IOT based solar powered Grass cutting machine with Bluetooth remote controlling App and height adjustment mechanism using microcontroller

1Assistant Professor, E&TC Engineering Department, D. Y. Patil Technical Campus, Faculty Of Engineering And Faculty Of Management, Talsande, Kolhapur, Maharashtra, India.

2345E&TC Engineering Department, D. Y. Patil Technical Campus, Faculty Of Engineering And Faculty Of Management, Talsande, Kolhapur, Maharashtra, India. ***

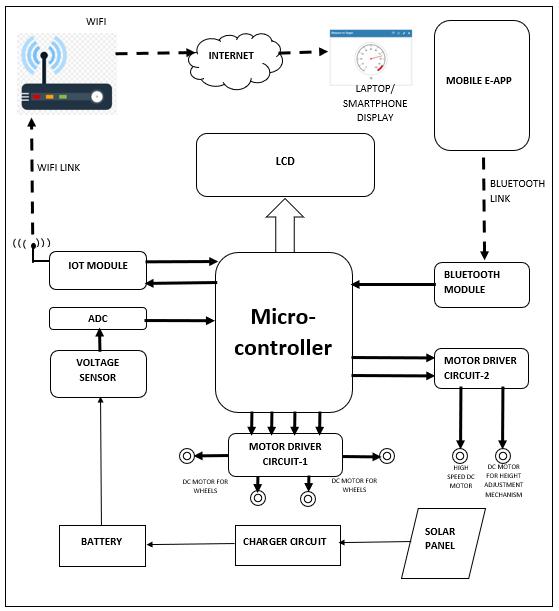

Abstract - The main purpose of this project is to design a grass cutting machine system which makes the grass cutting will very easy and more convenient. The IOT based solar powered grass cutting machine is one of the robotic vehicle. It is operated on battery and battery is energies by solar panel. This system requires 12 volt battery for giving power to robotic vehicle movement as well as grass cutter motor. The working principle of grass cutter and machine motor is completely controlled by microcontroller. It controls working of all motors. We can handle movement of vehicle motor with the help of microcontroller. In this project we are using Bluetooth technology for controlling the robotic vehicle. The Bluetooth handled by Android smartphone application. IOT is one of the important technology. This technology is usedin our project for checking the battery condition.

Key Words: Microcontroller, Bluetooth, IOT, Solar Power, DC Motor.

1. INTRODUCTION

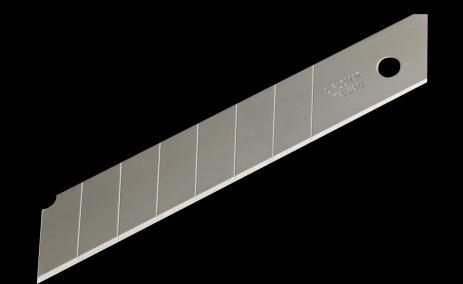

Nowadays, grasscutting machinebecomesa very popularinurbanIndia.Thismachineismostcommonlyused for furnishing the grass. DC motor, drivers circuits for controllingmotors,battery,solarpanel,blades,etc.arethe some main parts of our project. It is placed in a suitable structure in our project. The motors are connected to the electricsupplybyusingwires.Thelinearcutterbladesare attachedtothemotor. 'Providingahighspeedrotationto theblades,ithelpstocutthegrass'ismainworkingprinciple ofGrasscutter.Wheneverincreasingtherpmthattimethe bladewillgetkineticenergyandcutthegrass.Thecutting edgesofthecutterareverysmoothandaccurate.

The grass cutting machine is very easy to use in lawn, gardensandgrassfields.Forincreasingthebeautyofhome lawnsandgardens,grasscuttingmachineisthebestoption. Inourproject,rotatingbladesarecuttinglawns,gardensat evenlength.Hencepeoplecanabletoeasilymaintainbeauty oftheirlawns,gardens.

Solar energy is one of the renewable energy. This renewableenergyisproducedbythesunanditisavailable

infreeofcost.Weareusingthissolarpowerinourproject. With the help of solar panel, we convert sunlight into electricity. Thiselectricityisstoredinthebatteries.Battery isoneofthemainpartinourproject.Withthehelpofthis, wecanabletousegrasscuttingMachineatanytime.

Solargrasscutterhasverylessmovingparts.Duetothis itrequireslessmaintenanceandnomajordrawbacks.Our Grass cutting machine does not cause any environmental pollutionsuchlikefossilfuel,nuclearpower.Nowadays,IOT technology is widely used in the industry. It is advance technology.Thistechnologyweareusedinourprojectfor monitor and display the data using the Wi-Fi internet connection. For displaying the data, we are using LED display.WirelessBluetoothtechnologyisusedtocontrolling the machine. We operate the grass cutter machine by Bluetooth robot controls apps. This app is available on Androidplaystore.

2. LITERATURE REVIEW

Sivarao, T.J.S.Anand, Hambali, Minhat, Faizul[1] presented a review of researches done on the subject of automatedtractor.Anautonomoustractorisavehiclethat can operate without or with minimal human control, selfpropelledandguidedautomaticallyalongadesiredpath.The benefits from such a system are useful for agriculture industry by reducing labour cost and time, as well as improvingoutputefficiencybyeliminatinghumanerrors.

Pratik Patil, Ashwini Bhosale, Prof. Sheetal Jagtap[2] describedaboutanautomaticlawncutterthatwillhelpthe user to cut the grass in their lawn with less efforts. The differentsensorsareuseditwilldetectandavoidobjectsand humanswhilemowing.Themainobjectiveofthisautomatic lawncutteristhattheusercanspecifytheareathatistobe mownandalsotheheightofgrassasperthererequirement byusingthekeypad.Thisdesigncontainsamicrocontroller likeATmega16,multiplesensors,LCDDisplay,Keypad.

Ernest L. Hall [3] The system operates on the same principleastheLawnRangerexceptitusesacablebeneath the surface of a persons lawn. The mower uses this wire

alongwithitssensorstoallowtherobottomaneuveraround whilekeepingthesystemontrack.Themowerwillcontinue tooperateaslongasthemowerhasenergy,fromthesun. The robot is equipped with a flexible bu mper that when activatedbacksthemowerupandcontinuestherobotona different path. It has the advantage of cutting grass in the formofamulchsothattheuseofagrasscatcherorrakingis notrequired.

3.

Thespecificobjectiveofthisprojectwas

1. To develop an automatic grass cutting robot thiswouldbeabletohelpusersincuttingthe grassingardens.

2. Therobotwasmadeabletocoveralltheareaof flatland.

3. It was also considered that it should be moderatelycheapandeasytoimplementwith thehelpofthemicrocontroller.

4. Instead of requiring small details to be specified, the task in this project was carried outbyconsideringtheessentialdesignfeatures so that the system was able to autonomously execute its job in a manner that satisfies its desiredtask.

5. Theusershould beable to operate thisrobot fromadistanceof20feet.Grassheightshould mevariabledependingontheuser’schoice.

6. Theusershouldalsodecidethecuttingheight andadjustitaccordingly.

4.

TheAT89C52isan8bitmicrocontrollerwith8kbytes flash.Numberofinterruptsis8.TheAT89C52has40pins. The Atmel AT89C52 is a powerful microcontroller which

provideshighflexible.Itisacost-effectivesolutiontomany embeddedcontrolapplications.

ThisdeviceworksondualH-bridgemotordriverwhich allowsspeedanddirectioncontroloftwoDCmotorsatthe sametime.

ESP8266 is a low pass Wi-Fi module through this the microcontrollercanconnectviaWi-Fi.

TheuseofESP8266moduleissenddatatoawebsiteand receivesdatafromawebsite.ThroughESP8266modulewe can communicate with one microcontroller with another microcontrollerviaWi-Fi.

This HC-05 Bluetooth Module helps to send data from androidapplicationtothemicrocontrolleroverthewireless

© 2022, IRJET | Impact Factor value: 7.529 | ISO 9001:2008 Certified Journal | Page17

Bluetooth connection. Main use of this Bluetooth is controllingthemotors.

areas. The blades are attached to the motor. And it is controlledbymobileapp.

4.8.

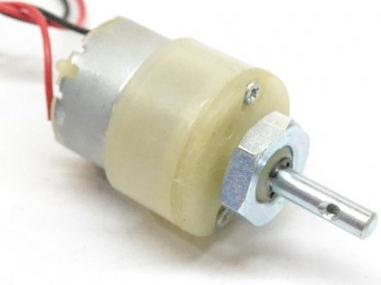

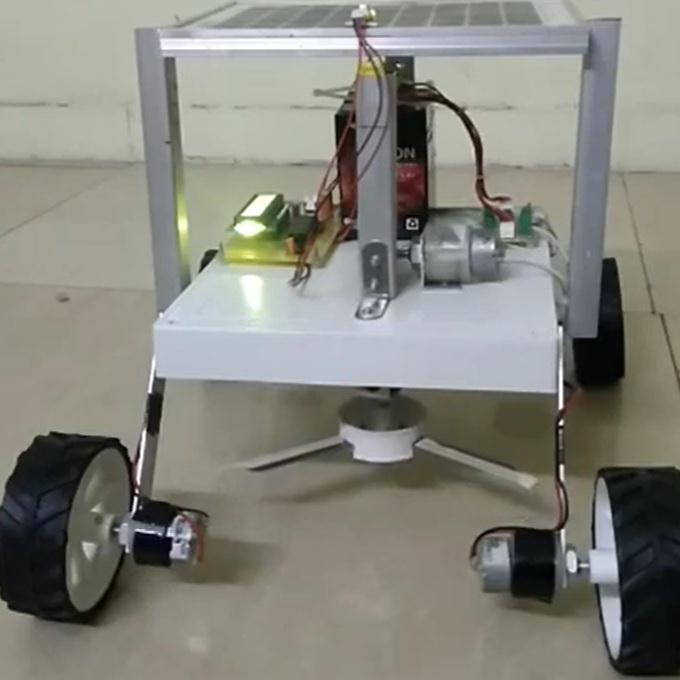

Hereinourgrasscuttingrobot,4wheelsaredrivenby the 4 DC motors and another 2 DC motors for cutter assembly. The DC motor converts the electric energy into mechanicalenergy.

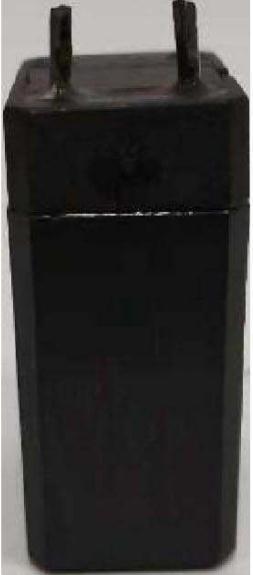

For this project, we need 12 v batteries to run this project.Withthehelpofsolarpanel,wechargethebattery andstoredtheenergy.

When the cloudy condition occurred in the environment and also solar panel not worked due to sun lightisnotavailablethattime,weusethebattery.Withthe helpofbattery,wecanabletocontinuoususethisproject.

TheuseofSolarPanelisconvertingthesolarradiation intotheelectricpowerusingphotovoltaiccells.

The grass cutting blades are the best for mowing largeareasoftoughgrass.Theyaremadeofsteel.Theyare availablewithalargeofdifferentteeth.Thedesignofgrass cuttingmachineisallowsittopowerthroughvariouswoody

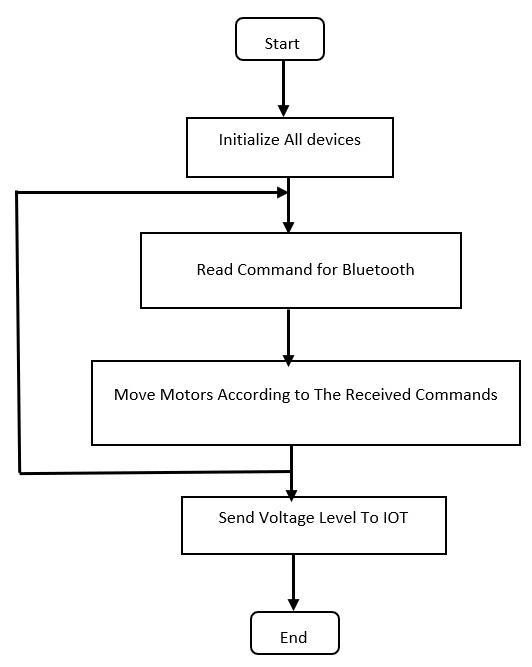

6. FLOWCHART

7. WORKING

Agrasscuttingrobotisbasicallya landmovingvehicle with4wheels.These4wheelsaredrivenby4dcmotorsof lowspeed.Thereisanotherdcmotorwithhighpowerand highspeedwhichwillbeusedforthecutterassembly.Agrass cuttingmechanismswillbeattachedtoit.Thismotorwillbe relativelylowspeed.Therewillbeanothermotorthatwillbe usedtosettheheightofthegrasscuttinglevel.Thismotoris coupled with a rack and pinion mechanism to adjust the height. All the DC motors are 12V-DC motors. The driver circuitswillprovidetherequiredcurrentforthemotors.

Thebatteryusedhereisa12V/1.5Ahrechargeabledry battery.Thisbatterypowerisusedtopowerthemachineand to all components. There will also a solar panel that will convert the solar radiation into electrical power using the photovoltaiccells.Thesolarpanelratingis12V-5W.Itwillbe sufficienttochargethebatteryduringthedaytime.Wecan alsoprovideadcchargerforchargingthebatterywhensolar powerisjustnotenough,i.e.,duringconditions.

Userwillbeprovidedwitharemoteandroidmobile whichwillworkonBluetoothcommunication.Theusercan give command to the robot using various keys on the controllingAndroidApp.Thefunctionslikeforward,reverse, left, right, stop, cutter ON, cutter OFF, height increase and heightdecrease.TheuserhastofirstpairtheBluetoothonce andthenstartcontrollingthegrasscutter.

TheuseofIOTtechnologyalsosignificanthere.Itis usedtodisplaythebatterychargingstatusoverthewebsite. There will be a voltage sensor connected to the battery terminalsthatwillsensethebatteryvoltageandgiveittothe ADC (Analog to Digital Converter) IC. It will convert the analog voltage value into the 8bit digital value for the microcontroller.

The microcontroller we are using here is a 8bit microcontroller.Themicrocontrollerwillworkaccordingto theprogramthatwewriteintoit.Themajorfunctionofthe controllerhereistotakedatafromsensoranddisplayiton theLCDdisplayandtotransmititoverthatWIFImodule.It alsoreceivesthesignalfromtheBluetoothmoduleandsend thesignaltothemotordrivercircuittorotatethemotorsin appropriatedirectionatappropriatetime.

8. HARDWARE OF PROJECT

9. RESULT

Nowadaysenergyplaysanveryimportantroleinlotof peoples life. Here the solar panel is used for charging the battery when it gets discharged. Here we can control the grasscutterwiththehelpofAndroidapplicationsothatwe cancutthegrassinanyshapewewantandevenwecancut thegrasswithoutmuchhumaneffort.Forthesimulationwe have used the proteus version 8.0 & KEIL VERSION 4or5 softwareinit.

Theresultbeforeandafterofthisprojectis

and innovative. The height adjustment feature is really helpfulfortheuser.TheBluetoothcontrolprovidesremote accesstotheuser.Itisequippedittheadvancedtechnology like the IoT. Solar panel makes charging of the battery effortless

REFERENCES

1. Sivarao, T J S Anand, Hambali, Minhat, Faizul , “ReviewofAutomatedMachinestowardsDevisingA New Approach in Developing Semi-Automated GrassCutter”,InternationalJournalofMechanical andMechatronicsEngineeringIJMME-IJENS,2010.

2. PratikPatil,AshwiniBhosale,Prof.SheetalJagtap, “Design and Implementation of Automatic Lawn Cutter”, International Journal of Emerging TechnologyandAdvancedEngineering,2014.

3. Technical Solutions, J. Hammond and R. Rafaels, “Build the Lawn Ranger”, Radio Electronics, June 1990,pp.31-49

10. FUTURE SCOPE

1. The solar panel can be fixed with light sensor, thus dependinguponthearrangementofsun;thepanelwill beslantingsuchthatthesunraysareincidentnormally at90degreetothesolarpanel.

2. Ifpanelusedofhighwattthanthemachinecanbeused duringnighttimeforgardenlighting

3. Byconnectingboxtypetransponderwecanalsouseit to transport file, books other stuffs from one place to anotherplace

4. Wecanusecameraforcapturingthecoveredarea.

11. ADAVANTAGES

1. Easytomovefromoneplacetoanotherplace

2. Operating principleissimple

3. Non-skilled personalsooperatethismachine

4. Nofuelconsumption

5. Compactsizeandeasytoportable.

12. CONCLUSION

Herewegetpollutionfreeandhazardfreegrasscutting machine.Someofthefeaturesofthismachineisveryunique

4. Ms Lanka Priyanka ,Mr Prof J Nagaraju ,Mr Vinod KumarReddy,“FabricationofSolarpoweredGrass CuttingMachine”,InternationalJournal&Magazine of Engineering, Technology, Management and Research,2015.

5. ErnestL.Hall, “ASurveyof RobotLawnMowers”, ErnestL.Hall,06October2015