Numerically and CFD studies on shell and tube heat exchangers

Chandrashekhar Pawar1 , Purushottam Sahu2 , Ghanshyam Dhanera31Reseach scholar, BM College of Technology, Indore

2Professor and HEAD BM College of Technology, Indore

3 Professors, BM College of Technology, Indore ***

Abstract - This study aims to investigate the effect of different baffle layouts on the STHX (rate of heat transmission and pressure loss) of the A tube heat exchanger. The addition of baffles to the tube and shell mechanism enhances the heat switch while also boosting pressure. Best one, doubled, helical, triple section, and flowery baffles are used in tube heat exchangers, and they are designed using SOLIDWORKS go with the flow simulation software (ver. 2015). A single segmental baffle exhibits the best mass price and heat transmission rate on the shell side, according to simulation results. There are almost no stagnation zones inside the helical baffle, which results in significantly less fouling and a longer operating lifetime due to less flow-induced vibration.

Key Words: Kern'stheoreticalapproach,ASPENSegmentalbaffles,Helicalbaffles,Flowerbaffles,Heattransfercoefficient, Pressuredrop,SOLIDWORKSflowsimulation.

1. INTRODUCTION

Oneofmoststronglycrucialcomponentsofanation'seconomicandsocialdevelopmentistheproductionofenergy.Demand fornaturalresourcesandenergyisrisingdailyasaresultofpopulationgrowth,industrialization,urbanisation,andexpanding globaltradeandproductionopportunities.Theusageoffossilfuelsasasourceofenergy,dependencyonforeignsourcesof fuel,highimportcosts,environmentalissues,andthequickdepletionofglobalfossilfuelreservesallraisetheimportanceof renewableenergysources.Currently,renewableenergysourcesaccountfor20%ofglobalenergyconsumption[1].

ApowerproductionsystemcalledtheOrganicRankineCycle(ORC)runsatlowtemperaturesandsubstituteshydrocarbonbasedorganicworkingfluidsforwater.Modelsofdifferentcomplexitylevelsforshell-and-tubeheatexchangers

Thestudyandanalysisofseveralheatexchangermodelshasbeenconducted.Thegeneralpresumptionsmadebyallofthe modelsareoutlinedinthelistbelow.

1.Radiationandheattransportratesinfluidsareinsignificant.Axialheatisalsonegligibleinbothfluids.

2.Theheatcapacityofthetubewallsiszeroinboththenormaldirectionandthedirection.

3.Thethermalcapacitanceoftheheattransmissionshellisdisregarded.thatisonlyonedimensionalandflow-oriented.

2Methodologies:theuseofheatexchangers

Aseparate,in-depthresearchwillbeneededtocovereachareaoftheapplicationofheatexchangersbecauseitissuchavast topic.Theiruseisfrequentlyfoundinhomeappliances,mechanicalequipment,andtheprocesssector.Districtsystemscanbe heatedusingheatexchangers,whichareincreasinglybeingusednowadays.Inordertocondenseorevaporatethefluid,heat exchangersareutilisedinairconditionersandfreezers.Theyalsoworkinpasteurisationunitsinmilkprocessingfacilities.[3]. Heat Transfer Characteristics. Theinlet/outlettemperaturedifferentialontheshellside,inlet/outletpressuredroponthe tube side, heat transfer area of the working fluid on the shell side, and heat transfer coefficient of the tube wall were all calculatedusingnumericalanalysis.First,thetemperaturedifferenceontheshellsidewascalculatedasthedifferencebetween themeasuredinletandoutlettemperatures.Likewise,thepressuredropwasalsocalculatedasthedifferencebetweenthe measuredinletandoutletpressures.

2. Methodology:

2.1STHX'slayoutwiththesimulationtoolASPEN

Aheatexchangercanbedesigned,rated,simulated,andpricedusingthissoftware.Here,theheatexchangercreatedusing Kern'stheoreticalapproachissimulatedusingASPEN.Alltheinformationpertainingtotheheatexchanger'sgeometryandthe

fluid'sparametersmustbeenteredintothesoftware'ssimulationmode.Thefluidstreams'inputtemperaturesandflowrates mustalsobespecified.ItprovidesaTEMAsheetthatshowstheheattransfercoefficients,pressuredropbothontheshelland tubesides,andotherdatathatareimportantinheatexchangerdesign.TheinputforASPENsimulationsoftwareprogramin thiscaseisasprovenwithinthefollowingdesk2,

I. ProblemDefinition

A. ApplicationOptions

1. General CalculationMode Simulation

LocationofHotfluid Shell-Side

SelectGeometryBased on SIstandards

CalculationMethod Advancedmethod

2. Hotside

Application Liquid,nophasechange

SimulationCalculation Outputtemperature

3. Coldside

Application Liquid,nophasechange SimulationCalculation Outputtemperature

B. ProcessData

I. PropertyData

PropertiesoffluidswereimportedformASPENdatabase

I. ExchangerGeometry

A. Shell/Heads FrontHeadType B-bonnet bolted or integral

V.

A.

B.

1. CodesandStandards

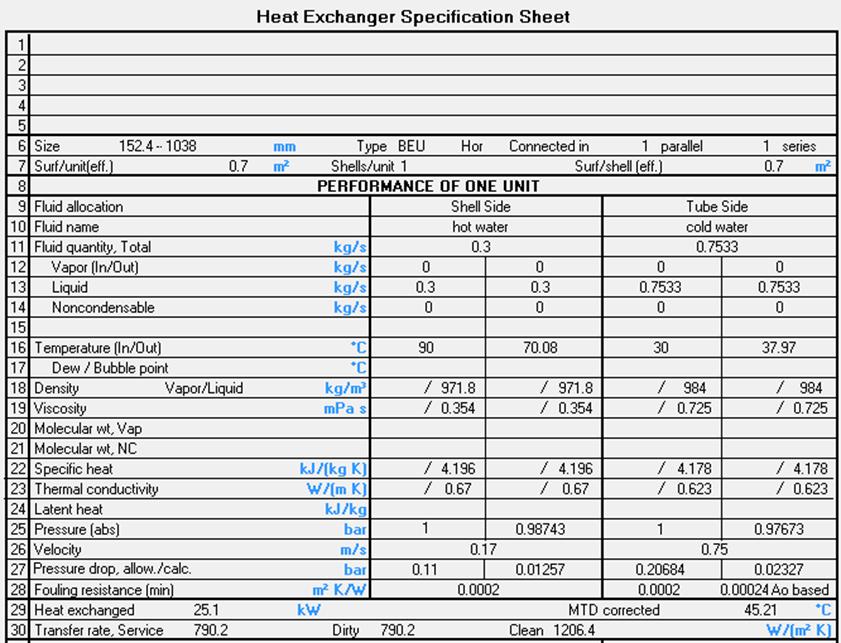

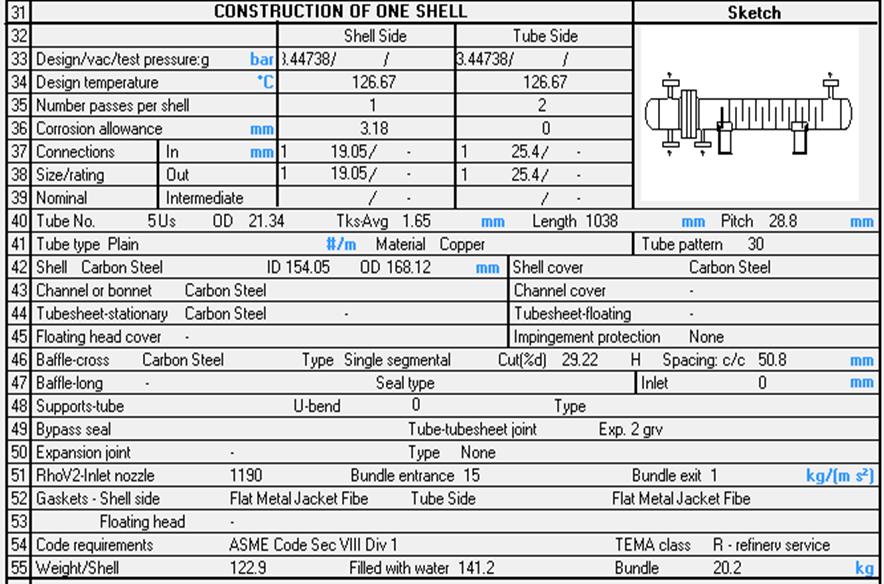

TEMAConstructionDetailsofShellandTubeHeatExchangerasprovidedbyASPENSimulation(Table3.2).Thespecification sheet shown in Fig. 3.1 and the TEMA specification sheet shown in Fig. 3.2 are the results of the APSEN Simulation programmed.

4. RESULTS ANDDISCUSSION

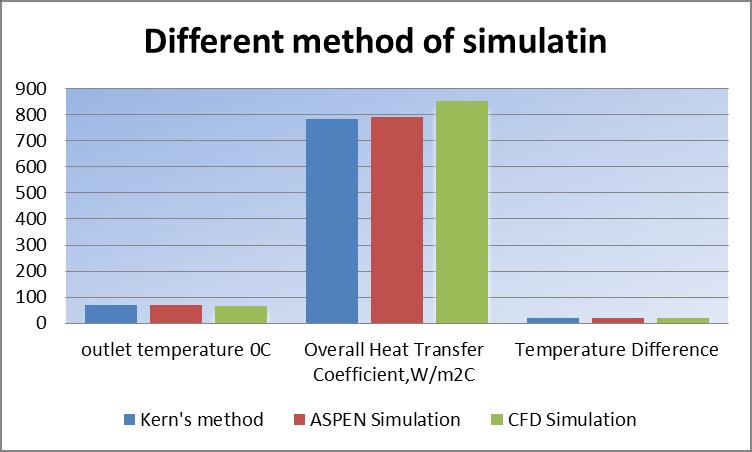

Table 4 assessment of normal heat switch Coefficient, Shell aspect outlet temperature and Shell side temperature difference predictions

4. RESULT AMD FUTURE SCOPE

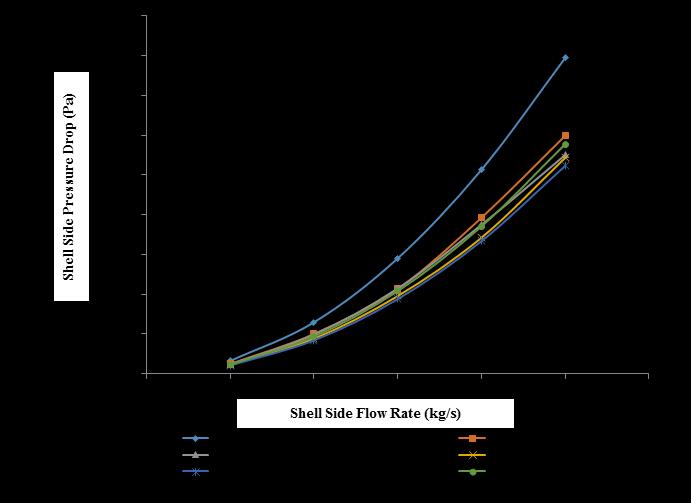

Withthesameinputparameters,aShellandTubeHeatExchangerwasconstructedusingKern'smethod,ASPENsimulation software,HTRIsimulationsoftware,andSolidWorksFlowSimulationsoftware.Theoverallheattransfercoefficientvalues were782,790.2,781.9,and852.6W/m2K,respectively.InCFDmodellingstudiesonshellandtubeheatexchangers,single, double,triple,helical,flowertypeA'type,andflowertypeB'typebafflelayoutshavebeenemployed.Thefollowingfindings camefromthesesimulationstudies:Althoughsinglesegmentalbaffleshavealowerpressuredropandahighertotalheat transfercoefficient,theyrequiremorepumpingforce.

1.Wherealittleagreementwiththeoutlettemperatureisattainable,double-segmentedbafflesmaybeusedinsteadofsinglesegmentedbafflessincethepressuredropwillbedecreasedby25%to30%,makingenergysavingsequal.

2.Helicalbafflesareeffectivebecausetheyreducepressurelossby30%to35%whencomparedtosinglesegmentedbaffles. Buttherehasbeena40%decreaseintheoverallheatswitchcoefficient.Accordingtothis,inordertocovertheareaneededto obtainthetemperaturedifferential,40%largertubesmustbeintroduced.Retrofittingwon'tbepossibleinthisscenario,but installinganewheatexchangerwithhelicalbafflesmightbejustifiedonthebasisofeconomics.Thissettingdisablestriple segmentedbaffles.

3. Because flower baffles reduce pressure drop by 25% to 35% while simultaneously lowering the overall heat switch coefficientby30%to35%withsinglesegmentedbuffers,theyarethemosteffectivebaffles.

4.FlowersBecausetheylessenpressure,FlowerB"baffles"aremoreeffectivethanFlowerB"baffles."Arashiscomparableto Flower,exceptithasbetterthermalperformance.

1.Kern'stechniqueandASPENsimulationresultsforatypicalheattransfercoefficientarecomparable,althoughreliableWorks softwarevaluesarehigherby9%.Whenusingthesoftwaresolidworks,theshellsidetemperaturedropisincreasedby6%.

REFERENCES:

[1] S. S. Shinde, S. S. Joshi, and S. Pavithran, “Performance Improvement in Single phase Tubular Heat Exchanger using continuousHelicalBaffles,” Int. J. Eng. Res. Appl.,vol.2,no.1,pp.1141–1149,2012.

[2] A. El Maakoul, A. Laknizi, S. Saadeddine, M. El, A. Zaite, M. Meziane, and A. Ben, “Numerical comparison of shell-side performanceforshellandtubeheatexchangerswithtrefoil-hole,helicalandsegmentalbaffles,” Appl. Therm. Eng.,vol.109,pp. 175–185,2016.

[3]R.ThundilKaruppaRajandS.Ganne,“Shellsidenumericalanalysisofashellandtubeheatexchangerconsideringthe effectsofbaffleinclinationangleonfluidflow,” Therm. Sci.,vol.16,no.4,pp.1165–1174,2012.

[4]F.NematiTaher,S.ZeyninejadMovassag,K.Razmi,andR.TasoujiAzar,“Bafflespaceimpactontheperformanceofhelical baffleshellandtubeheatexchangers,” Appl. Therm. Eng.,vol.44,pp.143–149,2012.

[5]A.VyasandP.Sharma,“AnExperimentalAnalysisStudytoImprovePerformanceofTubularHeatExchangers,”vol.3,no.6, pp.1804–1809,2013.

[6]S.Dogra,S.Kumar,G.Chaudhary,A.Kumar,andL.Chaitanya,“DESIGNINGOFCONDENSERSUSINGDIFFERENTMATERIALS ANDTHEIRCOMPARISION,”vol.2,no.2,pp.301–308,2014.

[7]Y.G.Lei,Y.L.He,R.Li,andY.F.Gao,“Effectsofbaffleinclinationangleonflowandheattransferofaheatexchangerwith helicalbaffles,”

[8]H.KotwalandD.S.Patel,“CFDAnalysisofShellandTubeHeatExchanger-AReview,” Int. J. Eng. Sci. Innov.Technol ,vol.2, no.2,pp.325–329,2013.

[9]J.F.Zhang,S.L.Guo,Z.Z.Li,J.P.Wang,Y.L.He,andW.Q.Tao,“Experimentalperformancecomparisonofshell-and-tubeoil coolerswithoverlappedhelicalbafflesandsegmentalbaffles,”Appl.Therm.Eng.,vol.58,no.1–2,pp.336–343,2013.

[10]D.BhattandP.M.Javhar,“ShellandTubeHeatExchangerPerformanceAnalysis,”vol.3,no.9,pp.1872–1881,2009.