Abstract - Inearly2022,productionofliquidwastewater hasbeenincreasedandmanagementofthisbi-producthas becomeachallenge.Themanagementofliquidwastewater producingfromwastewatertreatmentplantisdifficultand expensive.Whenthewastewaterishandledpoorly,itmay causedangerouseffectsonenvironmentandonhumanlife, too. The quantity of waste water produced in wastewater treatmentplantandthatshouldbedirectedintermsofmass andvolume.Alsoitisexpressedinthetermsofpercapita demand.Therearedifferentcharacteristicsofthisproduct i.e.,thickness,watercontent,etc.

The development of infrastructure and the steady populationincreaseinBhusawalcityhasledtodomesticas well as industrial sewage generation at large proportion. This has discharged into the fresh water bodies nearby whichcausestheunhygienicenvironmentalcondition.For thepropermanagementofthewastewaterandtoreduce and prevent the unhygienic occurrence, we need to find whether the waste water is re-usable or not, so we will conduct several laboratory tests on the generated liquid wastewatertofindthereparameters.Thispaperfocuseson determiningthewastewaterisreusableornotandfinding theircontent.Itinvolvescheckingthequalityofliquidwaste water producedbydeterminingit'sphysicalandchemical parameters i.e. total suspended solids , pH, alkalinity , chloridecontent,dissolvedoxygen

Key Words: Waste water, Management, Maintenance, Laboratory tests, Risk assessment, Population, Purified water

1. INTRODUCTION

Asweknow,Indiaislargecountryranking2ndinpopulation. Despitebeing2nd largest,duetolackofeconomicalbudget and technologies, management of waste water generated fromthesewagetreatmentplantcouldn’ttreatedproperly and released in surrounding water bodies which raised questiononhygieneandsanitaryinenvironmentandhealth oflivingbeings.Topreventrisingharmfulimpactthesewage bi-productwhichtobereleasedinwatersourcesneedtobe treatedproperly.Steppingforwardonpath,sewagewaste water generated from Bhusawal Sewage Treatment Plant

will give a chance to improvise the quality of content and alsotodetermine,re-usabilitytousetheminagriculture

2. Methodology

2.1 Total Suspended solids

We have done the test of TSS for finding dissolve solid in water,andTSSdefineassolidinwaterthatcanbetrapped byafilter.ThisworksontheprincipleofFilterawell-mixed samplethroughapreweighedstandardglassfiberfilterand then dry the filter, and the residue retained on it to a constantweightina103-105°Coven.Theincreaseinfilter weightrepresents TSS Takinga tripodstand weputin on table to each funnel was placed. Taking initial weight of Whatmanfilterpaperasw1.Weplacedthefilterpaperthree foldedonfunnel‘Afterthatwepouredwellmixedsampleon filterpaperwaitingforsometimewhentheoverallwatergot drainedoutweremovedthefilterpaperAtlastwetookfinal weightoffilterpaperalongtheresidue

2.2 Determination of Chloride content

TodeterminetheCl(-)ions,i.e.,chloridecontentpresentin thegivenwatersample,wehaveusedMohr'smethod.Inthis Mohr'smethod,titrationisperformedwithsolutionAgNO3 Theprincipleofthisexperimentis

The comparative study of waste water and purified water present in sewage treatment plant in Bhusawal city.Assistant Prof Vikas P Jadhao1 ,Pratiksha N Ahire2, Sagar B Bankar3, Trupti M Chavhan4 , Abhishek S Nagargoje5, Prachi M Birhade6 . 1Assistant Professor Civil Engineering Department , 2,3,4,5,6 Fourth year Civil Engineering Department, Government College of Engineering Jalgaon-425001[MS] India *** Fig -3:InstrumentusedforTSStest

+NaNO3

K2CrO4+2AgNO3 →Ag2CrO4+2KNO3

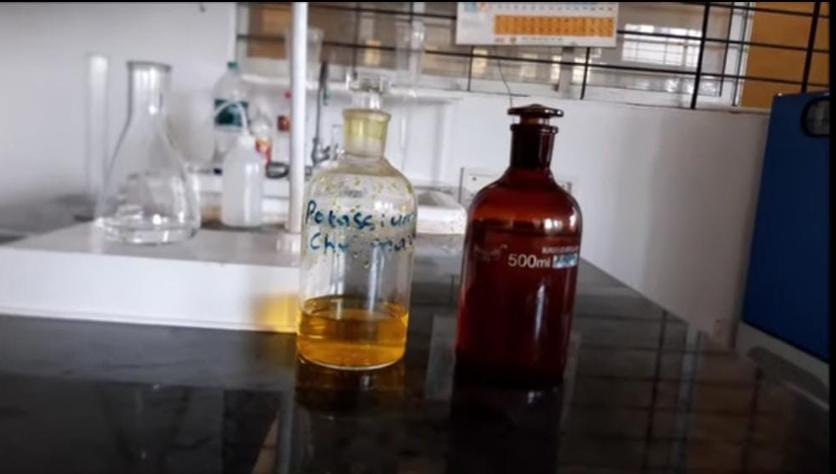

Thisexperimentwasperformedintheneutralmedium.As therearesomelimitationsforthismethod.Oneofthemis, theMohr'smethodcannotbeperformedinbasicmediumas it contains large number of Ag ions than chloride ions. In methodology, for performing titration process, standard solutionofsilvernitrate,indicatorassolublechromatesalt, potassiumchromateareused.Theaquiredwatersamples weretakeninthebeakerandtitratedagainstAgNO3(0.1M) Beforethat,theindicatorwasaddedinthesamplesolution, K2CrO4(5%).Inthistesttwotimestheprecipitationswere formed. They were AgCl and Ag2CrO4.And during the process,Ag2CrO4willprecipitateoutfirst.Attheendpoint, all Cl ions reacted with AgNO3 and formed AgCl and after thatadditionofextradropofAgNO3ledtoreactwithCrO4 ion (from indicator) and if formed reddish brown colored precipitatesofAg2CrO4.

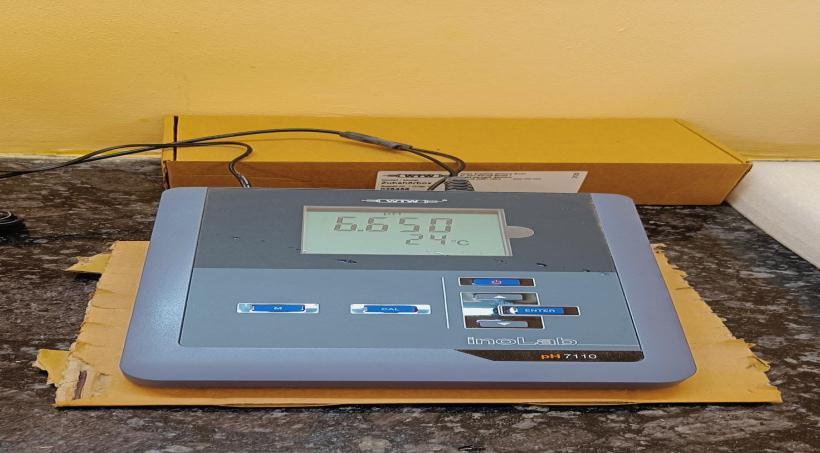

as the electrode has reading as zero so, it is good to start fromzero.AftertakingpH7readings,weturnedtheknobto thestandbymode,removingtheelectrodefromsolutionand cleantheelectrodewithtissuepaper,confirmingthatthere arenotracesofanychemicalontheelectrode,rinsingitwith distilled water. Then dipping it to buffer solution of pH 4, rotatedtheknobtopHmodeandadjustedthereadingto4. Wethenwaittogetreadingsstabilizedto4.Aftercalibration of pH mater is done, we dipped the electrode into sample and we set function knob to pH mode and allowed it to displaystabilizedreadingwegotreadingofPhofoursample as6.650

Fig -2: TestEquipmentforChlorideContent

2.3 Determination of Ph

We performed pH test on the water sample by using digitalphmeter.Inthismethod,wehadpHelectrodewhich was dipped into the distilled water, pH meter which had differentknobsforadjustmentandcalibrations,Ithadone functionalknobwhichhad3modes,pH,standbyandMV mode.WehadtomeasurethepH,sowerotatedinontothe pHmodeandduringthemeasurements,weturnedittothe standbymode.Originallyitwasturnedtostandbymodein un-used condition. It had temperature knob and one calibration knob which we rotated to set the standard pH values. Firstly we calibrated the pH meter for accurate measurementofthepHofsample,forthatweusedstandard buffersolutionofpH4andpH7(wepreparedbuffersolution accordingtotheinstructions).Weperformedtheexperiment at25°ctemperature.Wedippedtheelectrodeintostandard buffersolutionofpH7andturnedtheknobtopHmode.We wait till the readings become constant .We started the readingsfrombuffersolutionofpH7

Fig -3:PHTestingEquipment

2.4 Determination of Dissolved Oxygen

We have determined the oxygen in the given sample. the principle on whichthistest isbased isthat the amount of oxygenpresentinthewater.Waterbodiesreceiveoxygen fromtheatmosphereandaquaticplants.DOrapidlyoxidizes thedivalentmanganoustoitshighervalencywhichformsa brownhydratedoxideprecipitateafteradditionofNaOHand Kl. In the presence of iodide ions in an acidic solution the oxidized manganese reverts to the divalent state and liberates iodine from Kl equivalent to the original DO content.TheliberatediodineisthentitratedagainstSodium Thiosulphate solution with starch as an indicator, MnSO4 reactswithalkalitoformwhiteprecipitateMn(OH)2thus indicatingabsenceofoxygeninthesample

ThereactionsofDOare“Mn+++2(OH)→Mn(OH)2(white)”, “Mn+++2(OH)+1/2O2→MnO2 (brown)+H20”,“MnO2+2I+ 4H→Mn+++I2+2H2O”.

ROD bottles (capacity 300 ml), burette, pipettes, conical flask, burette stands, tile, measuring cylinder, weight balance, glass rod, beakers were used for the test. The reagents used in the DO test are Winkler's A, Winkler's B, starch indicator, concentrated sulphuric acid, standard sodiumthiosulphatesolution.Forperformingthetest,first wecollectedallthesamplesin300mlBODbottle.Thenwe

added 2 ml Winkler’s A solution and 2 ml of Winkler’s solutionwellbelowthesurfacethroughthewallsinterfered withthestopperimmediatelytoavoidbubbleformationin thesolutionandmixeditcarefullybyinvertingthebottleup and down . Allowing the brown precipitates settle down leavingclearsupernatant.Thenweaddedsulphuricacidto digesttheseprecipitates.Afterthiswemixedthemixtureby inverting the bottle several times up and down till yellow coloured solution appeared . Then we took 50 ml of this yellowsolutionandtitrateditagainstNa2S2O3(0.025N)by addingstarchsolutionasindicator.

4. Results

1. Theamountofchloridecontentpresentinthewater sampleis[Initial]=220mg/l.

2. Theamountofchloridecontentpresentinthewater sampleis[final]=7mg/l.

3. Theamountofdissolvedoxygendeterminedfrom thegivensampleis[initial]=260mg/l

4. Theamountofdissolvedoxygendeterminedfrom thegivensampleis[final]=159.95mg/l

5. Theamountoftotal suspendedsolidsdetermined fromthegivensampleis[initial]=6.8mg/l

6. Theamountoftotalsuspendedsolidsdetermined fromthegivensampleis[final] =7065mg/l

7. The initial p H was = 0.1. After the pH test, the observedfinalpHis=7.9

Fig - 8: TreatedWaterDischargeInNearWaterBodies

WedesignedsewagetreatmentplantforBhusawalcity.We tooksampleofwastewatergeneratedfromBhusawalcity. Duringtheprocessofdesignwegottoknowthepopulation ofBhusawalcityis187421(accordingtosensesdepartment 2011). We collected samples of inlet and outlet. As the purposewasperformingcomparisonstudyonthecondition of collected waste water before treatment and after treatment,weperformedsometeststocalibrateparameters andcontentspresentinbothcondition.Wefoundoutthat thecollectedwastewaterintheplantwasveryharmfulfor consumptionandwouldbecreatingahazardousimpacton environmentifreleasedasitisinthewaterbodiesandother resources. We found out that the pH of the inlet water sample was very high comparing to the treated water sample.Alsowefoundoutthatdissolvedoxygenlevelwas quite low and total suspended solids were greater in quantity as measured in milligram per litres, chloride content was also higher following the sequence. So by performingtestsonthetreatedwater,wegottoknowand could see the difference as how the treated water was consumableand reusableforhumanandotherlivingthings. Alsowasperfecttoreleaseinthewatersourcesandwater bodies in surrounding. Hence, concluding the results and values of the required parameters by the tests we have performed on the collected waste water sample from the sewage water treatment plant. They are mentioned as follows;

Theamountofchloridecontentdetectedinthesamplewas7 Mg/l.Thesamplehave159.95mg/llevelofoxygendissolved in it. There are 7.65mg/l of total suspended solids in the sample.Andlastlyis7.9pHwasofthesamplebeingpurified andtestedinthepHmeter.

REFERENCES

[1] Dr. Buddharana 1 Godbole et al. "Design of Sewage TreatmentPlantforViVirarRegion",InternationalJournalof EngineeringResearch,(2020)[2]ShrikantDhage"Designof Sewage Treatment Plant for Parbhani city", IRJET Journal 2019

[3] Pramod Sambhaji Patil et al. "Design of Sewage Treatment Plant for Dhule City" International Journal of EngineeringResearch,2016

[4] Gaurav C. Nagpurkar et.al. "Design of Wastewater Treatment plant in Nagpur City By Adopting SBR Techniques".InternationalResearchJournalofEngineering andTechnology(IRJET),2020

[5] Komal Ajabrao Gadekar et al." Case Study of 161 MLD Sewage Treatment Plant Kanchanwadhi, Aurangabad, Maharashtra",URASET,2020

[6] A. P. Hangargekar and P. K. Takpere. "A case study on waste water treatment plant. CETP (Common effluent treatmentplant)Internationaljournalofinnovativeresearch inadvancedengineering(UJIRAE)ISSN2349-2163Issue11, volume2November2015

[7] Prachi N. Wakode, Sameer U Sayyad. "Performance Evaluation of 25MLD Sewage Treatment Plant (STP) at Kalyan".AmericanJournalofEngineeringResearch(AJER) eISSN2320-0847p-ISSN:2320-0936Volume03,Issue-03, pp-310-316.

[8]N.MuthukumaranandDr.N.K.Ambujam."Wastewater treatmentandmanagementinurbanareas-Acasestudyof Tiruchirappalli city. Tamilnadu, India", Proceedings of the Third International Conference on Environment and Health.Chennai,India,15-17December,2003

[9] Sanjeev Kumar Sinha. Vikas Kumar Sinha, Samir Kr. Pandey, Anup Tiwari, "A Study on the Waste Water TreatmentTechnologyforSteelIndustryRecycleAndRese, American Journal of Engineering Research (AJER) e-ISSN 2320-0847pISSN2320-0936Volume3,Issue-04,pp-309115

[10]1.5LambeandR.S.Chougule,"Greywatertreatment andreuse".IOSRJournalofMechanicalandCivilEngineering (IOSR-JMCE)-ISSN:2278-1884,PP20-26

[11] Belchior, C., Araújo, R., Landeck, J.: Dissolved oxygen controloftheactivatedsludgewastewatertreatmentprocess usingstableadaptivefuzzycontrol, Computers&Chemical Engineering(2011)

[12]Ionescu,C.,DeKeyser,R.:RelationsbetweenFractional Order Model Parameters and Lung Pathology in Chronic ObstructivePulmonaryDisease. IEEE Trans.Biomed.Eng., vol.56,pp.978-987,2009

[13] Mainardi,F.:Fractionalcalculusandwavesinlinear viscoelasticity: An introduction to mathematical models. ImperialCollegePress,London,(2010)

[14] Cao, J.-Y, Cao, B-G.: Design of Fractional Order Controller Based on Particle Swarm Optimization.

International Journal of Control, Automation, and Systems, vol.4,no.6,pp.775-781,(2006)

[15] Luo, Y., Chen, Y. Q., Wang, C. Y., Pi, Y. G.: Tuning fractional order proportional integral controllers for fractionalordersystems.JournalofProcessControl,vol.20, pp.823–831,(2010)

[16] Monje, C.A., Chen, Y.Q., Vinagre, B.M.,Xue, D., Feliu, VFractional order Systems and Controls: Fundamentals andApplications.Springer-Verlag,London,(2010)

[17]Determination of Chloride content https://youtu.be/3aDuuYMjTUg

[18] Determination of chloride content image reference https://youtu.be/cWzRf-ycvbs

[19]Determination of dissolved oxygen content reference imagehttps://youtu.be/m9XGsEs55Qo