Modeling and Grey Relational Multi-response Optimization Performance Efficiency of Diesel Engine

Nitesh Kumar1 , Purushottam Sahu2 , Ghanshyam Dhanera3

Nitesh Kumar1 , Purushottam Sahu2 , Ghanshyam Dhanera3

1Reseach scholar, BM College of Technology, Indore

2Professor and HEAD BM College of Technology, Indore

3 Professors, BM College of Technology, Indore ***

Abstract - In conclusion the optimal settings of those factors for better performance of the tested engine which are 25% engine load 20% hydrogen 50 ppm mwcnt 220 bar ignition pressure and 21 obTDC ignition timing

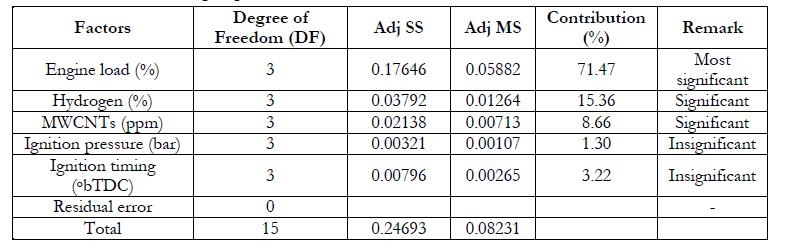

In conclusion the figure shows the optimal settings of those factors for better performance of the tested engine which are 25% engine load 20% hydrogen 50 ppm mwcnt 220 bar ignition pressure and 21 obTDC ignition timing. Table 6 displays the variance analysis (ANOVA) of the engine performance. It shows the influence and importance of each component on the performance as a whole. Engine load is discovered to be the most important factor, contributing 71.47% to the total, followed by hydrogen (15.36%) and MWCNTs (8.66%). Ignition pressure and timing made a very small contribution to the other two elements. To increase engine performance efficiency, substantial focus should be given to the aspects that have a significant impact.

Key Words: Dieselengine,greyrelationshipoptimisation,thermalefficiencyofthebrakes,fueluse,andemissions

1. INTRODUCTION

Bothhumanhealthandthe ecosystemare negativelyimpactedbythisphenomenon (Linetal.,2011;Arbabetal.,2013). Numerousstudieshavedemonstratedthatfossilfuelshaveaconsiderableimpactonthethinningoftheozonelayer(Oparanti etal.,2022).AccordingtotheInternationalEnergyAgency(IEA),therateofenergyconsumptionwouldbeapproximately53% by 2030 (Taufiqurrahmi & Bhatia, 2011). Meaning that the negative impact of using fossil fuels on the ozone layer's deteriorationby2030islikelytobeintolerable.Numerousstudieshavebeendoneonthevariousapproachestoovercome these difficulties. A single-cylinder, direct-injection diesel engine's potential for increased performance efficiency and decreasedcombustionemissionswasinvestigatedbyAbu-Jraietal.in2009.Intheirresearch,theyintroducedsimulated reformerproductgastotocompareengineperformance,combustion,andemissionsundervariousoperatingsituationstoa normal ultra-low Sulphur diesel (ULSD) and a substitute ultra-clean synthetic GTL (gas-to-liquid) fuel. They came to the conclusionthataperfectmixtureofGTLandsimulatedreformerproductgasgreatlyreducedNOxandsmokeemissions.An investigationonthecombustionandemissionsofadieseldirectengineinjection(DI)runningondiesel-oxygenatemixeswas conductedbyRenetal.in2008.Theyfoundthatregardlessofthetypesofoxygenatingadditions,therewasareductionin smokeconcentration;however,thesmokedecreasedwhentheoxygenmassfractionwithintheblendswasincreasedwithout raisingtheNOxandenginethermalefficiency.Ontheotherhand,ithadbeenshownthatwhentheoxygenmassfraction increasedintheblends,theamountsofCOandHCdecreased.Tostudythecombustionandemissions ofthecompression ignitionoftheengine,Lietal.(2015)fueledaninstantinjectiondieselwithpentanol.Additionally,therearenumerousstudies ontheoptimisationofinputvariablesfordieselengineemissionsandperformanceefficiency.Theperformanceandemissions ofadieselenginerunningonbiodieselwereoptimisedbySivaramakrishnanandRavikumarin2014.Ithadbeendiscovered thatthetestengineperformedbestatacompressionratioof17.9,afuelblendof10,andapoweroutputof3.81kW.Leungand colleagues(2006)optimisedtheinjectionpressure,timing,andplungerdiameterofthefuelpump.

2 Methodologies:

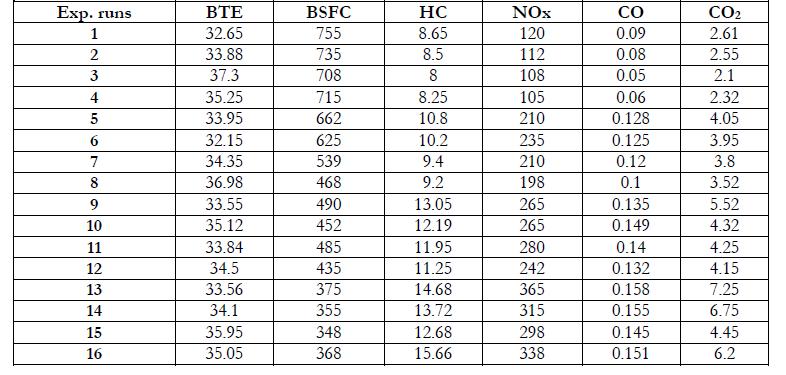

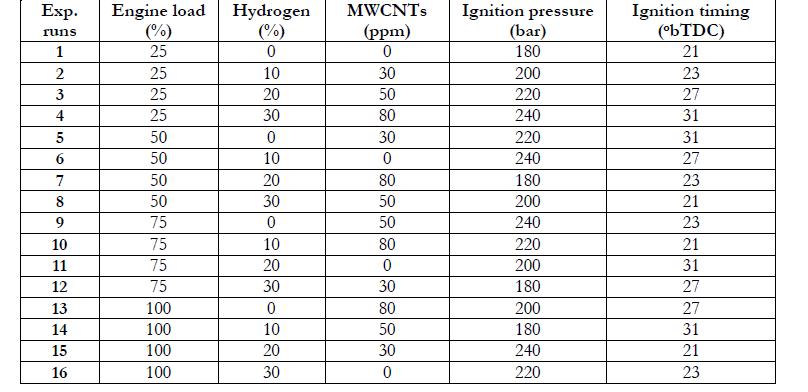

ThestudybyManigandanetal.(2020)wasfollowedbythisone.Theireffortprovidedtheexperimentaldatathatwasneeded foranalysis.Theexperimentalfactors,experimentalruns,andcorrespondingdatafortheanalysisinthisworkaredisplayedin Numbers1,2,and3,respectively.SoftwarecalledMinitab16wasusedfortheTaguchidesignandmodelling,andOrigin19was used for interaction plots and other types of plots. The experimental data shown in Table 3 underwent a grey relational analysis.Withtheuseofgreyrelationalgeneration,thedatawasfirstnormalized.AccordingtoEquation1,thehigher-thebetternormalizationconditionwasusedtonormalizethebreakthermalefficiency(BTE).

SoTaguchiDoEhasbeenusedtoidentifythecorrectcombinationofselecteddesignfactorandtheirlevelsinpresentstudy.For thepresentstudy,factorsandlevelswereselectedbasedonliteraturereviewarementionedinTable2

Table

Factorsandtheirlevels.

Specificationofthetestengine

ParametersSpecifications

GeneraldetailsSinglecylinder,4S,constantspeedcompressionignition

Engine,Dualcombustion

CoolAircooled

Bore86mm

Stroke106mm

Sweptvolume616.56cc

Compressionratio16.5:1

InjectionPressure240bar

FuelinjectionPistonpump

InjectorSolenoidcontrolled

Ratedspeed1800rpm

Therequirementforthehighestpossiblebreakthermalefficiencyisthebasisforthehigher-is-betternormalization.Afterthat, Equation2'ssmaller-is-betternormalizationconditionwasusedtonormalizetheremainingdata,whichincludedbreakspecific fuelconsumption(BSFC),hydrocarbons(HC),nitrogenoxide(NOx),carbonmonoxide(CO),andcarbondioxide(CO2).We needed those qualities to be as low as feasible, thus we chose the smaller-the-better normalization condition. The six performancetraitswerecomparedtoanidealsequence,xo(k)(k=1,2,...,16).

3 RESULTS AND DISCUSSIONS:

Thesecondnormalizedformula,typefactor,isacceptablefordefects.

Thefirstnormalizedformulaissuitableforthebenefit–typefactor.

Thesecondnormalizedformulaissuitablefordefect–typefactor.

The����(��)isthedatabeingpre-processedfortheithexperiment,and����(��)istheinitialsequenceofthemeanoftheresponses. Thedeviationsequence(Equation3)wassubsequentlycalculatedtoenablethedeterminationofgreyrelationalcoefficient (GRC).ThegreyrelationalgenerationandthedeviationsequenceofthesixexperimentaldataareshowninTable4.

Andthemaximumandtheminimumdifferenceshouldbefound.

a) b)Thepdistinguishingthecoefficientisanumberthatvariesfrom0to1..Thedistinguishingcoefficientpisusually setto0.5.

Inanalysis,Greyrelationalcoefficient canbeexpressedasfollows[15]:

Andthentherelationaldegreefollowsas:

WhereI(k)istheGRCvalueoftheparticularexperimentaldatadeterminedasafunctionofminandmax,theexperimental data'sminimalandmaximumdeviations.isthedistinguishingcoefficient,withawidelyacceptedvalueof0.5(Mahmoudietal., 2020;Abifarinetal.,2021a).

Deviatin sequence

Grey Relation Coefficient

.

4. Conclusion

Exceptforignitiontiming,theresultsdemonstratedaconsistentbehavioralpatterncausedbyengineconditions.Theoptimum valuesforEngineload(%),hydrogen,multi-walledcarbonnanotubes(MWCNTs),ignitionpressure,andtimingas25%Engine load(%),20%hydrogen,Nanoparticles50(ppm).220(bar)ignitionpressureand31Ignitiontiming(0bTDC),respectively.The optimumvaluesforBTE,BSFC,hydrocarbons(HC),nitrogenoxide(NOx),carbonmonoxide(CO),andcarbondioxide(CO2)are 36.0842,714.4110,8.09,113.16,0.0583and2.3414respectively.Thetrialrunstakenintoaccountintheanalysisdidnotinclude thediscoveredoptimalsettingsforgreaterengineperformance.Althoughconfirmationanalysisindicatedthattherewasa chance that the predicted ideal engine performance was within the confidence bound, experimental work based on the obtainedoptimalsettingsisstillrequiredeffectivenessoftheconfirmationanalysis.Engineloadwasthemostsignificant component,accordingtotheanalysisofvariance(ANOVA),contributingtoEngineloadisdiscoveredtobethemostimportant factor,contributing71.47%tothetotal,followedbyhydrogen(15.36%)andMWCNTs(8.66%).Ignitionpressureandtiming madeaverysmallcontributiontotheothertwoelements.Toincreaseengineperformanceefficiency,substantialfocusshould begiventotheaspectsthatsignificantlyaffect.

REFERENCES:

1. ScienceT.MULTI-RESPONSEOPTIMIZATIONOFDIESELENGINEOPERATINGPARAMETERSRUNNINGWITH WATER-IN-DIESELEMULSIONFUEL.2017;21(1):427-439.doi:10.2298/TSCI160404220V

2. YessianS,VarthananPA.OptimizationofPerformanceandEmissionCharacteristicsofCatalyticCoatedICEngine withBiodieselUsingGrey-TaguchiMethod. Sci Rep.Publishedonline2020:1-13.doi:10.1038/s41598-019-57129-9

3. SimsekS,UsluS,SimsekH,UsluG.Multi-objective-optimizationofprocessparametersofdieselenginefueledwith biodiesel/2-ethylhexylnitratebyusingTaguchimethod. Energy.2021;231:120866. doi:10.1016/j.energy.2021.120866

4. PatilAR,DesaiAD.ApplicationofTaguchiandresponsesurfacemethodologyapproachtoasustainablemodel developedforacompression-ignitionengineusingpolangabiodiesel/dieselblends. SN Appl Sci.2019;1(2):1-11. doi:10.1007/s42452-019-0163-7

5. SharmaA,SinghY,TyagiA.ApplicationofTaguchiandresponsesurfacemethodologyapproachtoasustainable modeldevelopedforacompression-ignitionengineusingpolangabiodiesel/dieselblends.Publishedonline2020. doi:10.1177/0959651820965301

6. WuH,WuZ.UsingTaguchimethodoncombustionperformanceofadieselenginewithdiesel/biodieselblendand port-inductingH2. Appl Energy.2013;104:362-370.doi:10.1016/j.apenergy.2012.10.055

7. UsluS.lEtherDopedDieselEnginebyTaguchiMethodMulti-ObjectiveOptimizationofBiodieselandDiethy. 2020;4:171-179.doi:10.30939/ijastech..770068

8. GanesanS,MohanrajM,KiranpradeepN,SaranRSG.MaterialsToday :ProceedingsImpactofDiisopropylEtheron VCRdieselengineperformanceandemissionwithcashewshelloilusingGRAapproach. Mater Today Proc. 2021;(xxxx).doi:10.1016/j.matpr.2021.03.628

9. PohitG,MisraD.OptimizationofPerformanceandEmissionCharacteristicsofDieselEnginewithBiodieselUsing Grey-TaguchiMethod.2013;2013.

10. SaravanamuthuM.OptimizationofEngineParametersusingNSGAIIfortheComprehensiveReductionof EmissionsfromVCREngineFuelledwithROMEBiodiesel.Publishedonline2022.

11. GanesanS,MohanrajM,KiranpradeepN,SaranRSG.MaterialsToday :ProceedingsImpactofDiisopropylEtheron VCRdieselengineperformanceandemissionwithcashewshelloilusingGRAapproach.2021;(xxxx).

12. TadkalS.ApplicationofRSMtooptimizeperformanceandemissioncharacteristicsofadieselenginefuelledwith Karanjamethylesteranditsblendswithconventionaldieseloil.2020;6(2):725-733.