Automotive Paint Shop Automation in Nigeria

Patrick Osakuade1 , Mohammed Moore Ojapah21Mechanical Engineering Department University of Port Harcourt, Port Harcourt, Nigeria

2Mechanical Engineering Department, University of Port Harcourt, Nigeria

1Graduate Student: 2Senior lecturer

Abstract - Theautomotiveindustry is currently facing a big challenge for the sustainability of its vehicle production operations and emissions due to economic, marketing, environmental and policy . A study has been carried out in a typical automotive manufacturing company in Nigeria to study their operational practice. In particular, the current level of painting operation and how the painting operation can be automated. A visitation to the automotive painting shop was done for on the spot assessment of their operating system and the level of technology that is currently being applied inthepaintshop.Itwasobservedthattheautomotive paint shop is still operating on human machine kind of painting operation of the vehicle body without the use of robotic system. The robotic system which is one of the disruptive technologies in the industries today of which industry 4.0 is the key enabler is already in full operation in the global key automotive paint shops. The use of robotic paintingsystemcomeswithalotofsafetyinparticularhealth hazard. and other benefit in terms of employability, technology advancement, and increased revenue to the industry. The study shows that if the automotive manufacturingandpaintshopinNigeriabeingakeyplayerin the Nigeria economy does not want to be left out in the industrial sector, it is now that they start to automate the paint shopbyensuringthat robotics systemsareinoperation in the paint shop.

Key Words: Automotive Industry, Industry 4.0, Automation, Painting, Manufacturing, Robot,

1. INTRODUCTION

Intheearlyyearsoftheautomotiveindustry,thevariationin the number of products offered by manufacturers were limited.AnexampleisHenryFord’spolicyin1918,halfofall cars in the US were model Ts. In recent time, due to advanced technology, growing market competitiveness, vehicle manufacturersmustprovidealargeproductvariety to meet customer requirements and this must be done ontime. To meet the demands of the modern market, the factory concept is beginning to change. The traditional industry is transforming into smart digital factories with automation[1].Thisiswheredisruptivetechnologycomes into play.. This goal can be reached by utilizing Virtual Reality.Suchanapproachenablesthetestingandvalidation of system specification, according to requirements, in the

earlydesignstagesofproductionplants.Inaddition,Virtual Realitycangivethebenefitofapossibilitytotrainstaffwho are going to work in designed lines before the commissioning.

The present day automotive production plant consists mainlyoffourshopswhicharethepressshop,thewelding shop,thepaintshop,andtheassemblyline,theseareusually separated by the buffers [2]. This paper focused on the automationofautomotivecompanyinNigeria.Inparticular, the paint shop. Methods like V- Model are successfully applied to both body shop and assembly line systems. Fortunately,thisiscouldbeanapplicablemethodologyand effective tools to simulate the automated and robotic painting process in the virtual environment. Thus, the operationsinthepaintshop,whichalsodoubleasthemost hazardousshopinanautomotiveassemblyplantneedtobe improvedintermsoftheautomationofoperationsthatare currently performed manually, and optimization of the wholeprocessincludingbuffercontrolsystem.

ThemovingassemblylinewasintroducedbyHenryFordin 1914,thisintroductionwasabletoreduceproductiontime from12.5hto93min.Everythreeminutesonecarleavesthe line and using less man power than previously [3]. The customerhadachoiceofseveraltypesofbodywork,butthe numberofavailablepaintcolorswaslimited.Fordwrotein his autobiography that in 1909 in which he told his managementteamthatinthefuture“Anycustomercanhave acarpaintedanycolorthathewantssolongasitisblack” [4].However,inthefirstyearsofproductionfrom1908to 1913, the Model T was not available in black [5] but in several colors depending on car’s purpose: gray–for town cars, red–for touring cars, and green–for coupes and landaulets(aswellassometownandtouringcars).By1912, allcarswerebeingpaintedmidnightbluewithblackfenders. The one-color concept was finally implemented in 1914. Ford suggested the use of black paint from 1914 to 1926, probably due to the low cost and durability. One hundred yearslaterFord’scolorstrategyhasbeenreplacedbymass customization: the more available colors, the greater the profit. What does it mean for the factory? This section focusesonimportantproblemareaswhichhavebeencaused bychangesinautomotiveproductionpolicy

1.1 The Ancient Paints

The earliest paints known were found in Europe and Australia[6].ThepaintfrombothEuropeandAustraliawere one-color, others utilized a palette of colors made from natural earthen materials. Most were applied by fingertip butothersappeartohavebeenappliedwithcrudbrushes madefromthefrayedtipsofsoftbranchesortwigs.These earlypaintsusedmanynaturallyoccurringcolorwhichare redandyellowironoxides,chalk,charcoal,terraverde,and othervariants.ThediscoveriesintheLibyandesertindicate thatsimilarpaintswereusedbytheearlyEgyptians.Their usageledtothedevelopmentofhieroglyphicswhich,inturn, ledtothePhoenicianalphabet.Similarartworkisproduced tothisdayinCentralAfrica.TheEgyptiansmayhavebeen the first to develop paint in Africa. While they used many naturalpigmentsandmaterialstheyappeartobethefirstto developsyntheticpigments.Egyptianbluewascomposedof lime, alumina, silica, soda ash and copper oxides. It was madebycalciningamixtureofsand,sodaandcopper.The Egyptiansemployedawidevarietyoforganicandinorganic materials as binders: gum arabic, egg white, gelatin, beeswax,etc.Inaddition,lime,plasterandplasterofParis were also used. About the same time the Japanese and Chineseweredevelopingtheirfamouslacquer.Thebasefor theselacquersisalatexextractedfromatreeknownasthe ‘Urushi’treeinJapan.Thistreebelongstothesamefamilyof plantsaspoisonivyandsimilarly,isquitetoxic.

1.2 Historic Development of Car Painting Industry

Following the overall advancement of industrial technologyfromthebeginningofthe20thcenturyuntilthe present, the car painting industry has seen significant changesintheformofmaterialsandprocesses.Duringthe firsthalfofthe20thcentury,theearlycoatingprocedures requiredweekstocompletesincetheyrequiredtheuseof airdryingpaints,layer-by-layersanding,andpolishing.The entirecoatingprocesswascarriedoutbyhand.

Themostsignificantturningpointsinthisfieldwerethe introductionofmassmanufacturing,whichrequiredquicker curingpaints,higherfilmperformanceintermsofcorrosion andcolorendurance,enhancedenvironmentalcompatibility, andcompletelyautomatedprocessesforincreasedreliability (Table1).

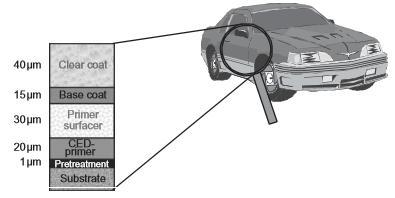

Withmanualapplication,thenumberofappliedcoatingshad beenloweredtofourorfivelayers(Figure1).Theselayers served to protect the primers from corrosion, provide smoothness and chip resistance for the primer surfacers (whicharefrequentlyappliedintwolayersatthefrontends and exposed parts), and provide color and weather resistanceforthetop-coatlayer.

Figure 1 Scheme of the multilayer coating of cars

Duetothesolventemissionsfromthesolvent-bornepaints, theprimerapplicationtechniquewasreplacedinthe1950s withdipcoating,whichwasmoremechanizedbutalsomore dangerous.Automobilemanufacturerswerethenrequiredto useeitheraqueouspaintsorelectrodepositionpaintsdueto explosionandfirerisks.Theelectrodepositionpaints,which werefirstdevelopedinthelate1960s,aremoreeffectivein terms of material transfer and throwing power, both of which are crucial for better corrosion protection of the interiorofthecarbody.

Table 1 Milestones and driving forces in the car coating process

Year Topics/Drivingforces Aspects

1920 Manualpainting Time-consumingprocess:weeks

1940 Massproduction Enamels/oven/time:day

1970 Improvedfilmperformance CED/2-layertop coat/new materials

1980 Environmental compliance Waterborne coatings /powder/transfer efficiency

2000 Automated processes First time capability/time:hours

Due to greater corrosion protection, cathodic coatings swiftly replaced anodic deposition coatings, which were mostly based on salinized polybutadiene resins, in the 1970s. Color and other effects like a metallic finish are createdbythebasecoats.TheUnitedStatesrecentlysawthe introductionofanintriguingtechnologybasedoncarbamate functioning[7]

Additionally,superiorflakepigmentsmadeofaluminumand newinterferencepigmentsthatchangecolordependingon theanglefromwhichtheyareviewedhavebeendeveloped as raw materials for the pigment section, which has increasedthebrillianceandcoloreffectsofvehiclecoatings.

Thetechnologyforcoatingandpaintinghasadvanced,and sprayapplicationmethodshavebeensignificantlyimproved. Painting craftsmanship is no longer required, thanks to simplepneumaticgunsandpressurepotsforpaintsupply. Thecreationofcoatingdevices,robots,andthecurrentlevel ofautomationarethe resultsofa number of reasons. The healthdangertothepainterswhowereexposedtosolvent emissionsfrompaintsinthesprayboothandtheinvestment insafetyequipment,whichisfrequentlyinappropriatefor painters, are two of the main causes. The risks associated with the electrostatic application technique are another factor.Anothercontributingproblemwastheunevenquality of a manual painting job. The time it takes today for the coatingprocess,includingpre-treatment,tofinishforacar bodyleavingthebodyshopandenteringtheassemblyline canbeasshortas8hoursthankstothelatestadvancements in wet-on-wet coating technology, coating machines, automatedcleaningprocesses,andmodernpaints[9].

For coating 10 units per day, modern paint operations requireinvestmentsrangingfromN25milliontoN2billion. Today,paintingtechniquesfortheautomobileindustryare largely standardized worldwide. The most common techniquesemployedtodayincludeinorganicpretreatment, cathodic electrodeposition, liquid or powder priming surfacer,liquidbasecoatings,andone-ortwo-component solvent-bornetransparentcoats.

Today, several automakers have chosen to aggressively incorporate environmentally friendly technologies since powder coatings technology has advanced to the point whereitisnowfeasible.Additionally,powderisrecognized astheprimersurfacerinNorthAmerica,atChrylserinallthe operational plants,atGeneral Motors(GM)fortheirtruck plants,andinallnewpaintfacilities.Powderisalsoutilized asaclearcoatinanumberofBMWfacilitiesinEurope[10]

1.3.

The"primersurfacer,"alsoknownasprimerorsurfacerin modern car Original Equipment Manufacturer (OEM) coating,providesthelinkbetweentheprimercoatandtop coat.Theprimersurfacerhasasignificantsellingpotentialof about130 000t peryearwhilehavinglow profit margins given the over 60 million vehicles that are produced annually[11]

There has been establishment of three technologies have nowwhicharestatedbelow:

1. Solventborneprimersurfacers

2. Waterborneprimersurfacers

3. Powderprimersurfacers.

Onlysolventborneprimersurfacerswereofferedabout20 yearsago.Thelegalrestrictionstolimitsolventemissions have prompted a progression in the replacement of the

solventborne primer surfacer. While powder primer surfacerswereintroducedintheUnitedStatesin2003with a marketshareofroughly26%,aqueous primersurfacers havelongbeenthedominanttechniqueinEurope.

The 1950s saw the adoption of a variety of primers. For instance,a laterprimersurfacerwasemployedalongwith both standard dip coatings and spray primers. Durable corrosion resistance was significantly improved with the introduction of electro-coating for the priming coat. Traditionaldipcoatswerecompletelyreplacedbyelectrocoats.Whentwo-coatfinishsystemsweredevelopedinthe middle of the 1980s, the cost savings were seen as indisputableatthetime.Additionally,thecapabilitiesofthe applied technique have an impact on the base coat's film thickness.Sincetheelectro-coatprimerisnotultraviolet(UV) stableorweather-resistant,somechalkingandsubsequent coat delamination result. Red and mica blue in particular wereparticularlyimpacted.

Thedevelopmentofaprimersurfacerwithzeroemissionasa UVbarrierwasdrivenbyvolatileorganiccompound(VOC) rulesintheUnitedStates,whichdemandthattheemission decrease achieved be maintained in the body shops. The powder primer was the technological advancement that couldsatisfythiscriterion.ChryslerandGMwerepersuaded by the powder primers' successful technological and environmental fusion. Chrysler was able to draw on knowledge of anti-chip powders, though, even before the debut of this method [12] Since then, progress has demonstratedthatahighleveloftechnologicalandoptical qualityispossible.Filmthicknessesofupto250mcanbe obtained through powder application, allowing for the replacement of the underbody protection materials in the doorsillarea,whichisparticularlyvulnerabletotheriskof stonechipping[13]

Asaqueousbasecoatingsbecamemoreprevalent,theuseof waterborne primer surfacers also increased to a standard level. Waterborne primer surfacers have made a big contribution to cutting down on solvent emissions in automotive OEM coating, together with waterborne base coatings.Germany'sautomotivemanufacturinghasincreased since1980by14%,butsince1990,emissionshavedecreased bymorethan50%[14].Workingtogetherwiththecoating industry,wewereabletoaccomplishthis.

2.0 Automation by Robot

Oneoftherecentdisruptivetechnologieswiththegreatest potential for use in the automotive production sector is robotics.Mostrobotsupuntilrecentlywerefairlybasic,oneapplicationdevices.Onlythankstothequickdevelopmentof artificial intelligence are robots reaching the potential applications we can currently foresee. Robots are getting brains so they can serve as more than just one-purpose machines with a few axes ofmotion. Robots can take ona

whole new range of issues if they can learn, develop, and thinksimilarlytohumans.Robots'realitywillchangeifthey canlearnfromoneanotherandfromthemselves.Robotics' potential today seems limitless [15]. They are used for a growingnumberoftasksthatgowellbeyondthoseonthe assemblyline.Robotsthatcanreademotionsandspeakare currently being created. Some robots are evolving to look uncannilylikehumansaspartofthisprocess.

2.1 Painting Robot

Anautonomouspaintingdevicewithsixrotatoryaxeswhich has three main and three hand axes that is freely programmable and is designed in the bend-arm style is known as a painting robot. A second traveling axis can be added to it. All painting operations on the interior and outsideofcarbodiescanbedonewithapaintingrobot.As statedbelow,thepaintingrobothassixmovementaxes:

1.Axis1(horizontalturningmovementofthehousingonthe basicbody)

2.Axis2(pivotingmovementofarm1onthebasicbody)

3.Axis3(pivotingmovementofarm2atarm1)

4.Axis4(rotatorymovementofthehandaxisdirectlyatarm 2)

5.Axis5(rotatoryangularlyoffsetmovementofthemiddle handaxiscomponent)

6. Axis 6 (rotatory movement of the hand axis at the atomizerflange)

The required robot kinematics can be achieved by using armsofvariouslengths,allowingtherobot'soperatingrange tobeappropriatelyadjustedtothepaintingtask[16].

2.2 Common Sensors and Actuators in Automotive Industrial Robots

Forindustrialrobots,sensorsareessential.Thesensorsaid inthedetectionoftheenvironmentandtherobot'smotion state.Thecontrollerwillissuetheappropriateinstructions, causingtherobottocarryouttherequiredtaskwiththeaid ofthoseinstructions.Thecommonsensorsusedinindustrial robotsaresummarizedasfollowsfollowingacriticalreview ofrecentliterature:

Tactile Sensors - Industrialrobotsalsorequirethe sense of touch to comprehend their surroundings since tactileperceptionallowspeopletoperceivemanyqualities of external objects and interact with their environment flawlessly.Tactilesensors,whichareemployedinindustrial robots that have the ability to feel touch, are therefore essentialpartstoincreasetheirintelligence.Sincetheyhave been developed for many years, tactile sensors are now

gradually being used in numerous robots. Capacitive, piezoelectric,piezo-resistive,andopticaltactilesensorsare the most common varieties [17]. The capacitive tactile sensor measures the contact force by using the change in capacitance.Althoughituseslittlepowerandhasexcellent spatialresolution,itsinterferencerobustnessissubpar[18]. Thepiezoelectrictactilesensorisbasedontheidea ofthe piezoelectriceffect,whichstatesthatwhenanexternalload is applied, an electrical charge will arise on the surface of piezoelectricmaterials.Ithasadecentfrequencyresponse andawidemeasuringrange,althoughitsresolutionmaybe better[17].Althoughtouchsensorsarebecomingmoreand more popular, their performance, as well as their adaptabilityandversatility,isnotyetextremelysatisfactory. The advancement of numerous technological fields, includingmaterials,electronics,pertinentalgorithms,andso forth,isnecessaryforthedevelopmentofthesesensors[19]. Thereisstill alongwaytogobeforetouchsensematches thatofahuman.

Visual Sensors - In recent years, visual sensing technologyhasadvancedquickly,andtodayitiswidelyused inavarietyofindustries,includingfacerecognition,threedimensionalreconstruction,andnumerousrobotics,among others. The processor processes visual sensor-captured imagestoextractinformationthatishelpfulforparticular applications. Cameras of all varieties, including RGB, multispectral, and depth cameras, are the major type of visualsensor[20].Thephotosensitivecomponentsfoundin numerouscamerasareoftenCCDorCMOS,whichworkon the basis of the photoelectric effect to convert light informationintoelectricalimpulses. CCDcamerasaremore adaptable and produce higher-quality images than CMOS cameras, although CMOS has an advantage over CCD camerasintermsofpriceandpowerusage[21].

Diverseinformationcanbeobtainedfromvariouscamera kinds.ThemostpopularformsofRGBcamerasareusedby peopleeverydaytocapturechromaticimagesonthebasisof theideathateverysortofvisiblecolorcanbecreatedusing threedifferentshadesofred,green,andblue,aswellastheir combinations.Duetotheircapacitytocaptureimagesina variety of spectrum bands, including visible and invisible wavelengths,multispectralcamerasareabletoobtaindata thatRGBsensorsareunableto[20].Stereoimagingismade possiblebydepthcameras,whichenhancetwo-dimensional imageswithdistanceinformation.Dependingonhowthey operate, they can be categorized as RGB binocular, structuredlight,andTOF.Visualsensorsarequitepopular duetotheirbenefitsofbeinginexpensive,providingawealth of information, and being simple to use [20]. However, processing visual sensor data is difficult and timeconsuming.Despitethenumerousalgorithmsthatscholars haveproposed,theirapplicabilityandadaptabilityremain unsatisfactory.

Laser Sensors -Sinceitwasdevelopedinthe20th century and possesses exceptional mono-chromaticity, directivity,andbrightness[22],lasersarefrequentlyused forawiderangeoftasks.Thetypeofsensorknownasalaser sensor makes use of laser technology to carry out measurement duties. They typically consist of a measurement circuit, a laser emitter, and a detector. The primarycategoriesoftheworkingmaterialintheemitterare solid, liquid, gas, and semiconductor. Most often, physical factors like distance, velocity, and vibration are measured usinglasersensors.Thetypicalvarietiesincludelaserrange finders,displacementsensors,scanners,trackers,etc.Time of flight (TOF), the triangulation method, and optical interference are the three major types of laser range measuringthatcanbeused[23].Thephenomenaofoptical interferenceisthegenerationofbrilliantanddarkfringesby superimposingtwolightbeamswithdifferentphases.Itis usedinlasertrackerstodeterminehowfaratargetthathas areflectorhastraveled.Contactlesstelemeteringusinglaser sensors is possible, and the speed and accuracy of the measurements are satisfactory [20]. However, because temperature, atmospheric pressure, and air humidity can affect a laser's wavelength, adjustment is necessary when thesevariablesvary.

Encoder - A sensor known as an encoder can convertanangulardisplacementorvelocityintoanelectrical impulse or a digital number. According to the detecting principles,itcanbesplitintofourcategories:photoelectric, magnetic,inductive,andcapacitive[24].Themostcommon kindisaphotoelectricencoder,whichconvertssignalsusing thetheoryofthephotoelectriceffect.Ittypicallyconsistsofa photoelectricdetectingdeviceandanopticallycodeddisc. Photoelectricencoderscanbedividedintoincrementaland absolute encoders based on the calibration mode of the codeddisc.

Square wave pluses are the result of incremental photoelectric encoders. The amount of the pluses can be used to calculate the rotation angle, and a zero-reference location is necessary to ascertain the rotating shaft's absolute position. Absolute photoelectric encoders can obtain the absolute position immediately because they producethebinarydigitalquantitythatcorrespondstoeach location of the axis. Due to its benefits of compactness, longevity, usability, and established technology, encoders have been extensively utilized for many years [25]. The numberofscribedlinesonthecodeddiscinasinglecircle determines the resolution of encoders. More lines can be used to differentiate smaller angles, which results in increasedresolutionbutalsohigherexpense.

Other Sensors -Inadditiontothefoursensortypes mentionedabove,othersensors,suchasproximitysensors, inertialsensors,torquesensors,acousticsensors,magnetic sensors,ultrasonicsensors,etc.,arealsousedinindustrial

robots to carry out various tasks. An example of a noncontact device that may detect approaching objects and produceanalogousswitchingsignalsisaproximitysensor. Based on the foundations of functioning, it can be divided into capacitive, inductive, and photoelectric types [26]. Capacitiveproximitysensorsusethechangeincircuitstatus broughtonbythedetectingelectrode'scapacityvariationto detectthingsthataregettingcloser.Tofunction,inductive proximity sensors rely on electromagnetic induction. The detecting coils are the sensing components of them, and whenametallicconductorapproaches,theirinductancewill change. Theyarefrequentlyusedtogaugetheacceleration, angularspeed,andazimuthalangleofmovingobjects.The inertialmeasurementunit(IMU)isthetermfortheirtriaxial combination. Dead reckoning (DR), which uses the integration method to determine how much an object is moving,istheunderlyingmeasurementprincipleofinertial sensors.Inertialsensorshavequick,pleasingprecision,but overtime,theinaccuracywillgrow[26].

Torque sensors – These are mostly employed to gauge the torque applied to shafts or mechanical power transmissionsystems.Theinductivetorquesensorandthe resistance strain torque sensor are the two most popular varieties.Theyoftenhave a torsionbaraswell assensing componentslikecoilsor resistancestraingauges.Torsion bars connect the input and output shafts. Torsion bar torsional deformation brought on by a torque can be convertedintoelectricsignalsbyvaryingtheparametersof thedetectingelements,allowingfortherealizationoftorque measurement.Soundwavescanbeconvertedintoelectric signals using acoustic sensors. They have a capacitive electretmicrophonefitted,andsoundwavescancausethe electretmembraneinthemicrophonetovibrate.Thiscauses avariationincapacityandproducesweakvoltage.Afterthat, thevoltageisconvertedforfurtheruse.Thebasicpurposeof magneticsensorsistomeasuremagneticfieldstrength.The Hall Effect serves as the basis for operation. This phenomenon occurs when electricity flows through a conductorandcreatesanelectricfieldthatisperpendicular tothedirectionofthemagneticfield.Thiscreatesapotential differenceontheconductor'ssurface.

Obstacle detection frequently makes use of ultrasonic sensors. According to the amount of time it takes to emit ultrasonic waves and receive echoes, they determine the distancebetweenobjects.Theyareinexpensive,havealow costandpowerconsumption,andarecompactinsizeand weight [27]. Industrial robots are multipurpose manipulators that can be reprogrammed to carry out a variety of tasks, according to [28]. An industrial robot's essential parts are its manipulator, controller, and teach pendant. A robot's user interface, which resembles a computerdisplayandkeyboard,isitsteachpendant.Robots can be classified into six types based on their coordinates andkinematics,andTable2listseachtype'sproperties.

Table 2: The Characteristics of the Types of Robot Coordinate Features

Cartesian

The arm has three prismatic joints, whose axes are coincident with a Cartesiancoordinator.Armhaslinear X,Y,andZmotions

Cylindrical The arm moves along the Y and Z axes. Robot can rotate around the base (a cylindrical coordinate system),normallyhas3DOFs

Spherical/polar The arm has one sliding and two rotational motions, a polar coordinatesystem

SCARA (selective compliance assemble.Arm

Twoparallelrotaryjointstoprovide complianceinaplane.Thehorizontal armhasthreeaxes

Articulated The arm has multiple rotary joints. The arm can reach any part in its workingenvelope

Parallel Arms have concurrent prismatic or rotaryjoints.

Thekinematicneedsofapplicationsdeterminethesortsof robots that can be used in production. Cartesian and cylindricalkindscanbeutilizedforsimplemovementslike painting a car. In automotive assembly processes like welding,sealing,andMH,articulatedrobotsarefrequently utilized.

Different degrees of freedom (DOFs) may be present in a robot.Arobot'sjointsandaxeseachintroduceaDOF.The robotneedsthreeaxesinordertotravelanywhereinspace. AsseeninFigure3,articulatedrobotshavethreerotational axes (roll, pitch, and yaw) that they can use to determine how the arm's tip is oriented. For instance, handling instruments like arc welding is a popular task for 5-DOF robots.Ifnecessary,asixthaxis(orjoint)canbeadded.

[28]. Transducers and encoders are both frequently employedsensors.Transducerstransformphysicalvariables intomoreusefulformsofdata,suchvoltage,forautomation. Encoders send information signals by combining sensoranalyzeroperations.

2.3 Paint Shop Design and Quality Concepts

One of the most intricate production processes in the car industryisthepaintshop.Thehigheststandardsaresetat thepaintshopfortheprocesses'environmentalfriendliness, productivityofthepaintinginstallations,andfunctionaland aestheticqualityofthepainting.Thesearetoblameforthe highlevelofautomationpresentinvehiclepaintingfacilities.

A typical coating line is around 300 meters long and can paint10unitsperhour.Abody'sdwelldurationrangesfrom 6to11hours.Acompletelyautomatedpaintshopemploys between 10 to 30 employees per shift, primarily for maintenance, process control, and troubleshooting. Both value-adding and non-value-adding scopes of work are presentintheprocesschain.Manuallabor-intensivetasks likesanding,polishing,cleaning,smoothing,andrepainting are examples of non-value-adding tasks. The ultimate abolitionofnon-value-addingoccupationsoratleasttheir reduction to the absolute lowest number is a future goal. Value-adding procedures are currently highly automated, andfullautomationisanticipatedinthefuture[29].

Theaimtolowerthecostperunit(CPU)isareflectionofthe mounting demand to cut costs. All Original Equipment Manufacturers(OEMs)havebeenusingthesamestandard painting procedure for many years, and it entails the processesofprimer,basecoat1,basecoat2,andclearcoat. Consolidatedtechniquesarecurrentlybeinglaunched,which have quicker process times and either do away with the primerapplicationorapplyallcoatingswet-on-wetwithout any drying in between. The field of surface coating technologyisundergoingsignificantchanges.Costreduction, environmental compliance, and increased quality are the evidentgoalshere[30].

2.4 General Layout

Themanufacturinglinelayoutinthepaintshophaschanged over time. In a paint shop, the various process steps are oftenorganizedacross several levelsofthestructure. The pretreatmentdippingtanksareonthelowerlevel.Thespray boothsandworkdecksarelocatedonthelevelabovethat. Theautomobile bodystoragespaceanddryerslocatedon the floor above this one. On the top floor, in the so-called penthouse,aretheair-supplyunits.

Asensorisadevicetodetectaphysicalobjectorvariable, suchastheexistence,position,force,andspeed,accordingto

Cleanroomdesignisfrequentlyusedtocreateinstallation areas, such as the primer and top coat area, where cleanliness is crucial. After a thorough washing, the automobile bodies are brought into this location. It is

prohibited to enter this region and particular attire is required[31].

Dryormoistprocedurescanbeusedtoautomaticallyclean the body's surface. The procedure has two parts in each situation. To remove dirt particles that may have been integrated into the surface, primarily during pneumaticspray treatments, the interior portions and seams are blasted out in the first stage. The body is pumped via a device that has air nozzles directed in the horizontal, vertical,andotherdirectionsatarateofmorethan40ms1.

Theairstreamscarrythedirtspeckstotheedgeofthezone, where filtering equipment traps them. The clean air is recycledandusedto refuel the nozzlesafter filtering.The body surface is cleaned in the second step using rotating rollers that have feathers attached to them. The feathers gather the dust that is drawn away from the rollers. The rollershaveprogrammedrotationalspeedsandarespaced apart from the body surfaces. Simple washing is another approach for cleaning the surface of the body. In this instance,thebodyiseitherwashedwithhigh-pressurewater jetsordippedandtreatedwithrevolvingbrushes,muchlike awashingstation.Thehigh-pressurewaterjetscleanoutthe dirt in the inner portions. Robots are used to steer the nozzlesintheproperdirectionforthegreatestoutcomes.

Shortleadtimes,straight-linematerialflow,compact,spacesavingdesign,consistentimplementationofdust-protection measures,concentrationofinstallationtechnologyandwork decks, short and easy access for operating and service personnel, and simplified maintenance and service conditions must all be met for a layout to be considered optimal.

Ergonomicsstudiescanbeundertaken,andsimulationsof the material flow or the robot stations can be included. Finally,avarietyofvirtualrealitytechnologiesallowforthe inspectionofthepaintshop[32].

2.5 Automation in the Paint Application

Fully automated paint application has gone through a number of stages of development. Machines were used to paint the automobile bodies' outside surfaces in the first stages.Therobotconceptevolvedfromthemachineconcept. Thischangewasmotivatedbytheneedforgreaterflexibility andefficiency.

Therefore, robotic installations offer greater freedom for vehicledesignandpaintingtasks.Thehigh-speedrotating atomizeriscurrentlyreplacingthepneumaticatomizerfor the second metallic application. In the future, exterior paintingwillmostlikelybeaccomplishedusingthebell-bell applicationusingrobots.Fullyautomaticinteriorpainting,a fieldofrobottechnologythathasalwaysexisted,hasmoved awayfrompneumaticapplicationduringthepastfewyears.

The most recent level ofadvancement asofyetis interior applicationwithrotatingatomization[33].

Forrobotpainting,therearetwodistinctmethodsofmoving or transporting the body, although they share some characteristics. Painting in tracking is the first approach, which involves moving continuously through the robot station.Paintinginthestop-and-gomethodisthesecond.In ordertofixandpositionthebodyfortherobots,thelatter requiresaquickdriveintotherobotstation.

3.0 V- Model

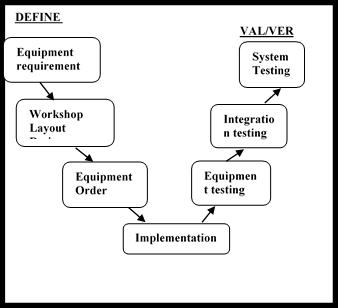

The V-model will be used for the implementation of the automation in the painting section as discovered by the researcher.

V-modelisanexampleofaPredictiveProductDevelopment model.Thismodelismainlyusedwhendevelopingheavily integrated systems, software development, or where test programsarephasedwiththedesign.Themajorfocusofthe V-Model is to ensure that testing planning and testing activityarealignedtocorresponddirectlywiththedesign activity being performed to obtain a useful and relevant assessmentoftheemergingdesign.OntheleftsideoftheVModel,itidentifiestheflowdownofthespecificationofthe equipment requirement, workshop layout design, and equipment order activities from the highest level of the section automation down to the lowest level of the componentfortheintendedsystem. Therightsideindicates the accompanying test specification and test design activities.Alsotherightsideidentifieswhentheevaluation activities occur that are involved with the execution and testingatvariousstagesoftheimplementation.

3.1 Proposed Automated Work Flow in the Body Paint Shop

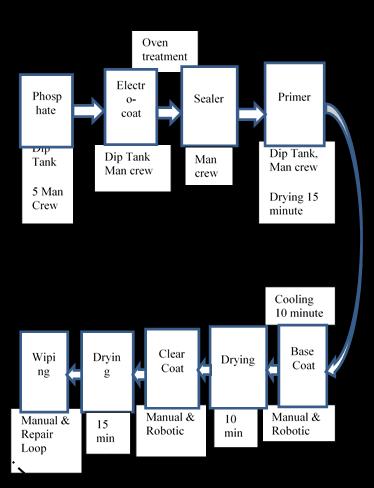

Inthepaintshop,thereareseriesofprocessingstepswhich are performed to prepare and coat the car body surfaces. Thesestepsare:(1)phosphate,(2)electro-coat,(3)sealer, (4)prime,(5)basecoat,and(6)clearcoat.Thephosphate processchemicallycleansthesurfaceandtreatthesurface soastopreparesittoacceptthepaintcoat.Theelectro-coat isforcorrosionprotection,edgecoverageuniformfilmand paintreduction.Thesealantisappliedfornoise,vibration and harshness (NVH), preventing water leakage and corrosion.Theprimingoperationaddsthefirstcoatofpaint. Basecoatingisthecoatthatprovidesthespecificcolortothe automobilevehiclebody.Theclearcoatisappliedforgood appearanceandcompletethecoatingprocessfordurability. The paint shop should be organized into six sections, corresponding to these steps. Between the sections, there are drying and cooling areas. Figure 4 presents the organizationofworkinthedepartment.

The phosphate operation is a fully automated dipping processwhichisachemicaltreatmentprocessinwhichthe bodyhandler,withvehiclebodiesonboard,aresubmerged inalargetankofchemicalsolutiontopreparethebodyfor painting.Thedippingtankislongandwidetoaccommodate thesuperstructure.Thevehiclebodiesaremovedthrough thetanksbycontinuouslymovingconveyor. Immediately afterphosphatecoatingisthee-coating.TheE-coatinguses electrodepositionprincipletoapplyaprimercoatlayeron top of the phosphate layer, this is done by immersing the vehicle body into an E-coat tank. This is also a fully automatedoperation.Afterthisoperation,thebodyismoved intotheovenforcureandforoptimumdurability.AfterEcoat, the next process is sealing. The sealing process is appliedtocovertheweldsandedgesofvehiclebodies.After this is the application of primer. The primer is usually powderedbased.Thispowderprocessrequirednosolvents, and the powder coating is usually preferred than liquid primer for primer operation. Although automated, phosphate, E-coat and primer each require man crew for maintenanceandmonitoring.Thesecrewsareincludedin thedirectlaborhourspervehicleallocatedtothepaintshop.

Following primer is an enclosed drying oven which must permit a total of 15 minutes average drying time for each vehiclebodyasitgoesthroughtheoven. Thedryingovenis wideandlargetoaccommodatethevehiclebody. Another 10 minutes must be allowed for the bodies to cool before going into the base coat line. The base coat line is a ventilatedpaintlineconsistingofa combinationofrobots andhumanstoperformthecolorbasecoat. Anaverageof tenminutesarethenprovidedforthebasecoattodrybefore goingintotheclearcoatline.

Figure 3 The Proposed Automated Work Flow in the Body Paint Shop

Afterclearcoat,thevehiclebodyisallowedtodryforabout 15 minutes. The paint drying areas in the plant should be adequateenoughforthevariousoperations.Thisisfollowed byaseriesofworkstationsinwhichthebodiesaremanually wiped,buffed,andinspectedforpaintingflaws.

There could be defect in the paint shop, and when this happens gthose vehicle bodies needing repair will be transferredtotherepairareaandarethensentbackintothe line before exiting the paint shop. Painted vehicle bodies withdefectsaresimplytakenofftheregularline,repaired, and then returned back onto the line at vacancies where other vehicles might have been removed for repair. The balancedelayandotherlinefactorsinthepaintshopinclude theeffectoftheexpectedworkloadintherepairloop.

Duringtheimplementationofthisprojectattheautomotive manufacturing/assembly plant, the average balance delay will becalculatednotcountingphosphateandprimerand theaveragemanninglevelwillbefoundonthepaintshop workstations. Repositioningtimeshouldalsobecalculated. Thebalancedelayandmanninglevelwillincludetheeffect of the robotic stations. The paint department should be

planned for a line efficiency (proportion uptime) of 95%. Each station in this department should be long and wide enoughtoaccommodatetheoperation.

4.0 CONCLUSIONS

This research and development contains theoretical contributionsinthetheoreticalframework,aswellasin the analysis.Firstlyathoroughliteraturereviewwasconducted to summarize the automation of the paint shop of the automotiveindustryinNigeria.Inaddition,visitationtolocal OEMwasconductedforonthesiteassessment.A V-model fortheimplementationofthisautomationinthepaintshop whichalsodepictsatheoreticalcontributionwasdesignedby theinvestigatoror

Theanalysiscontributestoexistingtheorybyproviding an overview on most influential challenges of automotive industrialpaintshopautomationbasedontheempiricaldata. Furthermore,thecross-caseanalysisenabledthisresearcher toclusterthechallengesbasedonhowcriticaltheywereseen by the company. This cluster depicts another theoretical contributionofthisstudy.

With regards to managerial implications of this research workitcanbesaidthatthefindings willhelpmanagersto achieve an understanding of paint shop automation in Nigeria.Awarenessofthesechallengesallowsmanagersto reactuponthemtoenableasmoothtransitionfromhuman machine paint shop currently in use across the nation to automatedpaintshop.Therefore,itcanbesummarizedthat thefindingsofthisresearchworksupportmanagersinthe decisionstepoftheautomationadoptionprocess.Overall,it can be said that this work contains valuable theoretical contributionsaswellasmanagerialimplications

Theauthorscanacknowledgeanyperson/authoritiesinthis section.Thisisnotmandatory.

REFERENCES

1. E. Angelucci, Albert0 Belluci: The Automobile - From SteamtoGasoline,McGraw-Hill,NewYork1974.

2. J.B.Rae:TheAmericanAutomobile,ABriefHistory,The UniversityofChicagoPress,Chicago1965.

3. Georgano,G.N.(1985).Cars:Earlyandvintage,1886–1930.London,UK:GrangeUniversal.

4. Ford,H.,&Crowther,S.(1922).Mylifeandwork.GardenCity, NewYork,USA:GardenCityPublishingCompany.

5. McCalley,B.W.(1994).ModelTFord:Thecarthatchangedth eworld.Iola,WI,U.S.:KrausePublications.

6. J. H. Boatwright: “Worldwide History of Paint”, in J. J. Matiello(ed.):Protective&Decor-ativeCoatings,Paints, Varnishes, Lacquers & Inks, vol. I, Wiley & Sons, New York.

7. Green,M.L.(2001)JournalofCoatingsTechnology.

8. Rochard,S.(2001)ModernPaintandCoatings.

9. Anonymous,Automobilproduktion(12/2000)38.

10. K¨onneke,E.(2002)Journalf¨urOberfl¨achentechnik.

11. DApublicationandBASFunpublishedstudy

12. deLange,P.G.(2004)PowderCoatings–Chemistryand Technology,Vincentz,Hannove

13. Thomer,K.W.,Vesper,H.(1997)I-Lack.

14. 4 Autojahresbericht (2004), Verband der Automobilindustriee.V.(VDA).

15. Batth,R.S.,Nayyar,A.,&Nagpal,A.(2018).Internetof RoboticThings:DrivingIntelligentRoboticsofFutureConcept,Architecture,ApplicationsandTechnologies.In 2018 4th International Conference on Computing Sciences(ICCS).

16. H.-J. Streitberger and K.-F. Dossel (2008) Automotive Paints and Coatings. WILEY-VCH Verlag GmbH & Co. KGaA,Weinheim

17. LiangZ,ChangG,Wang,Z.J,&EdmondC.X.L.(2017). Novel tactile sensor technology and smart tactile sensingsystems:areview.Sensors.

18. Uriel, M. H, (2016). Tactile sensors (Paris: Atlantis Press).

19. MohsinI.Tiwana,S.J.R.,&NigelH.L.(2012).Areview of tactile sensing technologies with applications in biomedical engineering. Sensors and Actuators A: Physical.

20. Francisco Y. N., Giulio R., Miguel T. T, George K, & FernandoA.C,(2017).ASurveyofRangingandImaging Techniques for Precision Agriculture Phenotyping. IEEE/ASMETransactionsonMechatronics.

21. Dave L. (2001). CCD vs. CMOS: Facts and Fiction. PhotonicsSpectra,LaurinPublishingCo.Inc.

22. Avanish K. D. & Vinod Y. (2008). Laser beam machining Areview.InternationalJournalofMachine ToolsandManufacture.

23. Markus-ChristianA.ThierryM.B.MarcL.RistoA.M.& Marc R. (2001). Laser ranging: a critical review of unusualtechniquesfordistancemeasurement.Optical Engineering.

24. Josef J. (2006). Summary of Untouched Circumgyrate Coder.GlobalElectronicsChina.

25. Shan C. (2018). The review of patented encoder technology.ChinaScienceandTechnologyInformation.

26. Hossein M. (2013). A technical review on navigation systems of agricultural autonomous off-road vehicles. JournalofTerramechanics.

27. HeZ.,&ZheyaoW.(2012).MotionMeasurementUsing InertialSensors,UltrasonicSensors,andMagnetometers With Extended Kalman Filter for Data Fusion. IEEE SensorsJournal

28. He(Herman)Tang(2017).ManufacturingSystemand Process Development for Vehicle Assembly. An SAE InternationalBook.

29. Mutschelknaus, R. (2006) ‘‘Staff optimisation and economyenhancementinthepaintshop–aninnovative conception’’,Proceedingsof5thInternationalStrategy ConferenceonCarBodyPainting,Berlin.

30. Challener,C.(2006)JournalofCoatingsTechnology.

31. Svejda,P.(2003)InProzesseundApplikationsverfahren (edsU.,Zorll,D.,Ondratschek),Vincentz,Hannover.

32. Domnick,J.(2003)Metalloberflache.

33. 5Svejda,P.(2007)Journalof¨urOberfl¨achentechnik.