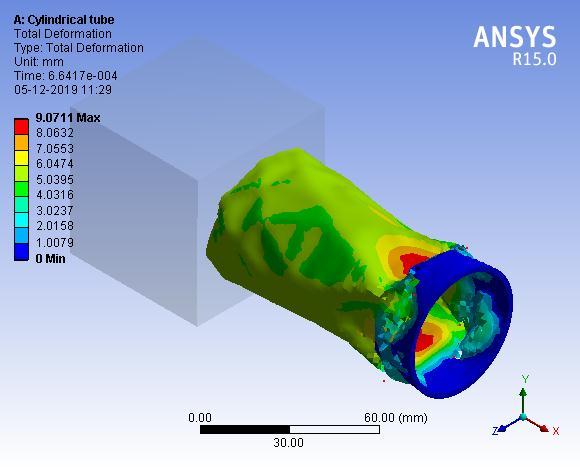

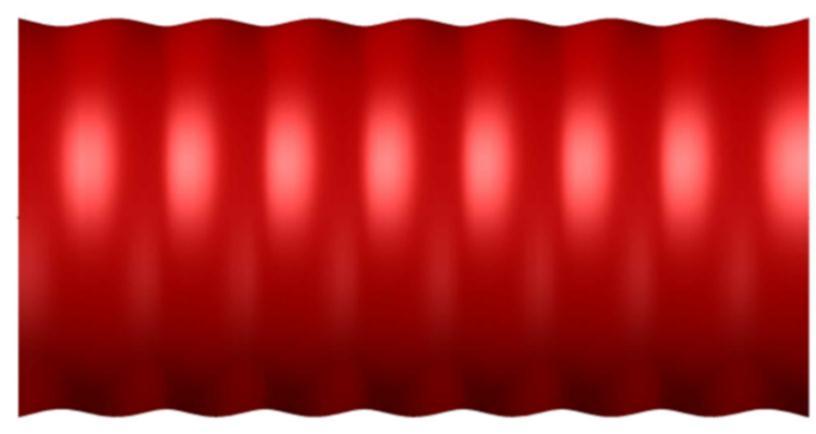

Theaimofthisstudyistoinvestigatetheeffectofcomplex geometryandstructureonthecollisionoftubes.Toachieve thisaim,twodifferentcompetitiondesignswerecreatedas shown in figures 2 and 2.1. Modify a parameter for each model to create a configuration file for each model to examinetheeffectofeachparameterontheextrusionscale. Profiles were modeled using both steel and aluminum materials to examine the factors affecting the response of eachprofile.

Numerical simulations included an axial impact using an impactorweighing1.7kgandaninitialvelocityof25m/s.

Allprofilesinthisstudyarethin-walledpipeswithacrosssectional area of 292,168 mm2 and a thickness of 2 mm. Select a profile from the printout using multiple decision methods.Thefirststepinthemultivariatedecision-making processistochooseafunctionalmodel.

Performanceevaluationsareusedinbothevaluations.The main category includes defined performance indicators, whiletheothercategoryincludesbasicproduction.Afterthe performance criteria are selected, a digital logic (DL) algorithmisusedtogenerateweightsforeachparameter.

3.1 Simple thin-walled tube

Thedesignofsimplethin-walledtubeismadeasfollows; Table -1: Specifications

Length 100mm

Diameter 44.5mm

Thickness 2mm

Material AluminumAlloy

3.2 Corrugated Tube

The technical specifications for designing the bellows are outlinedbelow:

GeneratrixofthecorrugatedsurfaceofadiameterDpipe:

include large geometric effects that also occur under dynamicloads.Peakbreakingloadisthemaximumloadto whichthespecimenissubjectedintheaxialdirection.Itis usuallyencounteredatthestartofcompression.

Thesizeandappearancecanbechangedbyaddingholes.It is represented by Pmax. The main purpose of this final analysisistofindthepowerabsorptionofthetwopipesand then compare them to get the more uniform pipe power absorption.InANSYS15.0,finiteelementanalysis,analysis ofimpactload,isperformedtoobtainthefollowingsolution. This impact analysis was performed in ANSYS using the EXPLICITDYNAMICStool.

whereA=amplitudeofsinusoidalcorrugation

x=arbitrarydistanceselectedalongpipelength

L=lengthofpipetube

k1=0,1&2(constant,linearandquadraticamplitudevariat ion)

k2=0,1&2(constant,linearandquadraticamplitudevariat ion)

n=numberoffluctuationsalongthepipelength

Forsinusoidalcorrugatedpipe(groove)k2=0)

4. Research and Analysis

Research into the behavior of electrical structures begins withimpacttestsandcompressiontests.Shockproperties

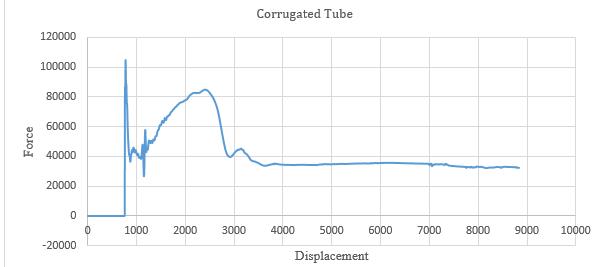

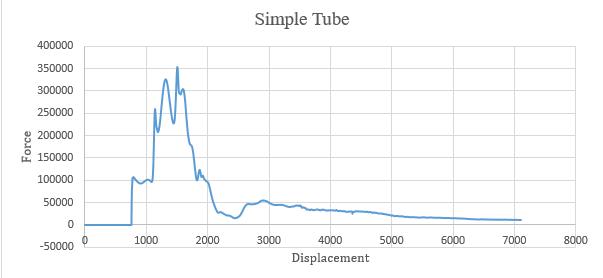

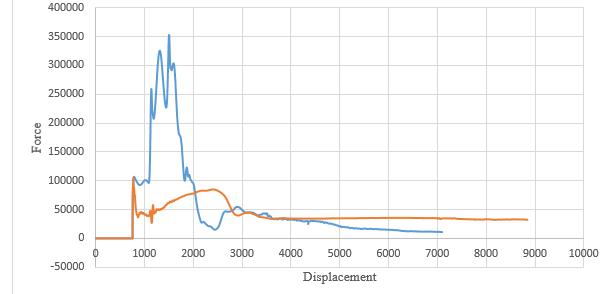

4.1 Absorption energy of Simple Tube

performance measurement, we can see that the energy absorption of objects can be calculated from force and displacement. Therefore, we prepared a picture of the energyandmotionofthetwopipesandcomparedthetwo pictures to study the energy absorption of the two tube shows the difference in strength and smoothness of the stomachdeformation.

Therefore,thesuctioneffectisbetterandthedeformationis softerafteracertaininertiaforceisappliedtothebellows.

5. LIMITATIONS

Features: Although 2090 aluminum alloy has many advantages,itmaynotbesuitableforall applications.For example,itmaynotbesuitableforhotapplications.

Corrosion:Aluminumalloysaresusceptibletocorrosionin someareasthatcanaffecttheperformanceofthepipe.

Production limitations: Vacuum design must take into accountthelimitationsofthematerialsusedtomanufacture it. For example, the capacity of the product will limit the depthofthegrooves.

StructuralStability:Thepipeshouldbedesignedtoretainits structural stabilityduringandafterdeformationsothat it canabsorbenergywell.

Test: Testing is required to ensure pipelines meet performancestandards.However,thiscantakealongtime andaddtotheoverallcostoftheproject.Whendesigninga pipemadeof2090aluminumalloymaterial,consideration shouldbegiventomaterialsuitability,corrosionpotential, manufacturinglimitations,stability,andtestingtoproducea pipethatmeetstherequirementswhileaddressingservice restrictions.

5.1 RECOMMENDATIONS

1.Grooveprofile:Thegrooveprofilecanaffecttheenergy absorption of the pipe. Darker grooves generally absorb more energy, while shallower grooves provide softer deformations.

2.WallThickness:Thewallthicknessofatubealsoaffectsits energyabsorptioncapacity.Thickerwallshelpincreasethe energyabsorptionabilityofthepipe,butcanalsoaddweight andmakeitunsuitableforsomeapplications.

3.Diameter:Thediameterofapipealsoaffectsthesuction power.Largerlinescanabsorbmoreenergy,butmayalsobe heavierandmoredifficulttopack.

Afterthefinalanalysis,wegotthechangeincontactforce andtimeversustimeforthetwotubes.Aswetalkedabout

4.TestingandVerification:Itshouldbetestedandverifiedto ensure it meets vacuum, suction and deflection requirements.Thismayincludeusingsoftwaresimulations orperformingphysicaltests.Whenthe

bellows is produced from 2090 aluminum alloy, it is recommended to choose a corrugated profile with a wall thicknessanddiametersuitabletomeettherequirementsof the application, which can take into account the energy absorption capacity and uniform deformation. It is also important to complete testing and verification to ensure systemsmeettherequiredstandards.

REFERENCES

[1]International Energy Agency (Retrieved on 11th April, 2022)Availablefrom:http://www.iea.org/

[2]The Global Status Report on Road Safety 2022 World HealthOrganization(WHO)Availablefrom:www.who.int

[3]TarlochanF,SamerF,HamoudaA,RameshSandKhalidK Thin-WalledStructures717-17

[4]TangZ,LiuSandZhangZA2020Thin-WalledStructures 6275-84

[5]NiaAandParsapourM2019Thin-WalledStructures74 155-65

[6]ZhangX,WenZandZhangH2018Thin-WalledStructures 84263-74

[7]GuangyaoL,FengxiangX,GuangyongSandQingL2019 InternationalJournalofImpactEngineering7768–83

[8]JianguangF,YunkaiG,GuangyongS,GangZandQingL 2019InternationalJournalofMechanicalSciences10363–73

[9]ShahiVandMarzbanradJ2022Thin-WalledStructures 6024-37

[10]P. Khalili, F. Tarlochan, A.M.S. Hamouda and K. Al –Khalifa, “Energy absorption capability of thinwalled aluminiumtubesundercrashloading”,JournalofMechanical EngineeringandSciences.

[11]ZaferKazancıa,b,*,Klaus-JürgenBathe,“Crushingand crashing of tubes with implicit time integration”, InternationalJournalofImpactEngineering(2018).

[12]PiyushDube,M.L.J.Suman,*VinodBanthia,“Lumped Parameter Model for Design of Crash Energy Absorption Tubes”.

[13]F.Tarlochan,Samer.F,“DesignOfThinWallStructures For Energy Absorption Applications: Design For Crash Injuries Mitigation Using Magnesium Alloy”, International JournalofResearchinEngineeringandTechnology.

[14]Raymond Joseph, Dr. M.A. Kamoji “Crash Analysis for Energy Absorption of Frontal Rails of a Passenger Car.”

International Research Journal of Engineering and Technology.

[15]NitinSGokhale“PracticalFiniteElementAnalysis”