SOIL STABILIZATION USING BONE ASH AND SILICA FUME

Towseef Ahmad Rather1, Er. Anoop Sharma2 ,

1M. tech student at Sri sai collage of engineering and tech

2Assistanr professor, dept. of civil engineering, sri sai collage of engineering and tech.11 ***

Abstract - Increasing amount of waste fibres have raised a serious concern among the environmental authorities, these are not only non - bio degradable but are also environmental hazard and disposal of the waste fiber has emergedasamajor problem.

These waste fibers are synthetic or semi synthetic in nature. Although these have some good properties but are potentially harmful for the environment and may cause plastic pollution which adversely effects the land and the environment. In recent years some serious steps have been taken to employ these waste fibers in enhancing the properties of the soil. The purpose of this work is to study the effect of waste fibers along the brick kiln dust as an additive ontheengineeringproperties of the soil through experimentation and observation. The engineering properties that were studied include basic Atterberg limits viz specific gravity, liquid limit, plastic limit, shrinkage limit, moisture content, optimum moisturecontent, dry density and maximum dry density, and direct shear strength . Percentages of polypropylene and BKD were varied by weight and by percentage and improvementinengineering properties of soil was observed with the addition of polypropylene and BKD. Further the properties of the reinforced soil were compared with those of the naturally virgin soil and the difference in the parameters was noted.

It was observed that PPF and BKD together have influenced the engineering properties of the soil.

Key Words: polypropylene,brick kilndust,plasticlimit, shearstrength,unconfinedcompressivestrength.

1. INTRODUCTION

Theprocessforincreasingsoilgeotechnicalfeatures,suchas subgrade characteristics, shear strength, expanding and shrinkingproperties,andbearinglimit,ismostlyused.More than a quarter of the area in India's Madhya Pradesh and AndhraPradeshprovincesiscoveredbytheextensivesoil, whichisalsoknownasblackcottonsoil.Montmorillonite,a mineralfoundinthesoil,causesthesoiltoexpandwhenit comesintocontactwithwater,makingitdangerous.

1.1 materials

1.1.2 Clayey Soil

Clay is a finely-grained normal stone or soil material that consolidatesatleastonemudmineralswithpotentialhints

ofquartz(SiO2),metaloxides(Al2O3,MgOandsoon)and naturalmatter.Geologicmudstoresaregenerallymadeout of phyllosilicate minerals containing variable measures of watercaughtinthemineraldesign.Mudsareplasticbecause ofmoleculesizeandcalculationjustaswatercontent,and becomehard,fragileandnon–plasticafterdryingorfiring. Dependingonthesoil'ssubstanceinwhichitisfound,earth canshowupindifferentshadingsfromwhitetodulldimor browntoprofoundorange-red

1.1.3 Chicken bone ash

Thecalcinationofbonesresultsintheproductionofawhite substanceknownasboneash.Anaveragesampleof bone ashwillhaveacompositionofaround55.82percentcalcium oxide, 42.39 percent phosphorus pentoxide, and 1.79 percent water. Although the precise composition of these compoundsmaychangedependingonthesortofbonesthat arebeingutilised,theformulaforboneashisoftenwritten asfollows:Ca5(OH)(PO4)3.Theaveragedensityofboneash isaround3.10g/mL,anditsmeltingpointis1670degrees Celsius(3038degreesFahrenheit).Calcificationallowsthe majorityofbonestomaintaintheircellularstructure.Atthe samplingspot,thesoilsamplewasretrievedfromadepthof about one metre. The sample of dirt was dried with the assistanceofanovensetat1100degreesCelsius.Thegrain sizeofsoilsampleswasevaluated,togetherwithAtterberg's limit,sothatthesoilcouldbecategorisedusingtheIndian SoilClassificationSystem(ISC).TheCBAusedinthestudy wasderivedfromvariouschickenbyproducts.Thechicken bones that were acquired were burned at an unregulated temperatureinanopenairenvironment.InordertogetCBA, the CBA was first allowed to cool, then milled, and then sievedusingasievewithanapertureof425micron.

1.1.4 silica fume

Theadditionofsilicafume(SF)totheconcretemixenhances themix's workabilityandmakesitmore mobile while yet maintaining its cohesiveness. This is the result of the soil particlesbeingmoreevenlydispersed,whichisalsorelated tothesurfacepropertiesofthesilicafumeparticles,which are smooth and absorb very little water as they are being mixedtogether.

Therecentstudydemonstratesthatanefficientapplication ofmicrosilicafumemayenhancethesubgradefeaturesof expansivesoil.Theresultsofanumberoftestscarriedoutin the laboratory indicate that the application of micro silica

fumeisaviablechoicefortheenhancementofthesubgrade featuresofexpansivesoil.

1. 2 Mixing Proportions

Table -1: Mix proportions of Soil(S), Chicken Bone Ash (CBA) and Silica Fume (SF) S.NO DESIGNATION (S:CBA:SF)

2. RESULTS

AND DISCUSSIONS

2.1 ATTERBERGS LIMITS

Table -2 index properties of virgin and reinforced soil

Table -1 index properties of virgin and reinforced soil

1.3 objectives

Todeterminesoilindexproperties(Atterberg’sLimits)

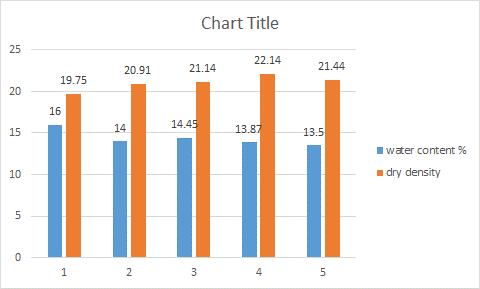

2.2 MDD AND OMC CONTENT

Table -3 MDD and OMC for soil–CBA– SF mix

TostudythechickenboneashandsilicafumeonCBRvalue oftheclayeysoil.

TofindtheoptimumquantityofBoneashandSilicaFume usedforthestabilisationofsoil.

Todeterminetheeffectchickenboneashandsilicafumeon UCS.

Todeterminethemaximumdrydensityandcorresponding optimummoisturecontent

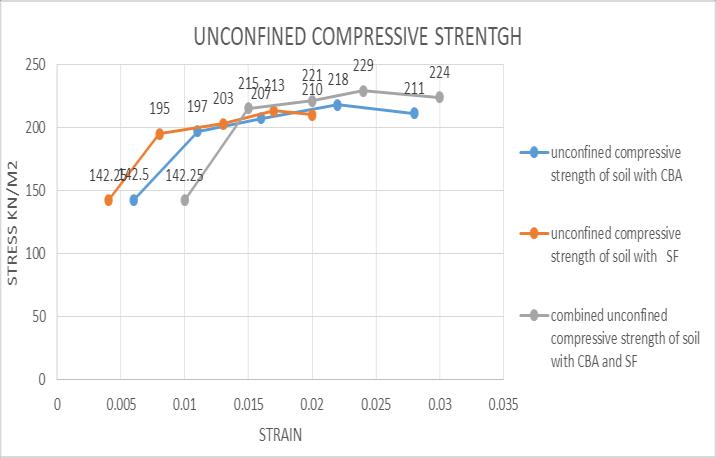

TheUCStestresultshowsthattheUCSvalueofClaysoilis 142.5kN/m2 and with addition of 2%upto 4% of CBA its increased10kN/m2 thendecreasedwiththeadditionof8% CBA.UCStestisperformedwithcuringperiodof3days

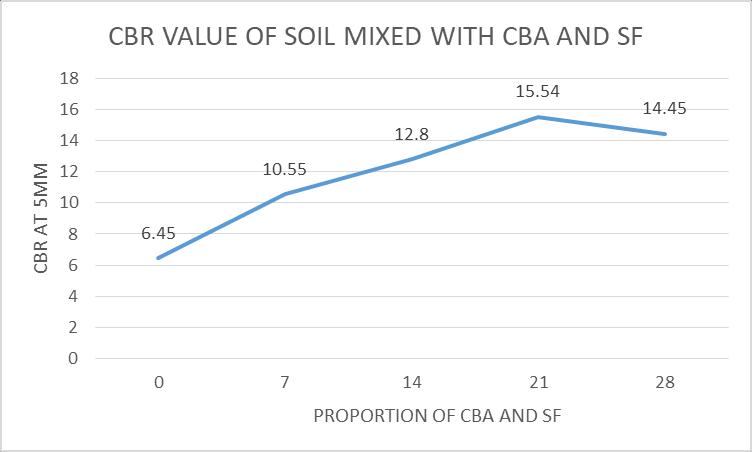

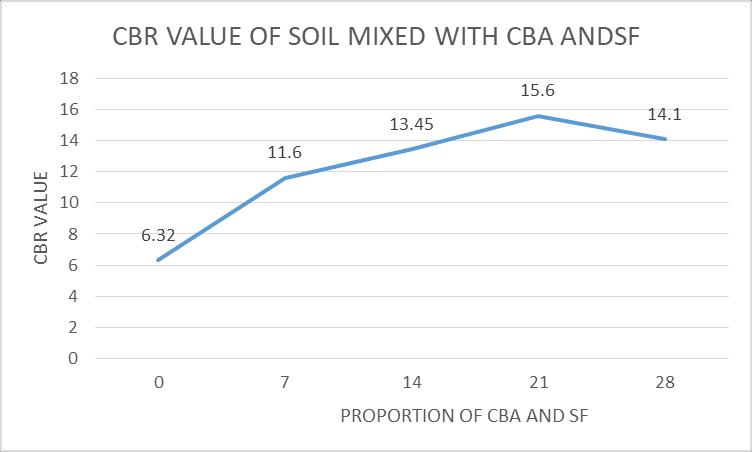

For soaked conditions, filter paper were placed on base plate.Surchargeplateoftheweightis5kgwereplacedover plate,wholemouldwereplacedinwatertankforsoakingof samplefor168hours.After168hoursmouldwastakenout ofwatertank.

3.

3.1 conclusions

On the basis of the lab tests, outcomes obtained from the testsshowedpromisingresultsandkeepingin viewthese experimentalinvestigationsthefollowingdeductionscanbe drawn.

1. Ithasbeenfoundthattheengineeringpropertiesof thesoilsampleweregreatlyenhancedbytheuseof CBAandSF

2. The individual use of CBA and SF also showed promisingresults.

3. Indexpropertiesofthesoilweregreatlyinfluenced bytheadditionofCBAandSF.Itwasobservedthat thatliquidlimitdroppedto31.8%from32.5%,the plasticlimitwasincreadedto25.1%from23.2%.

4. Theinvestigationofthegeotechnicalpropertiesof the soil used in this research has enabled us to

establish the effect of CBA on the soil California bearing ratio. The maximum amount of CBA that wouldallowforanincreaseforCBRvalueis6%and also by adding the percentage of Silica Fume the valuesofCBRagainrisesat20%ofsilicafume.

5. Accordingtothisresearchtoachievethemaximum shear strength of soil with the help of 6% of CBA mixed into soil by using the unconfined compressivestrengthtest.Afterthetestwefound theshearstrengthwasincreased.

3.2 future scope

1. Inthepresentstudyonlyupto8percentreplacementof CBAbysoilhasbeenconsidered.Theotherpercentages percentneedtobeinvestigatedinthefuture

2. From the results obtained from the tests it can be predictedthatCBAandSFhaveabilitytoenhancethe engineeringpropertiesofthesoil.

3. Extensive research should be conducted in order to exploremoreandmoreeffectiveuseofCBAandSFin engineeringpurposes.

REFERENCES

[1]AbdEl-Aziz.,Abo-HashemaM.,andEl-ShourbagyM.,“The effect of Lime-Silica Fume Stabilizer on Engineering Properties of Clayey Subgrade”,.Fourth Mansoura InternationalEngineeringConference(4thIEC),Facultyof Engineering,MansouraUniversity,Eygpt,April2004.

[2]A.ChaalaandC.Roy,“Recyclingofmeatandbonemeal animalfeedbyvacuumpyrolysis”,Environ.

[3] ACI Committee 226. 1987b. “Silica fume in concrete”: Preliminaryreport.ACIMaterialsJournalMarch-April:15866.

[4]Bell,F.G.,"EngineeringTreatmentofSoils",Chapmenand Hall,Publishers,London,1993.

[5]Biswas,etal.(2012).“UtilizationofRicehuskwithLimein SubgradeSoilforaRuralRoad.”InternationalConferenceon EmergingFrontierinTechnologyforRuralArea.

[6] Chen, F.H., 1981. Foundation on Expansive Soil, Development in Geotechnical Engineering 12. Elsevier ScientificPublishingCompany,NewYork,USA.

[7]ChoudharyAK,GillKS&JhaKN(2011),“Improvementin CBR values of expansive soil subgrade using geosynthetics,”Proc. Indian Geotechnical Conference, 569572.

[8]Collins,R.J.FeasibilityofProducingConcreteProducts fromMeatandBoneMealAshReport209-787Preparedfor RMCEnvironmentalFund,BritishResearchEstablishment (BRE),UK,2003.

[9] Dr. Adel A. Al-Azzawi, Khalida A. Daud ,Muhammed A. AbdulSattar“EffectofSilicaFumeAdditionontheBehavior of Silty-Clayey Soils” Journal of Engineering and Development,Vol.16,No.1,March2012.

[10] J. A. Conesa, A. Fullana and R. Font, “Thermal decomposition of meat and bone meal”, J. Anal. Appl.Pyrolysis2003,70,pp.619-630.