ELECTRIC POWER HAND TRUCK

1,2,3,4,5 Students,Yashwantrao Bhonsale Polytechnic, Sawantwadi, Maharashtra, India

6 Faculty, Yashwantrao Bhonsale Polytechnic, Sawantwadi, Maharashtra, India ***

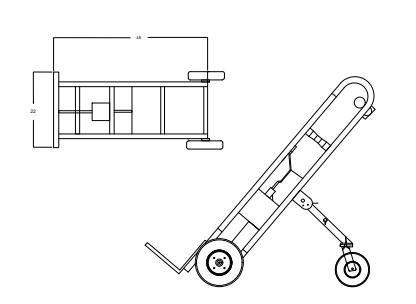

Abstract - Electric power hand truck is the electric drive system truck which can be used at the Construction site for weight lifting and supply of material. Basically, it’s fully electric and works on solar power which is renewable source of energy hence there is no need of any fuel. In electric power hand truck charge the battery by using solar panel. Electric power hand truck has zero emission. In India we see that people transport the materials at construction site manually it required more workers at the site for transport and lifting the material from one place to another place, which requires more labor cost. Also require machinery for heavy transportation of material. For reduce labor cost and easy transportation of the material we design Electric power hand truck. It can be built on the powerful electric drive system which works on solar hence helps to minimize the environmental pollution. It’s capable for handling the maximum weight at the construction site. Its design is very simple and easy to operate.

Key Words: BLDC Motor, Solar Panel, Controller, Electric Drive.

1.INTRODUCTION

The mini electric hand truck changes the way companies operate. Constructed using the robust electric drive technology utilised in all Overland Carts. Unique to this forklift truck is the built in versatility. The forklift truck has multiple attachments that can be added or removed quickly and easily via one pin. Each cart is driven by a rechargeable battery pack that has enough energy to last allday.

It consists of attachment including Hand Truck Attachment which comes standard with Transformer Hand Truck. Designed for general use. Mantis Attachment whichDesignedforoversizedloads.Thefronttwowheels moveonlyforwardandreversedirectionbutanothertwowheelmoveinanydirectionwhichhelptomovethishand truck in any direction. Multi Mover Attachment which Designed for oversized loads. It is fully run on solar energy,whensolarenergyisabsorbedbythesolarpanelit converts that solar energy into electrical energy. The batteryischargedonsolarandusedtorunthemotor.We designed this electric hand truck for construction side for transportation of heavy load from one point to another pointeasily.Thereisnouseoffuelsoitispollutionfreeas well as less running cost. Because it uses solar energy whichisavailableinnaturefreeofcost.

2. METHODOLOGY

The electric power hand truck is an upgrade version of manuallyoperatedhandtruck.Inthismechanismwehave to accelerate the motor speed and the hand truck will easilycarrytheload.Themainmotivetodesignthishand truck is reduced the workers problem, and perfect utilization of solar energy to drive the truck. There are different methods to drive this hand truck. In that wecan use fossil fuels like petrol, diesel and motors to drive the truck. There are two motors that are mostly us for this typeofapplicationaspertherequirements.

1. PMDC motor – permanent magnet motor has its own advantagesandit issuitableforlowtorqueapplication.It isuseinsomeoftheelectrichandtruckwherewerequire less torque. For this electric truck the motor require is very powerful which carry the heavy load easily and the speed is also low for this motor. The maintenance is frequent in this type of motor, the life of permanent magnetmotorislowandefficiencyisupto70-80%.

2. Hub motor- hub motor is also a very good option for electricpowerhandtruck.Itissmallinsizeandtheweigh is also less. For transportation of heavy load, we require hightorqueandthismotorprovidethattorqueeasily.But the reason is our hand truck is having four wheels in that fronttwowheelsisconnectedtogetherbyusingshaft,and itisdifficulttoconnectthehubmotorwithshaft.

3. BLDC Motor – the brushless DC motor is best and suitable for electric hand truck and we use for the truck. Because it is more powerful than the permanent magnet motor. The electric hand truck need high torque for its operation and this motor is perfect to run this electric hand truck. The controller is requiring in this type of motor to start and stop the motor also it is useful to controlthespeedofmotor.Thespeedofthemotorisvery high compare to permanent magnet motor. The maintenance is less for this motor because of absences of brushes,becauseofthatthelossesalsogetreduceandthe efficiency is increase up to 90%. If talking about the life span so it has typical life expectancy is 10,000 to20, 000 hours.

A brushed DC motor needs routine maintenance because brushesfrequentlyneedtobereplacedduetomechanical wear.Sparkingalsohappensasbrushestransportcurrent to the commutator. The armature's maximum speed and number of poles are constrained by brushes. A brushless DC motor does away with every one of these problems. A brushless DC motor needs an electronic control circuit to swap the stator magnets and maintain operation. As a result,aBLDCmotormaybelessdurable.

More efficiency, dependability, a longer lifespan, no sparking, less noise, higher torque per weight, etc. are benefitsofBLDCmotorsoverbrushedmotors.

Anothermaincomponentthatisusedinthehandtruck is battery. There are two batteries which is generally use that is lithium-ion battery and another one is lead acid battery. The charge store capacity is higher in lithium-ion batterybutitisverycostlythanleadacidbattery.Thereis no difference in the performance of these two batteries We have to make an electric hand truck in minimum budgetsowegofortheleadacidbattery.

Construction–

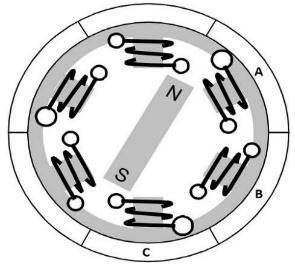

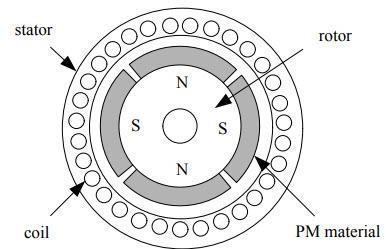

ABrushlessDCMotorissimilartoaBrushedDCMotorbut as the name suggests, a BLDC doesn’t use brushes for commutation but rather they are electronically commutated. In conventional Brushed DC Motors, the brushes are used to transmit the power to the rotor as theyturninafixedmagneticfield. Asmentionedearlier,a BLDC motor used electronic commutation and thus eliminatesthemechanicallytornbrushes.Themaindesign differencebetweena brushedandbrushlessmotorsisthe replacement of mechanical commutator with an electric switch circuit. Keeping that in mind, a BLDC Motor is a type ofsynchronous motor inthesensethat the magnetic field generated by the stator and the rotor revolve at the same frequency. Brushless Motors are available in three configurations: single phase, two phase and three phase. Out of these, the three phase BLDC is the most common one.

Fig. no. 2 constructionofBLDCmotor

The structure of the stator of a BLDC Motor is similar to that of an induction motor. It is made up of stacked steel laminationswithaxiallycutslotsforwinding.Thewinding in BLDC is slightly different than that of the traditional induction motor. Generally, most BLDC motors consist of three stator windings that are connected in star or ‘Y’ fashion (without a neutral point). Additionally, based on the coil interconnections, the stator windings are further dividedintoTrapezoidalandSinusoidalMotors.Ifwenow pass current through coils B and C one after the other (in that order), the rotor magnet will rotate in clock wise direction.Toincreaseefficiency,wecanwindtheopposite coils using a single coil so that we get double attraction. Further increasing the efficiency, we can energize two coils at the same time so that one coil will attract the magnet and the other coil will repel it. During this time, thethirdwillbeidle.

Working-

TheLorentzforcelaw,whichstatesthatacurrent-carrying conductor experiences a force anytime it is put in a magnetic field, is the same concept that underlies the operation of a BLDC motor. The magnet will feel an equal andoppositeforceasa resultofthereactionforce.Witha BLDC motor, the permanent magnet moves while the current-carryingwireremainsmotionless.

The stator coils become electromagnets and begin to produce a consistent field in the air gap when they are electrically switched by a supply source. Despite the fact that the source of supply is DC, switching causes an AC voltage waveform with a trapezoidal shape to be produced. Rotor rotation is maintained by the interaction between the permanent magnet stator and electromagnet stator. The controller chooses which coils to energise based on this sensor signal. When rotor poles approach hall-effect sensors, Low and High level signals are produced. The shaft's location is established by these signals.

Particulars Electric Hand Trucks

Outdoor Electric Forklift Truck

Jack EP Selling Electric Hand Pallet Truck

Manufacturer Overland carts Digging Weiying

Liftingheight Min60mm Min50mm Min 80 mm/ Max3000mm

Core Components

24V Lithium 20 amp hr rechargeable batterypack

Motor, Pump, Engine,PLC, Other

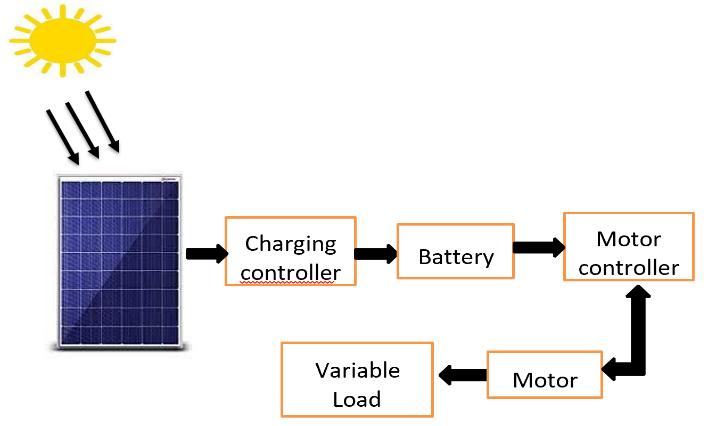

panel. When solar rays absorb by solar panel it converts thatsolarenergyintoelectricalenergyandgivetheenergy tochargecontroller.Chargingcontrollerhelptochargethe battery at the rated value of battery and protect from the damage.Whenwehavetodothework,thesupplyisgiven to motor by turn on the switch with the help of motor controller. The controller helps us to turn on or off the motoritalsohelpstocontrolthespeedofmotoreasily.

engine power source

Style Electric Electric Electric

Load Capacity 750 lbs (295 kgs) 1500kg 1500kg

Wheeltype Pneumatic Nylon Wheel Nylonwheel

Drive 24V600W drivemotor AC Motor (1.5kw AC Motor) DCmotor

Application

Construction works, Building Material Shops, Manufacturin gPlant

Energy & Mining, Food & Beverage Shops, Advertising Company, Other

3. DETAIL OF IMPLEMENTATION

garment shops, building material, machinery

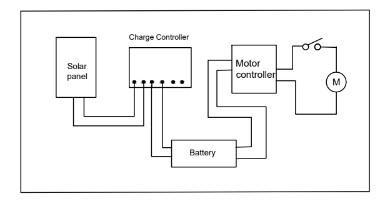

The above circuit diagram of electric power hand truck shows the connection charging point to utilization of energy to run this hand truck. It is consisting of solar panel, charge controller, battery, motor controller switch, motor.Thesolarenergyisabsorbedbythesolarpaneland it is connected to the charge controller which charges the battery at the safe value. There is another two terminal whichusedtoconnectdirectdcappliances. Thebattery isconnectedtothemotor controllerandthecontroller is givesupplyto motorandmotorstartrun.Butthereisone switch which is connected between the motor and controllertoonandoffthemotoreasily.

Thisblockdiagramofelectricpowerhandtruck describes theblockwiseinformationofourprojectofelectricpower and truck. It is consisting of solar, charging controller, battery, motor controller and motor etc. It is run on DC supplywhichisstoredinbatteryandchargebyusingsolar

Whenbatteryisfullychargedthentheelectrichandtuckis readytorun.Thenwejusthavetoturnontheswitchwhich is connected between motor and motor controller then motorgetthesupplyanditcanstarrun.Motorisconnected to electric hand truck through the chain when motor run then hand truck also run. After that we can vary the speed of motor as per the requirement, by using accelerator it helps to drive the motor as per the requirement. Then we have to add a variable load on the hand tuck and transfer the load from one place to another place. It also has one attachment which is box type structure use for the load transportation. When the battery gets dead then by using solarpanel,wehavetochargeitafterthatwecandrivethe electric hand truck for another application. The battery is capabletorun5-6hoursafterfullcharge.

4. CONCLUSIONS

In2022thepollutionisincreasedaybydayandgreenhouse gases are also increases. Electric power hand truck minimizes the Environmental pollution due to fuel combustion. We try to build up a power hand truck which cancarrythematerialatconstructionside.Thepowerhand truck is eco-friendly hence there is no air pollution. This hand truck is compact in size so it can use in small areas easily. The total running cost for lifetime is low. Since this powerhandtruck isuse electric motorso wecanvary the speed as per our requirements this helps in mounting and upside-down area. Our project is works on solar energy, which is everywhere in the environment so people can afforditonreasonableprice.

5. FUTURE SCOPE

Theintroductionofautomateddecisionmakingintoelectric power hand truck technology will make operations safer. Next generation of environmentally friendly power hand truck has an electric powered core which combines with rechargeable battery capacity technology. By removing unnecessary processes, electric power hand truck around the world can reduce man hours, emission and cost significantly. In future we can increase the load carrying capacity of electric hand truck. We also add suspension systemtodriveitforoffroads.

REFERENCES

[1] Time-Efficient Fault Diagnosis of a BLDC Motor Drive Deployed in Electric Vehicle Applications AdilUsman;Bharat SinghRajpurohit08February2021

[2] Charging and discharging characteristics of Lead acid and Li-ion batteries IEEE Neetu Meena, Vishakha Baharwani, Deepak Sharma, Arvind Sharma, Bishnu Choudhary,28April2014

[3] An Advanced Speed Control Scheme for the High Speed Blender Machine using BLDC Motor IEEE Jong-Nam Bae; Seung-Jun Kim, Jun-Hwi Park, Jin-Woo Ahn, Dong-Hee Lee24January2019

[4] Simulation and experimental validation of a hybrid forklift truck IEEEJ.Li,G.Lutzemberger,D.Poli,C.Scarpelli, T.Piazza19August2019

[5]Development of a Observe-By-Wire System for Forklifts Using Haptic Interfaces IEEEBaHaiNguyen,Jee-HwanRyu 02May2008

[6] Performance Improvement of BLDC Motor Speed Control Using Sliding Mode Control and Observer IEEE PranavShah; Pramod Ubare; Deepak Ingole; Dayaram Sonawane 04 November2021

[7] Computer Aided Modeling & Cost Estimation Of A Hand Truck Sagar Shelare, Machchhendra Sonpimple, Trupti Gajbhiye03Sepetember2017

[8] research summery on energy saving technology of forklift lifting system liu Panpan, Wang Yao, Zhang Zejian, Zhang Oijiu,LunFengyan(ICECTT)23Octomber2020

[9] Cost-Effective Solar Powered battery Charging system for Light Electric Vehicles Kamal Singh, kuldeep Sahay 27 December2019