Effect of Phosphoric Acid Stabilization And Fiber Reinforcement In Dredged Soil

Nimisha G Prasannan1, Ms Arya K S 21PG Student, Dept. of Civil Engineering, Sarabhai institute of Science and Technology, Kerala, India

2Assistant Professor, Dept. of Civil Engineering, Sarabhai institute of Science and Technology, Kerala, India

Abstract - Disposal of dredged sediment is a environmental burden. To improve the mechanical properties of sediment treatment techniques are required. Phosphoric acid can be effectively used as a stabilizing agent. dredged sediments stabilized with mixing varying % of phosphoric acid by 2,4,6,8,%. Optimum % of acid is obtained by standard proctor test and UCS test. Natural fiber reinforcement in soil helps to improve the tensile and compressive strength of soil Sisal fiber reinforcement in soil improve the ductile behavior of soil. In this project, reinforcement with sisal fiber is completed by randomly mixing with varying % of fiber. In this study various laboratory test such as standard proctor test and UCS test were performed to evaluate the use of varying % (0.25, 0.5, 0.75 &1) of sisal fiber - soil composite.

Keywords— unconfined compressivestrength(UCS), dredged sediment, phosphoric acid, sisal fiber.

1.INTRODUCTION

The disposal of contaminated sediment is a environmental burden. To improve the mechanical properties of the sediment soil stabilization and soil reinforcementareeffective.Differentmethodsareusedfor soil stabilization. The phosphoric acid can be used as a stabilizingagent.Fiberreinforcementinsoilhelpstoimprove the ductile property. Stabilized soil – fiber composite has severalapplications.Naturalflexiblefiberapplicationinsoil improvecompressiveandtensilestrength.Sisalfiberinsoil have many more advantages because it’s have excellent resistancetofungiandbetterinsulationagainsttemperature andsound

2. LITERATURE REVIEW

A.S. Michaels et.al.(2017) : Acidic phosphorous CompoundsasSoilStabilizers.Testsareconductedona soilhavingSpecificgravity2.69,Liquidlimit20%,and Plasticlimit14%.Soilatitsnaturalwatercontentwas blendedwithadditionalwaterinasmallBaker-Perkins sigma-mixer until visibly homogeneous. phosphoric aciddissolvedwithotheradditivesandmixed.Samples tested in UCS test. Provided phosphoric acid concentrationis1to10.

A.Chandel et.al.(2018) : Conductedastudybasedon the application of coir and fly ash in clayey soil. The obtained soil having a Specific gravity 2.72, Gravel –sand content 13.78 % ,Silt content 41.62 %, Clay content44.60% ,Liquidlimit37%,and Plasticlimit 26%.Thespecificgravitychangesfrom2.727to2.649 andthendecreaseswithincreasein%additionoffly ashfrom0%to16%.

J. Wei et.al.(2018) : ConductedastudyonSisalFiber and Polyurethane Admixture on the Strength and MechanicalBehaviorofSand.Inthis investigation,sisal fiber (SF) and water-based polyurethane (PU) were used to reinforce sand. A series of unconfined compressiontestswerecarriedoutonsandspecimens atdifferentpercentagesoffibercontents(0.2%,0.4%, 0.6%,and0.8%)andpolymercontents(1%,2%,3%, and4%).MaxUCSvalueoccursat3%addition.

K. Balaji et.al.(2019) : ConductedastudybasedonSoil StabilizationusingPhosphorusPentoxide..Thetestis conductedonaclayeysoilhavingspecificgravity2.5, liquid limit 58% and plastic limit 37.6%.standard proctor compaction test is done on the soil to determinetheOMCandMDDvalues.UCStestisdoneto determinethecompressivestrengthvalues.thestrength increasedat5to10%additionthendecreasedat15% addition.

Sandyarani et.al.(2018) : Conducted a study on StabilizationofblackcottonsoilbyusingSisalfiber.The testisconductedonblackcotton soilhavingMoisture content (%) 22.33 specific gravity 2.683, liquid limit 66.6% and plastic limit 27.20%. soil samples were prepared with adding varying % of sisal fiber (0.2,0.4,0.6 and0.8%) with varying length. Max MDD occursat0.4%additionandmaxUCSvalueobtainedat 0.4%addition.

M. E Kumar et.al (2019) : This study is based on InfluenceofSisalFibersonthePropertiesofRammed Earth. inthisstudyredsoilmixedwithdifferent%of (5,10,15and20%)ofOPCandsisalfiberwithvarying % (0.2,0.4,0.6,0.8 and 1%). The bamboo splits were treatedwithchemicalsolution.After28daysofcuring

periodthecubesweretestedforcompressivestrength, pull-outtestisdone.Thecompressivestrengthismore for20%mixtureaddition.

R.Marcal et.al.(2020) : This study evaluated the strengthcharacteristicsoflateriticsoilreinforcedwith wastestrips.15mmwidthppstripsofdifferentlength used in the soil. This combination is added in clayey sand and clayey soil. 0.25 to 2% of pp strips with varying length is mixed in soil. UCS and CBR test is conductedtodeterminethecompressivestrengthand bearing capacity of soil. And result showed that CBR valueincreasedto133%.

Marques A et.al.(2021) : This research uses stabilizationmethodbyusinglimeandphosphoricacid. Inthisprojectdifferent%oflimecontentwith55opf phosphoricacidisused.Varying%oflimecontentare 6,8,10,and12%. UCS test is done to determine the compressive strength value of soil. Max UCS value obtained at 12% of lime and 5% of phosphoric acid addition.

3. OBJECTIVES

Theobjectivesofthisstudyare:

Todeterminemaximumdrydensity,optimum moisturecontentandunconfinedcompressive strength of soil with different percentage of phosphoricacid.

Todeterminemaximumdrydensity,optimum moisturecontentandunconfinedcompressive strengthofphosphoricacidstabilizedsoilwith differentpercentagesofsisalfiber.

4. MATERIALS USED

The materials used in the project collected from various regions

4.1 Dredged sediment

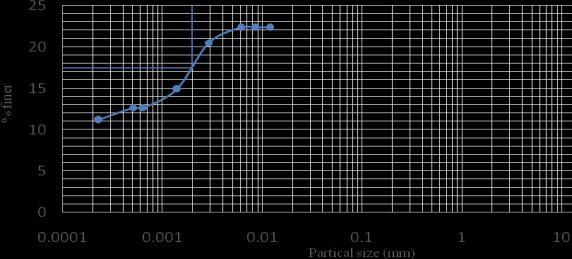

The soil used in the project dredged from Neyyattinkara.dredgedsoilwasairdriedinlaboratory. The soilgradationcurveisgiveninFig.1.Thesoilisclassifiedas silt of intermediate plasticity (MI). The compaction tests werecarriedoutonthesoil,andtheoptimumwatercontent (OMC)andmaximumdrydensity(MDD)are18%and14.51 kN/m3,respectively.ThesoilpropertiesareshowninTable 1

Table-1:Propertiesofsoil

Chart - 1: Gradationcurve

4.2 Phosphoric acid

Phosphoric acid is a colorless, and odorless substance.Itisusedinsoftdrinksforacidicproperties

4.3 sisal fiber

Thesisalfiberobtainedfromleavesofsisalplant.It havehigherstrengthanddurabilityithavebetterresistant tosaltwater.

Table - 3 : propertiesofsisalfiber

Tensilestrength(N/mm²) 400-700

Young’smodulus(N/mm² 38000

Table - 4 : chemicalcompositionofsisal

Chemical composition percentage

Cellulose(%) 65

Hemicelluloses(%) 12

Lignin(%) 9.90

Waxes(%) 2

5. RESULT AND DISCUSSIONS

5.1 Stabilization with phosphoric acid

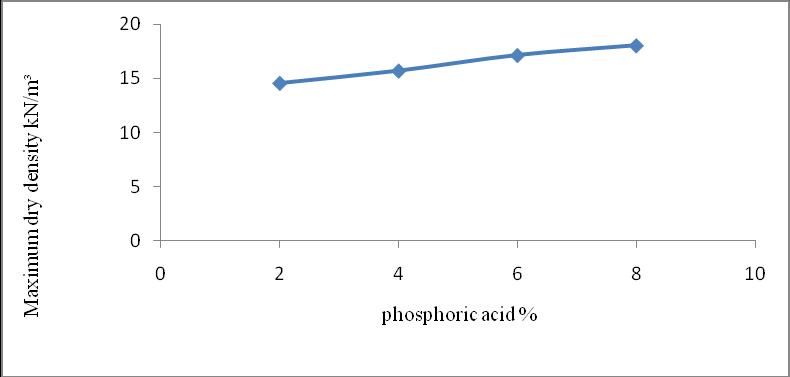

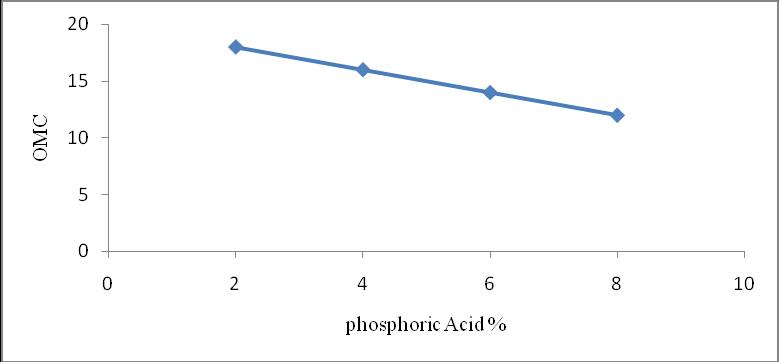

Theresultsofstandardproctortestin table 5 shown that , OMC decreased with respect to the increaseofstabilizingagent.Similarly,MDDvalueincreased withrespecttotheincreaseinphosphoricacid.Becausethe increase in dry volume weight of stabilizing material. Variation optimum moisture content & maximum Dry Density forvarying%ofphosphoricacidisshowninchart 2.

Table – 5 : variation optimummoisturecontent, maximum drydensityandUCSvalue forvarying%of phosphoricacid.

Chart - 2 : Variation optimummoisturecontent& maximum DryDensity forvarying%ofphosphoricacid.

Chart - 3 : Variation optimummoisturecontent for varying%ofphosphoricacid.

Chart - 4 : Variation maximum DryDensityforvarying %ofphosphoricacid.

Table – 6 :variation optimummoisturecontent, maximum drydensityandUCSvalueofstabilizedsoil withvarying%of sisalfiber.

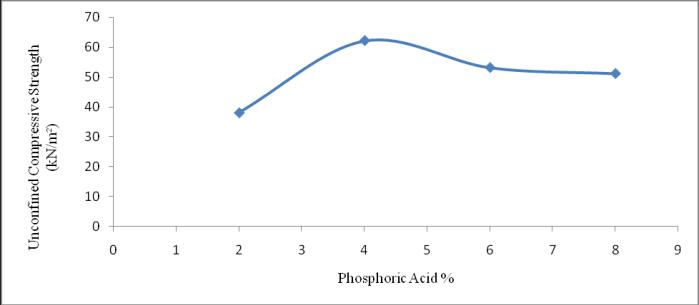

The result of the UCS test shown in chart5.Fromthisresult,theadditionofphosphoricacid in soil increase compressive strength values Maximum UCS valueobtainedat4%phosphoricacidaddition.UCSvalueof soil increased from 24.52 KN/m2 to 62.12KN/m2 at 4% phosphoric acid addition. Addition of phosphoric acid provedtobeagoodstabilizingagent.

Chart - 5 : Variation UCSvalueforvarying%of phosphoricacid

5.2 combination of sisal fiber with phosphoric acid stabilized soil

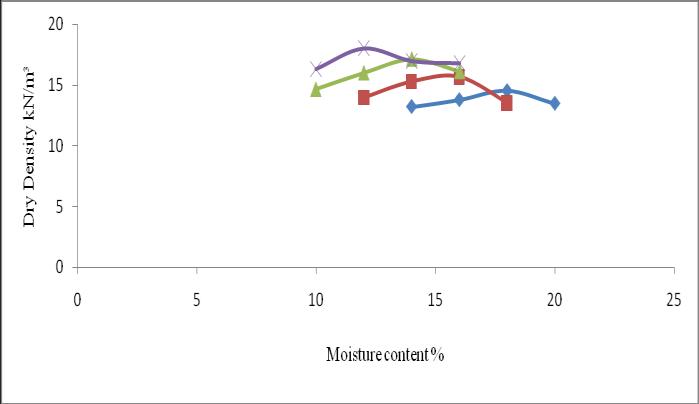

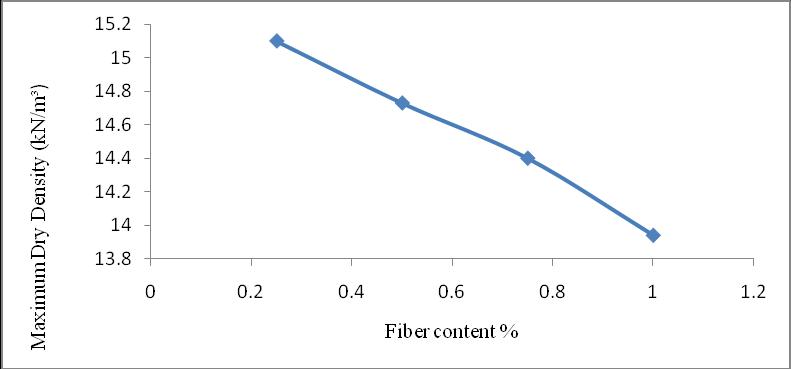

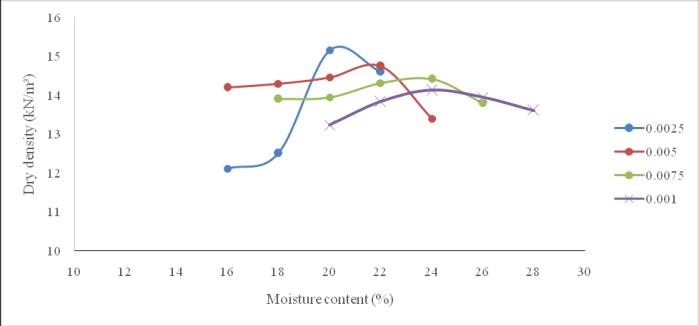

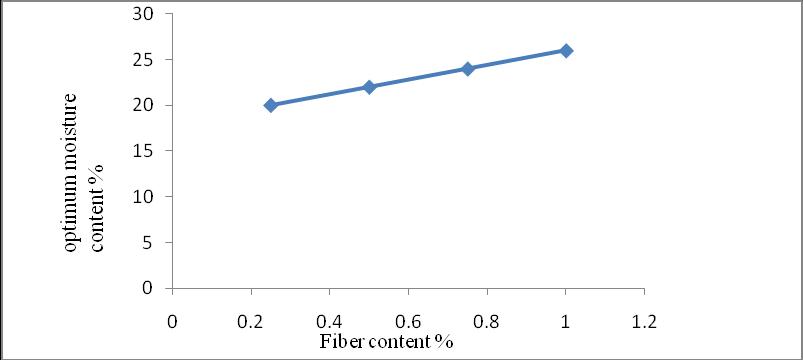

TheresultsofstandardproctortestandUCStestis givenintable6.ThevariationofMDDandOMCwithrespect different%ofsisalfiberandoptimum%ofphosphoricacid isplottedinchart 8.Resultshowedthatthereisaincrease in OMC occurs at increase in fiber addition. And there is decreaseinMDDoccursduetothereplacementofheavysoil massintolightweightfiber.

Chart - 7 : Variationofoptimummoisturecontent value forvarying% ofSisalfiberofstabilizedsoil.

Chart - 6 : Variationof maximumDryDensityvaluefor varying% ofSisalfiberofstabilizedsoil.

Chart - 8:

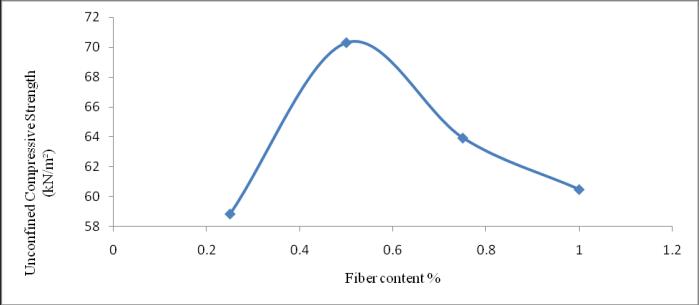

TheresultoftheUCStestshowninchart 9.From thisresult,maxUCSvalueobtainedat0.5%fiberaddition. UCSvalueofstabilizedsoilincreasedfrom24.52KN/m2 to 70.29KN/m2 at0.5%fiberaddition.IncreaseinUCSvalue observedduetotheinteractionbetweenfiberandsoilandit confinesthesoilparticles.AdecreaseinUCSvalueobserved after 0.5% fiber addition due to the interaction between fiber.Duetothisdecreaseinstrengthisobserved.

6. CONCLUSIONS

It is found that application phosphoric acid as chemicalstabilizerprovedtobeabetterperformanceinsoil. Andcombinationofsisalfiberandphosphoricacid insoil helps to improve the mechanical properties such as

compressive strength and tensile strength. In case of phosphoric acid stabilization UCS value of stabilized soil with respect to control sampleswas in the range of 24.52 KN/m2 to 62.12KN/m2. Similarly in case of soil-fiber compositeUCSvalueoffiberreinforcedsoil withrespectto control samples was in the range of 24.52 KN/m2 to 70.29KN/m².Additionofphosphoricacidasastabilization materialcanincreasethevalueofcompressivestrengthup to 116%.Sisal fiber reinforcement in stabilized soil can increasethevalueofcompressivestrengthupto186%.The use of natural fibers in soil improves the compressive strengthascomparedtothesyntheticfibers.

ACKNOWLEDGEMENT

Thisprojectwouldnothavebeensuccessfulwithout thekindsupportand valuablehelpofmanyindividualsand organizations.Iwouldliketoexpressmydeepest gratitude toallofthem.Ithanklordalmighty forprovidingmewith everythingthatIrequiredinsuccessful completionofthis project.IamhighlyindebtedtomyguideinchargeMs.Arya K S. Without her help, guidance and patience the thesis wouldnothavebeensuccessful.AndI expressmydeepest thankstotheHeadoftheDepartment,Prof.R.Jayachandran Nairfortheirguidanceandsupportinthisthesis.Mysincere thankstomyparents,friendsandallthosewhohavebeen instrumentalinthesuccessfulcompletionofthethesis.

REFERENCES

[1] A. Dahal & M. Lal (2021) ‘Performance enhancement of subgrade soil with marble dust and sisal fibers comparativeStudy’ Journal of emerging technologies and innovative research(JETIR) .

[2] A .K Sharma, P. Swetha & S. kolathyar (2019) ‘comparitive study of sisal and PVA fiber for soil improvement’Researchgate.

[3] A.Singh&RSharma(2018)‘AStudyofBlackCottonSoil by Using Sisal Fibre and Coconut Fibre’ International Research Journal of Engineering and Technology (IRJET).

[4] DebtanuSeth,SureshPrasadSingh &ShubhamSingh (2019) ‘Strength and Permeability Characteristics of FibreReinforcedLinerMaterial’ Elsevier Ltd.

[5] J.wei,F.Kong,J.Liu&C.Jiang(2018)‘EffectofSisalFiber and Polyurethane Admixture on the Strength and MechanicalBehaviorofSand’ Elsevier Ltd.

[6] JiliQu andHao Zhu(2020) ‘Function ofPalmFiberin Stabilization of Alluvial Clayey Soil in Yangtze River Estuary’ Journal of Renewable Materials.

[7] J.Francisco, M.Arteaga, S.Gluhar, A.Kaurin, & D.Lestan, (2021) ‘Simultaneous removal of Arsenic and toxic

metalsfromcontaminatedsoil laboratorydevelopment andpilotscaledemonstration’ Elsevier Ltd.

[8] J. Prabakar ,R.S. Sridhar ( 2002 ) ‘Effect of random inclusion of sisal fibre on strength behaviour of soil’ Researchgate

[9] K.Balaji&C.Sheba(2019)1587‘SoilStabilizationusing PhosphorusPentoxide’ International Research Journal of Engineering and Technology (IRJET) Volume:06Issue: 06 June2019.

[10] M.Amrutha&Dr.K.YRaneesh.(2016)‘EffectofStrength CharacteristicsofExpansiveSoilUsingSisalFibreand Waste Materials’ International Journal of Science and Research (IJSR) Volume5Issue9.

[11] S.Mazloomi,S.Nasseri,R.Nabizadeh,K.Yaghmaeian, M. Alimohammadi, S. Nazmara And A. Hossein Mahvi (2016) ‘Remediation of fuel oil contaminated soils by activated persulfate in the presence of MnO2 ‘ Soil & Water Resource.

[12] S.M.Kavitha,B.SMohamedC.Muniyappan&V.Sathish Kumar (2019) ‘ Stabilization of soil using sisal polypropyleneandhybridfibers’ lnternational Journal of Advance Research Ideas and Innovations in Technology

[13] V. S Mathada, Sandyarani & Sharanakumar (2018) ’Stabilization of black cotton soil by using Sisal fiber’ International Research Journal of Engineering and Technology (IRJET)

[14] W.Yankai,L.Yanbin,andB.Niu(2014)‚Assessmentof theMechanicalpropertiesofsisalfiberreinforcedsilty clay using Triaxial shear tests.‘The Scientific World Journal.