Demonstration of Pascal’s law by using Hydraulic Jack

Aditya Sonawane1 , Vaibhav Belhekar2 , Rahul Tandale3 , M.C. Shete41,2,3,4Mechanical Engineering Department, Pune Vidyarthi Griha’s College of Engineering and Technology and G.K. Pate (Wani) Institute of Management, Pune ***

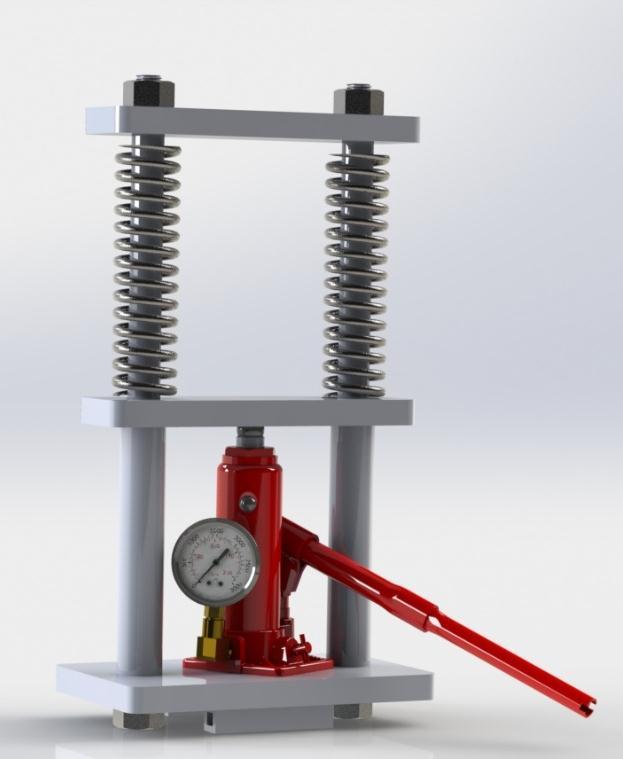

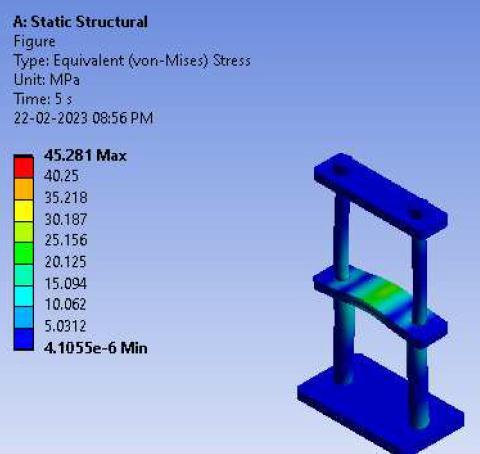

Abstract - This research paper presents an experimental demonstration of Pascal's Law using a hydraulic jack with a compression spring. The setup consists of two plates with a compression spring between them, two vertical bars, and a hydraulic jack mounted on the base plate. Pascal's Law states that pressure applied to a confined fluid is transmitted uniformly in all directions. In this experiment, we will apply force to the hydraulic jack, which will transmit the pressure equally to the two plates with the compression spring acting as a load cell. We will use pressure gauges to measure the pressure in the system and validate Pascal's Law. Additionally, we will perform a structural analysis of the supporting frame structure to ensure its safety and stability during the experiment.

Key Words: Pascal’sLaw,HydraulicJack,FluidMechanics, Demonstration

1.INTRODUCTION

Pascal'sLawisafundamentalprincipleoffluidmechanics. It states that pressure applied to a confined fluid is transmitted uniformly in all directions.[1] This law has numerous applications in engineering, particularly in the design and operation of hydraulic systems. A hydraulic jackisacommondevicethatoperatesontheprinciplesof Pascal's Law. In this experiment, we will demonstrate the applicationofPascal'sLawbyusingahydraulicjackwitha compressionspring.

1.1 Experimental Setup:

The experimental setup consists of two steel plateswithathicknessof20mmeach.Thetwoplatesare placed parallel to each other with 200 mm distance betweenthem.

A compression spring is placed between the two plates, acting as a load cell. The plates are supported by two vertical barswithaheightof500mmeach.Thehydraulic jack is mounted on the base plate and is used to apply forcetothesystem.

The hydraulic jack used in this experiment has a maximum load capacity of 2 tons. It consists of a pump, a cylinder, and a piston. The pump is used to create pressure, which is transmitted to the cylinder. The piston is attached to the cylinder and moves up and down as pressure is applied. The piston is connected to a metal platethatisplacedbetweenthetwosteelplates.

Pressure gauges are attached to the hydraulic jack. The pressure gauges are used to measure the pressure in the system.

1.2 Components:

1. HydraulicJack

2. Baseplate

3. Upper&MiddlePlate

4. CompressionSpring

5. TwoVerticalBars

2. DESIGN OF FRAME STRUCTURE

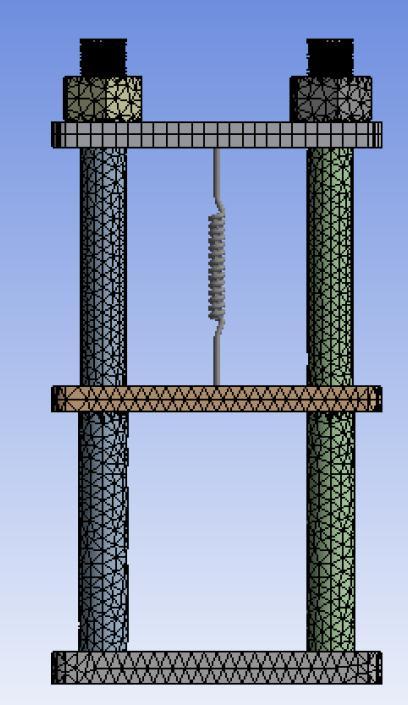

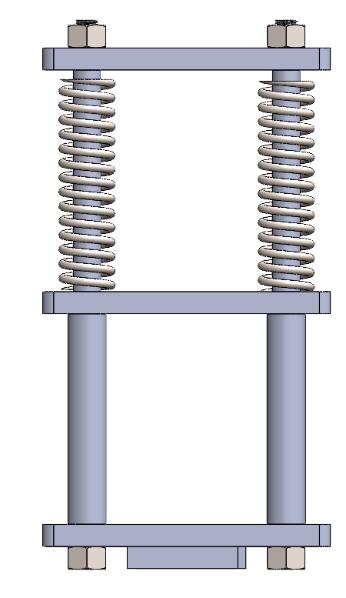

The frame structure for the experimental setup of demonstrating Pascal's Law using a hydraulic jack with a compression spring between two plates and two vertical columns was designed to provide stability and support to the system. The frame structure consisted of two vertical columnsmadeupofsteelrodsandabaseplatemadeupof mildsteel.

2.1 Design Validation

The design calculations were validated using finite element analysis (FEA) by using the ANSYS software. The materialpropertiesusedwereasfollows:

Table -1: MaterialPropertiesofMildsteel[2]

Parameter Value

Young'sModulus 210GPa

Poisson'sRatio 0.3

density 7850kg/m3.

Themaximumloadcapacityofthehydraulicjackusedwas 2tons.

Fig.2CadmodelFrameStructure

The design of the frame structure was based on the followingfactors:

The maximum load capacity of the hydraulic jack, the weight of the system, and the stability required for the system during the experiments. The dimensions of the vertical columns and the base plate were determined basedonthesefactors.

Calculation of the frame structure involved determining the load capacity of the columns and the base plate. The loadcapacitywascalculatedusingthefollowingformula:

LoadCapacity=(Allowable Stressx Cross-Sectional Area) /FactorofSafety

Theallowablestressformildsteel wastakenas250MPa, and the factor of safety was taken as 2.5. The crosssectional area of the steel rods and the base plate was determined based on the maximum load capacity of the hydraulicjack.

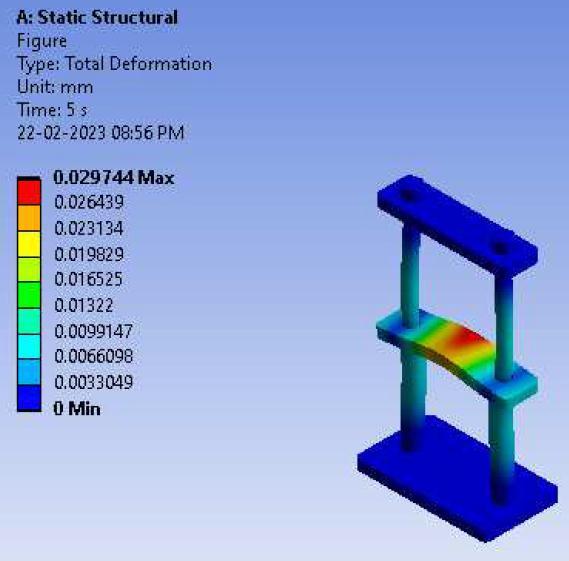

EquivalentStressAnalysis

The FEA analysis showed that the maximum stress in the system was well within the yield strength of the material, andthedeflectionofthesystemwasnegligible.Theresults indicated that the frame structure was structurally sound and stable under the maximum load capacity of the hydraulicjack.[3]

FEA analysis and experimental results demonstrated the structural integrity and stability of the frame structure underdifferentloads,confirmingthevalidityofthedesign.

Fig.5Deformationanalysis

Experimental validation of the design was carried out by conducting a series of experiments under different loads. The results obtained from the experiments were in good agreement with the FEAanalysis,andtheframestructure wasfoundtobestableandstructurallysound.

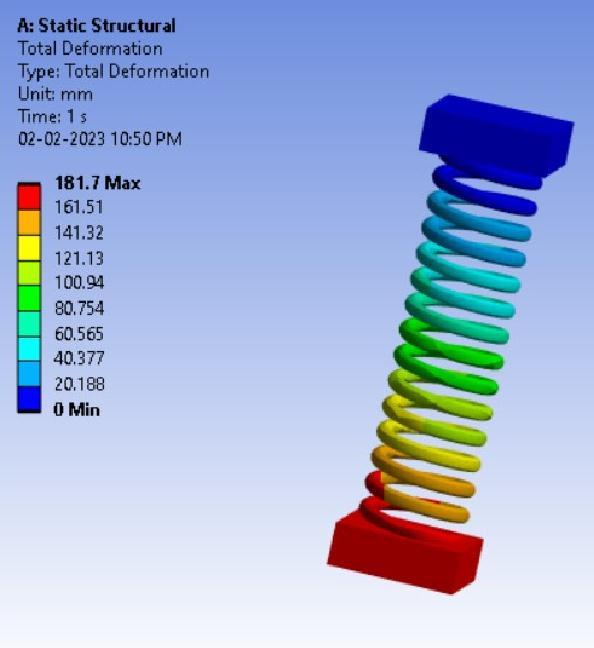

3.DESIGN CALCULATION OF SPRING [4]

1.Helicalcompressionspring

2.maxforce=2500N

3.Deflection=100mm

4.springindex=C=6

5.Sut(N/mm2)=2220or795or505

6.G(N/mm2)=72000or74000or26000

Forspringsteelgrade2=55316or55304

7.τ=0.5Sut

τ1=1110N/mm

τ2=1110N/mm

τ3=1110N/mm

K=1.2525

τ1=k= d12 =43.100 d1=6.57mm

d22=120.21=11mm

d32=189.09=14mm

Mean coil Diameter

D1=c×d1=42mm

D2=66mm

D3 = 84mm

Number of active coils

δ= n1= n1=

N1=12coils

N2=19coils

N3=28coils

Total number of coils

Takingsquareandgroundextendedsprings

Nt=N+2

Nt1 = 14 coils

Nt2=21coils

Nt3=30coils

Free length of spring

δ=

δ1=102.86mm

δ2=100.84mm

δ3=100.47mm

Solid length of spring =Nt×d

Sl1=98mm

Sl2=231mm

Sl3=420mm

Total axial gap =(Nt -1)×1

TAG1=13mm

TAG2=20mm

TAG3=29mm

Freelength=solidlength+TAG+δ

Fl1 = 214 mm (spring steel 2)

Fl2=352mm(55316)

Fl3=549mm(55304)

Pitch= ( )

P1=16.46mm

P2=17.6mm

P3=18.93mm

Fig.8SpringEquivalentstress

3.1 Material selection for spring

The compression of the spring was measured using a Ruler/Verniercaliper,andtheforceappliedtothesystem wascalculatedusingthefollowingequation:

F=k*x whereFistheforce, kisthespringconstant, andxisthecompressionofthespring.

4. EXPERIMENTAL PROCEDURE

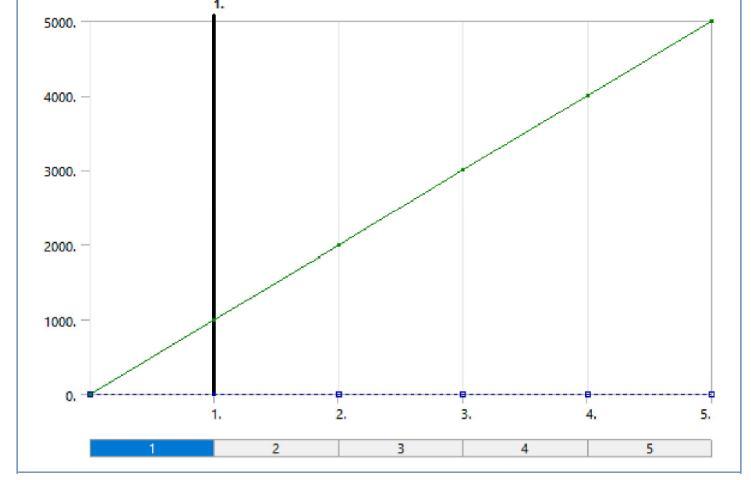

To demonstrate Pascal's Law, we will apply force to the hydraulicjackbypumpingthehandleofthepump.

The force will be transmitted to the piston, which will moveupwardsandpushthemetalplateagainstthelower steelplate.

As the force is applied, the pressure in the hydraulic jack willincrease,andthepressurewillbetransmittedequally tobothplates.

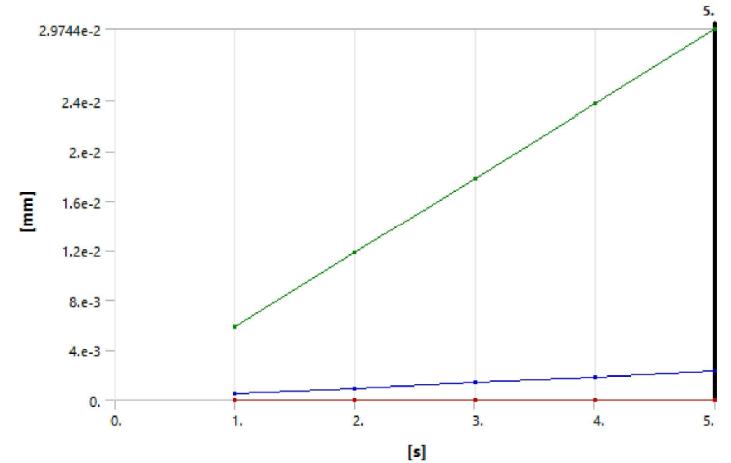

The compression spring between the two plates will compress as the force is applied. The compression of the springwillbemeasuredusingaRuler/Verniercaliper.The compression of the spring will be used to calculate the forceappliedtothesystem.

We will calculate the pressure at different points in the system.Thepressuregaugeattachedtothehydraulicjack willmeasurethepressureinsidethejack.

5.RESULTS AND DISCUSSION

Thepressuremeasuredatdifferentpointsinthesystemis showninTable1.

Thespringconstantwasmeasuredbeforetheexperiment, anditwasfoundtobe3.42N/mm.Thecompressionofthe spring was measured at different force levels, and the resultsarepresentedinTable3.

As shown in Table 3, the pressure measured at the hydraulicjackisthesameasthepressuremeasuredatthe top and bottom of thecolumns. This confirms the validity of Pascal's Law, which states that pressure applied to a confinedfluidistransmitteduniformlyinalldirections.

As shown in Table 4, the compression of the spring increases with the force applied to the system. This relationship is linear, as expected, based on Hooke's Law. The force applied to the system was calculated using the equationmentionedaboveandispresentedinTable4

As shown in Table 4, the calculated force is very close to the actual force applied to the system. This confirms that thecompressionspringisactingasareliableloadcell.

6. CONCLUSIONS

In conclusion, the experimental demonstration of Pascal's Law using a hydraulic jack with a compression spring between two plates and two vertical columns was successful.Thepressuremeasurementsobtainedfromthe pressure gauges and the compression measurements of the spring confirm the validity of Pascal's Law. The compression spring acted as a reliable load cell, and the calculatedforce wasvery closeto the actual forceapplied to the system. This experiment can be used to demonstrate Pascal's Law in a classroom or laboratory

setting and can be used to illustrate the principles of hydraulicsystems.

ACKNOWLEDGEMENT

We would like to express our gratitude to Pune Vidyarthi Grihas’s College of Engineering & Technology for providinguswiththenecessaryresourcestocarryoutthis research. We would also like to thank our project guide Mrs. M. C. Shete for her guidance and support throughout theproject.

REFERENCES

[1] Fluid mechanics and hydraulic machines, Dr. R.K Bansal,LaxmiPublications (Revised9th Edition)

[2] Material Properties https://materialproperties.org/mild-steel-density-strength-hardnessmelting-point/

[3] https://courses.ansys.com/index.php/courses/stress -and-local-equilibrium/lessons/equivalent-stresslesson-4/EquivalentStressAnalysis

[4] https://www.irjet.net/archives/V4/i4/IRJETV4I4718.pdf

[5] https://www.makeitfrom.com/materialproperties/ASTM-A227-Spring-Steel#:~:text=ASTM