An approach for the design of an automatic hand sanitizing machine using fog sanitizer

Hridhya AP11Department of Biomedical Engineering, EKNM Government polytechnic College, Thrikaripur, Kerala, India

Abstract - Since the onset of the COVID-19 pandemic, it is recommended to wash or sanitize ther hands several times a day. Also, there should not be much wastage of water or sanitizer. The scarcity of water pose more problems and excessive use of hand sanitizer can lead to dryness, cracks, redness or discoloration on skin and its flaking. It dangerous if it is ingested or gets into the eyes. To solve this problem, a system can be developed that allows to sanitize the hands without using more than 95% sanitizer. To disinfect with disinfectant or sanitizer, it should reach every millimeter of the hand. The machine designed is a fog-based system. When the user inserts the hands inside the box, the mist system activates automatically, converting the sanitizer into fog. After exposing the user to sanitizer mist for 5-15 seconds, the hands will be clean.

Key Words: Pandemic, sanitization, fog, humidifier, Arduino-uno,Covid-19

1. INTRODUCTION

The project is fighting the coronavirus pandemic by regularly washing hands and keeping public areas clean, considering the useless access to sanitizer caused by regular hand washing and control measures. When the user's hand is placed in the specified position on the machine, the sensor is activated and the mist system is automatically activated, turning the sanitizer in the container into fog. The mist maker module works on the principleofpiezoelectriceffect.Whena voltageisgivento the crystal, it vibrates at high frequency and turns the sanitizer into a thick cloud of fog. The system is based on Arduino Uno R3 microcontroller board Dry Fogging is a relatively new disinfection method that uses liquid disinfectants. Since the droplets are in the form of ultrafine dry mist, it prevent the chamber from falling easily ontothesurface.Thusthisprovidesa desirablequalityfor adisinfectionchamber.Thisfoghandsanitizercanbeused whenwidely.Indenselypopulatedcitiesandmetropolitan areas, there are several public spaces such as hospitals, shopping malls, and theatre toilets in trains and airports This system ensures proper sanitation and effective management of water consumption, while saving about 95%. Fog sanitizer can be used to wash your hands and maintain a non-contact environment. It also helps prevent thespreadofthevirusbyallowingmultiplepeopletohave accesstotheseaffectedpublicsanitizerbottles.

***

1.1 EXISTING SYSTEM

In the present system, in addition to the manually controllable sanitizer dispenser, the automatic sanitizer dispensers are widespread. In a manually controlled sanitizer dispenser, there will be a direct contact with the dispenserwhichcausesthespreadofvirusesorpathogens from one person to another. In the automatic sanitizer dispenser, the amount of sanitizer dispensed is over in quantity, so there will be a wastage of sanitizer and the over amount of sanitizer used several times will cause irritation and dry, cracked skin as well as redness or discoloration,andflaking.

1.2 PROPOSED SYSTEM

In the proposed system, the machine is integrated with a tank below it. The tank is filled with sanitizer. When the user inserts hands into the system, this automatically triggersafogmakersystemthatconvertswaterinthetank tofog.Thefogwillreachallcornersofthehandinlessthan 5secondsasitisingaseousstate(watervapor).After5-15 secondsofsanitizerfogexposuretheuser'shandisfree of anypathogens.Thisrequireslessthan95%ofsanitizerand there is no direct contact with the system. The main advantage of the system is it delivers only standardized amounts of sanitizer which will reduce the wastage of sanitizer.UVLEDsarealsoinstalledinthesystemthathas an ability to kill bacteria, viruses, mold, and fungi. It is a completelyautomaticsystem.

Themainhardwareincludes

2.1 Fog maker/ultrasonic humidifier

The ultrasonic humidifiers power circuit board with Atomizing Chip Moisture Film Humidification atomization machine is suitable for the atomization plate tablet with a diameter of 20mm. The principle of working of the ultrasonic Humidifier Piezoelectric Transmitter module is cavitationproducedbysoundwaves. Byprovidinga DCof 3-12V it will turn into a mini ultrasonic atomizer. The soundwavescontaincompressionandrarefactionanddue to extremely rapid movement, water droplets cannot sustain in their liquid state and get converted into vapor immediately. This vibration is produced by a piezoelectric filament. Piezoelectrictransducerdippedinawater.When powered it vibrates according to the high frequency, electronic signal and produces mechanical oscillation. Whentheoscillationspeedisincreasedtoahighlevelthen the water particles cannot follow the oscillating surface, andamomentaryvacuumandstrongcompressionoccur.It results in the formation of explosive air bubbles (cavitation). At cavitation, broken capillary waves are generated. Tiny droplets of dimension 1-micron diameter break on the surface tension of the water and are quickly dissipated into the air. It then converted into vapor form andabsorbedisintotheairstream

2.3 5v Relay modules

A power relay module can be considered as an electrical switch that is operated by an electromagnet. The electromagnetinthemoduleisactivatedbyaseparatelowpower signal from a microcontroller. When the electromagnetisactivated, itwill pullitselftoeitheropen orcloseanelectricalcircuit.

Arduino is an open-source hardware and software company. Its hardware products are licensed under a CCBY-SA license and software is licensed under the GNU Lesser General Public License (LGPL) or the GNU General PublicLicense(GPL).

The Arduino Uno R3 is a microcontroller board is a removable, dual-inline-package IC from ATmega328 AVR microcontroller.Thereare20digitalIOpins(amongwhich 6 can be used as PWM outputs and 6 pins can be used as analog inputs). It is possible to load the programs onto it fromtheeasy-to-useArduinocomputerprogram.

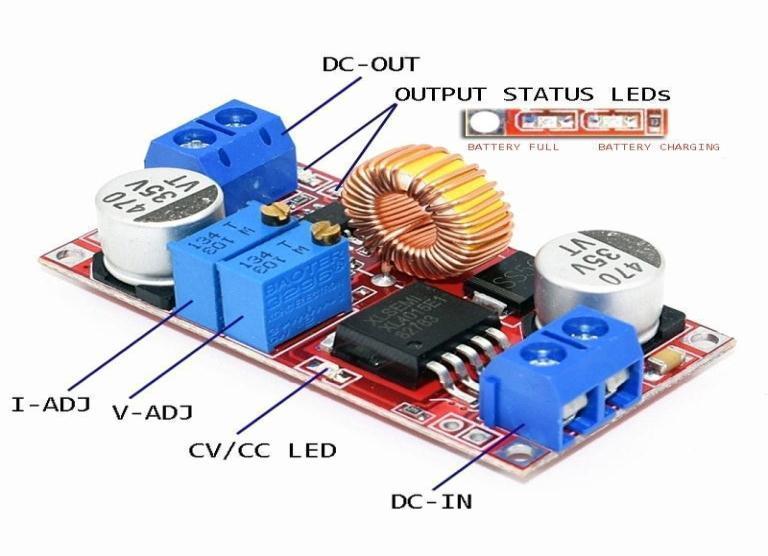

A buck converter (step-down converter) is a DC-to-DC power converter which steps down This module has onboard constant voltage and constant current control feature which is useful for general purpose power supply. There are two multi turn trim pots to adjust the output voltage and output current. Further, there are three LED indicators – the first one near the input connector is the constant-current (cc) indicator, while the next two LEDs are intended mainly for battery charging applications By slowly turning the voltage adjustment trim pot clockwise direction will raise the output voltage gradually, and a counter clockwise rotation will lower it. Similarly for the current.

2.5 SD card module

AnSDCardModuleoraMicroSDCardAdapterisa device which allows connection between aMicroSDcardanda MicrocontrollerlikeArduino.

2.6 Ultrasonic sensor

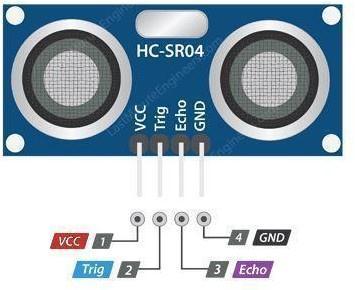

Fig-4: PinsOfUltrasonicSensor

An ultrasonic sensor is an electronic device that can measure the distance of a target object by emitting ultrasonicsoundwaves.Itwillconvertthereflectedsound intoanelectricalsignal.Therearetwomaincomponentsin ultrasonic sensors They are the transmitter that emits the sound using piezoelectric crystals and the receiver which receives the sound after it has traveled to and from the target

2.7 I2C LCD display

The I2C 16x2 Arduino LCD Screen uses an I2C communicationinterface.Itcandisplay16×2characterson 2lines,whitecharactersonabluebackground.Thisdisplay overcomesthedrawbackofLCD1602ParallelLCDDisplay inwhichthereisawastageabout8Pinson theArduinofor thedisplaytogetworking.

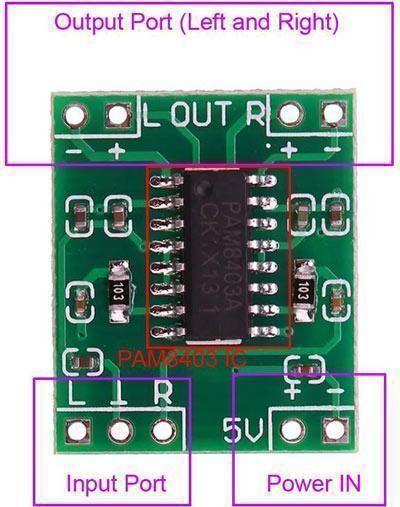

2.8 The PAM8403 amplifier

It isa dual-channel stereoamplifier that can produces 6W output. It has inbuilt short circuit protection. this IC itself doesnotrequireanykindofheatsink Itcandirectlydrive 4Ωor8Ωspeakers.Aproperspeakerwithnotmorethana 3W output rating must be used This is a stereo amplifier board The input section has two inputs L (Left) and R (Right) and common ground in between them. It does not require heatsink which also 25 saves additional board space.Irrespectiveoftheheatsink.

2.9 UV led

The germicidal effectiveness and use of UV rays is influenced by organic matter, wavelength, type of suspension, temperature, type of microorganism and UV intensity. UV-C is germicidal ultraviolet light. It works by deactivating the DNA inside bacteria, viruses, and other pathogens thus effectively stopping their capability to reproduce and spread disease. UV light in 200-280nm has theabilitytokillbacteria,viruses,mold,andfungi.

2.10 SMPS adaptor

The SMPS Power Adaptor - 12V/2A is a Switched mode power supply SMPS. It is an advanced power supply. It provideslowlossesandstableoutput.Thereisnoneedofa rectifier.Thishigh-qualitySwitchingPowerAdaptergivesa cleanregulated12VDCoutputatupto2A.Theyworkwith 240VACinput.

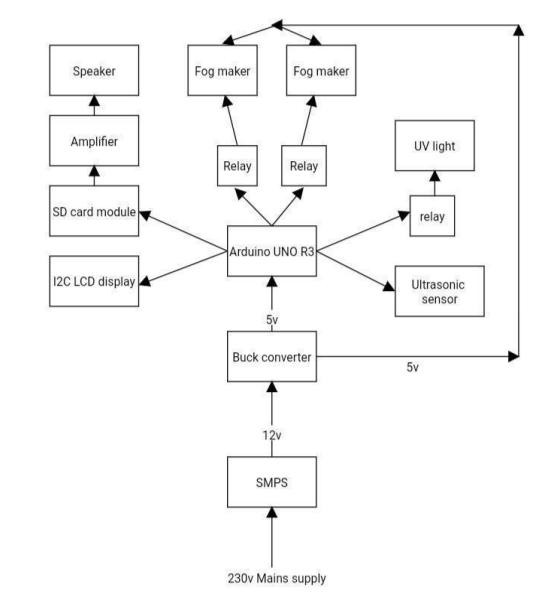

3. BLOCK DIAGRAM

The shape of the box is rectangular and it is made of plywood.Theplywoodiscutintoseveralpiecesandjoined togetherin theshapeofa box.Twoholesaremadeinthe front panel to insert our hands, and also a small rectangularshapedcutismadetoplacetheLCDdisplay.A speaker,dc switch and an smps adaptor plug is also fixed at the right side of the box. The box is divided into two chambers.Thecircuitpartisplacedinthelowerchamber and the upper chamber comprises two containers that containsanitizer.Thefogmakerfloatsonthesanitizerand it functions at its time. The division of the chamber helps to prevent falling the sanitizer droplets on the circuit and avoidtheshortcircuit.Thebacksideisopenable,thisway isusedtostockthesanitizerintothecontainer.Ahandleis providedonthebackpaneltoopen.

STEP4:TheDisinfectantSolutionisconvertedintotheFog.

STEP5:WearereadytogetourHandSanitized.

STEP 6: Check for the hand got sanitized by the machine. TheLCDdisplayandspeakersays"Thankyouforusingthe sanitizerdispenser".Ifthehandissanitized,gotothenext step.Otherwiserepeatstep2.

STEP 7: When the process is done, the machine will stop andgetreadyforthenextsensing.

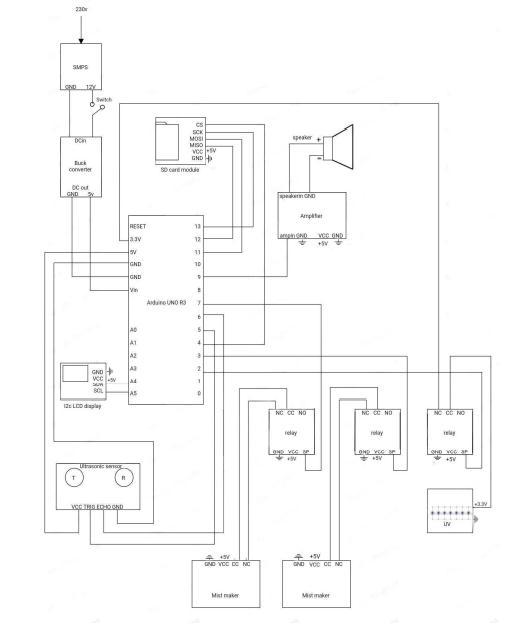

4. CIRCUIT DIAGRAM

First the 230v ac coming from the line supply is given to the SMPS adaptor which converts the voltage into 12v dc. This 12v dc output coming from the SMPS is connectedto thedcinpinsofthebuckconverterwhichconvertsthe12v dc into 5v dc. This 5v is used to power all other componentsinthesystem.This5visconnectedtotheVin pin of the Arduino, and ground to ground pin. So the Arduino is powered. The ultrasonic sensor is fully connected with the Arduino such that the VCC pin is connected to the 5V pin of the Arduino. TRIG pin to pin5, ECHO pin to pin 6 and ground to ground. The SDA pin of the I2C LCD display is connected to A4 pin of the Arduino andSCLpintoA5.The5vistakenfromthebuckconverter andgroundtoground.

CS pin of the SD card module is connected to pin 4 of Arduino,CSKpintopin13,MOSIpintopin11,MISOpinto pin12,The5vistakenfromthebuckconverterandground toground.ampinpinoftheamplifierisconnectedtopin9 of theArduino. Speaker in pin isconnected to thepositive of the speaker,and negative to negative pin, the 5v and groundisconnectedtothebuckconverter.

3.1 Steps to operate

STEP1:Insertyourhandsthroughthetwoholesprovided onthefrontpanel.

STEP2:checktheinputsensorforsensing

STEP3:Whenthesensorsensesthehands,theinformation goestotheArduinoandchecksfortheactivationoftheFog Maker.Atthesametime,theUVlightisalsoactivated.The LCD display placed over the front panel displays ``please wait"togetourhandsanitized.Thespeakerfunctionswith the LCD display which speaks the sentences shown in the display. If these are activated go to step 4 and step 5 otherwiserepeatstep3.

Mist maker 1 is connected to the normally closed pin and commoncontactpinoftherelaymoduleandthesignalpin of the relay module is connected to pin 7 of the Arduino. Mist maker 2 is connected the same as mist maker 1 but thedifferenceisthatthesignalpinoftherelayisconnected to pin 3 of the Arduino. 34 Another relay module is also usedfortheUVLEDs.Thenormallyclosedpinisconnected to the 3.3v pin of Arduino, common contact pin to the positive oftheLED and negative to ground.The signalpin isconnectedtopin2ofArduino

5. PROGRAMMING LANGUAGE

The program is written in the Arduino programming language. Due to their simplicity, the programs written using the Arduino IDE are called sketches. To save and uploadthemtotheArduinoboard,wehavetousethe.ino extension. Arduino programming language has three main parts.First,functionsthatallowtocontrolourboard.Using functions, it is possible to analyze characters, perform mathematical operations, and perform various other tasks

– e.g., digitalRead() and digitalWrite() which help to read or write a value to a certain pin. Another two are setUp() and loop(). A sketch always starts with setUp(), which executesonceafterthepower-uporresetourboard.After creatingit,useloop()tolooptheprogramrepeatedlyuntil power-offorresettheboard.Next,theArduinovaluesthat represent constants and variables. Most of the data types (array,bool,char,float,etc.)aresimilartothoseofC++.Itis possibletoperformtypeconversionaswell.Thestructure, the last part of the Arduino language contains small code elements,suchasoperators.

REFERENCES

[1] Pratibha RK, Kolhapure SA. Evaluation of the antimicrobial ecacy and safety of pure Hands as a handsanitizer.IndianJClinPract2005;15:19-27

[2] Weislander G, Norback D, Lindgren T.Experimental exposure to propylene glycol mist in aviation emergency training: acute ocular and respiratory effects. Occupational and Environmental Medicine. 2001Oct;58(10):649-55.

[3] Newman J, Hancock DD , Davis MA, Sheng H. Comparison of a dry hand-hygiene research and soap andwaterhandwashingtolessencoliformsonhands in animal exhibit settings. Epidemiol Infect. 2006;134:1024–1028.

[4] Healthimpactofhandwashing.WELLfactsheet2006. at: http://www.lboro.ac.uk/well/resources/factsheets/f act-sheetshtm/Handwashing.

BIOGRAPHIES

6. RESULT AND CONCLUSION

The proposed work has many important advantages and helps to kill viruses and bacteria in public places such as train stations, airports and theatres. Its portable design makes it easy to install and use in a variety of locations dependingonyourneeds.Thetechnologyusedisstillnew and very unstable. Using about 95% less sanitizer than traditional sanitising, it solves one of the wastage problems. The system is fully automated and avoids manual mistakes and spreading of viruses from one person to another. With this mechanism, people can operatethemcomfortably,contactless,andveryhygienic.

Hridhya AP, Lecturer in Biomedical Engineering, EKNM Government polytechnic College, Thrikaripur, Kerala, holds B-tech degreeinBiomedicalEngineering from Calicut University and MTech Degree in Ebedded system from APJ Abdul kalam TechnologicalUniversity.