Optimization in Supply Logistics Cost of Construction Projects of a Company

Lakshana.P1 , Luke Judson2

Abstract - The contribution of construction materials may account 50-65 % of the project cost due to inefficiency of logistics strategies for congested site in urban areas, the supply logistics cost of material raises from 17-25% goes till 49% of supply logistics cost. As a solution to this, tier 1 cities implemented the strategy of just in time with a consolidation center. However, cities of tier 2 and tier 3 still raising concern of supply logistics cost of congested site in urban areas and a consolidation center cannot be the solution for the single contractor. So suggested methodology is just-in-time with the intermediate warehouse by the contractor. Thus, it is of high essence that material resources are managed properly to reduce cost, achieve timely project delivery at the budgeted cost and quality through logistics strategies. This paper proposes the optimization strategy and evaluating criteria of the attributes in the supply logistics cost of the strategy with fixed, semi fixed, variable cost. The study further takes the supply logistics cost of a 3 projects of a same company to develop the methodology and to provide recommendations.

Key Words: Material management, supply logistics, optimization in logistics cost, transportation cost structure, warehousing cost structure.

1. Introduction:

Materials management is defined as "a whole concept encompassinganorganizationalstructureintegratingintoa single responsibility, the systematic supply and control of resources from demand identification through customer delivery." The contribution of construction materials may account 50 - 65 % of the project cost. The delivery service cost will account for roughly 17%-25% of the material cost, i.e., the physical distribution expense will approximate 10%-11% of the engineering project construction cost, indicating that physical distribution activity in engineering construction projects has a significant economic influence. (ChenDuiyong,2014)

This idea includes material functions such as planning, scheduling, purchasing, storing, transporting, and distributing.Productionandinventorycontrol,buying,and physicaldistributionarealldisciplinesthatarerepresented. (Klooster)

Throughthisstudy,optimizationofsupplylogisticscostinof acompanywillbeanalyzed,assessedandmethodologyare proposed to identify the attributes of Transportation and warehousinginlogisticscoststructureandidentificationof methodstoevaluatetheattributesand analysesandasses the attributes in the case study to provide a structured methodology of cost optimization for intermediate warehouse.

1.1 Material Management

1.1.1 Material classification

Materials can be classified into different categories dependingontheirtypeandsizeweneedorusetechnique onsite.

Type of material

Bulkmaterial

E.g.

Concrete,sand

Baggedmaterial cement

Pelletedmaterials

Packagedmaterial

Loosematerials

Doors,frames

Tiles,pipes,electricalfittings

Reinforcement bars, glass panels

1.1.2 Management of material resources

Theemphasisofmaterialsmanagementisthemanagement ofmaterialresources.Itassessesmaterialcostsandmakes efforts to reduce them. The essential cost of resources, accordingtoclassicalphilosophy,isthecostofgettingthem. However, in today's environment, materials management takes into account not only the cost of materials, but also theircosts.Thismeansthatmaterialcostsandmaterialcosts shouldbereducedtoaminimum.Thesematerialexpenses aretypicallyconcealedand arenot labeled as"materials." Instead,theyarelabeledas"overheads,""scrap,""storage," andsoon.(AshwinPatil,2013)

Theprimarygoalofmaterialsmanagementistominimize anyhiddenmaterialexpenses,regardlessofhowtheyappear inthelogisticscost.

Mostspecificmaterialsimpactedintheconstructioncostare Concrete,Cement,Steel,Aggregates,BrickworkandFlooring

1.2 Logistics Introduction

Contractors are typically merely single connections in logisticchainsthatdeliveritems,services,information,and financingtoaproject.Incontrasttotheindustrialindustries, whichbenefitfromlong-termcollaboration,Incomparison tosuppliersandconsumers,buildinglogisticsnetworksare farmorecomplicatedtomonitorandoptimize. (M.Muya1)

1.2.1 Types of Logistics strategies

JustinTimeTechnique/Pullsystem

o Justintimewithconsolidationcentre/just intimebysuppliers

Just in case/ Push system (Construction ConsolidationCentres,2016)

1.2.2 Logistics cost

Thelogisticscost(LC)inthebuildingconstructionprojectis calculated as the Summation of the transportation cost, orderingcost,inventorycost,anddamagecost.

LC=CT+CO+CI+CD

Insomeprojecttransportationcostishigh.Sotounderstand the cost percentage of transportation cost, ordering cost, inventorycost,damagecostis49%-57%,9.9%-15%,11.5%24.5%, 15 %. (Amornsawadwatana, Logistics Costs EvaluationinBuildingConstructionProject)

Table 2 Types of cost associated with offsite logistics

Costs associated

Offsite Logistics

Transport Cost of inputs required for placing andmaintainingthe vehicle on the road (Licensing,taxes)

Type of cost

SemiFixed

Labor (Driver cost andpackerscost) Variable

Vehicle cost –

Preference type of vehicleforquantity

Semi Fixed/ Variable

Maintenance cost of vehicles(oilcharges, tirechargecleaning), Fuelcost

Transportation to storage Loading and Unloading through equipment/labor

Warehouse –handling

Variable

SemiFixed

Warehousesetup SemiFixed if congested site, land cost rent to store materials + Transportationfrom warehouse to constructionsite

SemiFixed

Labor-security SemiFixed

Maintenance cost –

Electricitybill Variable

1.2.3 Attributes

To assess the suitability of attributes in implementing a logisticstrategyinaparticularstudy.

Table 3 Resource consumption during storage (Author)

Logistics process Category Resource

Storageatsupplieryard Labour Worker(handling)

Equipment Handlingtruck Material stocking

Storage at intermediate warehouse

Capital Rent

Table 4 Resource consumption of transportation from supplier to construction site (Author)

Logistics process Category Resource

Transportation (to constructionsite)

Labour Truckdriver Inspector

Equipment Truck Material

Transportation (to intermediate warehouse)

Labor Truckdriver Inspector

Equipment Truck Material

Logisticsprocess Category Resource

Loadingandfix Labour Worker(handling)

Equipment MobileCrane

On-sitestorage stocking Truckdriver Inspector

Capital Opportunitycostfrozen inon-sitestocking

2. Case study data collection and analysis

2.1 Introduction

The nachimaar engineering consultant is a construction company that deals with several projects in the southern region of Tamil Nadu. For a further understanding of optimizingcost,threecasestudieshavebeentakenfromthe same company which are located in Thirunelveli, Thiruchirapalli, and Thanjavur. The case study sites are located in the urban areas. The company procure the materials directly and store it in the construction site without any intermediate warehouse. Due to space constraintthesematerialsareprocuredevery20-25days. Furtherdetailsofcasestudywillbebrushed.

Table 6 Case study Details (Author) Description

In the case study 1, material cost about 63.4% of total constructioncost.Inwhichhalf(36.6%)ofthecostarebulk materials and pelleted materials. concrete takes 17.1% of materialcost.Thesitecanstoreonlyfor2-3days.

In the case study 2, material cost about 55.4% of total constructioncost.Inwhichhalf(36.6%)ofthecostarebulk materials.concretetakes19.4%ofmaterialcostthesitecan storeonlyfor5days

In the case study 3, material cost about 53.7% of total constructioncost.Inwhichhalf(36.6%)ofthecostarebulk materials,concretetakes18.1%ofmaterialcost.Thesitecan storeonlyfor5days.

Using the Just in time strategy, the bulk materials are ordered and stored directly in the site warehouse by a company

2.1.1 Supply of materials of case studies for 3 months

Table 7 Supply of materials of each project for 3 months (Author)

The supply materials for first 3 months are taken. The quantitiesarecalculatedasper BOQ,schedule ofthe each projectandfirst2projectsstartsinthesamemonthand3rd casestudystartsafter2months.

2.1.2

The Percentage of logistics cost from the materials cost is 27.7%,45%,30.79%forsite1,site2andsite3respectively.

2.1.3 Details of plants of cement, aggregate and steel

The warehouse has been selected on the basis of transportationroutefrom manufacturing/plant/quarryto site,security,rentalrate,laboravailability,distancefromthe site.

2.1.5 Location of site, warehouse, cement, aggregate and steel

Theconstructionsitesarelocatedinthecenterof thecity whichprohibitsthetravelofHGVvehiclesintheparticular timeat11pmto5am.Sothewarehousecentersaretakenin thehighwayroadaround50kmsawaywhichwillreducethe rentalrentalso.

2.1.4 Location and distance details of plants from warehouse

The company is procuring the cement from the branded cementfactoryandaggregatesareprocuredfromthenear quarries. Even though there is availability of local brands plants in Tamil Nadu, the company prefers from JSW and Tatasteels.

2.1.6 Type of Vehicle, dimensions and Rentalrate

2.1.7 Vehicle Type and Labour Charges

The labor charges for a driver are given in 2 ways one is lumpsumandotherwayiskmperway.Lumpsumrateper trip by truck driver is 10,000 – 30,000 depends upon distance travel, location and type of HGV vehicle they driving.

Table 11 Vehicle Type and Labour Charges (Author)

Vehiclebodytype Distance travel per day Labour Rate

HGV 100-150km/day 50/kmor7.4/hr

LGV Upto400km/day 30/kmor3.2/hr

2.1.8 Rental rate

Rentalratedependsonthearea,landrentonthelocation.

Table 12 Rental cost of warehouse(Author)

2.2 Total logistics cost are

Supply logistics = TC(CC(semifixedcost)+CV(variable cost)) +WC(CC(semifixedcost)+CV(variablecost))+LC (CC(semifixedcost)+CV(variablecost)) Thecostincrease, causedbyachangeinleadtimeofprocessesandordercycle time.Thecostincreasecausedbyachangeincargoturnover andstocklevel.

2.2.1 Analysis

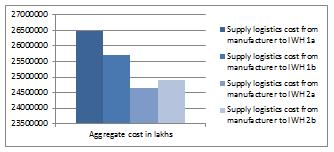

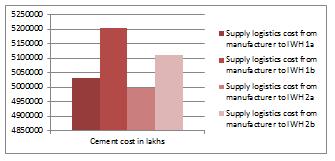

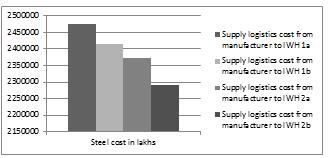

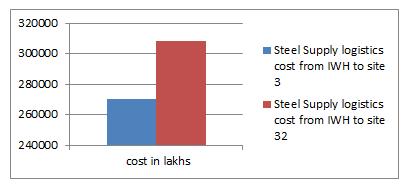

2.2.1.1 Cost from supplier to intermediate warehouse

2.2.1.2

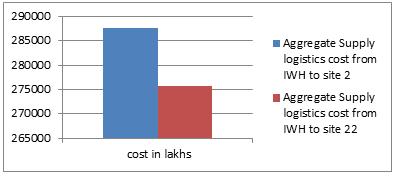

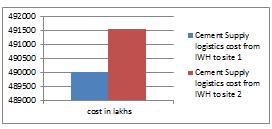

Thelogisticscostofthesite withintermediatewarehouse reducesthelogisticscostby7%-19%fromthiscase.When compared with each scenario, the price of transportation fromquarries/plantstoanintermediatewarehousebyroad indicated a potential optimal plan. These elements can be capturedbydefiningappropriatenumberofvariousdecision variablessuchasdistance,fastestroute,timetakentoreach thedestination,andvehiclesize.Theresultsshowedthatthe percentagesavinginlogisticscostandthefeasiblesolutionis obtained from 16 possible routes (refer above table). The leastpossiblerouteis4-5%lesserthantheotherroutes.

4. Recommended Methodology for Logistics cost

Thispapercontainstheconcludingremarksforthecompany whichdealswithseveralconstructionprojectsincongested siteinaurbanarea.Transportationvehiclesizeforcarrying thebulkmaterialsof 1700–6000ton useHGVofmedium sized can transport comparatively in lesser cost of 3-8% thanhighsizedofHGVduetoitsperdaytravelconstraint which may increase the no of hours travel due to that maintenance and fuel charges will be high. if we take low sizedHGVvehicle,speedofthevehicleincreasebutthenoof transport increase so the transport vehicles rate takes doublethetimes.

Intermediatewarehousingcanbeplacedatthedistanceof 150 km maximum for easy shipping from intermediate to site,thenwhichwillbetravelledthroughLGVs.soitcanhave lessernooftripsgenerated.

5. Conclusion

The conclusions drawn for the optimization of supply logistics cost which to answer the company with several projects in congested site in a urban area and it can be concluded using recommending a logistic strategy just in timewithintermediatewarehouseforacompanywhichhas several projects in the same areas. It is concluded by identifying the appropriate approaches for intermediate warehouseandthetransportationbyfindingandevaluating the attributes in the logistics cost with fixed, semi fixed, variablecoststudyasabase.

Theabovethemethodologyofjustintimewithintermediate strategy will help to understand the variables of cost in transportationandwarehousinginthelogisticscostandthe percentageofsupplylogisticscostreduced.Thisstudyhas gone as far as a review of transportation cost and warehousing cost from supplier to site via intermediate warehousingofaprojectofsamecompany.Thus,itcanbe concludedthatthisdissertationpaperdevelopsavaluable methodologyforevaluatingthelogisticscostofcompany.

6. References

1. Construction Consolidation Centres. (2016).London: Transportforlondon.

2. Abdallah,H.(2004). Guidelines for Assessing costs in a logistics system. Unites States Agency for InternationalDevelopement.

3. Adithya A.Pande, S. (2016). Study of material managementtechniquesonconstructionprojects. International Journal of informative & futuristic research

4. Aiswarya Sreekumar, D. P. (n.d.). Sustainable Retrofit for Adaptive Building Reuse–A Facility

Management Approach for Highlighting and Cataloguing Deficiencies for Retrofit Decision Making.

5. Amit Moza, V. K. (2022). Evaluating Project ComplexityinConstructionSectorinIndia;. Journal of Engineering Research and Sciences

6. Amornsawadwatana, S. (n.d.). Logistics Costs EvaluationinBuildingConstructionProject.UTCC EngineeringResearchPapers2005.

7. Amornsawadwatana, S. (n.d.). Logistics Costs Evaluation in Building Construction Project. Industrial-Academic Annual Conference on Supply Chain and Logistics Management.

8. Anna sobotka agata czarnigowska, k. s. (2016). Logistics of construction projects.

9. Anna SOBOTKA, A. C. (20 5). LOGISTICS OF CONSTRUCTIONPROJECTS.

18. M, A. (2019). A Material Management in ConstructionProjectUsingInventoryManagement System. IRE Journals .

19. M.Muya1,a.D.(n.d.).Constructionmaterialssupply logistics. ijert

20. MalekGhanem,F.H.(2018).ANEWPERSPECTIVE OFCONSTRUCTIONLOGISTICSANDPRODUCTION CONTROL: AN EXPLORATORY STUDY. https://www.researchgate.net/publication/326377 294.

21. Moza,A.P.(2022).MethodologyforEstablishinga ModelforAssessingPerformanceofPublicProjects in India. International Journal of the Built Environment and Asset Management, Inderscience publisher.

22. Nawaj Kalim hannure, s. s. (2016). Comparative study of traditional material management and materialmanagementwithICTapplication. current trends in technology and science

10. Ashwin Patil, S. v. (2013). Analyzing Material ManagmentTechniquesonconstructionprojects.

11. ayegbs, C. (2017). An assessment of material managementonbuildingconstructionsites.

12. ChenDuiyong,J.S.(2014).Engineeringconstruction projectsitelogisticsmanagement.

13. Dawood, N. N. (n.d.). MATERIALS MANAGEMENT SYSTEMS FOR THE CONSTRUCTION INDUSTRY . Middelsbrough:TheUniversityofTeesside.

14. Hisham said, k. e.–r. (n.d.). Optimizing material Management and storage on construction sites.

15. Kapoor, E. S. (2022). Cost benefit analysis for rehabilitation of buildings: case of Indian Medical Association, New Delhi. International Journal of Structural Engineering

16. Klooster, M. t. (n.d.). Improving materials management at a Residential Building. Netherlands: UniversityofTwenteEnschede,TheNetherlands.

17. Kumari,N.T.(2022).AnalysisofSmokeProduction and Movement in Shopping Malls/Centers. International Journal of Town Planning and Management

23. Ng, Y. F. (n.d.). Applying activity-based costing approachforconstruction. IJERT.

24. Nidhi Gupta, S. K. (2019). Effectiveness of Amendment of GCC on Claims by CPWD in 2019. International Journal for Research in AppliedScience & Engineering Technology (IJRASET

25. Paul, V. K. (2021). Post Pandemic Impact on PlanningOfDistrictHospitalsinIndia. International Journal of the Built Environment and Asset Management.

26. Peltokorpi,O.S.(n.d.). A new model for construction material logistics: from local optimizationoflogistics towards global optimization of on-site production system.

27. RahulKumarGupta,V.K.(2022).OptimizationOf Project Progress Using 3d Laser Scanning Technique. InternationalJournalOfArchitecture And Infrastructure Planning

28. Rastogi, R. P. (2022). Analyzing the Impact of ChallengesinPrefabricatedBuildingConstruction SupplyChains. Journal of Engineering Research and Sciences

29. Rastogi, R. P. (2022). Analyzing the Impact of ChallengesinPrefabricatedBuildingConstruction SupplyChains. Journal of Engineering Research and Sciences, JENRS.

30. Rybakov,D.S.(2017).Totalcostoptimisationmodel for logistics systems of trading companies. International Journal of Logistics Systems and Management

31. Singh, V. P. (2022). Feasibility Study of Adaptive Reuse of Old Buildings. International Journal of Housing and Human Settlement Planning,

32. Sinha, A. (2014). The Sacred Landscape of Braj, IndiaImagined,Enacted,andReclaimed. Landscape Journal.

33. SKSolanki,R.R.(2022).CostAnalysisofFunctional Retrofitting Measures in Buildings. Journal of The Institution of Engineers (India).

34. Solanki, S. K., & Paul, V. (2022). Comparison between service life prediction methods for buildingrehabilitation:applicationonacasestudy. Journal of Building Pathology and Rehabilitation

35. voigtmann,J.(n.d.). Construction logistics planning by simulation.