AN EXPERIMENTAL INVESTIGATION 0F STRENGTH PARAMETERS OF GLASS FIBER USING M30 CONCRETE

1Assitant professor, Department Of Civil Engineering, Gayatri Vidya Parishad College for Degree and PG Courses(A), Rushikonda, Visakhapatnam, A.P, India.

2,3,4,5,6B.Tech , Department Of Civil Engineering, Gayatri Vidya Parishad College for Degree and PG Courses(A), Rushikonda, Visakhapatnam, A.P, India. ***

Abstract - Concrete is a major product which is widelyused in every construction site and it is being used as per the strength required for the structure. Inmoderndaysvarietiesof admixtures are being used in the concrete for gaining more strength and durability as per the requirement and also to enhance the properties of concrete like compressive strength, split tensile strength etc. There has been a substantial growth in the use of glass fiber in the concrete for enhancing its properties and also for arresting the micro cracks. Hence, the glass fiber is generally being used in the present days structures. In this studies we are making an experimental investigation of strength properties of glass fiber in concrete with different proportions like 0.1%, 0.2%, 0.3% tothe weight of cement to determine its effect in its properties like compressive strength, split tensile strength, and flexural strength.

Key Words: Glassfiber,compressivestrength,durability, flexuralstrength,microcracks.

1. INTRODUCTION

ReinforcedwithFiberConcreteisacompositematerialwith a high tensile strength made of a matrix with a random distributionordispersionoftinyfibers.Sincethecracking strengthofconcreteisboostedbytheuniformlydispersed fibers'presence,andthefibersalsoserveascrackarresters. When fibers are added to concrete at a given amount, the strainqualitiessuchascrackresistance,ductility,aswellas flexurestrengthandtoughness,areallimproved.Corrosion isavoidedandthecharacteristicsofconcreteareimproved with alkali resistant glass fiber such as increased tensile strength, improved impact resistance, increased shear strength,andimprovedwaterresistancebecauseofitssemicrystallinestructure,whichisknowntobreakeasilyunder impact. Conventional concrete exhibits the characteristic knownas"brittlefailure."Whensubjectedtoexplosiveforce, this is very risky due to the production of ballistic debris, whichmaycauseseriouscollateraldamage.AsGRFCdoes notundergobrittlefailure,thisisnotthecase.Becausethe glass fibers are randomly distributed and laid out in all directionswithinthematerialmatrix,theytendtoholdthe material together. Ballistic debris is drastically minimised

with GFRC. In order to determine if glass fiber reinforced concretemanufacturedwithOrdinary portland cementis suitable for marine and hydraulic constructions, it was decidedtoconductanexperimenttodeterminethestrength anddurabilityofthematerial.

2. OBJECTIVE

ThemainobjectiveofGFRCistoincreasetensilestrengthin concrete.Glassfiber intheconcrete helpsinarrestingthe microcracksandincreasesthedurabilityofstructure.

3. SCOPE

The present data indicates that there is significant improvementinthestrengthpropertiesoftheconcreteby usingglassfibers.Furtherstudycanbeextendedtoknow the mechanical properties of fiber reinforced concrete by adding combination of fibers. We can also study different parameters like frost resistance, fatigue life, drying shrinkageoftheconcretewithandwithoutfibers.

4. METHODOLOGY

Identificationofproblem

LiteratureReview

Procurementofmaterials

Conductingtestsonmaterials

Castingofconcretespecimens

Testingthepreparedspecimens

ResultsandDiscussions

2. EXPERIMENTAL PROGRAMME

2.1 Materials used

2.1.1 Ordinary Portland cement

The cement used in the experimentation was Ordinary Portlandcement Thephysical propertiesoftestedcement aregiveninTable.1

from a different combination of those elements and other mineralswillchangegreatly.E-glassisatypeofglassthatis widely available and has high electrical insulating characteristics

2.1.2 Fine Aggregates

Manufacturessandpurchasedfromthesupplierwasusedas fineaggregate.Thesandusedconfirmedtogradingzone-2as perIS:383-1970specification.

2.1.3 Coarse Aggregates

The crushed stone aggregate by locally quarry purchased from the supplier. The coarse aggregates used in the experimentation was 20mm and downsize aggregate. The physicalandmechanicalpropertiesaregiveninTable.2

2.2 MIX PROPORTION

Design of concrete mix needs not only the knowledge of material properties and properties of concrete in plastic condition,italsoneedswiderknowledgeandexperienceof concreting. Even then the proportion of the materials of concretefoundoutatthelaboratoryrequiresmodification andreadjustmentstosuitthefieldconditions.

Properties Results

Permissiblelimit

Impactvalue 10.1% Shouldnotbemore than30%

Crushingvalue 17.84% Shouldnotbemorethan 30%

SpecificGravity 2.68

2.1.4 Glass Fibers

2.6-2.8

2.2.1 Casting of Concrete Specimen

Theglassfiberusedisalkali-resistanceglassfiberwhichhas a cut length of 12mm. The constant proportions of 0.1% fibersupto0.3%areusedbyweightofcement. Aluminum oxide, calcium oxide, and silicon dioxide are the three primarycomponents needed to create glass.Glasses made

ConcretewaspreparedbyamixproportionsofM30 grade concrete.Thedifferentpercentageoffiberslike0.1,0.2,0.3 wereadoptedintheexperimentalprogramme.Glassfibers wereaddedinthemixbyweightofcement.Theentiremix was homogeneously mixed with calculated amount of water. The compressive strength test specimens were of dimensions150×150×150mm.Thesplittensilestrength

test specimens were of dimensions 150mm diameter × 300mmlength.Theflexuralstrengthtestspecimenswereof dimensions100×100×500mm.Thesespecimenswerecast andtestedafter3days, 7daysand28daysofcuringasper ISspecification.

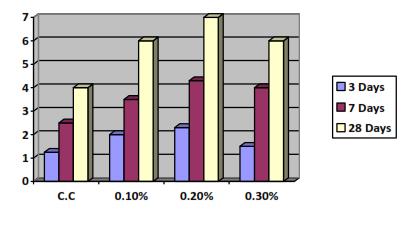

3.2 Flexural Strength:

The flexural strength of GFRC increases with increasing percentage of glass fibers. The percentage increase in flexural strength is maximum at 0.2% of glass fiber at 28 dayscuringofGFRC.Thepercentageincreaseinglassfiber from 0.1% to 0.2% has also increased in percentage in flexural strength from 33.3% to 84% compared to the conventionalconcreteatthelevelof3daysofcuring.Thus canbeobservedthatadditionofglassfiber hassignificantly increasedtheflexuralstrength.

3. RESULTS AND DISCUSSIONS

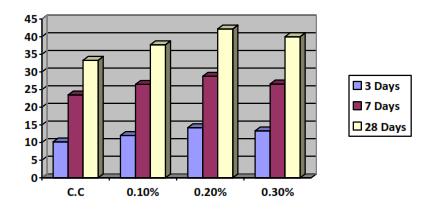

3.1 Compressive Strength

Using cube samples of M30 Grade concrete, compression strengthtestswerecarriedoutusingacompressiontesting equipment.Theaveragestrengthvalueswereevaluatedon threesampleseachbatch.Astheproportionofglassfiberto cementweightrisesupto0.2%,thecompressivestrengthof GFRCat3days,7days,and28daysexhibitsanincreasing trend. Further observation reveals that after 28 days of curing at M30 0.2% glass fiber, the highest compressive strengthisattained.

Table.5.AverageFlexuralStrengthofM30

Table.6.AverageTensileStrengthofM30

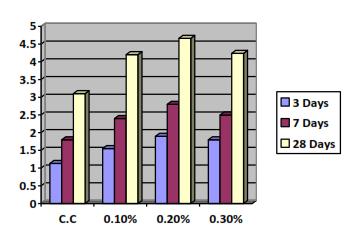

3.3 Split-tensile strength:

ThesplittensilestrengthofGFRCincreaseswithincreasing percentageofglassfibers.Thepercentageincreaseintensile strengthismaximumat0.2%ofglassfiberforboth7days and 28 days curing of GFRC. Thus it can be observed that additionofglassfibershassignificantlyincreasedthetensile strengthinboth7daysand28dayscuring.

4. CONCLUSION:

Inthisstudy,itisconcludedthatthevarietyofGlassFiber Concrete made with Ordinary Portland Cement is an excellent choice for marine and hydraulic structure constructions,ascompressivestrength,flexuralstrengthand tensile strength increases with increase in percentage of glassfiberwithrespecttoweightofcement Asthetensile strengthofthiscompositerises,lesssteelreinforcingmaybe needed,reducingtherateofmarinestructuresdeteriorating Astensileandcompressivestrengthincreaseswithincrease inpercentageofglassfiberwithrespecttoweightofcement, marineandhydraulicstructuralelementscanbeprovided with extra concrete cover supported by glass fiber, which makesithardforelementsthatcausedeteriorationtoreach thesurfaceofsteelreinforcements,preventingcorrosionand increasingthelifeofconcreteintheseenvironments.

5. REFERENCES

[1] N.Shakor,S.S.Pimplikar,“Glassfiberreinforcedconcrete useinconstruction” InternationalJournalofTechnology andEngineeringSystems,Jan-March2011-Vol.2.No.2

[2] K.

glassfiberconcrete”ARPNJournalofEngineeringand AppliedSciences,Vol.5,No.4,April-2010

[3] Er. Lakshit Gupta, Er. Harpreet Singh, ”Steel and glass fiber reinforced concrete: A Review” International Research Journal of Engineering and Technology,Vol5,Issue:2Feb-2018

[4] C.SelinRavikumar,T.SThandavamoorthy,“GlassFiber Concrete:InvestigationonStrengthandFireResistant Properties” IOSR Journal of Mechanical and Civil Engineering,Vol-9,Issue3,Sep-Oct2013

[5] Muhammed ISKENDER, Bekir KARASU, “Glass Fiber Reinforced Concrete (GFRC)” EL-Cezeri Journal of ScienceandEngineering,Vol-5No:1,2018(136-162)

[6] AmitRai,Dr.Y.PJoshi,“ApplicationsandPropertiesof FiberReinforcedConcrete”AmitRaietalInt.Journalof Engineering Research and Applications” Vol-4, Issue:5(version1),May2014

[7] DineshKumar,L.K.Rex,V.SSethuraman,V.Gokulnath, B.Saravanan“HighPerformanceGlassFiberReinforced Concrete”ELSEVIERJournal(2020)

[8] Yan L, He-ming Cheng Zhi-guang M, “Fatigue Performances of glass fiber reinforced concrete in flexure”ELSEVIERJournal,(2012)550-556