AN EXPERIMENTAL STUDY ON THE MECHANICAL PROPERTIES OF CONCRETE BY PARTIAL REPLACEMENT OF CEMENT WITH COCONUT SHELL ASH AND COARSE AGGREGATES WITH PLASTIC WASTES

1 M.Tech.Student, SSCET Badhani, Pathankot, Punjab, India

2Assistant Professor, SSCET Badhani, Pathankot, Punjab, India ***

Abstract - Cement, Coarse aggregate,Fineaggregate,Water and Admixtures are used in combined form to prepare concrete. The demand for concrete is expected to rise by the year 2050 by which the estimated production of concrete is about 18 billion tonnes annually There is huge demand of concrete as the construction paces with time. The cement production pollutes our environment and causesthedepletion of our natural resources. Other concrete constituents like coarse aggregates, generally obtained fromcrushedrockscan pollute the environment too. Most of the researchers have already worked a lot to reduce the use of cement and replace cement with such suitable materials,which givetheproperties like the concrete. The focus is being put forwarded to the utilization of industrial and agricultural wastes, as they are the environmental burden. In this experimentalwork, coconut shell ash partially replaced cement by percentages of0%,8%, 16%, 24% and 32% and coarse aggregateswithplasticwastes at pace of 0% , 12%, 24%, 36% and 48% are done to make sustainable concrete mix M20 Grade of concrete mix is prepared for experimentally investigate the fresh and hardened state properties. Cubes, Cylinders and Beam specimens were prepared and cured for 7days and 28 days before testing. From the study it has been observed that the test results shows optimum proportion for concrete mix and are within acceptable limits.

Key Words: Coconut Shell Ash, Cement, Coarse Aggregates, Plastic Wastes, Compressive strength, Tensile Strength, Flexural Strength, Concrete mix, Workability.

1. INTRODUCTION

Bytheyear2050,theconcreterequirementisexpectedto about18billiontonnesannuallyforconstructionprojects. Consequently,thecementdemand isalsoincreasingwith everypassingday.Thepresentuseofcementisevaluatedto bearound12milliontonnesperyearandisyetexpanding daybyday Thefactualdatastatethatone-tonnesofcement productionexhaustaroundonetonnesofCO2,whichdirectly affectsouratmosphere.Other,constituentsofconcretelike coarseaggregatesobtained bycuttingandblastingofhills and mountains also affects the environment. With the previous studies, researchers have done number of

investigationsonthereductionofusageofcementi.e.itis partiallyreplacedwithothersuitablematerialslikeGGBFS, Silica Fumes, Coconut Shell Ash, etc. and makes the sustainable concrete. Some researchers also studied over the concept of aggregate replacement with substitute of other wastes. The versatility, strength and durability of cement are of utmost priority over other construction materials.Thebasicmaterialsforconcreteproductionare: cement, fine aggregate (sand), coarse aggregate (granite chippingsorgravel)andwater,andsometimesadmixtures arealsousedtoimprovethepropertiesofconcretemix.The overallcostofconcreteproductiondependslargelyonthe availability of these basic constituents. Reduction in construction costs and the ability to produce light-weight concrete structures (LWC) are added advantages. The primaryaimofthisstudyistodeterminingthesuitabilityof partialreplacementofcementwithcoconutshellash(CSA) andCoarseaggregateswithPlasticWastesinconcretesoas tominimizetheirilleffectsintheenvironmenttoo

1.1 ADVANTAGES OF COCONUT SHELL ASH

1. Because of its superior natural structure and low ash content,coconutshellisagreatmaterialformanufacturing carbonblack.

2. A substitute for cement that can be used to partially replacecementisagriculturalwaste.

3.CO2emissionsarenearlynonexistent.

4.Enhancestheconcretemix'sstrengthanddurability.

5.Lessensthemix'spermeability.

6.Increasestheconcrete'scapacitytobeworked.

1.2 ADVANTAGES OF PLASTIC WASTE IN CONCRETE

1. Increasepumpabilityoverlongdistancesandmix cohesiveness

2. Increaseimpactresistance,abrasionresistance,and freeze-thawresistance

3. Strengthentheplastic'sresistancetoshrinkageduring curing.

4. Increaseductilityandstructuralstrength,

5. Minimizetheneedforsteelreinforcement,

6. Crackwidthsshouldbenarrowedandstrictly controlledtoincreaselongevity.

2. LITERATURE REVIEW

Edmund T.S.J.*, Jun Hon C., F Hejazi and M. S. Jaafar (2019) studiedaboutpartialreplacementofaggregateswith plastic Waste and stated the mechanical properties of the concrete. With different percentage replacement of aggregateswillaffectthedifferentpropertiessuchasslump, compressivestrengthandultimatestrengthof theconcrete and compare with the control sample in order to find the suitable percentage of the waste plasticto replacementof aggregatesfortheconcrete used.Itwasfoundthat partial aggregatesreplacementhaslowercompressivequalityofthe concrete, almost the same or lower slump test value for ordinary concrete and waste plastic concrete and lower density for the waste plastic concrete compare to the ordinaryconcrete.

Aadeala A.J, olaoye J.O & adeniji A.A (2020) researches about Potential of cement replacement with coconut shell ashinConcreteProduction.Concretecubeswereproduced usinggradedlevelsof0,10,15,and20percentreplacement ofCSAforOrdinaryPortlandCement.Theconcretemixratio of1:2:4withwatercementratioof0.5wereusedandtotalof 60cubeswereproducedandcuredinwaterfor7,14,21and 28 days. Workability, density, compressive strength and waterabsorptionweredeterminedinaccordancetoBritish Standards and pozzolanic property in accordance to AmericanStandards.Theresultsshowedthatthedensitiesof concretecubesfor5%replacementwasabove2400Kg/m3 while compressive strength were 25.17 N/mm2 , 24.72 N/mm2,23.08N/mm2and20.94N/mm2instepof5%up to20%at28days.Itwasobservedthat10%replacementof CSA as has the lowest water absorption of 0.66%. XRF analysis showed that the CSA belongs to class F. Thus, replacement of OPC with CSA from 5% up to 15% is recommendedfornormalweightconcreteproduction.(BS 8110:2,1985).

Mohd Fazil Danish, Dr. Kuldeep Dabhekar, Dr. Isha Khedikar, Manish Lende(2020) researchesaboutreview on partial replacement of coarse aggregate. This waste material must be reused so as to manage the restricted naturalaggregateandtodecreaseconstructionwastes.This articleistiedinwithlookingintotheideallevelofvarious materialassubstitutionofcoarseaggregateaswellasfine aggregate.

Naraindas Bheela, Sajjad Ali Mangib & Shanker Lal Meghwar (2021) Thisresearchexplorestheuseofcoconut shellashtopartiallyreplacecement.Thisstudy'sobjectiveis to see how different quantities of coconut shell ash (CSA) behaveinconcrete.Coconutshellisaplentifulresourceand awasteproductinthelocalagriculturalareas.Incontrast, the manufacture of cement releases a lot of poisonous chemicals into the atmosphere, which contributes to environmentalpollutionandtheproductionofgreenhouse gases. CSA might therefore be used as a cementitious componentinconcretetopromotesustainabledevelopment. It has been discovered that adding 10% CSA to concrete improves its mechanical qualities, such as compressive strength,splittensilestrength,andflexural strength,after each curing day. Also, the workability of fresh concrete decreasedasthepercentageofCSAincreasedwhereasthe modulusofelasticityincreasedwhen10%ofCSAwasused in concrete. Moreover, the usage of CSA in concrete can lowertheoverallcostofproducingconcretewhilelowering theoverallcarbonfootprint.

2.1 OBJECTIVES

1. Tominimisetheuseofcementandmakeaneconomical concretebyreplacingcementwithagriculturalwastes i.e.CSA.

2. To optimise the percentage of Coconut Sell Ash and Plastic Coarse Aggregates for mixing in M20 grade concrete.

3. To Study the workability of concrete by slump test containingvaryingpercentageofCoconutSellAshand PlasticCoarseAggregates.

4. TodeterminemaximumvalueofCompressiveStrength, SplitTensilestrengthandFlexuralstrengthofconcrete containing Coconut Sell Ash and Plastic Coarse Aggregates.

3. MATERIALS

3.1 CEMENT

The cement used in this research is 43 grade OPC of trademarkACC.

3.2 WATER

The potable water used in concrete mix to maintain its strength. The pH range of water should be within normal limitsinordertopreventconcretequalityissues.

3. 3 FINE AGGREGATES

The particles which are passing through 4.75 mm sieve knownasfineaggregates.TheFineAggregatewasusedin thisstudyconfirmingtoIS:383-1970.

3.4 COARSE AGGREGATES

Coarse aggregate and its grading are carried out in accordance with the instructions in IS: 383-1970. The aggregatesutilizedis10mminsize.Here,angular-shaped crushedpebblesareusedinexperimentalwork.

3.5 COCONUT SHELL ASH

Coconut shell, has cause copiously obtainable agricultural wastefromlocalcoconutindustries.Thecoconutshellwas obtained from local areas of Jammu to carry out our experimentalwork.ThepropertiesofCoconutshellashare discussedbelowinTable3.1

3.6 PLASTIC WASTE

The reuse of plastic waste as a substitute for aggregate in concreteproductioncanhelpinmitigatingandaddressing theenvironmentalpollutionproblemsrelatedtoplastic.The properties of plastic waste as coarse aggregates are discussesbelowintable3.2

Source: Jurnal Kejuruteraan 33(1) 2021: 27-38 https://doi.org/10.17576/jkukm-2020-33(1)-03

Source: Ahmad et.al. Performance Evaluation of Plastic Concrete Modified with E-Waste Plastic as a Partial Replacement of Coarse Aggregate. Materials 2022, 15, 175. https://doi.org/10.3390/ ma15010175

4. RESULTS AND

5. CONCLUSIONS

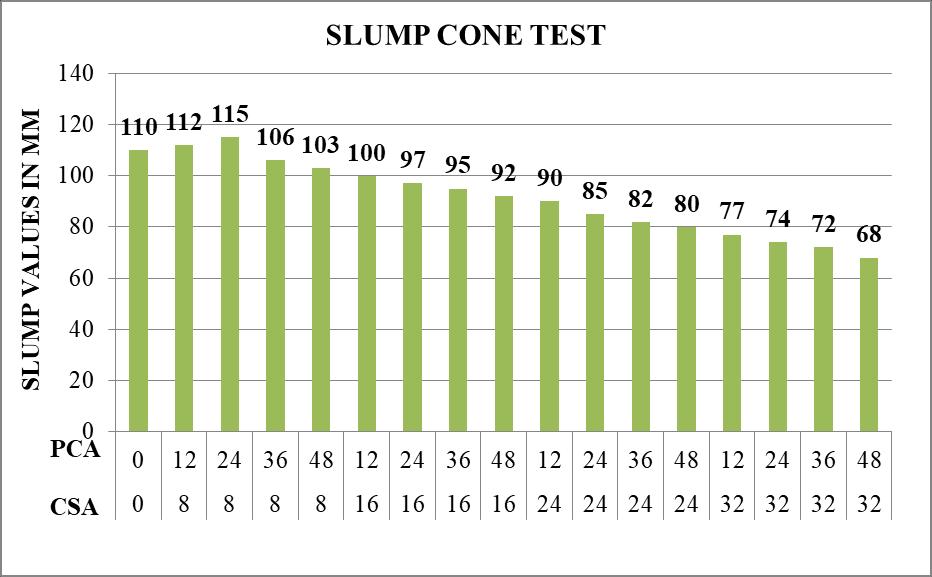

1. Theplasticwasteusedinthisresearchwillhelps to enhance the workability of the concrete upto certain percentage. The slump values represents the workability of the mix as 115 mm where CSA replace cementby8%andPCAreplacedcoarseaggregatesby 24%.

2. After the replacement level of CSA8%PCA24%, the slump values goes on decreasing with the reason of increasing the percentage levels of coconut shell ash. CSAhaswaterabsorptionpropertyleadstodecreases thewatercontentinthemix.

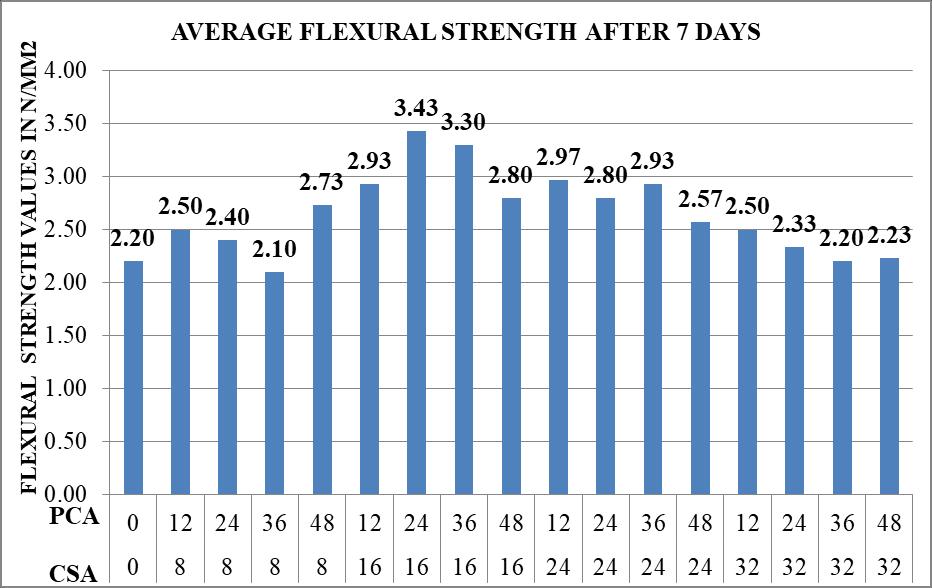

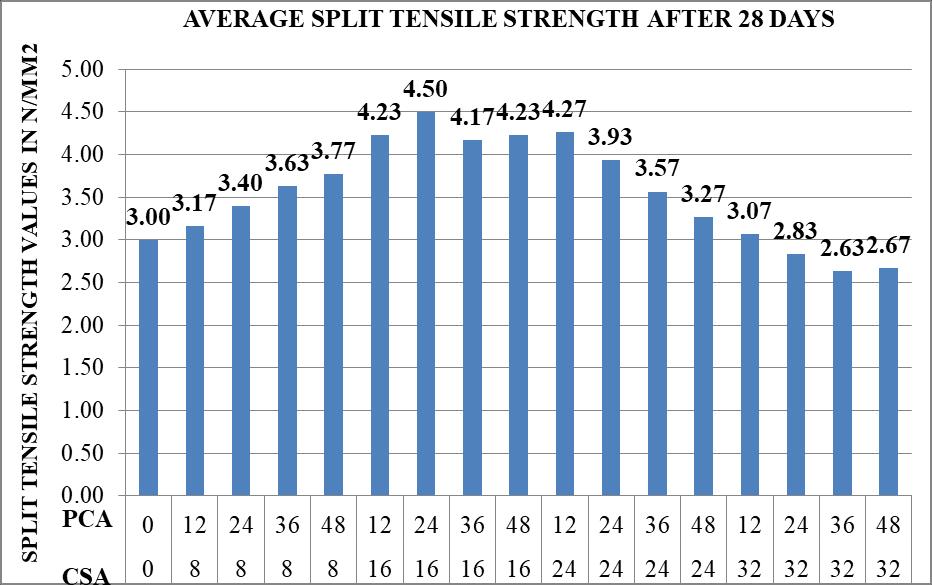

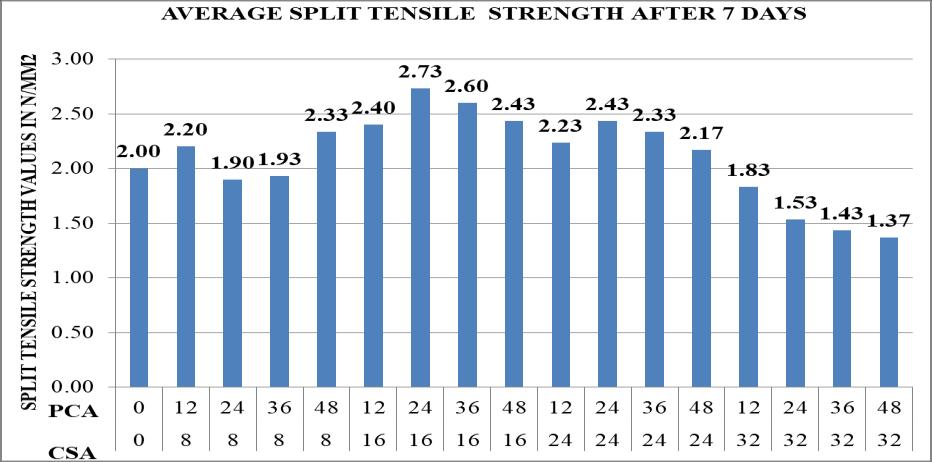

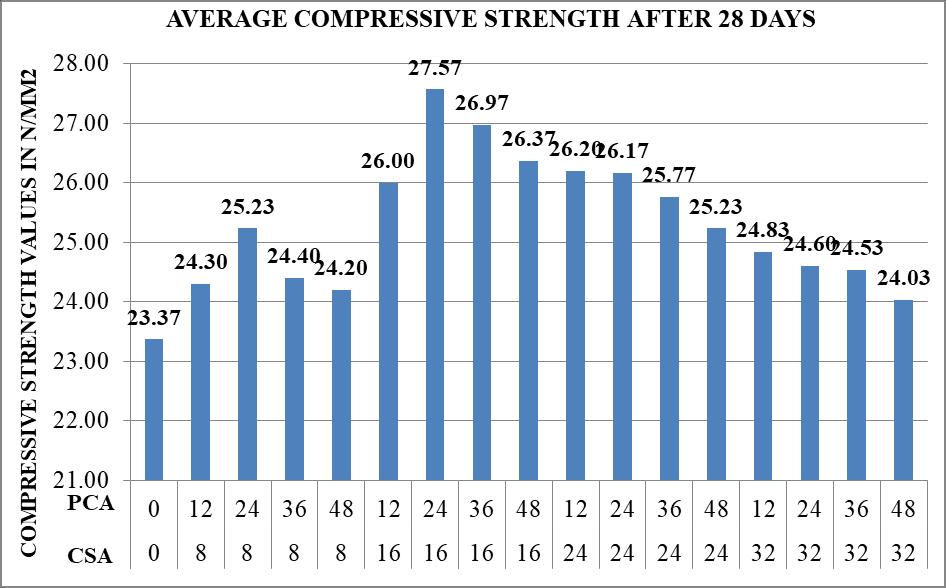

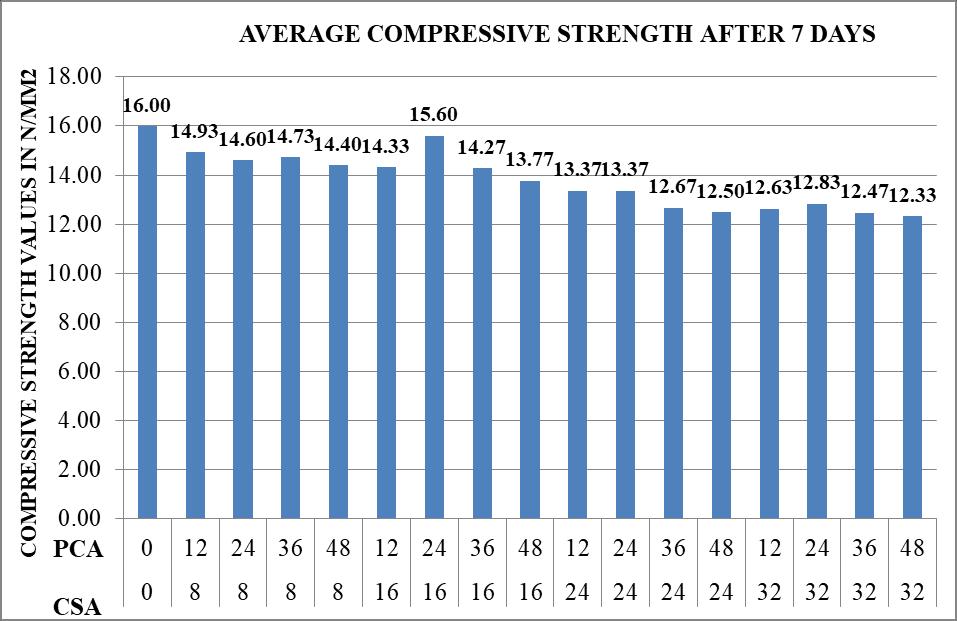

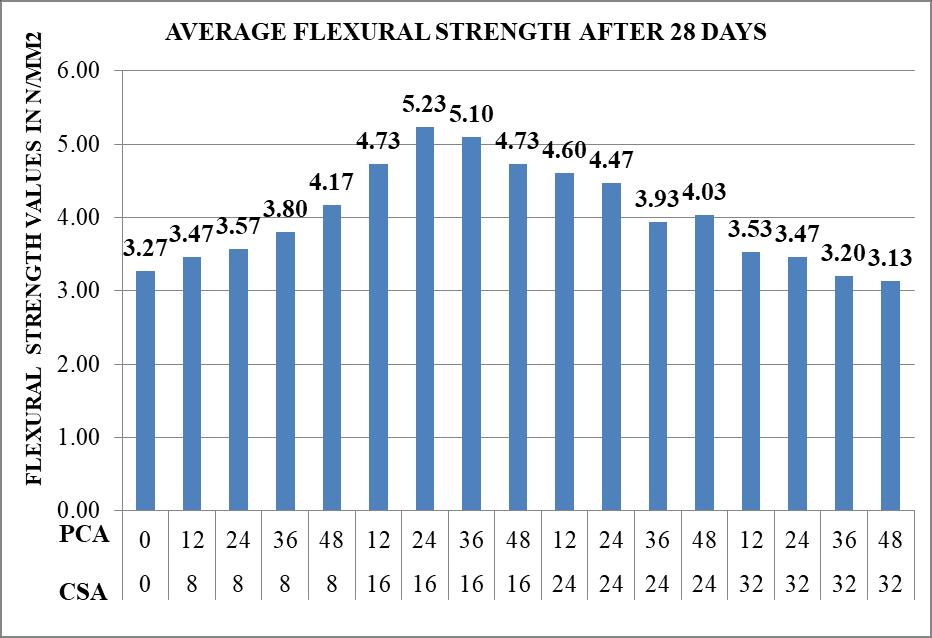

3. Theoptimumstrengthparametersareobtainedforthe mixisCSA16%PCA24%.

4. Thecompressivestrengthobtainedattheoptimummix is 15.60N/mm2 and 27.57 N/mm2 for 7 days and 28 days,respectivelyrepresentsthemaximumvalues.

5. The Split Tensile Strength of mix achieves maximum valueof2.73N/mm2and4.50N/mm2whenCSAis16% PCAis24%areaddedtoconcretemix.Thevaluesare calculatedafter7and28daysofcuring.

6. The Flexural Strength observed maximum with 16% CSAand24%ofPCAi,e.3.43N/mm2and5.23N/mm2of mixaftercuringof 7daysand28days,respectively.

7. The overall cost of the concrete is reduced due to utilizationofwastematerialsinconcrete.Thesewaste materials are available as free of cost or at very low pricesinmarket.Thusintroducingwastematerialswill lowerthestructurecostandcontributesinprotecting theenvironment

REFERENCES

1. AshwiniManjunathBT(2016)“Partialreplacementof E-plastic Waste as Coarse-aggregate in Concrete” Procedia Environmental Sciences 35(2016)731–739 doi:10.1016/j.proenv.2016.07.079

2. Fernando, P. R. (2017) “Mechanical and physical propertiesoffiredclaybrickpartialdopedwithcoconut shell ash” American Journal of Energy and Natural Resources 6(5):pp.58-63.

3. Fernando, P.R., Aazir, S.M., Pushpalatha, N., Puvanakanthan,N.andNishantha,V.H.T.,(2017)“The performanceofthelowcostmasonrycementblocksasa partial substitution of coconut shell ash” American Journal of Mechanical and Industrial Engineering 2(6): 212-220

4. Bhartiya, A. and Dubey, M., (2018) “Replacement of cementwithcoconutshellashandeggshellpowderfor preparation of fresh concrete” International Research Journal of Engineering and Technology (IRJET) 5:12721275.

5. S.Osubor,K.A.SalamandT.M.Audu(2019)“Effectof Flaky Plastic Particle Size and Volume Used as Partial Replacement of Gravel on Compressive Strength and Density of Concrete Mix” Journal of Environmental Protection 10(2019),711-721.

6. Naraindas Bheel et.al. (2021) “Coconut Shell Ash as CementitiousMaterialinConcrete:AReview” Journal Kejuruteraan 33(1) 2021: 27-38 https://doi.org/10.17576/jkukm-2020-33(1)-03