Determination And Collation Of Pavement Condition Index Based On Indian Road Congress (IRC) And American Society For Testing and Material (ASTM) Methods For Roads In Jalgaon City

1,2,3,4,5 Student, Btech, Civil Engineering, Government College Of Engineering Jalgaon-425001[MS]India 6Assistant Professor, Civil Engineering Department, Government College of Engineering Jalgaon-425001[MS]India ***

Abstract - The Pavement Condition Index (PCI) is a straightforward, handy and inexpensive way to monitor the condition of surface of the roads, identify maintenance and rehabilitation needs well as to make sure that road maintenance expenses are spent judiciously This research paper is a step in the same direction, to develop Pavement Condition Index for the selected roads in Jalgaon city. The study area includes urban road sections of various roads of the Jalgaon city of overall length of 18 km . In this research paper, pavement condition is determined and compared in terms of surface distresses existing at the time of field evaluation and pavement condition index is determined using two different methods which shows prominent similarities in results

Key Words: Pavement Condition Index, IRC, ASTM, Pavement Distress, Asphalt Pavement Evaluations.

1.INTRODUCTION

This research paper presents the pavement performance evaluationfortenchosenurbanroadsectionsofJalgaoncity. The pavement condition indicator used to represent the pavementconditionofchosenselectedurbanroadsections is, combined Overall Pavement Condition Index (OPCI). These indices were developed severally then combined together to form an OPCI giving significance of each indicator.Thepavementconditiondatawasaccumulatedin the year 2022-23, which involves measurements of longitudinal and transverse cracking, alligator cracking, potholes,rutdepth,patching,raveling,roughness,structural deflectionandskidresistanceforallthe chosentenurban road sections. All the individual condition indices and the combined index ranged from the value 0 to 100. The pavementconditionwasratedbasedthesevaluesas0-10: Failed;10-25:Serious;25-40:VeryPoor;40-55:Poor;55-70: Fair;70-85:Satisfactory;85-100:Good

Thus this research is fundamentally focused to carryout a relative study of pavement condition indexes (PCIs) evaluatedbytwostandardtechniquespropoundbyIRCand ASTM. In addition, this research also developed a PCI predictionmodelbasedonthedistressintensityofAlligator

cracking,longitudinalortransversecracking,Depressionor settlement, Raveling, Potholes, and Patch work. The PCIs were estimated based on the field database information collected by visual inspection survey on selected Low volumeroadsectionsoflengthintheJalgaoncity.

2. METHODOLOGY

2.1 Method as per ASTM D6433

2.1.1 Considering Sections

Toassesstheworthofapavement,firstofall,thepavement nexus should be classified into branches (such as streets, parkingareas,etc.)andeachbranchshouldbeclassifiedinto segmentsthathavecertainharmoniouscharacteristicsright throughtheirareaorlength,suchasstructuralcomposition, construction history, traffic and pavement condition. A sampleunitisanyconspicuousareaofthepavementsection. Itisthesmallestcomponentofthepavementnexus Criteria forconsideringsectionsisasfollows,

First,thesamplesizeshouldbechosenadequatelythelength ofthesampleshouldbe30manditswidthistakenequalto widthoftheroad.Thesecondstepistoevaluatethenumber ofsamplestobeselectedforinspection.Thenumberoftotal samplesNinabranchisprocuredbydividingthelengthof thebranchbythelengthofthesample,asshownbelow:

N=Lengthofthesection/Lengthofthesample

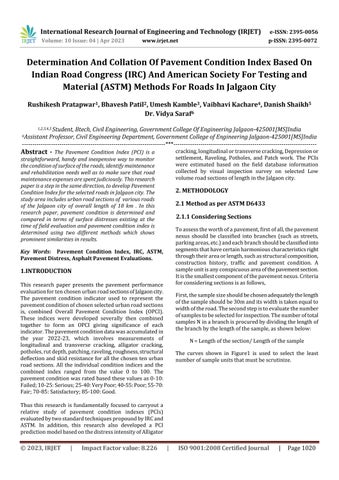

The curves shown in Figure1 is used to select the least numberofsampleunitsthatmustbescrutinize.

ConsiderPCIrangecurveforAsphalt=25

Tofindthenumberofsamplestobesurveyed,startontheN scale,proceedverticallytothesuitablecurve(PCIrange= 25)andreadthevalueonthenscale.Thiswillgivenumber ofsampleunitsshouldbesurveyed.Thespacingintervaliof theunitstobechosenistakenfromthefollowingequation:

i=N/n

where,

iisthespacingbetweenthesamples

Nisthetotalnumberofsamples

nissamplestobesurveyed.

Allthesamplenumberswithinafeaturearenumbered,and those that are multiples of the interval i are selected for evaluation.Thefirstsampleunittobeinspectedshouldbe selectedatrandombetween1andisampleunits.

2.1.2 Inspecting Distresses

For the scrutiny of distresses of the chosen road, one or moresectionsoftheroadselected.Lengthofthesectionwill be30m.Sectionisselected sothatitcoversmorenumber distresses in it. Then each distress is evaluated and its dimensionsarenoted.Thetypesofdistressesareasfollows

1. Alligatorcracking

2. Bleeding

3. Blockcracking

4. Bumpsandsags

5. Corrugation

6. Depression

7. Edgecracking

8. Jointrefectioncracking

9. Lane/shoulderdropoff

10. Longitudinalandtransversecracking

11. Patchingandutilitycutpatching

12. Polishedaggregate

13. Potholes

2.1.3 Density Calculations

Densityofthedistresses,measuredinsquaremetre(m2)is calculatedasfollows:

Density=(Distressamountinm²/Sampleunitareainm²) ×100

Densityofdistressesmeasuredinlinearmetre(bumps,edge cracking,jointreflectioncracking,lane/shoulderdrop-offas wellaslongitudinalandtransversecracks)iscalculatedas follows:

Density=(Distressamountinlinearm/Sampleunitarea inm²)×100

Density of distresses, as measured by the number of potholes,iscalculatedasfollows:

Density=(Numberofpotholes/Sampleunitareainm²) ×100

Afterthedensityofdistressesforeachdistresstype/severity combinationiscalculated,thedeductvaluesareevaluated from the suitable distress deduct values. Then CDV is determined.

2.1.4 Severity calculations

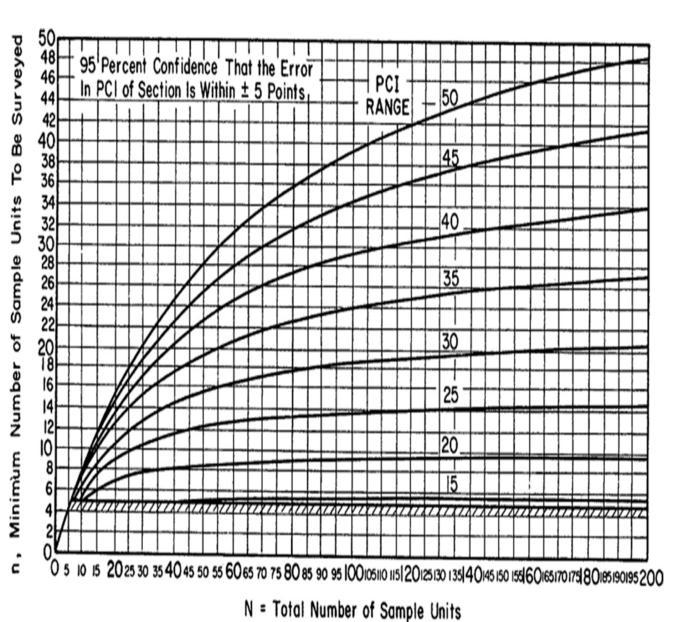

Thecircumstantialdescriptionofvarioustypesofdistresses considered with their level of severity is given in Table No.1The distress index is evaluated using the principle of Maximum Allowable Extents (MAE). The maximum allowableextent(MAE)forlow,mediumandhighseverity levelforeachtypeofdistresswhichisusedtoevaluatethe PCIhasalsobeengiveninTable.

Table1:Distresstypeandseverity

Corrected deduct value is obtained. The corrected deduct valueistakenfromthegraph.Thegraphiscorrecteddeduct valueagainsttotaldeductvalue.Thegraphiscomprisedof variouscurveshavingdifferentqvalues.Theqisthetotal numberofdeductvaluesgreaterthan2.Then,byselecting appropriate curve of q, the corrected deduct value for corresponding total deduct value is obtained. While determiningtheCDV,ifanyindividualdeductvalueishigher thantheCDV,theCDVissetequaltothehighestindividual deductvalue.

2.1.8 Calculating PCI value

Once Corrected Deduct Value is obtained, PCI value is calculatedbysubtractingCorrectedDeductValuefrom100. Then, by comparing value the PCI value with given range, ratingoftheroadisgiven.ThePCIcanbefoundoutbythe

PCI=100–CDV

Table2:PCIRating

2.1.5 Preparing data sheet

After scanning distresses in the sections of the road and determiningthetypesofdistressesandtheirseverities,the data sheet is produced. The datasheet comprises all distresses,theirseverity,densityanddeductvalue

2.1.6 Deduct value calculation

After obtaining densities of each distress, deduct value of eachdistressisevaluated.Thedeductvalueisobtainedby comparingthedensityofthatdistressinthestandardgraph. Graphisofdeductvalueagainstdistressdensity.Thereare three curves in the graph representing severities of distresses as low, medium and high. According to the severityofthedistresses.

2.1.7 Total Deduct Value and Corrected Deduct Value

Oncealldeductvaluesarecalculated,totaldeductvalueis obtained.Totaldeductvalueissumofalldeductvalue.Then

ThePCIofthepavementsectionisdeterminedbyaveraging thePCIofitssampleunits.Ifanyadditionalsampleunitsare inspected,aweightedaveragemustbeused.Theweighted averageiscomputedbyusingthefollowingequation:

PCIᴀ=(N-A)PCI₁/N+APCI₂/N

Where,

PCIᴀ=PCIofpavementsection, PCI1=averagePCIofrandomsamples, PCI2=averagePCIofadditionalsamples, N=totalnumberofsamplesinthesection,and A=numberofadditionalsamplesinspected.

2.2 Method as per IRC:82-2015

2.2.1 Considering Section

Inthismethodthepavementisalsodividedinto branches (suchasstreets,parkingareas,etc.)andeachbranchshould be divided into sections that have certain consistent characteristics throughout their area or length, such as structural composition, construction history, traffic and pavementcondition.Asampleunitisanyidentifiableareaof the pavement section. It is the smallest component of the pavementnetwork.

First,thesamplesizeshouldbeselectedproperlybecause; thetotal widthofthepavementwill varyaccordingtothe typeofroad.Itwasdecidedtoselectthesamplesize30m long.Thesecondstepistodeterminethenumberofsamples tobechosenforinspection.Thenumberofsampleunittobe inspectedwillbesameasthatofprevious.

2.2.2 Inspecting Distresses

Fortheinspectionofdistressesoftheselectedroad,oneor moresectionsoftheroadselected.Lengthofthesectionwill be30m. section is selected so than it covers more number distresses in it. Then each distress is inspected and its dimensionsarenoted.Thetypesofdistressesinspectedare asfollows(AswehaveselectedurbanroadsinJalgaonCity),

1. Cracking

2. Raveling

3. Potholes

4. Settlement

5. Rutdepth

2.2.3 Density Calculation

Densityofthedistresses,measuredinsquaremetres(m2)or squarefeet(ft2),iscalculatedasfollows:

Density=(Distressamountinm²/Sampleunitareainm²) ×100

Density of distresses measured in linear feet or metres (bumps, edge cracking, joint reflection cracking, lane/ shoulder drop-off as well as longitudinal and transverse cracks)iscalculatedasfollows:

Density=(Distressamountinlinearm/Sampleunitarea inm²)×100

Density of distresses, as measured by the number of potholes,iscalculatedasfollows:

Density=(Numberofpotholes/Sampleunitareainm²) ×100

2.2.4 Assigning Rating

Accordingtothedensityofthedistressinthegivensection theratingisgiventothecorrespondingsection.

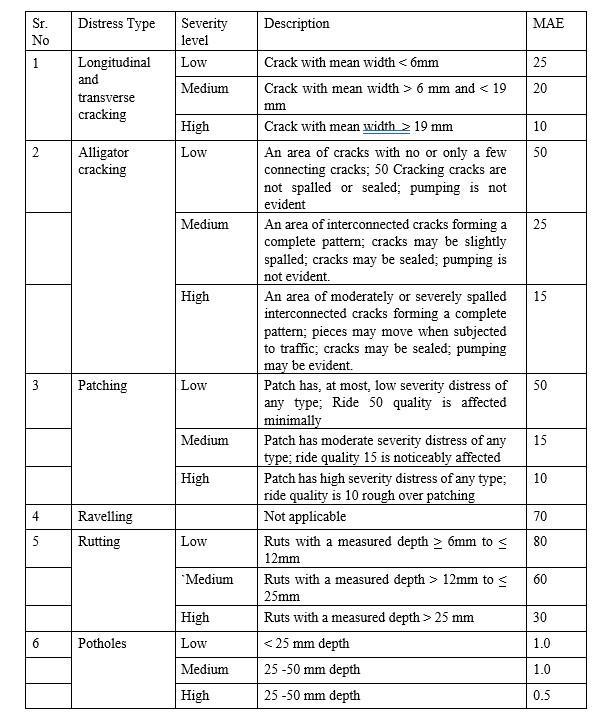

2.2.5 Assigning weightage (Fixed Multiplier Factor)

After assigning rating to each parameter an appropriate weightage is given to rating value of each parameter for calculationofweightedratingvalueofeachparameter.The Followingweightagehasbeenfixedforeachparameteras shownbelow,

2.2.6 Calculation Of Weighted Rating Value

TheFinalRatingValueiscalculatedbytakingtheaverageof theWeightedRatingValues ofallparametersviz.cracking, ravelling, potholes, shoving, patching, settlement and rut depth.Similarly,finalratingforothercategoryofroadsmay alsobeworkedout,usingthesameapproach.

2.2.7 Calculating PCI Value

AccordingtotheAverageoftheweightedratingvaluePCIof thesectionisdetermined.

Table5:WeightedRatingValue

PavementCondition WeightedRatingValue

Good

Fair

2.1to3.0

1.1to2.0

Poor 0to1.0

3. Comparison between Methods

AsinASTMthepavementisclassifiedasFailed,Serious,Very poor, Poor, Fair, Satisfactory and Good. But in IRC the pavementsectionis classifiedasPoor,FairandGood. The relation between the two methods can be established as follows,

Table6:ConditionClassification

Good Good,Satisfactory, Fair Fair,Poor

Poor VeryPoor,Serious,Failed

ThepavementconditionratingfromASTMandIRCcanbe co-relatedasfollows,

Table7:ConditionRating

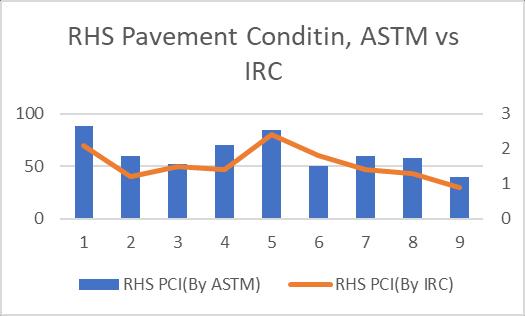

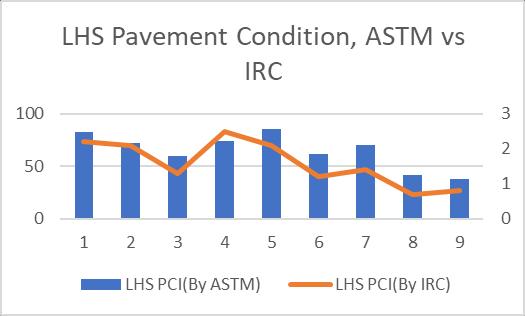

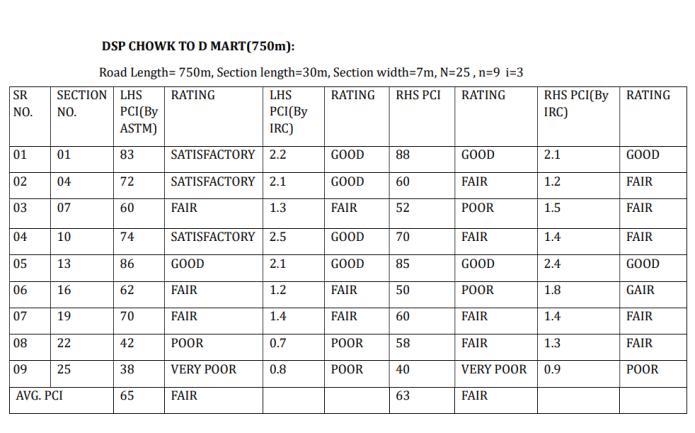

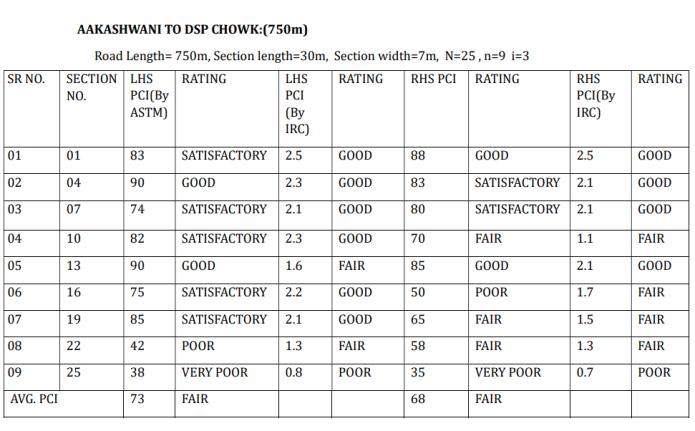

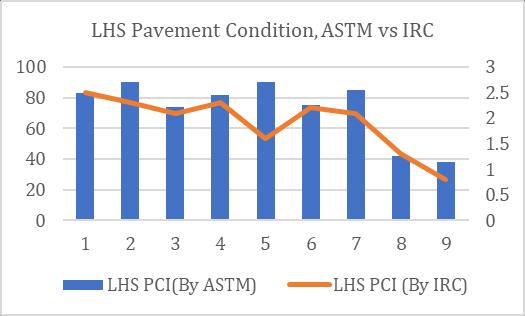

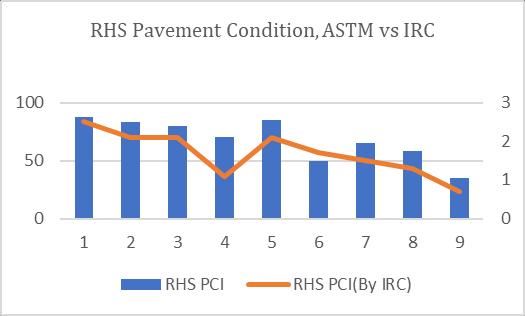

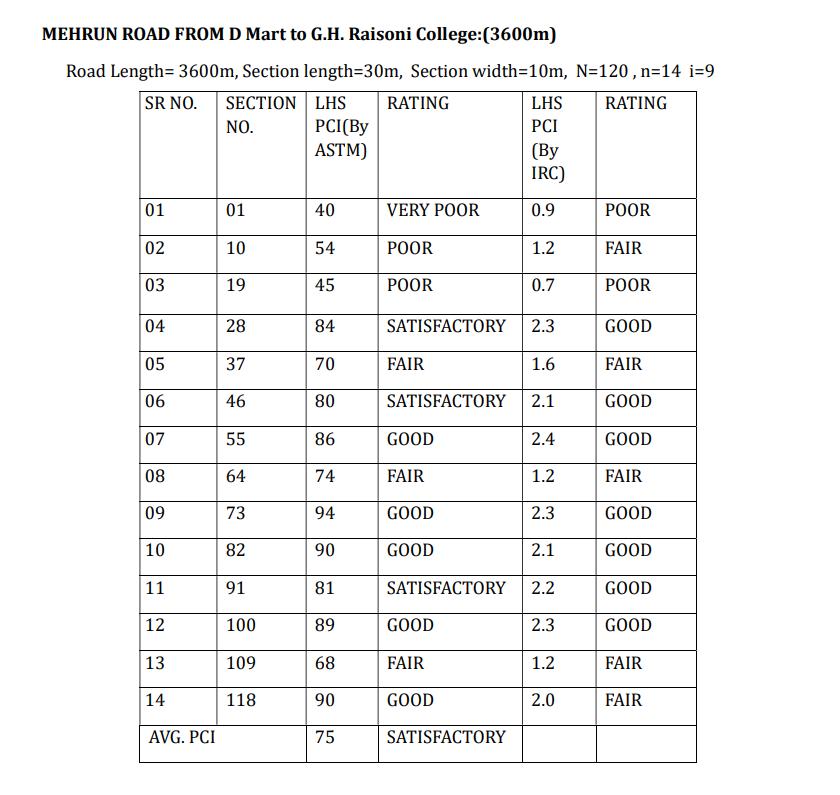

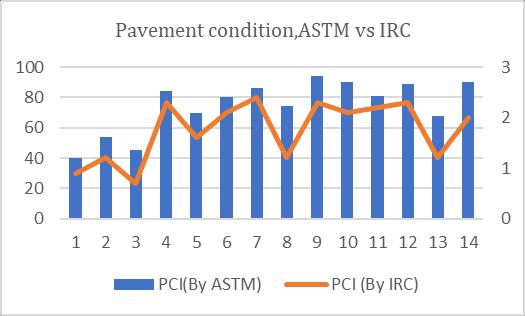

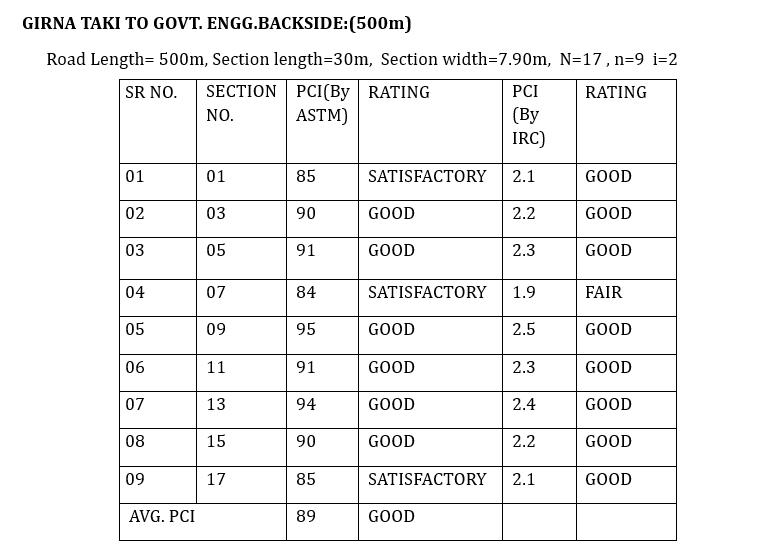

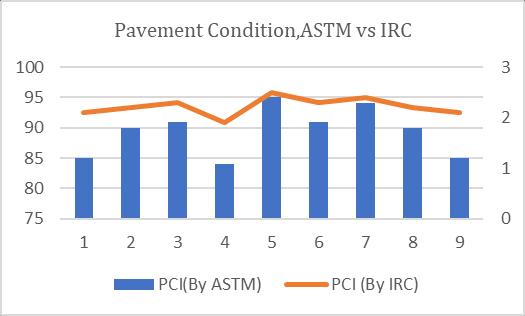

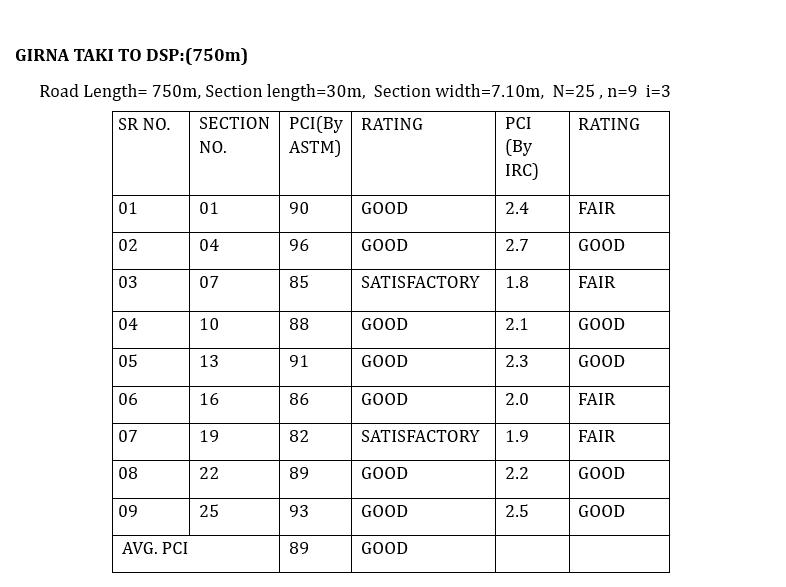

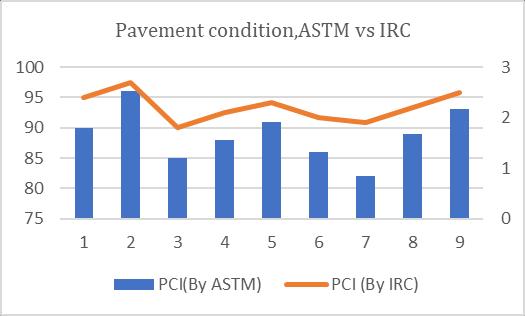

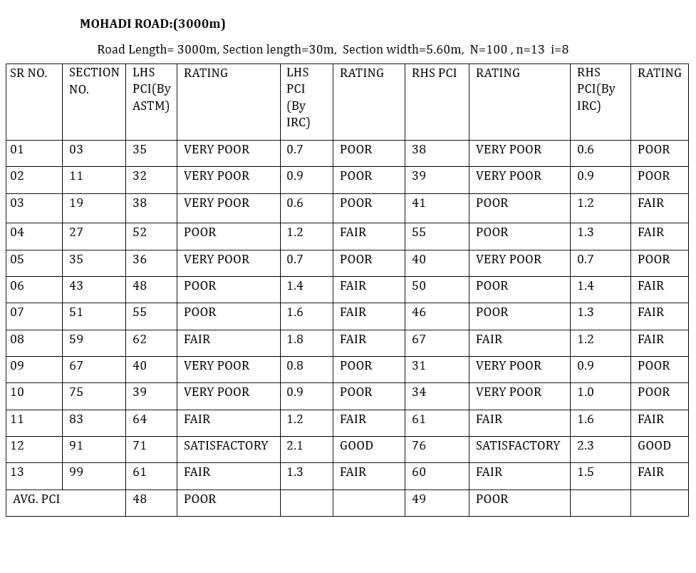

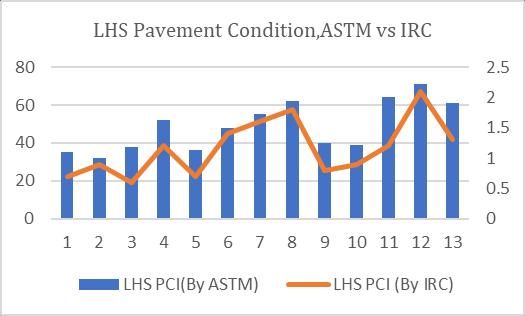

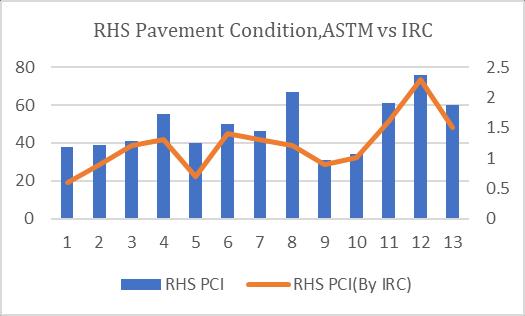

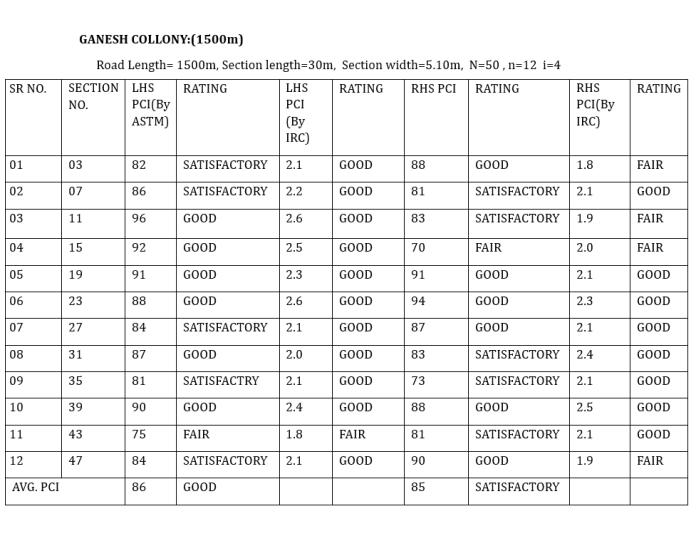

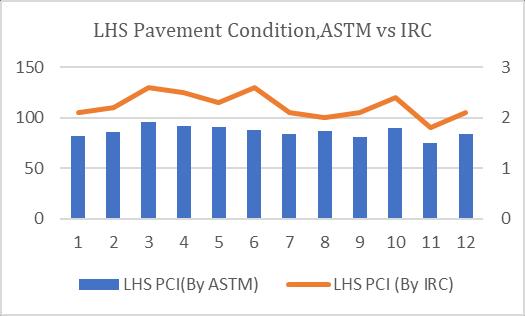

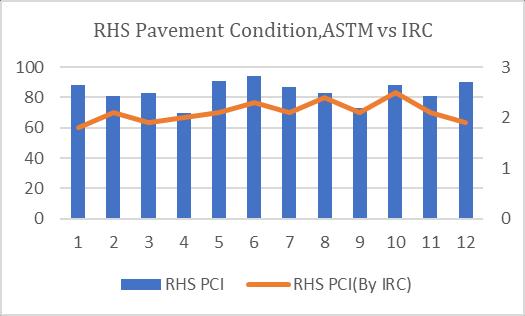

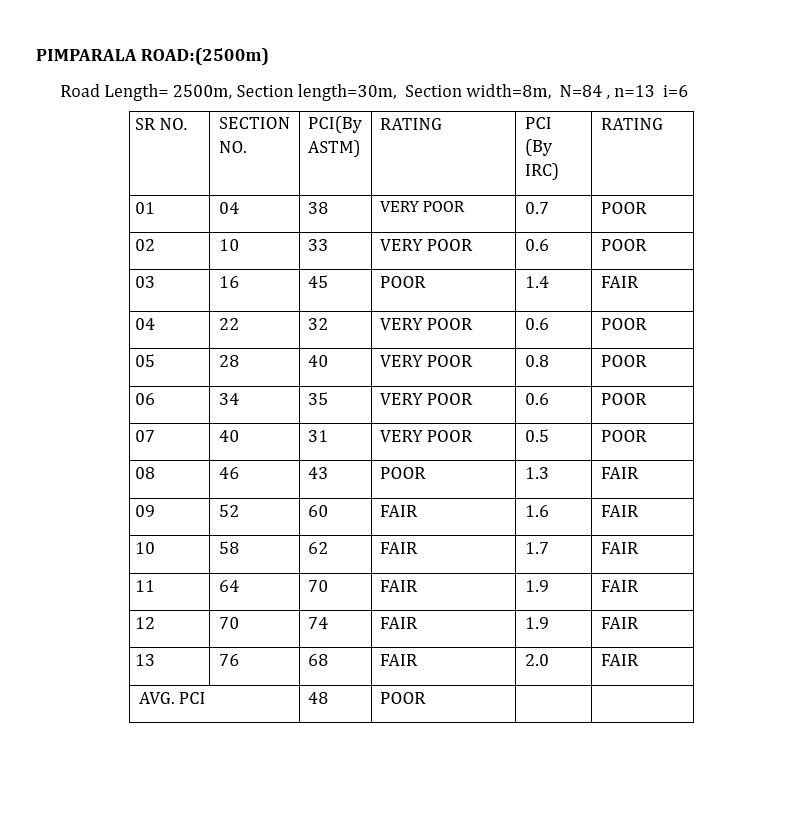

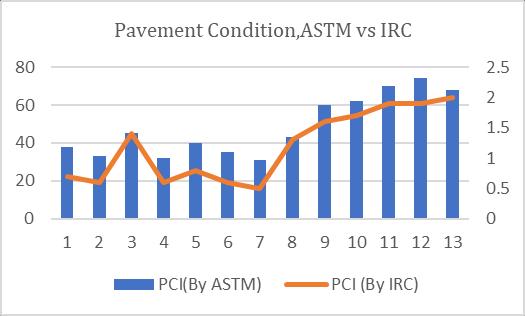

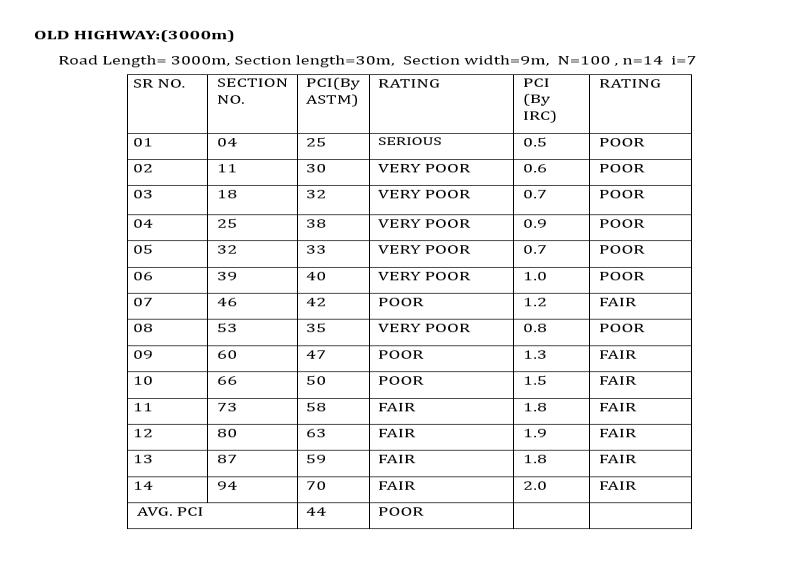

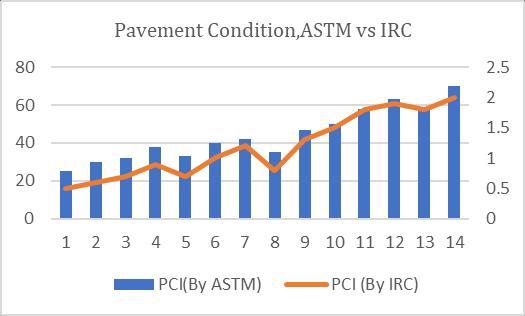

4. Result And Observation

Thepavementconditionratingforthedifferentroadsunder observationareasfollows,

Table

Good 70to100 2.1to3.0

Fair 41to69 1.1to2.0

Poor 0to40 0to1.0

4. Conclusion-

The objective of the paper is to develop a Pavement PerformanceIndexforruralroadstoassesstheperformance oftheseroads.

Thus, in this paper various pavement deteriorating parameterswereidentifiedthroughliteraturereviewThe ObjectiveofthepaperistodevelopaPavementPerformance Index for rural roads to assess the performance of these roads.

Thus, in this paper various pavement deteriorating parameters were identified through literature review The objectiveofthepaperistodevelopaPavementPerformance Index for Urban roads in Jalgaon city to assess the performance of these roads. Thus, in this paper various pavement deteriorating parameters were identified. The similarityinthepavementratinginboththemethodsisin rangefrom0.81to0.97

InASTMmethodweconsiderthedistressseverity,itsdeduct value,totaldeductvalueandcorrecteddeductvalue,butin theIRCMethodweonlyconsiderthedensityofthedistress onpavementitsRatingisgivenasperIRC82:2015,thenavg oftheweightedratingvaluegivesthePCIoftheroad.

ThePCIRatingoftheselectedroadsintheJalgaoncitywill varyinbetweenPoortoVeryGood(ByASTM),FairtoGood (ByIRC).

5. REFERENCES

[1]Procedia,SocialandBehaviouralScience,Developmentof OverallPavementConditionIndexforUrbanRoadNetwork.

[2] Prof. Dr Fareed M. A. Karim, Dr Khaled Abdul Haleem RubasiandDrAliAbdoSaleh.TheRoadPavementCondition Index (PCI), Evaluation and Maintenance. A Case Study of Yemen.

[3] ASTM D6433-07, American Society for Testing of Materials “Standard Practice for Roads and Parking Lots PavementConditionIndexSurveys”UnitedStates.

[4]IRC:82-2015,firstdivisionIndianRoadCongress,New Delhi“Codeofpracticeformaintenanceofbituminousroad surface”.IndianRoadCongress.

[5]MohammadTariqandDr.S.S.Pimplikar,“AComparative StudyonPavementConditionRatingMethods forFlexible Roads,”IJEDR,vol.5,issue3,2017.

[6] Mohammad Tariq and Dr. S.S.Pimplikar, “A Review of PavementConditionRatingModelsforFlexiblePavements”, IRJET,vol.6,issue6,June.2019.

[7] Soliman Abu-Samra and Tarek Zayed, “Pavement Condition Rating Using Multiattribute Utility Theory”, J. Transp.Eng.,PartB:Pavements,2017.

[8] Anurag Sinha and Pratik Hagawane,” Method ComparisonofPavementConditionRatingbasedonIRC& ASTMGuidelines”,Volume:07Issue:05,May2020.

[9] Sigurdur Erlingsson (2013) “Failure Modes in Pavements”FlexiblePavementDistressModes,Pp:03-12.

[10]HighwayPreservationSystem,Ltd“PavementCondition EvaluationManual”HighwayPreservationSystem,Pp:01-27