Pick and Place Robotic Arm utilizing Microcontroller and Wireless Communication

Umar M. Pirjade #1 , Sahil R. Tonde#2, Zia-Ur-Rehman Junnedi#3, Shekhar S. Wankhede#4 , Prashant A. Kamble#5 , Amita N. Dubey*6

#Department of Electronic and Telecommunications, JSPMs RSCOE Polytechnic, Tathawade Pune *Head of Department, of Electronic and Telecommunications, JSPM’s RSCOE, Polytechnic Tathawade Pune

Abstract - The purpose of this study is to design a prototype of a robotic arm which can be controlled through wireless technology. In this scheme, robotic arm of 4 Degree of Freedom is manufactured and is controlled wirelessly through a mobile app developed using MIT inventor [1] which works on Bluetooth technology. Data from the app is sent serially via Bluetooth transmitter and thereby processed on the receiver which is then used as a reference to control the robotic movement Successful tests on the linear movement of the robot were performed which results in elevation of robot deployment potentials.

Key Words: Robotic arm 4 DOF, Robot remote control, BluetoothModuleHC-05

1.INTRODUCTION

The development of robotics technology basically aims to assist humans in performing a particular job, and it is a veryfastevolvingresearchfieldtoday.Somespecifickinds of robots that can ease human task are arm robot (manipulatorrobot).Armrobots aredesignedtohold,lift, and move objects. Robotic Arm are mainly used due to their ability of higher precisions and accuracy which can result in constancy in greater production quality and less productiontime.

The Robotic Arm can be controlled wirelessly using the Bluetooth Technology, it is interfaced to the microcontroller using a Bluetooth module known as HC05. An app is developed for the android platform, which communicates serially from the android smartphone to the HC-05 module, which then is processed and executed usingmicrocontrollerandthecorrespondingservos.Basic layoutoftheroboticarmisinspiredbyreference [1].

1.1 Background

A.Definition:

ThetermrobotwasfirstintroducedinEnglishin1921bya CzechoslovakianplaywrightnamedKarelCapekinhisplay titled R.U.R (Rossum's Universal Robots). Robots in the earliersenseare"forcedlabour"whichmeansslavelabour, but in the modern sense of the word, the robot has undergone extension of meaning [2]. A Robotic arm is

basicallyamachinewhichisverysimilartoahumanhand, it consists of a combination of links attached in series or parallel.Itcanbecontrolledbyprogrammingittoperform aspecifictask [3] .

Arduino UNO is a microcontroller board based on the ATmega328P.Ithas14digitalinput/outputpins(ofwhich 6canbeusedasPWMoutputs),6analoginputs,a16MHz ceramic resonator, a USB connection, a power jack [4] ArduinoUnocanbepoweredthroughaUSBconnectionor by an external power supply, and the power source is selected automatically. It can be operated at a voltage of 7Vto12V.

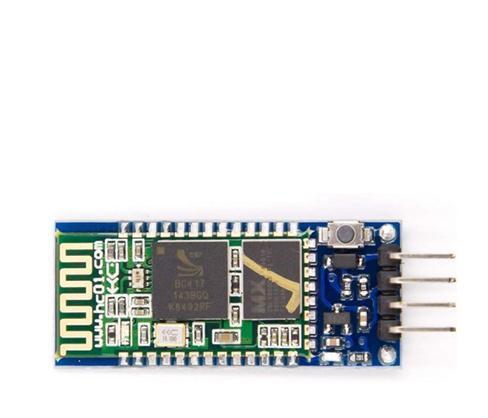

HC-05 is a Bluetooth module which is designed for wireless communication. This module can be used in a master or slave configuration. Bluetooth serial modules allowallserialenableddevicestocommunicatewitheach

otherusingBluetooth.Itworksonthefrequencyof2.4GHz ISM Band. It operates on 3.6V to 6V and its range is approximately10meters.

D.ServoMotor:

Servo motor is a DC motor with a closed feedback system in which the position of its rotor will be communicated back to the control circuit in the servo motor. This motor consists of a DC motor, a set of gear, potentiometer, and the control circuit. Potentiometer serves to define the limitsoftheangleofrotationservo.Whiletheangleofthe axis servo motors regulated by pulse width signal sent throughthelegsofservomotorcable [2] .

2)Wireless communications module HC-05 as sender and recipientofthedatainstructions.

3)Motorservoactuator180degreesasrobotarms.

4)Barrel Jack adapter for external power supply for Arduinoandperipherals.

5)Android Supported Smartphone to transmit data for controlofarm.

6)SensorShieldV5.0forServomotorsconvenience.

7)The components of electronics, cables, PCB (Printing CircuitBoard),leadandconnectors.

B.Software:

Thesupportingsoftware’susedinourworkare:

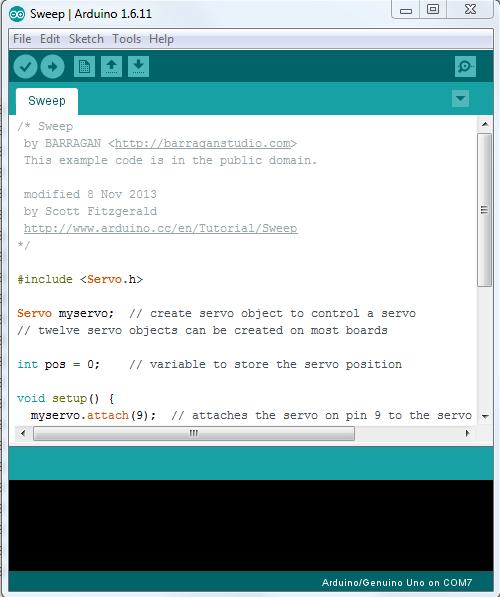

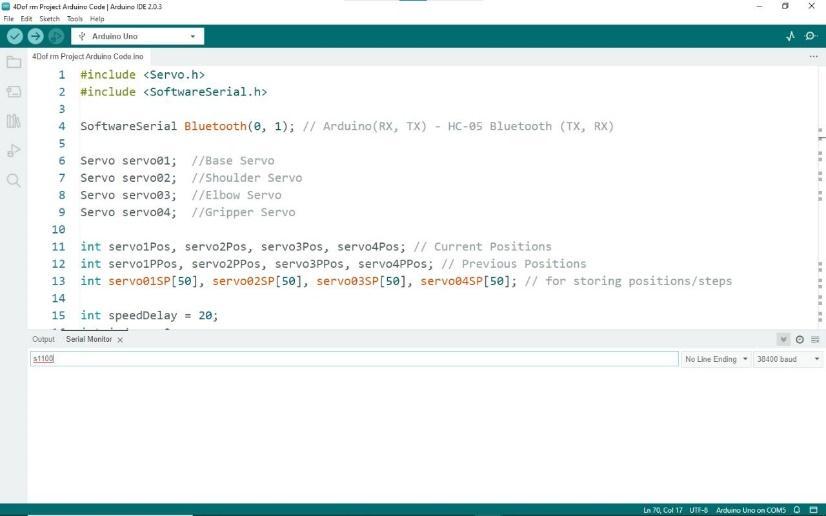

1)The Arduino IDE is used to create the program in the microcontroller.

2)MITappinventor

3)BlenderforModelvisualization

C.HardwareDesign:

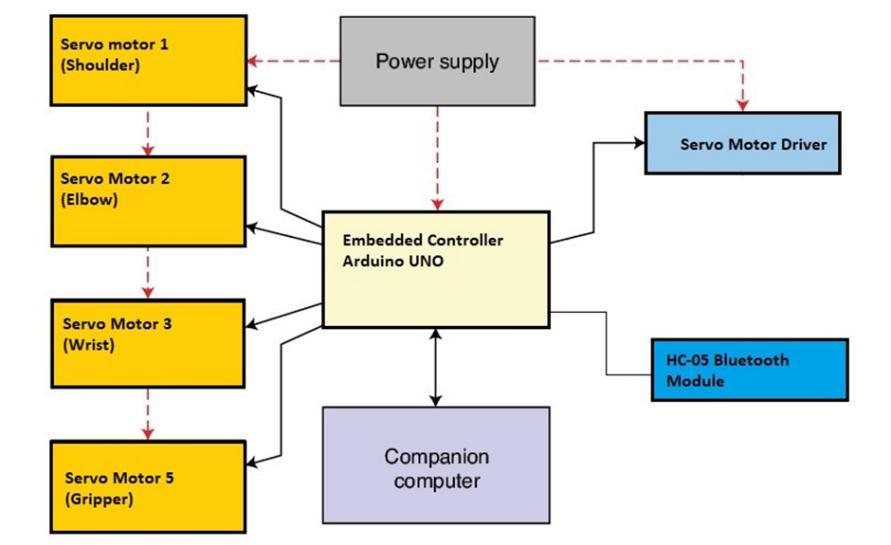

Thegeneraldescriptionofthesystemcanbeobservedon blockdiagrambelow:

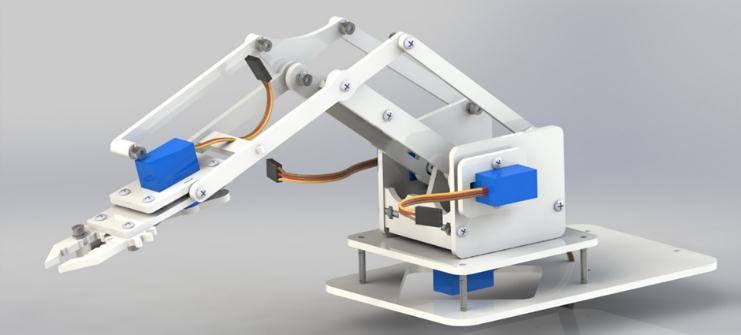

In our work the robotic arm we deigned is visualized in thepictureabove.Inthisconfigurationwehave4Degrees of Freedom, named Base, Shoulder, Elbow and Gripper. Eachjointisrotatedorgivenanangularadjustmentusing servo motor, Servo Motors are electromechanical devices which converts the electrical energy into angular mechanicalenergy.

2. Design Methods

A. Materialandtools:

Materialsusedinthedesignofhardware,amongothers:

1)ArduinoUnoR3Microcontrollerasadata processor.

2. RESULTS AND DISCUSSION

Table1:TheRobotSpecifications

CheckeduploadingthetestcodesfromArduinoIDEtothe microcontrollerasshowninFig.7

A.Designrealization:

Roboticarmof4Degreesoffreedom,despiteofitslimited jointsofaxesitcanstillcarryoutmultipletaskscarriedout inthreedimensions,suchaspickandplace,pull,andpush testsubjectswhichweighuptoapproximately150gms

B.TestingMicrocontrollerandSensorShieldV5.0:

To test the microcontroller and the sensor shield, a single servo motor is connected, and sample sketches or programswereruninordertoconfirmthefunctionalityof thehardwarebeforehand.

C.BluetoothModuleTesting:

Bluetooth Module is tested by connecting the smartphone to the HC-05 Bluetooth Module and monitoring output on the serial monitor which is integrated in Arduino IDE as showninFig.7andFig.8

D. Running the robotic arm with complete configurations: -

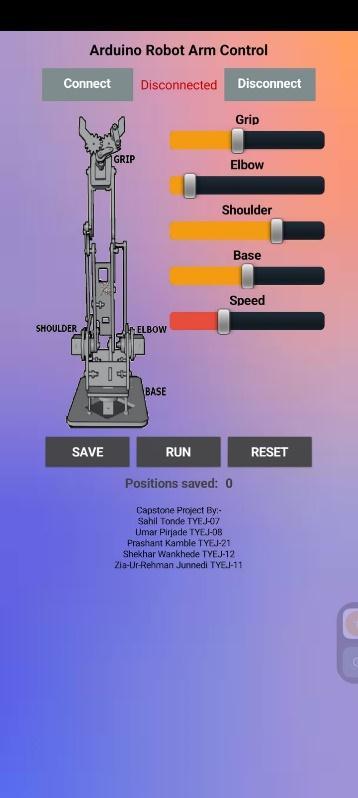

App developed using MIT App inventor is installed on smartphone and all the required connections are made properlyaccordingtotheblockdiagramandschematics.

As the mechanical aspects were inspired by the reference [6], assembly and modifications to the gripper were made toachieveourparticulargoal.

App contains sliders to adjust robotic arm’s joints as shown in Fig.9. The Robotic arm moves according to the valuesandlimitsimplementedintheapp.

Arm jitters due to a continuous stream of data from android app to the serial of HC-05 Bluetooth Module as shown in Fig.8. Continuous stream of data fed to the Arduino microcontroller makes it an invalid data string whichisthemainreasonbehindthejitters.

This can be resolved by sending data from the app if and onlyifthesliderisadjustedandthefingerisliftedofffrom theslider. Thiswill causethesliderto sendonlyone data string, which in return will make processing function as expected.

3. CONCLUSIONS

1)The Four Degree of Freedom (4DOF) has enabled the robotic arm to perform the designed movements very well. Furthermore, the mobile robot successfully follows thecommandfromeachinputvariablesliderfromtheapp tomovetheroboticarm.

2)Even though the robotic arm has only 4DOF it can still perform crucial tasks accurately and precisely if the jitter problemissolved.

REFERENCES

[1] DIY Arduino Robot Arm with Smartphone Control [Online] Available at: https://howtomechatronics.com/tutorials/arduino/d iy-arduino-robot-arm-with-smartphone-control/

[2] I.B. Alit Swamardika, I N. Budiastra, I N. Setiawan, N. Indra Er “Design of Mobile Robot with Robotic Arm Utilising Microcontroller and Wireless Communication”,International Journal ofEngineering andTechnology(IJET),ISSN (Print):2319-8613ISSN (Online):0975-4024

[3] Sharath Surati, Shaunak Hedaoo, Tushar Rotti, Vaibhav Ahuja, Nishigandha Patel, “Pick and Place RoboticArm:AReviewPaper”,InternationalResearch Journal of Engineering and Technology (IRJET), Volume: 08 Issue: 02 | Feb 2021, e-ISSN: 2395-0056, p-ISSN:2395-0072

[4] ArduinoTM.(t.t.).ArduinoUnoR3.[Online].Available: https://docs.arduino.cc/hardware/uno-rev3

[5] ElectronicsWings, HC-05 Bluetooth Module [Online]. Available: https://www.electronicwings.com/sensorsmodules/bluetooth-module-hc-05-

[6] Youtube channel SriTu Hobby “How to assemble and control a 4 DOF robot mechanical arm kit with Arduino”. [Online]. Available: https://www.youtube.com/watch?v=Q9JOKQaIR1w& t=663s&ab_channel=SriTuHobby

BIOGRAPHIES

UmarMurtuzaPirjade, PursuingDiplomaofThreeyears inElectronicsand Telecommunication,JSPM’s RSCOE,Polytechnic,Tathawade Pune.

Zia-Ur-RehmanMohammed RafiqueJunnedi, PursuingDiplomaofThreeyears inElectronicsand Telecommunication,JSPM’s

RSCOE,Polytechnic,Tathawade Pune.

SahilRohidasTonde, PursuingDiplomaofThreeyears inElectronicsand Telecommunication,JSPM’s

RSCOE,Polytechnic,Tathawade Pune.

ShekharSandeepWankhede, PursuingDiplomaofThreeyears inElectronicsand Telecommunication,JSPM’s

RSCOE,Polytechnic,Tathawade Pune.

PrashantAshokKamble, PursuingDiplomaofThreeyears inElectronicsand Telecommunication,JSPM’s

RSCOE,Polytechnic,Tathawade Pune.

AmitaN.Dubey, HeadofDepartment,ofElectronic andTelecommunications,JSPM’s

RSCOE,PolytechnicTathawade Pune