International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 03 | Mar 2023 www.irjet.net p-ISSN:2395-0072

Behavior of Hot Asphalt Mixture Modified with Carbon Nanotube and Reclaimed Asphalt Pavement

Hadeer Asem1, Abdallah Wahdan 2, Sameh Ahmed Galal 3

1 Assistant Lecturer, Civil Engineering Department, Higher Future Institute for Engineering, Fayoum, Egypt ,PHD Researcher in Azhar University, Egypt

2 Professor, Civil Engineering Department, Faculty of Engineering, Al- Azhar University, Cairo, Egypt

3 Professor, Civil Engineering Department, Faculty of Engineering, Fayoum University, Fayoum, Egypt ***

Abstract

Nowadays, nanotechnology is widely applied in pavement engineering to improve the properties of materials and performance. Nanotechnology can be considered as the measurement on nanometer scale that affects the material used in pavement due to its unique characteristics. Therefore, this new technology might indirectly solve the current pavement construction problems.

During the past years’ different researchers have studied the causes of failure of flexible pavements and they offered variety of alternatives for solving these failure problems such as rutting, fatigue and low temperature cracking which are sourced from many reasons for example moisture susceptibility and temperature sensitivity of either asphalt, aggregate or the asphalt mixture as a whole. Therefor recycling using the RAP with nano carbon tube is used to improve asphalt properties. Due to economic reasons and the need for environmental conservatism, there has been an increasing shift towards the use of Reclaimed Asphalt Pavement (RAP) materials in the pavement construction industry. The majority of HMA mixtures in Egypt are produced only from virgin materials although there are about 4 million tons per year of reclaimed asphalt materials, because it continuous pavement milling or scraping processes, are not used. The increasing number of roads which are removed (RAP) and decreasing the wastes in a way that will not negatively affect the environment. Reclaimed Asphalt Pavement(RAP) obtained from damaged pavement used in hot asphalt mixtures has evolved into regular practice in many countries around the world. Use of these materials in the past has not only proved to be economical but also environmentally sound. Mixing Rap in virgin materials in the light of the increasing cost of asphalt, shortage of asphalt and pressing need to preserve the environment. In this investigation, it has been attempted to promote technical characteristics of asphalt mixture using carbon nanotubes as an additive material for bitumen with reclaimed asphalt pavement. In this study, marshal test parameters of hot mix asphalt, modified with carbon nano tube with Rap, are investigated and compared to conventional asphalt mix. In this study marshal test parameters of modified asphalt by .5, 1.0, 1.5, 2.0 and 2.5% carbon nanotube and 20%, 30%, 50% and 70% Rap content in bitumen was evaluated considering marshal test, then results were compared to conventional asphalt mix. Obtained results shown, using carbon nanotube with rap improves hot mix asphalt stability and flow.

Keywords

Hot asphalt mix, Carbon nanotubes, Reclaimed Asphalt Pavement, Marshall test

1. Introduction

Theuseof Reclaimed AsphaltPavement (RAP)in theconstructionofroadsand resurfacingof existing roadsis economically beneficial and environmentally sound. The huge road modernization exposes challenges of various concerns pertaining to depletionofresourceslikegoodsoilandaggregates,longruntogetgoodqualityaggregatesandincreaseinfuelconsumption etc. Moreover, the supply of bitumen, whose cost keeps on increasing, is dependent on foreign sources, and energy that is neededforprocessing new materialsisbecomingcostlier everyday. The recycling ofexisting bituminous mixesaretheonly alternatives, through the reuse of aggregate and bitumen. Use of the recycled materials in the road construction has been favored over fresh materials in the light of increasing cost of bitumen, rarity of good quality aggregates and the priority towards preservation of the environment. Considering the material and construction cost alone, it is estimated that using

recycledmaterials,savingrangingfrom14to34%fromasphaltlayercostcanbeachieved.Itisuniversallyrecognizedthat an important benefit of asphalt as a pavement construction material is its ability to be recycled. This factor is becoming more relevant as the use of rap in RAP in asphalt mixtures could produce important benefits in terms of performance and economics.

TwoCNT-asphaltcementmixingproceduresincludingsimpleandwetprocesseswereinvestigated.Viscoelasticpropertiesof modified AC incorporated with 0.1, 0.5, and 1 (%w/w) CNT were evaluate, adding carbon nano tubes (CNTs) provides an enhancement of rutting resistance potential along with the resistance to thermal cracking (2). The need to replace outdated pavement materials with new ones that are of higher quality, comply with current safety regulations, and are more dependableaswellasecologicallyfriendlyhasariseninrecentdecadesasaresultofasharpincreaseintrafficloads(4).Three different percentages of carbon nanotubes (CNTs) (0.1%, 0.5%, and 1% by mass of asphalt cement) were used to modify conventional asphalt cement (60/70) adding CNTs into asphalt cement enhances the performance of asphalt concrete pavement in bothhotand coldweather, whichin turn prolongsthepavement’sservicelifeand savesmaintenance expenses (1). Instead of using materials in large scale, we can use nanomaterials which are defined as restructuring of matter in the order of nanometers (i.e., less than 100nm) to create materials with fundamentally new properties and functions. Nanotechnologiesarethedesign,characterization,productionandapplicationofstructuredevicesandsystemsbycontrolling shape and size at nanometer scale. In last years, many researchers try to use organic and nonorganic additives such as polymers,fibers,nanoclayandcarbonnanotubetoimprovemechanicalpropertiesof asphalt(11),(8),(7),(6),(5),(3).Due totheiroutstandingqualities,carbon-basednanoparticulesandplateletshavealsoattractedalotofattentionrecentlyamong the diverse nanomaterials. CNTs in particular the most promising addition to improve the performance of building and structuralmaterials(9),(10).Itiswidelyseenashavinghugepotentialtobringbenefitsindiverseareassuchasproductionof stronger and lighter materials (13). In recent years, numerous researchers have experimented with the use of organic and inorganic additives to enhance various physical and rheological properties of asphalt binder and asphalt mixture. These additives include polymers, nanoclay, nanofillers, crumb rubber, fibres, and bio-rejuvenators (18). In the field of civil engineering,whilealargeamountofresearchhasbeencarriedoutinthelastdecadeoncarbonnano-modificationofcementbased materials (Oncel and Yurum, 2006) and polymer composites ( 11),(12).One of the most desired properties of nanomaterials in the construction is their ability to mix with bituminous- based on structural materials. Carbon nanotubes (CNTS) were discovered by Iijima in 1991 as the fourth form of carbon ( 14). CNT can now be considered as the ‘’king’’ of nanomaterials as it is being used in many applications i.e medicine, electronics, energy and environment, etc. (15). Carbon nanotubes(CNTs) arehollowtubularchannels,formed eitherbyonesingle wallscarbonnanotube(SWCNTs) ormaltywalls carbon nanotube (MWCNTs) of rolled graphene sheets (16). Since CNTs exhibit great mechanical properties along with extremely high aspect ratios (length to diameter ratio) ranging from 30 to more than many thousands, they are expected to produce significantly stronger and more ductile bituminous composites than traditional reinforcement materials (e.g. glass fibersorcarbonfibers).Infact,becauseoftheirsize(rangingfrom10nmto20nm)andaspectratios,CNTscanbedistributed inamuchfinerscalethancommonfibers,Laserablation(12).Carbonnanotubesusedinthisinvestigationwereproducedby chemical vapor deposition technique with diameters from 10 up to 20 nm and different length. Asphalt recycling has many benefits like preservation of the environment and reduction land filling, energy conservation and improved pavement smoothness, cost saving over traditional rehabilitation method and improved pavement physical properties modification of existingaggregategradationandasphaltbinderproperties.

2. Research Methodology

The mechanical behavior of bituminous depends on the structural elements and phenomena that occur in a micro and nano scale.Asaresult,nanotechnologycanmodifythemolecularstructureofasphalt,whichleadstoimprovementinthematerial’s properties. Nanotechnology can also improve the mechanical performance, durability, and sustainability of asphalt mixture. One of the most desired properties of nanomaterials in the construction sector is their capability to confer a mechanical reinforcementtobituminousbasedstructuralmaterials {1} .Whilealargeamountofresearchstudieshasbeencarriedoutin the last decade on modification of asphalt binder by different nano particles like nano clay {2} , nano zinc oxide {3} , nano silicondioxide {4} ,nanotitaniumoxide {4} ,carbon nanofibers(CNFs) {5} .Fewstudieshave beenconducted inthearea of carbon nano tubes (CNT)- with RAP[ modified binders and mixtures. In this paper carbon nano tube is mixed with asphalt mixturetostudyenhancementthepropertiesofasphaltwithcarbonandthechangesthatoccurinthepropertiesofmixtures. TheMarshaltestwasusedtoevaluatephysicalandmechanicalpropertiesofHAM.

3. Materials

3.1 Reclaimed Asphalt Pavement (RAP)

Reclaimedasphaltpavement(RAP)isthetermgiventoremovedand(or)reprocessedpavementmaterialscontainingasphalt and aggregates. These materials are generated when properly crushed and screened, RAP consists of high- quality wellgradedaggregatescoatedbyasphalt.

3.2Carbon Nanotube

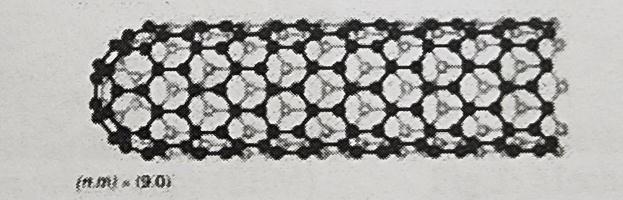

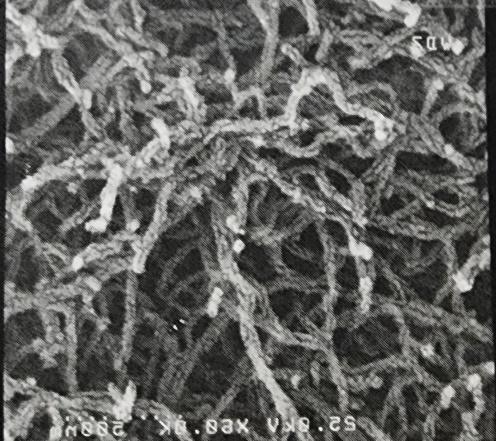

Since CNTs exhibit great mechanical properties {7 { } 6} along with extremely high aspect ratios (length- to- diameter ratio) rangingfrom 30to more thanseveral thousand {8} ,theyare expectedto produce significantlystrongerand more improved bituminouscompositesthantraditionalreinforcingmaterials(e.g.,glassfibersorcarbonfibers).Thehighspecificstrength,the chemical resistance, the electrical conductivity, and the thermal conductivity of carbon nanotubes (CNTs) make them attractive for use as reinforcement to develop superior bituminous composites {9} , {11} . Some researches have been performedonmixingprocessofCNFsinasphaltmixturesbutnotforCNTswhichareabout100timessmallerthanCNFsand harder to disperse and figure 1 show Carbon Nanotube under microscope. Dispersion of CNTs has been one of the largest challengesduetotheaggregationofthenanotubes {11}

3.3 Bitumen Material and Aggregates

Materials used in the experimental investigation included neat bitumen 60/70-penetration grade which was obtained from SuezNasrPetroleumCompany(NCP).Thepercentagesofasphaltusedtopreparemixturesarefrom4%to6%increasingabout .5%.Laboratorytestswerecarriedoutonasphaltanditsspecificationofasphaltarepresentedintable1throughtable3. The aggregates used was brought from the quarry from the western Assiut road. The aggregate was a combination of coarse aggregate with specific gravity 2.573, the fine aggregate with specific gravity 2.508 and mineral filler and were graded with AASHTO1993whichispresentedintable4andvirginaggregateswithoutRapshowsinfigure2.

AcommerciallyavailablemultiwallCNTswithpurityupto95%,wasusedinthisresearch.Allmixtureswerebuiltaccording toASTMD1559(ASTM,2002).TheimageofCarbonnanotubeswaspresentedinfigure1.AlsothecharacterizationofCarbon nanotubes(CNTs)issummarizedatthetable5.ThecontentRAPinthemixturewas20%,30%,50%,and70%,bymass.

4. Experimental Procedure

In this study, various percentages of RAP are used with virgin aggregates and different percent of Carbon Nanotubes to evaluate the properties of HMA. The percentages of Rap are 20%, 30%, 50%, and 70% by mass. Figure 3 shows the mix of aggregates with RAP. Five different percentages of CNT were chosen to produce bitumen- CNT blends (.5%, 1%, 1.5%, 2% and2.5%byweightofthebasebinder).Scanningelectronmicroscope(SEM)imageofCarbonnanotubes(CNTs)areshownin figure 4. Five different percentages of RAP were chosen to mix with virgin mix and with CNTs (20%, 30%, 50%, and 70%). Therearefourphasesofmixturesvirginmix,CNTswithbitumen,RAPwithbitumenandCNTswithRAPandbitumen.

4.1Marshall Test

TheMarshallmethodofasphaltmixdesigniswidelypracticedinconstructionmaterialslaboratoriestoselectandproportion aggregateandasphaltmaterialsforpavementconstruction.Thefocusisondetermininganoptimumasphaltcontentthatwill provide maximum power to the mix with minimum deformation from axle loads. Marshall stability and flow test values, density, and air voids in the mix and test was carried out to evaluate the physical and chemical properties of the asphalt mixture,withoutadditivesorwithRAPandCNT.Marshallstabilityisthemaximumload(inkilograms)theasphaltsamplecan supportwithoutbreakingwhenloadedandMarshallflow isthedeformationread(inmillimeters)duringthemaximumload andfailure.Inthisstudy,mechanicalpropertiesofthesamplesarecomparedwitheachotherandfinally,amountofmaterials andtheresultingchangeswillbedetermined.Figure5showsmarshalltestaccordingtoASTMD6927.

5. Analysis and Results

TheMarshalltestwascarriedoutondifferentasphaltratiostodeterminetheoptimalratio,and5.5%achievedthebestratio. The test was carried out repeatedly on different rap ratios, measuring the different stability and flow ratios, then re-testing withdifferentratiosofrapwithdifferentpercentofcarbonnanotubes.CombinationofRapanddifferentpercentofCNThad been done with the following percentages (.5%, 1%, 1.5%, 2% and 2.5%) and mixing virgin aggregate with Rap 20%, 30%, 50%, and70% by weight of the base binder. In addition, Rap and CNTs were mixed with virgin aggregates in their different percentages.Table6summarizedstabilityofasphaltmixtureswithRAPandCNTs,whiletable7summarizedflowofasphalt mixturewithRAPandCNTs.

Andmakingacomparisonamongvaluesofstabilityandflowasshowninfigure6andfigure7.

Fromtable6andfigure5itcanbeconcludedthatusingC.N.TwithRAPincreasethestabilityofHotAsphaltMixture,50%of RAP with different percent of carbon nanotubes achieved best results of stability for example at 50% RAP and 2.5% C.N.T stability increase 14% in comparison with virgin mixture By comparing the ratios of RAP alone without additives, which achievedtheworstresultsduetothehighpercentageofbitumenpresentintheasphaltmixture,whichfacilitatedthefracture process.. 50%Rap with different percent of C.N.T achieved the highest stability specially at 2.5%CNT. At 50% RAP and 2.5% C.N.Tflowincrease15.5%incomparisonwithvirginmixture

6. Conclusions

Due to the increasing development of nanotechnology and special features of carbon nanotubes and to reduce the huge amountofRaptosavetheenvironmentandmoney,youcanusethemastheidealchoiceinasphaltmixtures.Theaimofthis study was experimental investigation on the effects of using carbon nanotubes and Rap on hot mix asphalt marshal parameters.Basedonthelaboratorytestresults,thefollowingconclusionswereobtained:

- 50%RapwithdifferentpercentofCNTSachievedbestresultscomparisonbetweendifferentmix.

- AddingRaponlytovirginaggregatesistheworstsolutions.

- Asamplecontaining2.5%CNTand50%Rapachievedhighstabilityandflow

- Theadditionoftherapaloneachievedlessstability.

- Thebestratiosincomparisonaremixing 51% RapandalldifferentpercentofCNTs.

7. REFERANCES

1- MohamedSamirEisa,AhmedMohamady,MohamedE.Basiouny,AymanAbdulhamid,JongR.Kim,(2022).Mechanical PropertiesofAsphaltConcreteModifiedwithCarbonNanotubes.

2- Faramarzi, M., Arabani, M., Haghi, A.K., Mottaaghitalab,V. (2015). Carbon nanotubes Modified Asphalt Binder PreparationandCharacterization.

3- Zadshir,M.,etal.,2018.Investigatingbio-rejuvenationmechanismsinasphaltbindervialaboratoryexperimentsand moleculardynamicssimulation.

4- Ehdi Zadshir, Fangliang Chen, Xiaokong Yu, Xin He, Irene Nigro, Maddalena, (2022). Mixing Cabon Nanotubes with AsphaltBinderthroughafoamingProcesstowardhigh-performanceWarmMixAsphalt.

5- Ziari,H.,andMoniri,A.,(2019).Laboratoryevaluationoftheeffectofsyntheticpolyolefin-glassfibersonperformance propertiesofhotmixasphalt.

6- Tahami, S.A., et al., (2019). The use of high content of fine crumb rubber in asphalt mixes using dry process. ConstructionandBuildingMaterials

7- Vol,H.V.,etal., (2017). Evaluation of asphalt mixture modified with graphite and carbon fibers for winter adaptation: thermalconductivityimprovement.

8- Tyson, B.M., et al., (2011). Carbon nanotubes and carbon nanofibers for enhancing the mechanical properties of nanocompositecementitiousmaterials.

9- Treacy, M.M.J, Ebbesen, T.W, and Gibson, J.M. (1996). Exceptionally High Young's Modulus Observed for Individual CarbonNanotubes.

10- DeHeer,W.A.(2004).Nanotubesandthepursuitofapplications.

11- Bai, J.B. and Allaoui, A. (2003). Effect of the Length and the Aggregate Size on the Improvement Efficiency of the ExpermentalInvestigation.

12- Chong,K.P.andGarboczi,E.J.(2002).SmartandDesignerStructuralMaerialSystems.

13- Makar,J.M.andBeaudoin,J.J.(2003).CarbonNanotubesandtheirApplicationsintheConstructionIndustry.

14- Bergman,C.P.,andJungdeAndrade,M,(2011).NanostructuredMaterialsforEngineeringApplications.

15- GuopingZhang.,(2007).SoilNanoparticlesandtheirInfluenceonEngineeringPropertiesofSoils.

16- Michael, A. Wilson, Nguyen H. Tran, Adrian S. Milev, G.S.Kamali Kannangara, Herbert Volk, G.Q. Max Lu., (2008). NanomaterialsinSoils.

17- GrobertN.,(2007).CarbonNanotubesBecomingClean.

18- Cong,P.,Xu,P.,andChen,S.,2014.Effectsofcarbonblack ontheanti-aging,rheologicalandconductivepropertiesof SBS/asphalt/carbon blackcomposites.