COMPARATIVE ANALYSIS OF STRENGTH OF ECOFRIENDLY MORTAR MADE WITH PARTIAL REPLACEMENT OF NATURAL FINE AGGREGATE WITH FLY ASH

ARPIT JAIN¹, Dr. SANJAY BHANDARI², Dr. PRADEEP PUROHIT³

1 Research Scholars, Civil Engineering Department, Samrat Ashok Technological Institute, Vidisha (M.P.) 464001, India.

2. Professors, Civil Engineering Department, Samrat Ashok Technological Institute, Vidisha (M.P.) 464001, India. ***

Abstract - In the modern world, there is a shortage of River occurred fine aggregate (river sand), and industrialists are disposing of industrial waste inappropriately and improperly, like fly ash, which has resulted in a ban and lack of approval from the regional administrative system assembly or the state and local government in order to protect ecology and ecosystem from resource depletion and ecological/ environment pollution. A result, Fly ash is among the best sand alternatives. Fly ash has partially replaced natural sand in order to ensure the production of environmentally friendly mortar as to raise strength, we also recommended using fly ash in place of some sand. This analysis is also beneficial to the environment because it reduces pollution from industrial harmful waste disposal. Also, because to the issue of a lack of natural resources, less natural fine aggregate is being used. The use of Fly ash as partial sand in mortar, on a large scale, will be highly advantageous to the construction industries and serve to conserve ecology and its resources, this attempt to be highlighted in this study.

Key Words: Natural Fine Aggregate, Fly ash, Resource Scarcity, Eco-friendly

1.INTRODUCTION

Environmentallyfriendlymortarproductionisnowcrucially needed in the construction industry to protect the environmentandour world. Utilisinga smalleramount of thelimitednaturalaggregate,whosesuppliesaredepleting in fast way. The infrastructure of India’s is feeling the consequences of the current global environment, which is makinghighqualitynaturalaggregateslikeriversandmore and more scarce. Also, it is performed by using industrial wastes as possible, such as fly ash, which reduces the requirement for landfill space. In India, fly ash ponds are currentlyspreadacross65000acresofland,andbyAugust 2022,IndianIndustrieshadgenerated270.82milliontonnes ofFlyash.Uncontrolledflyashdisposalhasaneffectonthe localsurroundingAndclimateduetoitsweightlessandfine property, flyashnotonlyconsumesacresoflandsbutcan alsogoairpollutionifimproperlycontrolled.Foranumber ofpurposes,includingtheproductionofhigh-performance mortarandconcretemixtures,flyashhasbeenutilisedasa

substitute resource for building sector. The Fly ash is a pozzolanicsubstancethatisaddedtomortarandconcreteto improve propertieslikecompressivestrength.

1.1 FLY ASH

Thewaste,whichisconveyedbythefluegasesfromthe boiler, is a fine powder that is generated during the combustion of ground or crushed coal and is stored in electrostaticprecipitate.Flyashisasphericalparticles,sizes thatrangesfrom-0.045mmto+0.6mm.

1.2 FLYASH CLASSIFICATION

According to ASTM C-618, fly ash is divided into two generalcategories:ClassFandClassC.Thekeyvariations between these two kinds are the amount of presence of calciumoxide,silicondioxide,Aluminiumoxideandiron.

Class F Fly ash –ThecategoryofFlyashhasalime(CaO) percentage of 10% or less, is often produced by burning anthracite coal and old bituminous. Due of its pozzolanic properties, glassy silica and Class F Fly ash require a cementingagent.

Class C Fly ash –FlyashfromburningofSub-bituminous coal or lignite is classified as Class “C,” and it frequently contains20%ormorepercentageoflime(CaO).Thistypeof fly ash doesn’t require an activator, and it frequently has higher levels of sulphate and alkali than Class “F” fly ash does.

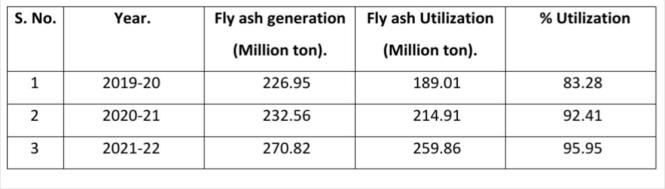

The table, which displays the production and consumption of fly ash during the course of the last three years,from2019–2020to2021–2022.

Source:AuthorityofCentralElectricity

The Analysis suggests a mortar procedure for partially substitutingNaturalFineAggregate(Sand)withflyashwith conventional mortar without the use of plasticizer. As a potentialimprovementtotheabovementionedproblemsof scarcityofnaturalresourcesandenvironmentproblemand pollutioncausedbyunsuitabledisposalofflyash.

Considerthatthe(1:3)ratioof mortar’scomponentsare thebinder(Cement),NaturalFineAggregate(Sand),andthe addition percentage Of Fly ash mixed in some % of sand greaterto20%as22%,24%,and26%forexperiment.One conventionalmix(1:3)willalsobemadeinaddition.Aspart ofthetestprocedure,thecompressivestrengthofmortaris analysed containing varying percentages of fly ash as percentage of sand replacement and compared with a conventionalmortar.

2. EXPERIMENT ANALYSIS

2.1

Materials:

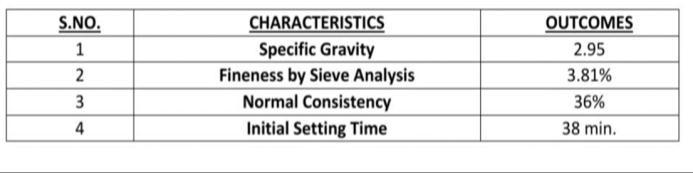

2.1.1 Cement :- It acts as the binder in the mortar. As followedtheIS:1489Part1-2015,cementofPPCgradetobe usedinthisexperiment.Inaclosed-circuitballmillofvery effective separator, clinker particle of cement is combined withtheappropriatelevelofGypsumandFlyashtoproduce Portland Pozzolana Cement. According to pertinent tests conductedasfollowedinIS:4031-1988,PortlandPozzolana Cement has the following physical qualities, which are displayed:

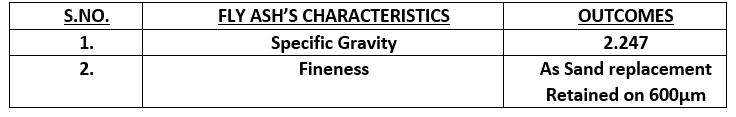

(b) Fly ash:- Flyashisusedasafineaggregatealternative for making mortar. A full understanding of the attributes, characteristics,advantages,andusesofflyashisessential formortartofunctionasitshould.

FlyashofClassCclassed

TakenbyproductproducedbyBINAREFINERYLTD(BPCL), Bina(M.P.)

Better packaging, Pozzolonic attributes, and internal cure attributes ofFlyashmakesanidealpartialalternativefor sandintheconstructionofEnviro-friendlyandgreenMortar.

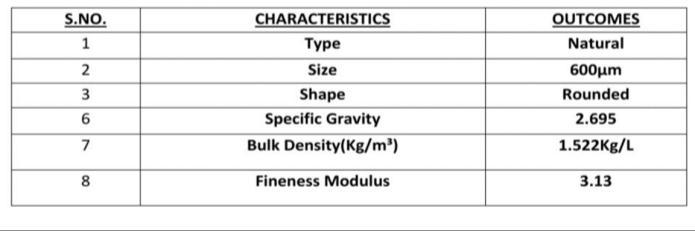

2.1.2 Fine Aggregate

(a) River Sand:- NaturalSandisacrucialingredientin the mortar mixture because it creates the proper adhesionbetweencementandaggregate.Sandsize inrangeofISsieveofopening4.75mmorless.As per definitionsinIS:383-1963,thesandwillpassed fromsievewitha1.18mmopeningandretainedon a600μm.Riversandoflocalavailableiscollected fromriverbedsandutilisedfortheexperimentof 600μm.

2.1.3 Water:- Water is an essential component of mortar because it facilitates chemical processes that result in cement paste, hydrates cement, and contributes to the mortar’s strength after appropriate curing. Without any turbidity,alkalinity,ororganiccontent,weusedordinarytap water.

2.2 EXPERIMENTAL

2.2.1 Mix proportion:- Thefollowingaretheseveralmortar

1:3proportions

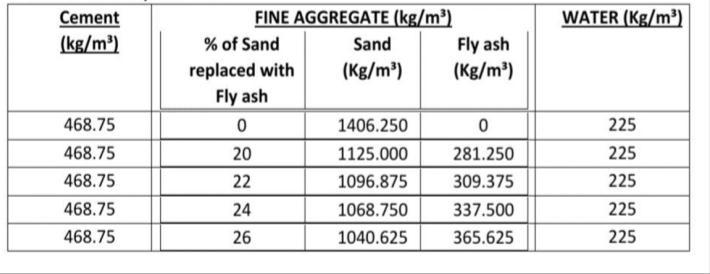

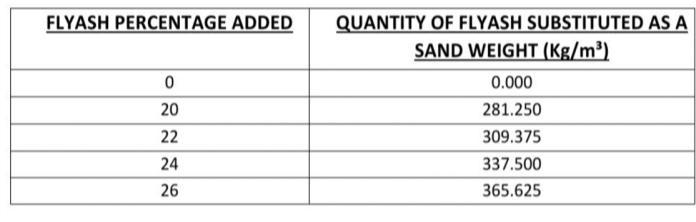

Table 2.4 Proportion of Mortar that is mixed in a 1:3 with Fly ash added partially as sand replacement

2.2.2 Batching/ Mixing :- InaccordancewithIS:2250-1981. Ingredients like as cement, fine aggregate (sand with Fly ash),andwaterareweighted.Ingredientswerethenmixed byhandafterthat.Themixingoperationwascontinuedfor5 minutes or Until the mix were gets its consistency and homogenousity. The ingredients have been thoroughly mixedbutBeforetheInitialSettingTimebegins,themixture isinitiallypouredintothemoulds.

2.2.3 Pouring/Compaction of Fresh Mortar:- Freshly Mortariscompactedwithahandtampingrodofatarateof 20to25strokesineverylayer.Themortarsamplesarewell compressed by tamping. When pouring the cube sample mould,thepropercompactionis mustrequiredtoeliminate airspaces.

2.2.4 Cube Casting:- Themouldisnowfilled,andas ithas been thoroughly mixed and it is compacted with a 60 cm sized rod. Pour the remaining mortar onto the mould and compactitagain,justasyoudidforthelayer1.Finishthe topofthecubemouldnowbyusingthetrowel’sblade. The70mmx70mmx70mmcube-shapedmouldtaken.

2.2.6 Curing:- The filled mouldshouldbekept in a clean areaforcomplete1day.Afterthefirst24hours,demouldthe cubeandimmediatelykeepthemouldsinfresh,cleanwater. The water that the cubes are maintained in needs to be replaced every week and kept at a steady 27 +-2°C temperature.

Up to the test day, the sample was properly cured in accordancewithIS:456:2000.

2.3 MORTAR HARDENED CHARACTERISTICS

Compressive Strength:- The ability of a structure to withstandloadsorpressuresappliedtoitssurfacewithout splitting, deflecting, or degrading is known as its compressive strength. The mortar be pour into mould in layeredmannertoensureproperCompactionthatthereare novoidsinthemixture.Thesecubesundergocompressive testafter7and28daysofcuring.Inordertoensurethatthe load should be applied at gradual rate of 35N/mm2 per minute till specimen fails. The Mortar’s compressive strength isthencalculatedbydividingtheloadatthepoint offailureofcubesbythecross-sectionalareaofspecimen.

3. RESULT AND OBSERVATION

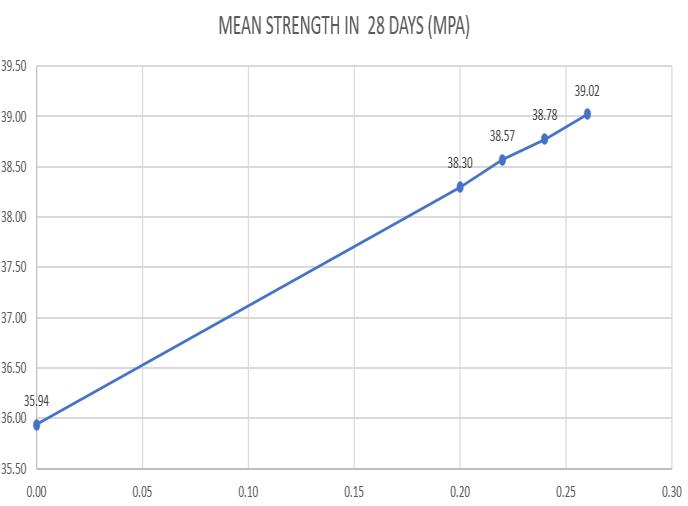

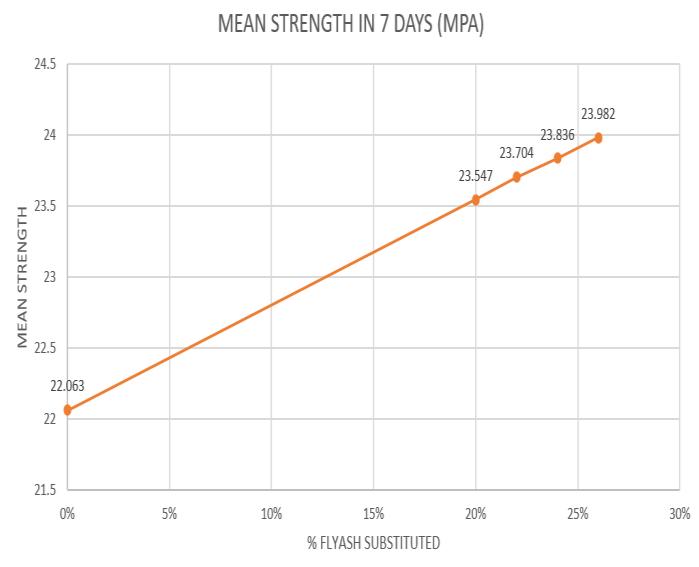

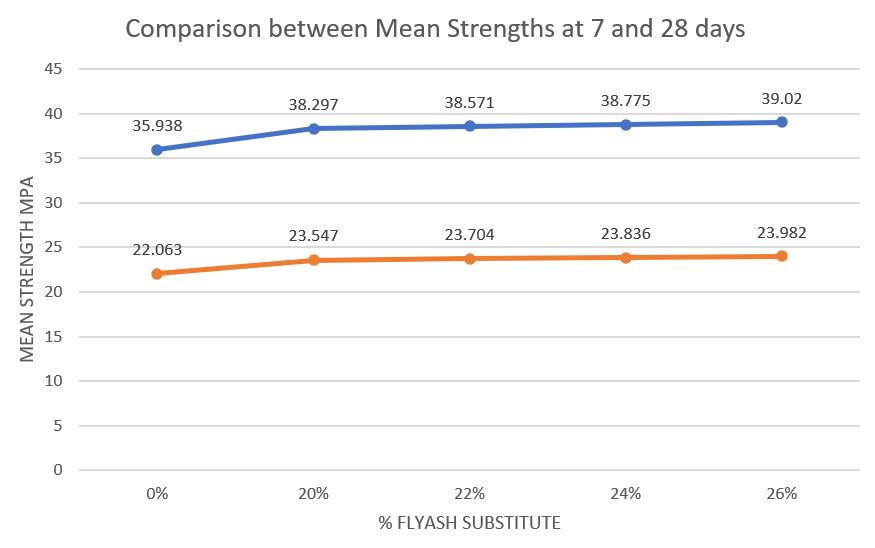

Compressive Strength:- Fly ash was replaced for natural sandinvariedamounts(0%,20%,22%,24%,26%)when castingof30cubesofnaturalsand.Eachsampleunderwent a7and28-daycureperiodaspertestconductedday.Inthe current investigation, replacing varying percentages of fly ashwithsandresultsinaincreaseinthemeancompressive strengthofmortar.

Table 3.1 Compressive Strength with Utilizing Natural sand with Partially Substituted Sand by Fly ash

Graph 3.1 Mean Compressive Strength of Mortar Cubes with Natural sand and with various percentage level substitution of Sand by Fly ash at 7 days

Graph 3.2 Mean Compressive Strength of Mortar Cubes with Natural sand and with various percentage level substitution of Sand by Fly ash at 28 days

4. CONCLUSIONS

The concluded results of an experiment on the effects of using fly ash as a partially alternate for natural sand on compressivestrengthofmortarareasfollows:-

When fly ash is added to mortar as a partial substituteforsomepercentofthenaturalsand,the strength of the mortar increases by around 6.5% when Fly ash added to 20% of natural sand as compared to mortar made with 100% natural aggregate. Causes the compressive strength in mortartosteadilygrow.Moreover,a+2%interval increaseinflyashcontent,for22%,24%,and26% replacementlevels,causesaprogressiveincreasein thecompressivestrengthofmortar.

Thepartiallypreparedflyashmortariseffectivefor load-bearingmasonryconstructionsaswellasfor regular masonry brickworks and stone works, masonryforreinforcedbrickworks,andallplaster projectsduringmoistclimate.

UsingFlyashasasomepercentagefornaturalsand helps the environment by minimising pollution

Causedbyimproperdisposalofflyashbyindustrial house.

5. ACKNOWLEDGEMENT

Ourdeepestgratitudegoesouttoeveryonewhoprovideus thechancetocompletethisdissertation.Also,wewouldlike to express our deepest thank to Dr. Rajeev Jain our Department Head, and Dr. J.S. Chauhan Post Graduation Coordinator professor in the civil department, whose suggestions and encouragements supports us to plan our dissertation. I owe a great deal of gratitude to my Dessertation Guide and Advisor Professor Dr. Sanjay

BhandariandProfessorDr.PradeepPurohit,forlettingme work under their expert guidance, deeply monitor this research,andofferingawealthoftechnicalsuggestionsand advicethatmadeiteasierandmoresuccessfultocomplete.

REFERENCES

1. CodeIS:4031(Part6)–1988.“METHODSOFPHYSICAL TESTSFORHYDRAULICCEMENT”.

2. BIS Code IS : 2250 – 1981. “CODE OF PRACTICE FOR PREPARATIONANDUSEOFMASONRYMORTARS”.

3. BIS Code IS 383 (1970): “Specification for Coarse and FineAggregatesfromNaturalSourcesForConcreteand Mortar”.

4. BISCodeIS456(2000): “PlainandReinforcedConcrete -CodeofPractice”.

5. IS 1489:2015 Part 1 & 2. “Requirements of Portland PozzolanaCement”.

6. BIS Code IS 3466 (1988): “ Specification for masonry cement”.

7. BISCodeIS2116(1980):“Sandformasonrymortars–Specification”.

8. IS1542(1992):“SpecificationforSandforplaster”.

9. M.L. GAMBHIR (2006), Concrete Technology, Tata McGrawHillPublicationCo.Ltd.,India.

10. “REPORT ON FLY ASH GENERATION AT COAL / LIGNITEBASEDTHERMALPOWERSTATIONSANDITS UTILIZATIONINTHECOUNTRYFORTHEYEAR2021–22”, CENTRALELECTRICITYAUTHORITY,MINISTRYOF POWER,NEWDELHI.

11. “REPORT ON FLY ASH GENERATION AT BPCL BINA REFINERY,BINA(MADHYAPRADESH).

12. 12.UllsS.N.,B.V.VenkatramaReddy,PPrasannaKumar. “PropertiesofFlyashblendedMortar”.

13. 13. Rakesh Soni. “Behavior of FLY ASH in CementConcrete Pavement”,Volume: 02 Issue: 05 | August2015.

14. 14.SarathChandraKumar.Bendapudi.“Contributionof Fly ash to the properties of Mortar and Concrete”. InternationalJournalofEarthSciencesandEngineering, ISSN0974-5904,Volume04,No06SPL,October2011, pp1017-1023.

15. 15.ShirishV.Deo,ArunD.Pofale.“ParametricStudyfor ReplacementofSandbyFlyAshforBetterPackingand Internal Curing”, Open Journal of Civil Engineering, 2015,5,118-130.

16. 16.K. V. Madurwar, A. N. Burile, Arti M. Sorte. “CompressiveStrengthofCement&FlyAshMortar:-A CaseStudy”.

17. 17. N.P. Rajamane and Ambily P.S. “ Fly ash as a sand replacement material in concrete -A study”. Article in IndianConcreteJournal·July2013.

18. 18.G.Sarangapani;B.V.VenkataramaReddy;andK.S. Jagadish.“Brick-MortarBondandMasonryCompressive Strength”. DOI 10.1061/ (ASCE) 08991561(2005)17:2(229).

19. 19.SheerazAhmedChandioandFarazAhmedChandio. “EffectofFlyAshontheCompressiveStrengthofGreen Concrete”.Engineering,Technology&AppliedScience Research,Vol.10,No.3,2020,5728-5731.

20. 20. Amarnath Yerramala , Rama Chandurdu C and Bhaskar Desai V. “INFLUENCE OF FLY ASH REPLACEMENT ON STRENGTH PROPERTIES OF CEMENTMORTAR”Article in InternationalJournalof EngineeringScienceandTechnology·August2012.