EXPERIMENTAL STUDY ON COMPRESSIVE AND SPLIT TENSILE STRENGTH OF LOOFAH FIBER REINFORCED CONCRETE BY PARTIAL REPLACEMENT WITH PERLITE POWDER

Praveena P. P1 , Er Rajeev V. S2

1 PG Student, Dept. of Civil Engineering, Universal Engineering College, Thrissur, Kerala

2Assistant Professor, Dept. of Civil Engineering, Universal Engineering College, Thrissur, Kerala ***

Abstract - Materials currently viewed as workable substitutes for natural sources include industrial and building wastes. Perlite powder can enhance the strength qualities of concrete, according to earlier research on the subject. Perlite is an amorphous volcanic glass with a high water content that is often created when obsidian is hydrated. It is a commercial commodity and an industrial mineral that is valuable for its low density after processing. Perlite is also used sparingly as a clay addition in ceramics, cryogenic insulation, and foundries. The explosives sector uses it as well. Perlite is frequently utilised in biotechnological applications due to its thermal and mechanical stability, non-toxicity, and strong resistance against microbial assaults and organic solvents. This study looked into the strength characteristics of concrete reinforced using loofah fibres and perlite powder. The sponge gourd, commonly known as loofah fiber, is a cheap natural fibre reinforcement. The loofah fibre is treated for 24 hours with a 4% con. NaOH solution, followed by a distilled water wash. Perlite powder is a superior cementitious material that can be used in place of cement in some applications. The Loofah fibre was added to the concrete at 0, 0.5%, 1%, 1.5%, and 2%, and 10% of the cement was replaced with perlite powder. The mix ratio is M30.Along with the curing times of 7 and 28 days, the compressive strength test and split tensile strength test of cast concrete are noted.

Key Words: Loofah fiber, perlite powder, Compressive strength, Tensile strength, Natural fiber, Chemical treatment

1. INTRODUCTION

Due to its excellent environmental adaptability and great compressive strength, concrete is one of the most widely used structuralmaterials.Concretecanbeusedinavarietyofspecialistandchallengingengineeringscenarios,butitslimitations includebrittleness,lowtensilestrength,andpoorfracturegrowthresistance.Therefore,itiscrucialtooptimiseandimprove concretestructurestomeetvariousengineeringrequirements.Numerousinvestigationsonfibre-reinforcedconcretehave shownthataddingfibrescanenhancethemechanicalpropertiesofconcrete.

Giventheiradvantagesfortheeconomy,theenvironment,andthepossibilitytoberecycledasbuildingmaterialsfornewgreen structures, natural fibres are thought to be worthwhile for use in the creation of composites. The biological, chemical, economic,andenvironmentalbenefitsofnaturalfibrescangreatlyenhancethefinalpropertiesoffibrecompositesandtheir useinavarietyofcontemporaryapplications,includingthoseinthebuildingandotherindustries.Growinginpopularityasa naturalreinforcementforconcreteandtransformationmaterialforenvironmentalapplications,suchaswastewatertreatment, isluffacylindricalfibre.Despitehavingalowdensity,cellularmaterialpossessesexceptionalmechanicalandphysicalqualities. Itismadeupofanetworkofconnectedstrutsorplatesthatformtheedgesandfacesofcells.

1.1 Loofah Fiber

Thespongegourdplant,whichiswidelycultivatedinIndia,Asia,andAfrica,yieldsloofahfiber,atypeofnaturalfibre.Recently, loofahfibrehasbeenusedtomakereinforcedpolymers.Itisafastevolvingsubstancewiththealluringadvantagesoflow density and affordability in comparison to metals and other fibre-reinforced materials. By replacing artificial fibre reinforcements in composites, natural fibres have a great chance of lowering CO2 emissions while also conserving nonrenewableresources.Thestrengthanddurabilityofconcreteandloofahfibrecanbothbeimprovedbytreatingthemwith4% NaOHsolution.afterbeingcleanedwithdistilledwaterandlefttodryfor24hoursatroomtemperature

1.2 Perlite Powder

Perliteisanamorphousvolcanicglasswithahighwatercontentthatisoftencreatedwhenobsidianishydrated.Itappears spontaneouslyandpossessesthepeculiarqualityofconsiderablyexpandingwhenheatedtoanappropriatetemperature.Itisa commercialcommodityandanindustrialmineralthatisvaluableforitslowdensityafterprocessing.Whenperlitereaches

temperaturesbetween850and900 oC,itsoftens. Thematerialexpandsto7–16timesitsinitialvolumeasaresultoftrapped watervaporisingandescapingfromthesubstance'sstructure.Duetothebubbles'reflectivity,theexpandedmaterialisabright white.Thebulkdensityofunexpandedperliteisapproximately1100kg/m3,whereasthebulkdensityofnormalexpanded perliteisapproximately30-150kg/m3.

2. MATERIALS USED

2.1 cement

Forthisinvestigation,PortlandPozzolonaCementfromUltratechisemployed.ThetestswerecarriedoutinaccordancewithIS: 4031-1988,andtheoutcomesmetISStandards.PortlandPozzolanaCement(PPC),incontrasttoOrdinaryPortlandCement,is createdbycombiningpozzolanicingredients.Table1providescharacteristicsofcement.

2.2 Fine Aggregate

M Sand served as the fine aggregate. Fine aggregate was subjected to laboratory tests to ascertain its various physical characteristicsinaccordancewithIS2386(PartsIandIII)andIS:383-1970.Table2liststhefineaggregate'scharacteristics.

2.3 Coarse Aggregate

Ascoarseaggregates,20mm-sizedcrushedrockisemployed.OnthebasisofIS:383-1970andIS:2386(PartIandPartIII)1963,variousexperimentsoncoarseaggregatewerecarriedout.Thecharacteristicsofcoarseaggregatewereidentifiedandare showninTable3.

2.4 Perlite

PerliteoreconsistsmainlyofSiO2,Al2O3andlesseramountsofseveralmetaloxidessuchassodium,potassium,iron,calcium andmagnesium.Perlite hasseveralattractivephysicalproperties.Unexpanded(raw)perlitehasabulkdensityaround1100 kg/m3(1.1g/cm3),whiletypicalexpandedperlitehasabulkdensityofabout30-150kg/m3.Thepropertiesofperlitearegiven

intable4.Perliteisatypeofvolcanicrockwithpearlylustre.Itexpandsandbecomesporouswhenheated.Colourofcrude perliteislightgreytoglossyblackwhereas,thecolourofexpandedperliterangesfromsnowywhitetogreyishwhite.

1

2

3

4

2.5 Loofah Fiber

Similartoasponge,loofahisaporous,skeletalfibrethathasdevelopedanetworkoffibresthatarearrangedlongitudinally, transversally,andasloops.Theloofah'scentralsectionhasathree-dimensionalfibrenetwork.Intransverseorientation,the fibre'saveragediameterrangedfrom0.247to0.381mm,whileinlongitudinaldirection,itrangedfrom0.295to0.418mm. It hasa0.353g/cm3averagedensity.Thepropertiesofloofahfiberaregivenintable5.

2.6 Loofah Fiber Treatment

Theseedsweretakenoutoftheloofahfibresbeforeuse,andthefibresweretrimmed.Thecutsamplesweregivena4%weightbasedNaOHtreatment.AfterbeingcompletelysubmergedintheNaOHsolution,theloofahfibresweretreatedfor24hoursat roomtemperature.Followingathoroughrinsingwithdistilledwater,theloofahfibresweredriedinthesuntoremoveany remainingmoisturebeforebeingpackagedinpreservedbagsandkeptinstorage.Afterthatperiodofstorage,thefibrewascut inananglesothatitwasnotstraightandwasslicedinto1cm.

3. TESTING OF SPECIMEN

3.1 Compressive Strength

Thecalculationtookintoaccountthespecimen'sactualdimensions.Aftertheprescribedamountofcuringtime,specimenskept inwaterwereremovedfromthewaterandallowedtoairdry.Thecubeswereputinthecompressivetestingapparatuswiththe oppositesideofthecubereceivingaload.Thespecimenissubsequentlysubjectedtothemaximumload,whichisthennoted. Thehighestforcethatwasappliedtothespecimenduringthetestisdividedbythecrosssectionalareatogetthespecimen's compressivestrength.

3.2 Split Tensile Strength

Thecalculationtookintoaccountthespecimen'sactualdimensions.SpecimensAftertheallottedcuringtime,itemsthathad beeninwaterwereremovedandairdried.Untilnomoreloadcanbesustained,applytheloadwithoutshockandgraduallyraise it at a rate to produce a split tensile stress of roughly 1.4 to 2.1 N/mm2/min. Note the greatest load that was put on the specimen.Thegreatestloadappliedtothespecimenduringthetestmustbedocumented.Theloadmustbeincreaseduntilthe specimenfails.

4. RESULTS AND DISCUSSIONS

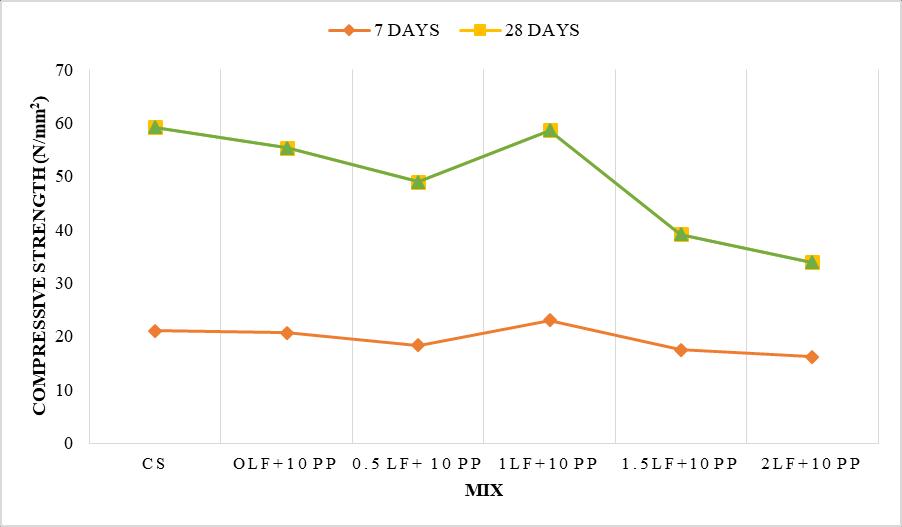

4.1 Compressive Strength

Thebestsubstituteinconcretewithvariouspercentages,add10%cementwithperlitepowderandloofahfibre.Themaximum strengthwastestedusingthetestfindingsaddLF1+10%Perlitetoamixture.Comparativelytotheadditionof0.5%and1%of Loofahfiber,compressivestrengthisdecreasedaftertheadditionof1.5%and2%fibre.Upto1%isthemaximumamountof

luffafibrethatcanbeusedbeforecompressivestrengthstartstosignificantlydecline.Thisismostlycausedbythetinyparticles and voids in the concrete mixture. Because of this, between the ages of 7 and 28 days, the compressive strength will drop.Compressivestrengthofspecimenisshownintable6

(LF1–

)

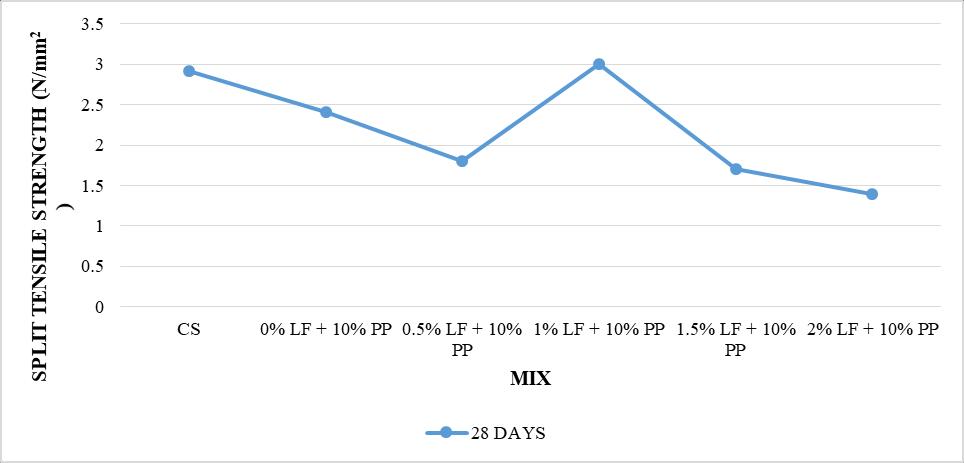

4.2 Split Tensile Strength

Thestrengthofmixturesafter7and28daysisbestachievedbyreplacing10%ofthecementwithperlitepowderandadding loofahfibreinvariousamounts.Resultsofthetest:M30+10%PP+1%LFgivesthehighestTensilestrengthofanycomposite concrete.Duetothehighpozzolanicpropertiesofperlitepowder,itproducesheatduringhydration,reducingconcretestrength when used in large quantities. However, when luffa fibre is included, the reduction in strength is smaller as compared to compositematerials.

Table- 7: SplitTensileStrengthTestResults

5. CONCLUSIONS

Accordingtotestresults,addingnaturalfiber(loofah)toconcreteproducessuperioroutcomes.Naturalloofahfiberis inexpensive,lightweight,andreadilyavailableascompositematerials.Italsohasgoodtensilestrengthrelativetoother fibers

Thestrengthresultsfor0%,0.5%,1%,1.5%,and2%ofloofahareimprovingovertimewithboosts.However,the strengthattributesresultsfor1.5%and2%ofloofahfiberaredeterioratingovertime

Incomparisontootherproportions,1%loofahfiberand10%perlitepowderprovidethebestcompressiveandsplit tensilestrength

ACKNOWLEDGEMENTS

IwishtothanktheManagement,PrincipalandHeadofCivilEngineeringDepartmentofUniversalEngineeringCollege,Thrissur, affiliatedbyKeralaTechnologicalUniversityfortheirsupport.Thispaperisbasedontheworkcarriedoutbyme(PraveenaP.P), aspartofmyPGcourse,undertheguidanceofEr.RajeevV.S.(Assistantprofessor,CivilDepartment,UniversalEngineering College,Thrissur,Kerala).Iexpressmygratitudetowardshisforvaluableguidance.

REFERENCES

1. S.Anandarajet.al(2022)“StrengthpropertiesofluffafibrereinforcedconcretecontainingRHAascementreplacement” MaterialsToday:Proceedings,52,1817-1820

2. RaghdaOsamaAbd-AlFtahet.al(2022)“Assessmentonstructuralandmechanicalpropertiesofreinforcementconcrete beamspreparedwithluffacylindricalfibre”casestudiesinconstructionmaterial,Vol.11,Issue08

3. P.O.Awoyera,etal.,“Thermalinsulationandmechanicalcharacteristicsofcementmortarreinforcedwithmineralwool andricestrawfibers”,J.Build.Eng.53(2022),104568.

4. Ruslan,I.;Ruslan,B.;Evgenij,K.”TheEffectofMetalandPolypropyleneFiberonTechnologicalandPhysicalMechanical PropertiesofActivatedCementCompositions”.CaseStudies.Construction.Material.(2022),16,e00882

5. A.R.deAzevedo,etal(2021),“Technologicalperformanceofaçaínaturalfibrereinforcedcement-basedmortars,”J. Build.Eng.33,101675

6. Kaplan,G.andBayraktar,O.Y(2021).“TheEffectofHempFiberUsageontheMechanicalandPhysicalPropertiesof CementBasedMortars”.Res.Eng.Struct.Mater,7,245–258.

7. Iniya,M.PandNirmalkumar,K.(2021)”AReviewonFiberReinforcedConcreteUsingSisalFiber”.IOPConf.Ser.Mater. Sci.Eng.,1055,012027

8. Fokam, C.B et al (20210.” Cement Mortar Reinforced with Palm Nuts Naturals Fibers”: Study of the Mechanical Properties.Rev.Compos.MatériauxAv,30,9–13.

9. Zhang,Petal(2020)“FractureModelsandEffectofFibersonFracturePropertiesofCementitiousComposites A Review”.Materials,13,5495

10. Marvila,M.et.al(2020)“DurabilityofCoatingMortarsContainingAçaíFibers.CaseStudy”.ConstructionMaterials,13, e00406

11. Bayapureddy,Y.etal.(2020),“SugarcaneBagasseAshasSupplementaryCementitiousMaterialinCementComposites: Strength,Durability,andMicrostructuralAnalysis.“J.KoreanCeram.Soc57,513–519

12. Berenguer, R etal (2020), “Durability ofConcrete Structures with SugarCane Bagasse Ash”. Adv.Mater. Sci.Eng., 6907834