“ENHANCING CONCRETE PERFORMANCE WITH SUPERPLASTICIZER:A MIX DESIGN STUDY”

Assistant Prof Vikas P Jadhao1 , Khushal A Ganani2 , Sandesh S Jadhav3, Kamal A Mundada4 Karan V Sonawane5 , Pranjal J Wani6

Assistant Prof Vikas P Jadhao1 , Khushal A Ganani2 , Sandesh S Jadhav3, Kamal A Mundada4 Karan V Sonawane5 , Pranjal J Wani6

1Assistant Professor Civil Engineering Department, 2,3,4,5,6Fourth year Civil Engineering Department, Government College of Engineering Jalgaon-425001[MS] India ***

ABSTRACT -

Inthisworld,concreteisthemostalternatehandmaterialusedafterwater.Itcontainsconcrete,sand,coarsetotalsandwater. Alongside these materials different admixtures can likewise be employed which can upgrade the properties of cement and reducethewatercontentinmixture.Inourdesignworkweaimtoexaminethesimilarityandvariationbetweenconcretemix design by using the IS method, also to intimate suitability of mix design through experimental investigation by using Superplasticizer Inthis exploration work53gradeof Pozzolona PortlandCement,locallyavailablefineaggregateand coarse aggregate and superplasticizer (FOSROC SP 430) were named, based on IS 456-2000 and IS 10262-2019 norms for determining quantitiesand proportion of concretehavinggrade M25, M30,M40.Compressive strength was determined at7 days,14daysand28dayscuringperiodandeventually,comparetheresultsbycheckingstrengthanddurabilitycriteria.

ConcreteMixDesignusingSuperplasticiser isapopulartechniqueintheconstructionindustrytoproducehigh-performance concrete with improved workability and strength. Super plasticisers are chemical admixtures that are added to the concrete mixtoimprove its flowabilityand reduce theamount ofwater required, withoutcompromisingthestrength or durabilityof the concrete. Fosroc SP430 is a commonly used super plasticiser that can help to reduce the cement content of concrete mixtures, resulting in cost savings and a reduced environmental impact. This abstract paragraph will focus on the topic of concrete mix design using Fosroc SP430 super plasticiser and the potential benefits of reducing cement content, including improvedsustainabilityandreducedcosts.TheapplicationofFosrocSP430in concretemixdesigncanleadtothecreationof high-performance, environmentally friendly concrete with reduced carbon footprint, making it a popular choice among designersandcontractors

Keywords- Mixdesign,ISmethod,Compressivestrength,FosrocSP430

1. INTRODUCTION

Concreteisahomogeneousmixtureofcement,aggregateandwater,whichisusedinthevariouscivilengineering fields.The basicbuildingmaterialismostpopularbecauseofgoodstrength,durabilityandprovidentinuse.

Concrete blend designstyles aresubstantially basedon graphs,charts,tablesand onempirical relationswhich is developed byusingavailablematerialsthroughtrialsandexaminations.

Foraltitudinous structures andpre-stressedconcrete,useofhighergradesofconcreteisnecessarytoachievethemaximum strength. AccordingtoIS456-2000fordurabilityconsiderations,weuse highestgradeofconcreteformoresevere exposure conditions.Toincreasethestrengthanddurabilityofconcreteweusethechemical admixturessuchasAirEntrainers,Water Reducers,

SetRetarders,SetAccelerators,Superplasticizers

For Ordinary and Standard grades of concrete only IS system is used for different placing condition, for the specified depression(slump)value that ranges from25mmto 150mm. Predictedonthe nominal maximum size ofaggregate,electthe maximum water content for range of 25 to 50 mm slump by using I.S. 10262:2009 (table 2). Quality material gives better strengthandcontinuitytotheconcrete.Qualityisatrip,notadestination,itisanonstopimprovement.

2. LITERATURE REVIEW

ThistaskincludestheassessmentonexperimentalexaminationofblenddesignmethodofconcretebyusingIS10262-20149 &IS456-2000

1. Abdul Aziz and A Ramakrishnaiah (2019)

This study look into for resolving the most suitable concrete blend in order to achieve the target mean strength. In this exploration work 43 grades of ordinary Portland cement, sand and aggregate were selected based on IS:456- 2000 and IS 10262-2009 standard for determining amounts and proportions for concrete having grade M25. The instance having size 150mm×150mm×150mmwastestedattheageof7and28daysofcuringperiod.

2. Ozuzun and Uzal (2021)

Superplasticizers (SPs) play a significant part in the sustainable growth of the concrete assiduity due to the combinations' droppedwaterandPortlandcementcontent.Itisnecessarytodevelopeco-efficientindispensabletypesofsuperplasticizers

Incomparisontolignosulfonate-(LS)andnaphthalene-grounded amalgamation,theplasticizingperformanceofahumic-acid grounded superplasticizer generated from leonardite as a natural organic matter and its influence on hydration & characteristics of Portland cement were deliberate. Through the use of isothermal calorimetry and thermo-gravimetric proportionsoftoughenedpastes,theresultofLHAonthehydrationofPortland.

3. METHODOLOGY

3.1 Objectives of Mix Design

Thedesireofconcreteblenddesignisto makesurethe mostoptimumproportions oftheelementaccoutrementsto fulfilthe requirementofthestructurebeingerected.Ensuingobjectivesmstbeconsideredwhilemixdesigning:-

a) Toachievetheasked plasticityintheplasticstage,minimalstrengthinthetoughenedstage

b) Durabilityinthegiventerrainconditions.

c) Toproduceconcreteaseconomicallyaspossible.

3.2 Basic Considerations

Fordesignofconcreteblendfollowingkeypointsmustbefollowed

a) Price-Thepriceofconcreteismadeupof

Materialprice

Outfitprice

Labourprice

b) Identification -Fordesigningconcretemixessaturationpointshouldbekeptinmind:-

Compressivestrengthrequiredmustbeminimum

water/cementratioshouldbeminimum

Toavoidlesscracksmaximumcementcontentshouldbethere.

Maximumaggregate/cementratio

c) Plasticity – Whiledesigningconcretecompositesfollowingpointsmustbekeptinmindsforbetterworkability

Thethicknessofconcreteshouldnofurtherthanthatnecessaryforplacing,compactingandfinishing.

Furtherworkableconcretemeanslowerstrengthwhichisdependsonwatercementrate.

d) Firmness and continuity- It is depends on only water cement rate, to achieved maximum strength use suitable admixturesandqualityparaphernalia

3.3 Materials Used: Thefollowingmaterialswereusedinconcretemixeddesign

i) Cement:-AmbujaPPC53gradeofcementwasused.

ii) Coarse Aggregate:- Coarse Aggregate of 20 mm & 12.5 mm were used which was passing through 20mm and 12.5 sieve wasusedindesign.

iii) FineAggregate:-Sandwhichwaspassingthrough2.36mmsievewasusedindesign.

iv) Admixture:- Conplast SP430 is a chloride free, superplasticising admixture based on selected sulphonated napthalene polymers.Itisfunishedasadarkbrown(colour)solutionwhichinstantlydispersesinwater.0.5-2%byweightofcement canbeaddedinmixdesignaccordingtobrouchreofSP430

v) Water:-Potable(drinkable)waterwasusedhaving Ph6.5

4. PROCEDURE

WehaveperformedvarioustestsforconcreteMixDesign.

1. Sieve analysis of Fine Aggregate:-

Todeterminethegradationofsandandinwhichzoneitiscoming.Inthepracticalweperformed,sandwaspresentinZoneI.

2. Specific Gravity of Coarse Aggregate:-

Specificgravitywillshowwhethersomethingwillfloatorsink&inidentificationofstone. Inour practicalspecificgravityof coarseaggregatewasfoundtobe2.66.

3. Specific Gravity of Fine Aggregate:-

It is used to calculate the solid volume & percentage of voids in aggregates in computations of yield. Specific Gravity of fine aggregatewasfoundtobe2.74.

4. Specific Gravity of Cement:-

Specificgravityunrelatebadparticleswhicharelighterthanotherparticles.Todeterminethesolidvolumeofallaggregatesin concretemixdesign,wedeterminethespecificgravityofcement Todeterminethetestwerequirecement,gavel,water.2.85 isthespecificgravitywhichwehavedetermined

5. Specific Gravity of water:-

SpecificGravityofWateris1.

6. Water Absorption of Coarse And Fine Aggregate:-

Water absorption gives an suggestion to determine strength of aggregate. Aggregates are porosive in nature if it has more waterabsorptionandaregenerally weconsideredthem as unfitunlesstheyarefoundtobe tolerablebasedonstrength, jolt andhardnesstests.Waterabsorptionofcoarseaggregateandfineaggregatewasfoundtobe1.86%and2.72%respectively.

The moisture content in aggregate is used to decide the envelope content for HMA during manufacture of the mixture in a plant. To obtained familiar quantity of aggregate some policy must be required like, the aggregate must be warmed up to withdraw the moisture in air, and the percentage of moisture determined. Moisture content of Coarse aggregate & Fine aggregatewasfoundtobe1.21% &2.04%respectively.

This test can be used incontinently to identify the variations which are to be made in the superplasticizer lozenge The saturation point is the point at which no lozenge can be added beyond its point as further addition of superplasticizer does not increase fluidity. significantly but could affect in segregation the achromatism lozenge can be taken as the optimum superplasticizer lozengeforagivencementpaste.Inourpractical,wehavegoteffectiveresults at1.5%byweightofcement andmintimewastakenatthatpoint.

To perform this test, we have to ensure that same concrete batches are of persistent standard and strength. Concrete gets weaker&weakerasmorewaterisaddedtoit.Weneedtoincreasethecementcontent ifclientneedahigherworkabilityor moreflaccid concrete(a higherslumpresult) toensuretheconcretestill reachesitstargetstrength. Toensurethequalityof concrete this is one of the test we performed. Water is the foe when it comes to concrete strengths. In our performance of slump cone test we have assumed the slump to be 100 mm, 100mm & 75 mm for CMD with admixture for M40, M35, M25 respectivelyandwegottheresultsas110mm,100mm,80mm.

5. CONCRETE MIX DESIGN USING IS METHOD:-

Design M25 concretebasedontheprovisionsofIS-10262-2019forthefollowingdata.

a) Typeofcement-PPC53

b) Exposurecondition-Moderate

c) MaximumsizeofC.A-20mm

d) Specificgravityofcement-2.85

e) SpecificgravityofC.A-2.66

Step 1) Target mean strength of concrete

Fck=fck+ks =25+1.65×5 =33.25N/mm2

f) SpecificgravityofF.A-2.74

g) TypeofAdmixture-Superplasticizer

h) Sieveanalysiszone–I

i) Methodofconcreteplacing-normal

j) Degreeofsupervision–good

ReferIS-10262-2019,table1,StandarddeviationS=5

Step 2) Water cement ratio selection

ReferIS-456-2000,table5 ForM-30concrete,maximumw/cratio=0.5

Step3) Water content selection

ReferIS10262-2019,table4

For20mmaggregate,Maximumwatercontentis=186kg/m3 (forslump25to 50mm)Wehavetoincrease3%ofwatercontentforevery25mmslumprange Toattainmaximumof75mmslumprange=3%increaseinwatercontent

Estimatedwatercontentfor75mmslump=186+ 3 100 ×186 =191.58kg/m3

Assumingwaterreductionas20%byaddingsuperplasticizer(SP430)=191.58–20/100x191.58 =153.26kg/m3

Step 4) Cement content calculation

Watercementratio=0.44

cementcontent=153.36/0.44=348.32 kg/m3AccordingtoIS-456-2000 ForModerateexposurecondition, Minimumcementcontent=300 kg/m3300kg/m3 <348.32kg/m3,HenceOk.

Step5) Volume of CA and FA content

IS10262-2019,table3,volumeofCAcorrespondingto20mmsizeaggregateandFA (ZoneI),&aftercorrectionaccordingtocl.5.5.1

VolumeofCA=0.612, VolumeofFA=1-0.612 =0.388

Step 6) Mix calculation

(a)Volofconcrete=1m3

(b)Volof entrappedair =0.01m3

(e)VolofChemicaladmixture(1.5%byweightofcement) =1.5/100x348.32 =5.22kg =5.22 x 1 1.2 1000

(f)Voloftotalaggregate =((a-b)-(c+d+e) =((1-001)-(0.122+0.1532+0.00435) =0.710m3

(g)Massofcoarseaggregate

=(f)×Volumeofcoarseaggregate×specificgravityofcoarseaggregate×1000) =0.710×0.612×2.66×1000 =1155.82kg

(h)Massoffineaggregate

=((f)×Volumeoffineaggregate×specificgravityoffineaggregate×1000) =0.710x0.388x2.74x1000 =754.81kg

Step 7) Mix Proportion on adjustment in water, coarse aggregate & fine aggregate (if the coarse and fine aggregate is in dry condition, water absorption and moisture content correction)

(a) Cement=348.31kg/m3

(b) Fineaggregate=749kg/m3

(c) Coarseaggregate=1147.55kg/m3

(d) Admixture=5.22kg/m3

(e) Water=164.65kg/m3

(f) w/cratio=0.44

NOTE:- CoarseAggregateof20mm&12.5mmareusedinthe60:40respectively.

In this way, Similarly M30 & M40 Grade was designed according to IS456-2000 & IS 10262-2019.

Table No-01- Test materials required for concrete mix design with admixture(if coarse & fine aggregate is in dry condition)

Table No-02- Test materials required for concrete mix design (if coarse & fine aggregate is in dry condition)

6. RESULTS

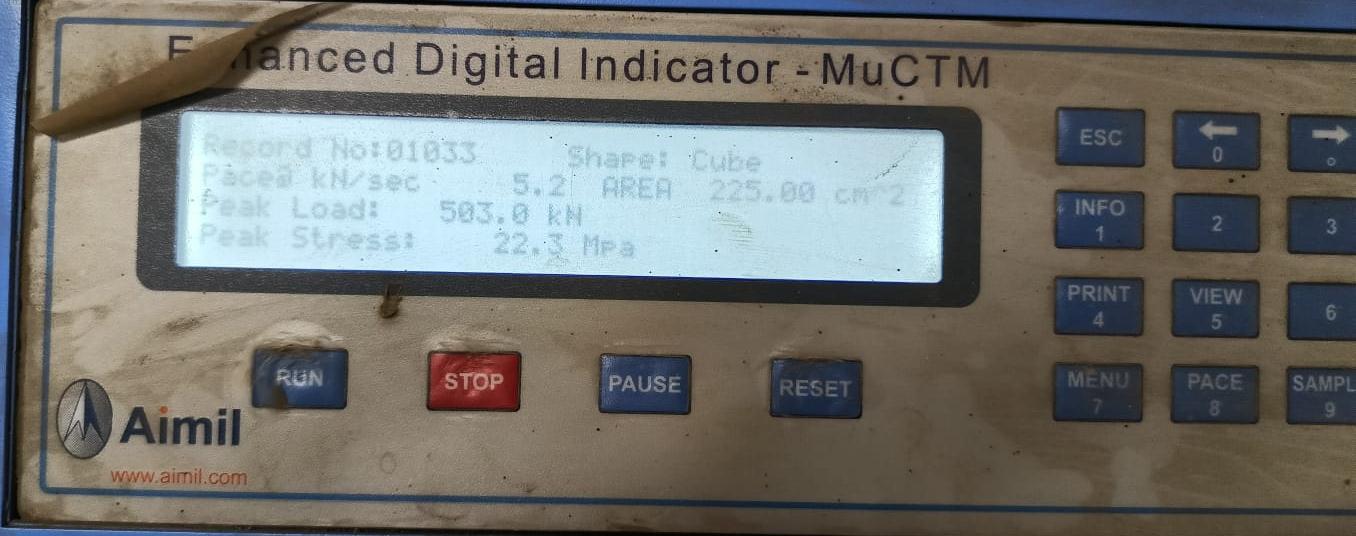

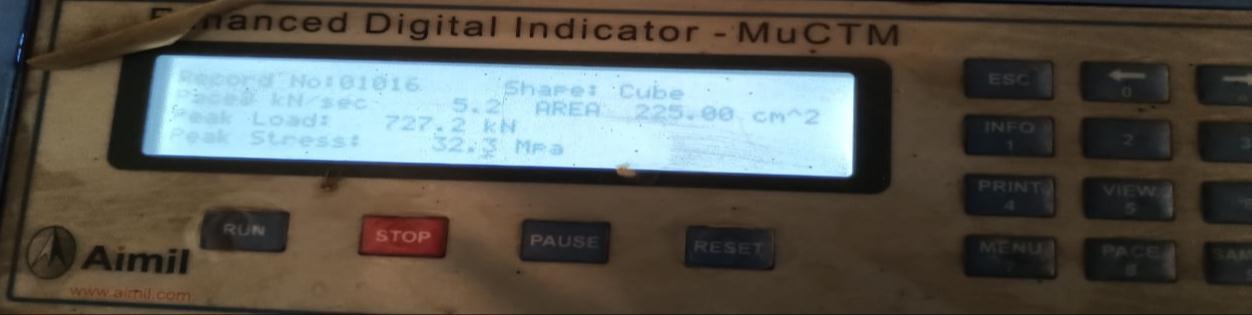

Compressive strength of various grades of concrete was tested at 7days,14days and 28 days curing period. Following experimentaltestresultswereobtained.

6.1 Compressive strength

Todeterminecompressivestrengthofvariousgradesofconcretespecimenbyusingdigitalcompressiontestingmachine (CTM).

Table No-03- The following results were obtained from compressive strength test of mix design using admixtures.

Chart 2- Test Results for Compressive Strength without admixtures

7. CONCLUSIONS:-

Thefollowingconclusionsweredrawnfromtheinvestigation.

The strength of a concrete mix using Super Plasticiser Fosroc SP430 is comparable or even higher than traditional concretemixes.

The use of Fosroc SP430 superplasticizer in concrete mix design allows for a reduction in the water-cement ratio, resultinginadenserandstrongerconcretewithimprovedworkability.

The superplasticizer's ability to improve the workability of the concrete mix without compromising its strength or durability means that high-performance concrete can be produced with less cement and water, reducing the overall carbonfootprintandcostoftheconstructionproject.

Studies have shown that concrete mixes using Fosroc SP430 superplasticizer have higher compressive and flexural strengththantraditionalconcretemixes.

Thisisbecauseofthedenser,more homogeneous mixture with reduced porosity, whichleadstoimproved strengthand durability.

Additionally, the reduction in water-cement ratio due to the use of the superplasticizer can lead to a reduction in shrinkageandcracking,furtherimprovingthelong-termstrengthanddurabilityoftheconcrete.

ThismakesFosrocSP430a popularchoiceamongdesignersandcontractorswhoseek toimprovethesustainabilityand cost-effectiveness of their construction projects while maintaining high-qualitystandards the use of Fosroc SP430 can lead to improved finishing of the concrete, as well as enhanced durability and resistance to chemical attack. Overall, the incorporation of Fosroc SP430 superplasticizer into concrete mix design represents a significant step forward in the constructionindustry.

Inconclusion,theuseofFosrocSP430superplasticizerinconcretemixdesignoffersseveraladvantagesovertraditional concretemixturesasperIS10262:2019

8. REFERENCES:-

1. Abdul Aziz and A Ramakrishnaiah ,“Analysis on mix design of M25 grade of concrete- A case study on modification of terminal building at silchar airport” International Journal for Research in Applied Science & Engineering Technology| Volume 7 Issue VI, June 2019.

2. K.Param Singh, U.Praveen Goud, S.Madan Mohan and Dr. S. Sreenatha Reddy, “Comparative study of concrete mixed design” International Journal of Innovative Research in Science, Engineering and Technology, Volume 0 5, Issue 9, September2016.

3. Mohd. Ahmed, Saiful Islam , Sohaib Nazar and Roohul A. Khan , “ A Comparative study of popular concrete mix design methodsfromqualitativeandcost-effectivepointofviewforextremeenvironment”ResearchArticle- CivilEngineering, October2015.

4. M.S.Shetty:“Concretetechnologytheoryandpractice”.

5. ISCode:383-1970,“Specificationforcoarseandfineaggregatefromnaturalsourceforconcrete”.(SecondRevision)

6. IS456:2000“Codeofpracticeforplainandreinforcedconcrete”BureauofIndiaStandard,fourthedition,NewDelhi.

7. IS-10262:2019“Indianstandardconcretemixproportioning–Guidelines”,(SecondRevision),NewDelhi,India

8. https://www.ijraset.com/research-paper/influence-of-superplasticizers-conplast-sp-430-on-fresh-properties-of-selfcompacting-concrete

9. FosrocconplastSP430Brouchre