International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 03 | Mar 2023 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 03 | Mar 2023 www.irjet.net p-ISSN:2395-0072

Madaka Ruchith Rao*1 ORCiD: 0000-0001-5394-6025

Luke Judson2, Parnika Singh Yadav3

Department of Building Engineering and Management School of Planning and Architecture, New Delhi, India. ***

Abstract - Supply Chain Management is the handling of the flow of the materials and services in the project, it includes extraction of raw components to delivering and commissioning of the final product. A company or an organization creates a network of service providers and suppliers for the efficient and reliable quality of service and goods. Using SCM in construction industry will help a lot to the companies in various ways, and many researches have also been done in adoption of SCM in the field of Construction. The Purpose od the research is to identifying the problems which are occurring while adoption of SCM in the construction field and the solution in form of methods and framework for wide spread adoption of SCM in Construction

Key Words: SupplyChainManagement,BarriersinImplementation,AHP,ConstructionIndustry,Strategies.

Supply Chain Management is turned out to be very efficient and economical in various fields of industrial & bossinesssector,butintheConstructionIndustrytheSCMhasbeenadoptedbyveryfewcompaniesandisnotbeenvery efficient in this field. In recent times some research works have been done on integration of supply chain management (SCM)inthefieldofConstruction

As per the research done they have concluded that the construction industry is lagging behind when compared to otherindustriesinIndia, evensome of theverylarge construction firmswith huge amount of work experience arestill facing problemsinhavinga collection ofConsultants andSubcontactors,suppliers thatcanreliedupon for qualityand cost-effective completion of project within the stipulated time. This intended to say that the very few companies have longtermlinkageswith theirconsultantsorsubcontractorsetc., whichis a majordrawback intheindustry (Madhukar, 2016)

Thebenefitsofapplyingsupplychainmanagementprinciplesinconstructionare,reducerealtimecostescalations with on time ordering and supply of the materials, improvement in productivity, long term relation with the major contractor and suppliers, competitive advantages, repetitive type of work with increasing efficiency, more responsive andreliableworkflow,anticipationofmaterialrequirementbeforehand (Papadopoulos,Zamer,Gayialis,&Tatsiopoulos, 2016)

When we think of SCM in construction recent works are there for the integration of SCM but even though its not been widely adopted in the field. There are lots of issues and constrains in the wide adoption of SCM principles in the construction for example one of the major reasons is the Fragmentation, individuality of project its becoming hard to keep the date updated for such large types of chains manually, the research done have shown the advantages of the integrationofSCMinconstructionbutthereisnodetailresearchonproblemsarisingwhileadoptingtheseprinciplesof SCMandhinderingthelargescaleadoptionintheIndianConstructionIndustry.

1.2 Aim:

Toimprovethelarge-scaleadoptionofsupplychainmanagementinIndianConstructionindustry

1.3 Objectives:

1. To identify the major barriers which are hindering the wide adoption of supply chain management in constructioninIndianContext

2. ToOrganizetheidentifiedissuesintomajorcategoriesandanalyzetheinterdependencyoftheseissues.

3. Prioritizetheissuerankwiseandassestheimportanceofbarriers.

4. TosuggestthesolutionforanyofthemajoridentifiedbarrierintheimplementationofSCM

Objectives

Objective1

Identifythe Issuesin adoptionof SCM

Objective2

Organizethe issuesinto categoriesand analysethe interdependen cy

Objective3

Prioritizethe Importance of Issues

Objective4

Suggesting theSolution forthemajor identified Issue

Organisingthebarriersinto IdentifiedSubheadsthrough analysis&expert intervention.

DevelopmentoftheAHP

PairwireComparisonof IssueCategories

WeightageofIndividual Barriersthroughsurvey

IdentifyingtheRanking AnalysisofIdentified CaseStudies

ComparisonofSolutions fromVariousCasestudies

Conclusion& Recommendations

Outcome1

Listof barriers which hinderingthe adoptionof SCM

Outcome2

Relationship betweenthe barriers.

Outcome3

Identifythe MajorIssues inaranked order

Outcome4

Methodsor Solutionsto overcomethe Issues

Chapter1

Chapter2

Chapter3

Chapter4

Chapter 5

Chapter 6

Supply Chain Management (SCM) is useful in achieving high level performance in the field and also provide significant benefits to the construction companies, it is very effective if there is a good integration, coordination and managementofthechain,fromsupplierstoclients.(RastogiR.P.,2022)

There are lot benefits of using the supply chain management in the field of construction some of them are, reduce real time cost escalations with on time ordering and supply of the materials, improvement in productivity, long term relation with the major contractor and suppliers, competitive advantages, repetitive type of work with increasing efficiency, more responsive and reliable work flow, anticipation of material requirement beforehand. (Papadopoulos, Zamer, Gayialis, & Tatsiopoulos, 2016)Cost reduction and waste reduction, Risk reduction, with a more certain final projectcost,Valueforclient,Enableslong-termplanning,Ongoingbusinessorrepeatbusiness.(Al-Werikat,2017)

Subcontractorsplayamajorroleinsupplychainmanagementensuringusageofminimumtime,costand material.(Durai&Sentamilselvan,2016)

ToapplySCMinconstructionitisnecessarytodistinguishsomecharacteristicsoftheconstructionproductionsystem,as follows:

Theconstructionproductisforasingleclientmostofthetimes.

Theproductchangesforeachproject.Notallthepartsandmaterialscanbestoredatsite.

Theplace,equipmentandmethodsofproductionchangeforeachproject.

Constructionpersonnelhaveahighrotationindexduringconstructiontimeandbetweenprojects.

Althoughtheconstructionprocessisdifferent,SCMcanbeusefulandeffectiveinconstruction-(WilliamJ.O’Brien,2009)

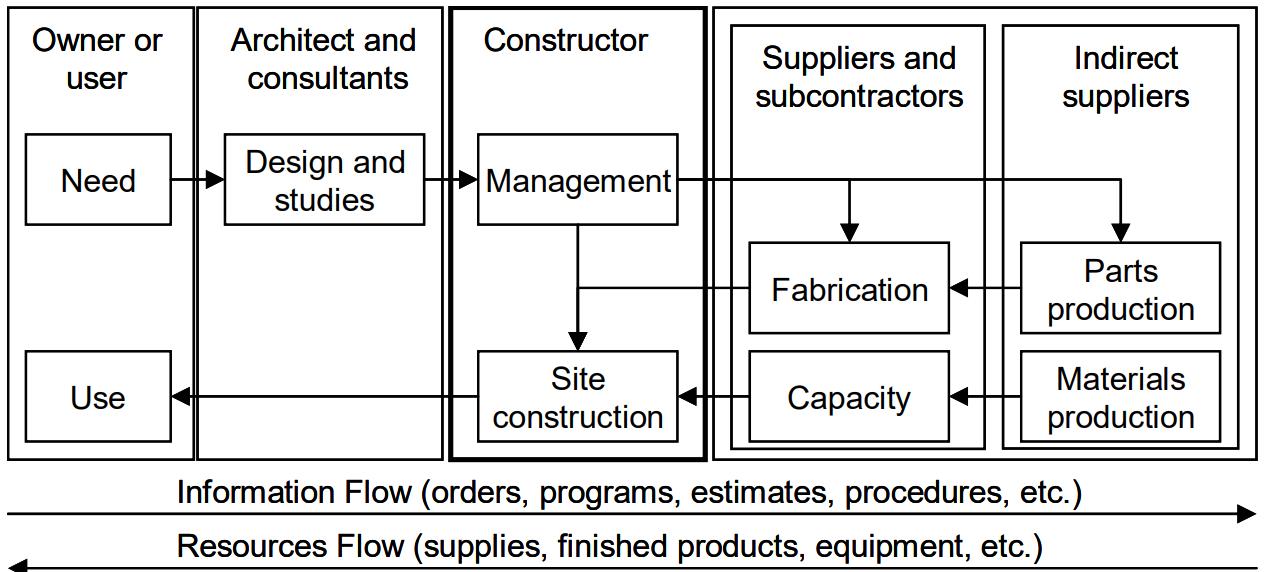

Thisisaconceptualrepresentationofconstructionsupplychainandtheparticipantsinvolvedandtheirmodeof interaction.Aconstructioncompanymayhavesimilarsupplychainfordifferenttypesofmaterialsorgoods.

The Construction Supply chain as per this model states that suppliers & subcontractors play a major role in the whole process,whereasthemaincontractororPMChastoorganizeandsupervisetheprocessw.r.tthequality&timelyflowof work&Information.

2.4 Construction Supply Chain Management Techniques - (Papadopoulos, Zamer, Gayialis, & Tatsiopoulos, 2016)

Suppliers’andSubcontractors’Development

PerformanceMeasurement

Benchmarking

KnowledgeManagement

WasteIdentificationandElimination

InformationTechnology

S

1 StrategicManagement

2 Logistics

3 Relationships

GlobalStrategy

ChangeManagement

CapacityDevelopment

Planningandcontrolofmaterialflows

Integrationofmaterialsandinformationflows.

Procurement,

Objectivesalignment,

Topmanagementsupport,

longtermcommitment,

Collaboration,

Communication,

ProblemSolving,

RiskSharing.

4 BestPractices

ContinuousImprovement

Leanthinking,

Just-in-time,

Offsitemanufacturing,

Sustainability.

5 OrganizationalBehavior InformationandCommunicationTechnology(ICT)

Table 1:Core Elements Underlaying in Construction SCM ( (Puppo & Carlos, 2021) Element

Amount

JointPlanning

BreadthofSupplierBase

Amount of sharing risks and rewards Eachonitsown

Speed of Operations, Information & Inventory Levels

Table

“Warehouse”Orientation (Storage,safetystock) interruptedbybarriers,localized tochannelpairs

Risks and rewards are shared over the longterm

“DistributionCenter”Orientation (InventoryVelocity)interconnecting flows;JIT,Quickresponseacrosschannel

TheAnalyticHierarchyProcessisamethodfororganizing& analyzingthecomplexdecisions,itprovidesarationalframe workforaneededdecisionbyQuantifyingitscriteriaandalternativeoptions,relatingtheseoptionstooverallgoal.

Itattemptstobenefitfrommathematicandexpertknowledgetoclassifycriteriaandfoundknowledge.Itisusedinalmost alldomainsandinvarioussituationstohelpindecision-making (Sael,Hamim,&Benabbou,2019)

1 Equal Sameimportance

3 Moderate Elementmoderatelyfavoredthanother

5 Strong ElementStronglyfavoredthanother

7 VeryStrong ElementVerystronglyfavoredthanother

9 Extreme Elementextremeimportantthanother Table 3: AHP Importance intensity Satty's Scale

Note: TheReciprocalsareusedforinverseRelation,2,4,6,8canbeusedforintermediaterelationships.

FromVariousLiteraturestudiestheBarriersforthelarge-scaleimplementationofSCM inconstructionareIdentified are listed Below some of the barriers are repeated or may be similar all these will be refined and sub categorized in further process.

AsPertheLiteratureStudiestheseIssuesCanbe Classifiedinto6Majorsubheads

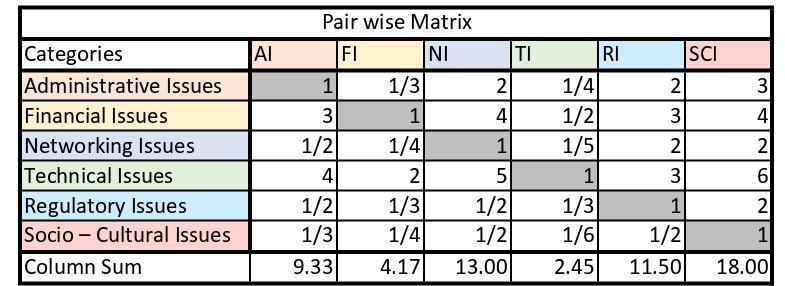

Step 1: Pair-wise Barrier Category Weightage

PairwiseComparisonmatrixdonebycomparingtheweightageofeachcategorywitheachotherinthepreferenceoftheir importance to adoption of SCM. To get Category weightage after identifying the pairwise matrix, divide each cell with columnsumtogetNormalizedMatrix.ThesumAverageofeachrowwillgivetheCategoryWeightage.

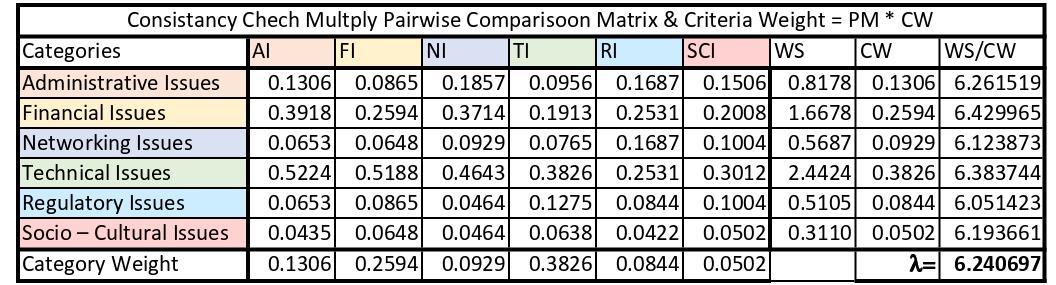

Check for the Consistency:

Multiply each Column with its category weight to get a matrix. Sum of each row gives the weighted sum of each category.max isobtainedbyAverageofWeightedsub/Categoryweight

Consistency Ratio (CR) =CI/RI =0.0481/1.24=0.0388<0.1(CRShouldbelessthan0.1asperAHP)

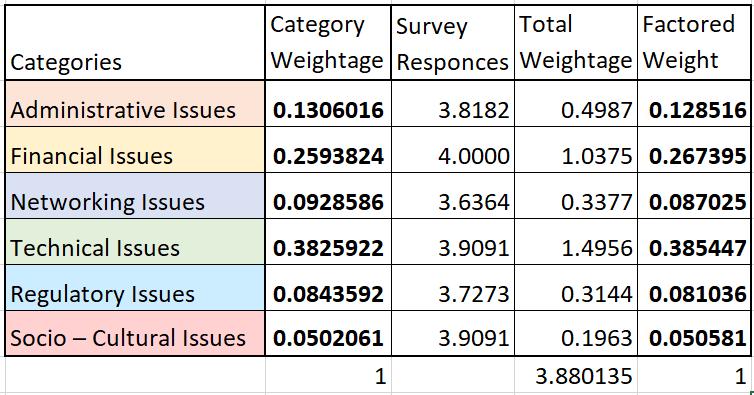

SinceCR<0.1; Matrix is Consistent & can be used for Decision Making. Step 2: Scale of preference of Barrier Category using Survey data Step 3: Qualitative ranking of importance of the Respondent.

ThesurveyisconductedtoanalyzetheImportanceoftheidentifiedbarriers. ThemajorfocusofsurveyistoknowtheimplementationalissuesforlargescaleSCMinconstructionfield.Theimportance ofrespondentisbasedontheirareaofworking,andaccordingtothistheorderofPotentialrespondents.

The next level of potential respondents are the employees who are dealing with only the procurement process of materials,theyaremanagingonlyprocurementserviceetc.

ThethirdlevelofrespondentsaretheServiceprovidersthemselves,theyincludeConstructioncompanyrepresentatives orContractors/SubContractors&Suppliers.Theyareleastpreferredbutstilltheirresponseisalsoavalidoutcome.

3. Contractor/Sub Contractor, Construction company representative, Suppliers.

Dependingontheirareaofinfluencetherespondentsaregivenweightage.

To get the relative weights of importance of each barrier a survey is conducted among the above-mentioned respondentgroupsandtheweightageismultipliedaspertheirrespondentcategorytogettherelativeweightage.

Structure of Survey:

TheSurveyincludesEachbarriercategoryandIndividualbarrierineachsection. ThescaleofImportanceasa Potential Barrier.[1LeastImportant&5MostImportant] PotentialBarrierintermsofBarrierforAdoptionofSCMintheirOrganization Surveyhad7Section,outofwhich1st ismarkingimportanceofBarrierCategory,remaining6aremarkingimportanceof individualBarrierineachcategory.

5. CASE STUDIES & ANALYSIS

5.1 Case Study 1: Kirby Building Systems, Hyderabad (Alghanim,1999) Organization

Established:1999inIndia

Building)

Warehouses, Factories, Metro stations, Aircraft Hangers, Supermarkets, Steel Buildings, Sports stadiums, Auditoriums, etc.Other productsincludestructuralsteel,sandwichpanels,storagesolutionsetc.

of Projects

ii.SteelBuildingErectionServices

Tomanageallthesecomponents&ToprovideInformationsharing

KirbyisusingvariousTechniquesandPracticessuchas:

i. SAP-ERP(Implementedin2014)

ii. CentreofEngineeringExcellence(CEE)

iii. IntegratedEnterpriselandscape

iv. Sourcingofrawmaterials

Example Project – VEGA Production Unit, Hyderabad.

PMC:KPMAPMC

PEBManufacturers:KirbyBuildingSolutions

YearofConstruction:2022

Typology:IndustrialStructure Client:VegaAutomations

Location:PhaseIIIIndustrialsector,Hyderabad,Telangana.

EVM Report

TheEVMreportisonthedateof6monthsfromthestartoftheprojectwhichistheHalfdurationofthetotalprojecttime.

Table 10:Planned cost & planned amount of completion for PEB work

Theprojecthasfacedlotofdelayduetovariousfactorsbutsince KirbywasusingSCMintheirorganization,theywereabletodecreasetheimpactwhencomparedtotheotherCivilworkin thesameproject.

Analysis:

Using the above techniques, the Kirby is able to finish the project with minimum time and minimum wastage of material.Theabilitytoshareaccurateandfasterinformationhelpedinreducingtheexcessmargins.

TheyhavetheirownCentreforEngineering&ExcellencewhichiskindofR&Dandtrainingcenterwhichenables their staff to get trained in using these modern techniques like ERP systems which helps in improving the supply chain managementsystemoftheorganization.

IntegrationofallthedataintheERPhelpsingettingtherealtimedataandwhichinternhelpsinmanagingtheprocess ofSCMaccurately.

One more important practice used by this organization to achieve benefits of SCM are self-sourcing of the Raw materials from the trusted & Qualified suppliers, keeping ties with such suppliers instead of sourcing individually on time,andsharingofinformationhowmuchtoproduceaspertherequirementbeforehandhelpsinavoidingshortageof rawmaterialanddecreasessuddenfluctuationofmaterialpricesduetohighdemand&Shortagekindofissues.

Organization Details: Established:2017

Type of Organization:MaterialProcurementCompany

Range of Products: RMC, Flyash, Construction Chemicals, Aggregates, Cement, Light Weight Concrete, FRC, HSC, SCC, PerviousConcrete,Otherproductsincludestructuralsteel,etc.

Services Offered:

i.CloudManufacturing.

ii.RetailasaService.

iii.EquipmentBanking.

AsperthemtheLargercompaniesaregettingbenefitsofsupplychainmanagement,butsmallercompaniesareunable togetthiskindofbenefitsmaybeduetosmallerordersizeorpresenceofmultiplemiddlemaninthetradition procurementchainorduetosupplychainforvariousmaterialsisfragmentedandunorganizedInfra.Marketprovidesa solutionforlargelyunorganizedConstructionIndustryinthefieldofprocurement,Toachievethis,theyarefollowing Techniques&Practicessuchas:(Mathur,2022)

Takingtheprocurementprocessonline.

Bringingparityandtransparencyinpricing.

Enhancedtechnologyplatformconnectingclientrequirementsdirectlytoitssupplychain

Applyingmoderntools&approachestoremoveunnecessarytimeandcosts

Integratednationalsupplychainhelpsinquality,scaleandefficiency.

The Infra.market is a startup Organization established to provide the benefits of using the SCM in procurement systems, Inventory management & Equipment management even to the small-scale companies which were unable to get these benefits as large companies due to smaller order size or presence of multiple middle man in the tradition procurement chain orduetosupplychainforvarious materials is fragmented and unorganized.

This Case study provides many major solutions for the problems or issues identified above regarding the largescaleadoptionofSCMintheindustryofconstruction.

The infra.market is able to this by various techniques and practices and is also mentioning that the companies are saving an amount if 5-7% of their initial input costs which is like quantifying the benefits of use of SCM which was oneofthebarrieridentifiedintheabovestudies.

Organization Details: Established:2018

Type of Organization:BuildingConstructionCompany

Typology of Buildings:ResidentialHousing,IndividualandGroupHousing.

Services Offered:

i.ResidentialConstruction

ii.CommercialConstruction

iii.Construction Material Sales.

Brick and Bolt emphasis on simple model:

Plan - Build - Track - Settle in

They offer a kind of turn key solutions at a lower price compared to the market, they are able to do this without compromisinginthequalitydueto someTechniques&Practicessuchas:

MaintainingaCompletesupplychainofConsultantstoSuppliers.

ProvidingrealtimeTrackingbyuseofTechnology.

MaintainingcleartransparencyamongtheSupplychain.

Providingsimpletoolforclientsforcalculationofoverallcosttomaterialrequirementetc.

UseofEscrowModelformoneytransactions

Qualityassuranceisoneoftheirmajorpractice,theyhave340+qualitychecksbyinhouseteam.

Theyarealsousingaapptosendtherealtimetracking&statusofconstructiontotheclients.

Analysis:

ThebrickandBolthaveimplementedtechnologyastheirbasicstrategytooffercleartransparency,realtimetracking, andintegrationof theirservicesthroughsharingofinformationetc.,thishelpedthemachievingSuccessintheirfieldof constructionandalsoSCMwithinit.

They have their own set of consultants and contractors and suppliers with in the chain, even if contractor is making delaystheyarealsopenalizingthem,itislikeevenwithinthechainthearetryingtokeepdiscipline&transparencyand confidenceintheirimplementationprocess.

Having the consultants in the supply chain is helping them in overcoming the issue of problem of risk in sharing of drawingswhichwasoneoftheissuesasmentionedabove.

Their main Strategy to get bulk order is they are ordering for themselves along with some of the local construction contractors,sotheyareactingasasupplier,bydoingthistheyareincreasingtheiramountoforderfrommanufacturerto getthegoodsinlowestprices.

6 Comparison & Identifying the solutions of the ranked Barriers of solutions opted in the Case studies.

6.1 Comparison of Scope & Type of work.

S

1 ScopeofWork asperSCM Model.

c.

b.

b.Construction

c.Supplier/ Sub-Contractor

2 Typeof Organization PEBManufacturer Material Procurement Design& Construction

Remarks

Thereisdistinctvariationscopeofwork butallofthesehaveSupplier/Sub Contractorincommonandthisalsoshows SCMcanbeimplementedatvariousstages.

ThisshowsthatSCMishelpfulinalltypes ofOrganizations.

3. Yearof Establishment 2014 2017 2018 Implementationofmoderntechnologyis majorkeytosuccess

Table 11: Case studies organizational setup Comparison

S No. Issues

1 Inadequate informationSharing systems

2 Lackofexpert supplychain professionals

3 Ineffective problem-solving mechanism

Case Study 1 Kirby PEB

UsingSAPERP Systemtoshare Information.

CEEistryingto trainits employees.

Throughtheir R&Dtheyhave createdamodel forSCMinPEB

Case Study 2 Infra.Market

Useswebbased onlinesystemfor Information

Theyareconnecting withSCMExperts

Theyhavean effectiveSCMModel forMaterial management.

Case Study 3 Brick & Bolt

Appbasedreal timesharingof information.

Theyare connectingwith SCMExperts

Theyhavecreated amodelforall typesofSCM.

Remarks

Allcompaniesareusing technology-basedITtoolsto overcomethis.

Outsourcingofexpertstotrain peopleaboutSCMishelpingthem.

Allorganizationhavedeveloped theirownmechanismofSCM, so,thesecanbetakenasexamplein India.

S No. Issues

1 Lackof performance measuring& incentivesystem

Case Study 1

Theydon’thave cleartoolto measureit.

2 Costof Implementation Initiallytochange, ithadacost,But thebenefitsare nowmorethan Investment.

3 Sharedrisks& rewards

Theyareaccepting toshareRisks& Rewards

Case Study 2

UsingSCM,thesavingis upto5-7%cost,the performancecanbe measured

Becauseofclear commitmenttowards useofSCM,theyhave createdaCost-effective model

Theyareacceptingto shareRisks&Rewards

Case Study 3

Providesacost estimatortocompare thebenefitsofusing SCM.

Theyalsostartedwith clearIdeaofcomplete SCMsolution,soitis profitablenow.

Theyareacceptingto shareRisks& Rewards

Remarks

Incentivesystemisnotthere butthebenefitsareclearly measuredinCasestudies.

Thecostofimplementation maybehigherbutinlong termitishelpingthem&the industrywithlotofintangible benefits.

SincetheRewardsareless butconsistentunlike Traditional,andalsoriskis decreasing.

S No. Issues

1 Lackoffunctional integrationand cooperation

2 Lackofclear responsibilityand difficultyin decisionmaking

3 Organizational boundaries

Case Study 1 Kirby PEB

Theyareusing Integrated Enterprise landscape.

In2014,while adoptingSCMclear setof responsibilitiesare assigned.

Reframedthe existing Organizational boundariestoadopt SCM.

Case Study 2 Infra.Market

Webbasedintegrated Supplychaintoensure Co-opt.

Thecompanystarted onbasisofSCMhave assignedSCmanagers etc.

Theyformed organizational principlesonthebasis ofadoptingSCM.

Case Study 3 Brick & Bolt

Appbasedrealtime integrationof functionaloperations.

Thecompanystarted onbasisofSCMhave assignedSCmanagers etc.

Theirprinciplesareto providecomplete solutionwhich includesSCM.

Remarks

TheOrganizationshave adoptedTechbased solutionforFunctional integration.

Theorganizationshavenow clearlyassignedtherolesof decisionmakingtoSC managersetc.,toovercome thisIssue.

Reframingisthebest solutionforexisting organizationwiththehelp ofSCMexpert,togain benefitsofSCM.

S No. Issues

Case Study 1 Kirby PEB

1 Measuring demands Demandtosupplier issharedbefore itselfwithinSC.

2 Lackof competitiveness SCMhelpedin overpoweringtheir rivals

3

Poor&improper communication amongsuppliers

S No. Issues

1 Inflexible Organizational Systemsand Processes

2 Lackwillingness toshare information

3 Non-aligned Strategicand Operating Philosophies

Theyhaveidentified setoftrusted Suppliersthis helpedin cooperation.

Case Study 2

Infra.Market

OncetheSCis connected,thenthe Demandisshared directly.

Techbasedmodel helpedintheir Success.

Theyhavecomplete setofestablishedSC tillindirectSuppliers

Case Study 3 Brick & Bolt

Consultantsare directlyinvolvedso thedemand estimationdone.

Completesolution modelmadeit feasible

Theyhaveownsetof supplierssincethey arealsointo materialsupply.

TherealtimeSharingofinfo helpsindemandestimation beforehand.

Competitivenessisnow increasedsincetherearenew Startupemerging.

Havingtrustedlimitedsetof supplierswillensureproper communicationamongthe suppliers.

Case Study 1 Kirby PEB

In2014,theyhave changedtheir Systemtoadopt SCM

Sincetheyarethe designersofPEB, theyhavenoissues inSharingofInfo.

Theyhaveselected stakeholderswith similaroperating philosophies

Case Study 2

Infra.Market

Theyhadsosuchissue sincetheystartedwith SCMitself.

Thisisoneoftheissues inthis,butifBOQare doneearlyitcanbe avoided.

Theyhavedeveloped anoperatingstrategy toprovideSC.

Case Study 3 Brick & Bolt

Theyhadsosuchissue sincetheystartedwith SCMitself.

Theyhavetheirown setofconsultants,so sharingisnotamajor problem.

Nosuchissuebecause ofhavingallin stakeholdersunder one.

TheOrganizationalsystem havetobechangedto supportSCMatsomecost.

Thesharingofinfocouldbe doneeitherwithintrusted suppliersorshouldquantify beforehand.

Selectionofstakeholders& changingtheiroperation proceduretowardsSCMcan helpinovercomingthisissue.

S No. Issues

1 Inadequate TrainingofSCM inInstitutional Level

Case Study 1 Kirby PEB

Outoftheirscope

Case Study 2 Infra.Market

Outoftheirscope

Case Study 3 Brick & Bolt

Outoftheirscope

Remarks

Theyaretryingtraintheir professionalstoimproveSCMin Construction

2 Resistanceto Change Understanding benefits,andnew techhelpedin.

3 Fearofextra workloadandloss offlexibility

UsingofTech compensatedthe extraworkload SCM.

Easyofadoptionasa startupmadeit possible.

UsingofTech compensatedthe extraworkloadin SCM

Easyofadoptionas astartupmadeit possible.

UsingofTech compensatedthe extraworkloadin SCM

Understandingbenefitsand improvedeasyofadoptionleduse ofSCM.

Theworkloadwhichmay increaseiscoveredbytheuseof tech-basedsolution.

ThesolutionstheseorganizationshaveappliedcanbetheinferredasthesolutionforlargescaleadoptionofSCM,oreven some solutions are different with respect to different case studies, so relevant solution can be preferred as per the suitability.

Even though these three models have given solution of major problems, but still there some issues which cannot be addressedbythesemodelsofsolutionstheyarelistedbelow:

1. Someofthemodeldoesn’thavecleartooltomeasurethebenefitofSCM.

2. Theoperationalextentorreachabilityofthematerialtoremoteplaces.

3. Availabilityoftherequiredmaterialaspertheclientattherequiredlocation.

4. It cannot be applicable to the fragmented orders which are very less in Quantity even in multiple order scenarios.

ThepreviousstudiesincludetheadvantagesofusingSCMintheconstructionindustrybut,itwasnotclear howto adoptthe SCM,whatwerethemajorchallengesoccurringwhileadoptionofsupply chain andatwhichlevel SCMcanbe adopted,fromtheanalysisofcasestudies,wecanconcludethatSCMcanbeadoptedatvariousstages,itisnotconfinedto only few type of construction such as PEB or Pre Cast, it can be used for traditional type of construction like cast in situ, The model of Supply chain can be of sub-contractor and Supplier, and this supply chain can be connected to various contractors, or in other case it could have a set of contractors, sub-contractor, supplier and they can be connected to various consultants, Similarly there could be a supply chain of Consultant, Contactor, sub-contractor and they can be engagedtoa particularclient.All thesemodesofSCM modelsare beenimplementedsuccessfullyinthecasestudies,and adoptingthistypeofsupplychainswill helpinkeeping thesupplychainforlongerperiods,andtheycanshare risksand rewardsthroughoutthelifeofsupplychain.This methodofsupplychainwillhelpinlinkingthefragmentedsupplychain intheindustryofconstruction.Bystudyingtheabovesolutionshoweachissuehasbeenaddressedwecansuggestthemas thesolutiontoadopttoimplementSupplychainmanagementinConstructionevenformsmallscaleindustries

Some of the methods that could be adopted to overcome the Major challenges:

TrainingoftheemployeesregardingtheSCMconcepts

Technologybasedsolutionforinformation&communicationsystemforrealtimesharingoftheinformation.

ToreframetheorganizationstructuretoadoptSCMintheirorganization,sincethebenefitsoftheSCMcanbegained.

OutsourcingtheexpertsinsupplychainmanagementtoadopttotheSCMsystem.

Identifya model ofSCM,aspertheirtypeofoperations&scopeofwork,orcanfollowtriedandtestedmechanismof theorganizationsusingSCM.

GPS based delivery system can help in avoiding delays of material due to traffic issues, especially for materials like RMC.

SincethebenefitsofSCM arenowbeenclearlymeasured,organizationcanchangetheirgoalstoachievetheresource optimization,andreducingcost&wastagerecyclingusingSCM.

Contractors can connect with organization which can provide a supply chain including, sub-contractor, supplier and chainofmanufacturesetc.togainthebenefitsofSCMevenifheisworkinginsmallscale.

Consultants can avail the organization who are providing whole supply chain including the contractors to the manufacturesforthesame.

1. AlZaabi,S.A.(2013).AnalysisofinteractionbetweenthebarriersforimplementationofSCM. Internationsl Journal for Advance Manaufacturing Technology Vol 68(1-4),895-905.

2. Alghanim.(1999). Kirby Building Systems .Retrievedfromkirbyinternational:https://www.kirbyinternational.com/

3. Al-Werikat,G.(2017).SupplyChainManagementInConstruction;Revealed. INTERNATIONAL JOURNAL OF SCIENTIFIC & TECHNOLOGY RESEARCH, VOL 6,106-110.

4. Amade,B.(2016).BARRIERSTOTHEIMPLEMENTATIONOFSUPPLYCHAINMANAGEMENT(SCM)INTHEDELIVERY OFCONSTRUCTIONPROJECTS. Serbian Project Management Journal, Vol 6,37-50.

5. AmitMoza,V.K.(2022).EvaluatingProjectComplexityinConstructionSectorinIndia;. Journal of Engineering Research and Sciences.

6. Bhattacharya,S.(2018). Brick & Bolt Home Construction.Retrievedfrombricknbolt.com:https://www.bricknbolt.com/

7. Durai,V.C.,&Sentamilselvan,D.K.(2016).ASTUDYONSUPPLYCHAINFRAMEWORKINCONSTRUCTIONIndustry. International Journal of Research -GRANTHAALAYAH,16-26.

8. Govindan,K.,&Kaliyan,M.(2013).BarriersanalysisforgreensupplychainmanagementimplementationinIndian industriesusinganalytichierarchyprocess. Int. J. Production Economics,1-14.

9. Gowda,J.(2017). Infra.Market : Reshaping the world’s largest ecosystem through technology.Retrievedfrom Infra.MarketIndia:https://infra.market/

10.Gupta,H.(2020).Barriersandovercomingstrategiestosupplychainsustainabilityinnovation. Resources, Conservation & Recycling vol 161,1-16.

11.Khutale,S.D.,Shusma,D.,&Kulkarni,S.(2013).ImprovementinSupplyofConstructionMaterialforConstruction IndustryinSataraCity-byapplyingSupplyChainManagementTool. IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE),47-53.

12.Madhukar.(2016). Construction Suppy chain management for reengineering construction industry. Bangalore: Builtconstructions.in.

13.MahmoudE,M.J.(2021).BarrierstoachievingsustainableconstructionprojectprocurementintheProvateSector. Cleaner Engineering and Technology Vol 3,100-125.

14.Mathur,K.(2022,march).WearedigitisingtheentireValueChain-PankajPhadnis,NationalHead–Retail, Infra.Market. Distribution Channels and Innovation ,pp.24-26.

15.Moza,A.P.(2022).MethodologyforEstablishingaModelforAssessingPerformanceofPublicProjectsinIndia. International Journal of the Built Environment and Asset Management, Inderscience publisher.

16.Naskar,S.(2021). Supply Chain Management in Prefacbrication Industry. NewDelhi:SPAD,Seminar1.

17.Negi,M.,Ahuja,V.,&Baruah,P.(2017).SustainablesupplychainmanagementinIndianContructionIndustry. National Conference on Sustainable Supply chain management an Indian perspective. Noida:CRIMM.

18.NidhiGupta,S.K.(2019).EffectivenessofAmendmentofGCConClaimsbyCPWDin2019. International Journal for Research in Applied Science & Engineering Technology (IJRASET

19.Papadopoulos,G.A.,Zamer,N.,Gayialis,S.P.,&Tatsiopoulos,I.P.(2016).SupplyChainImprovementinConstruction Industry. Universal Journal of Management 4(10),528-534.

20.Parikh,K.,&Pitroda,P.J.(2013).CONSTRUCTIONSUPPLYCHAINMANAGEMENTINCENTRALREGIONOFGUJRATIN INDIA:SCOPE,BENEFITSANDBARRIERS. JOURNAL OF INTERNATIONAL ACADEMIC RESEARCH FOR MULTIDISCIPLINARY,360-363.

21.Puppo,W.,&Carlos,L.(2021).CoreElementsUnderlyingSupplyChainManagementintheConstructionIndustry:A SystematicLiteratureReview. Buildings,2-20.

22.Rastogi,R.P.(2022).AnalyzingtheImpactofChallengesinPrefabricatedBuildingConstructionSupplyChains. Journal of Engineering Research and Sciences, JENRS.

23.Rastogi,R.P.(2022).AnalyzingtheImpactofChallengesinPrefabricatedBuildingConstructionSupplyChains. Journal of Engineering Research and Sciences.

24.Sael,N.,Hamim,T.,&Benabbou,F.(2019).ImplementationoftheAnalyticHierarchyProcess. International Journal of Emerging Technologies in Learning (iJET),78-93.

25.Sahu,S.,&Rao,K.N.(2020).BarrierstoAdoptionofSupplyChainManagementinINDIA,ATheoreticalModelandScale OPERATIONS AND SUPPLY CHAIN MANAGEMENT,476–495.

26.Salami,E.,&Aydinl,S.(2016).BarrierstotheImplementationofSupplyChainManagement-CaseofSmalltoMedium SizedContractorsinTurkey. International Journal of Science and Research (IJSR) VOL 5,516-520.

27.Sen,R.(2016). Supply chain management in construction Industry. NewDelhi:SchoolofPlanning&Architecture.

28.Serpell,A.,&Heredia,B.(2010).SUPPLYCHAINMANAGEMENTINCONSTRUCTION:DIAGNOSISANDAPPLICATION ISSUES. Supply chain management in construction,455-465.

29.SKSolanki,R.R.(2022).CostAnalysisofFunctionalRetrofittingMeasuresinBuildings. Journal of The Institution of Engineers (India).

30.Solanki,S.K.,&Paul,V.(2022).Comparisonbetweenservicelifepredictionmethodsforbuildingrehabilitation: applicationonacasestudy. Journal of Building Pathology and Rehabilitation

31.Soo-yong,K.(2020).Supplychainmanagementinconstruction:criticalSupplychainmanagementinconstruction: critical. International Journal of Construction Management,1-9.

32.StanleyE,M.G.(2008).Benefits,Barriers,andBridgestoEffectiveSupplyChainManagement. Supply Chain Management 13,35-48.

33.Stewart,R.B.(2016).ExplorationoftheBarrierstoImplementingDifferentTypesofSustainabilityApproaches. Procedia CIRP 48,22-27.

34.SulaimanHasim,M.A.(2020).IssuesandAdoptionProcessforSupplyChainManagementofMaterialsinConstruction Projects. AIP Conference Proceedings (pp.1-8).Selangor,Malaysia:AIPPublishing.

35.ThomasL,S.(1980). The Analttic Hierarchy process. McGrawhill.

36.Vrijhoef,R.,&Koskela,L.(1999).RolesofSupplyChainManagementinConstruction. University of California, Berkeley,, (pp.26-28July).CA,USA.

37.WilliamJ.O’Brien,C.T.(2009). Construction Supply Chain Management Handbook. London,NewYork:CRC Press,Taylor&FrancisGroup.