RUBBERISED FIBRE REINFORCED CONCRETE

PABBU LAXMI PRASHANTH, RAMANLAWAR ABILASH

The compressive, split tensile and flexural strengths of concretehavebeenobservedtodecreasewiththeincrease ofrubberquantity.

The present experiment is carried out to investigate the freshandhardenedpropertiesofbinaryblendedconcrete with 20% of Fly ash, by weight of cement, as partial replacement of cement and replacement of 0%, 5%, 10%, 15%and20%ofsandwithCrumbrubber,byvolumeand addition of Coconut fibres at 0.1%, 0.2% and 0.3%, by weight of cement. Compressive strength of concrete is measured by testing standard cubes (150mm x 150mm x 150mm) at the age of 28 days, split tensile strength of concrete is measured by testing standard cylinders (150mm Ø, 300mm height) at the age of 28 days and impact resistance of concrete is measured by testing beams(100mmx100mmx500mm)attheageof28days

Keywords: Crumb Rubber, Coconut Fibre, fly ash, Compressive Strength, Split Tensile Strength, M30 grade concrete.

1. NTRODUCTION

1.1 General

Concreteisthemostwidelyusedconstructionmaterialall over the world. The importance of concrete in modern society cannot be underestimated. Typical concrete is a mixture of fine aggregate (sand), coarse aggregate (rock), cement, and water. The aggregates, both fine and coarse, are bound together by cement when mixed with water. Since the late 1800s onwards, when consistent mass produce Portland cement became readily available, the world has been transformed by the design and constructionofallsortsofconcretestructures.

Admixtures

A material other than the primary ingredients of concrete viz-a-viz water, cement and aggregates that is addedtothemixtureimmediatelybeforeorduringmixing to modify the properties of fresh or hardened concrete is defined as admixture. Ordinary Portland Cement (OPC) is one of the main ingredients used for the production of concrete and has no alternative in the civil construction industry.

1.2 Types of Pozzolanas

The Pozzolanic materials can be divided in to two types Naturalpozzolanas Artificialpozzolanas

Natural pozzolanas suchasClayandShale,Diatomaceous earth,Opalineshales,VolcanictuffsandHumilitiesetc.,are processed involving crushing, grinding and size preparation,includingthermalactivationifnecessary.The natural pozzolanas have lost their popularity in view of the availability of more active pozzolanas available as industrialby-products

Artificial pozzolanas such as Fly ash, Blast furnace slag, Micro silica, Silica fume, Rice husk ash, Metakaolin are major industrial by products. Practical experience has revealed that addition of mineral The reaction can be shownas

Pozzolana+CalciumHydroxide+Water→C–S–H(Gel)

Alkalis

a)Sodiumoxide(Na2O)0.58

b)Potassiumoxide(K2O)

FLY ASH:

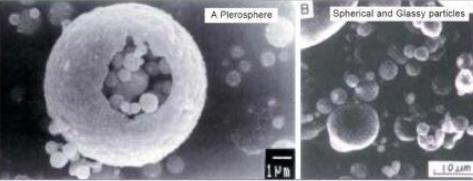

Fly ash, an artificial Pozzolana, is the unburnt residue resulting from combustion of pulverized coal or lignite, mechanical or electrostatic separators called hoppers collectitfromfluegasesofpowerplantswherepowdered coal is used as fuel. India is a resourceful country for fly ash generation with an annual output of over 110 million tones,bututilizationisstillbelow20%inspiteofquantum jumpinlastthreetofouryears.

1.TypeF,lowcalcium,8%CaO

2.TypeCI,intermediatecalcium,8–20%CaO

3.TypeCH,highcalcium,20%CaO

1.3 Physical properties of Fly ash:

1.3.1. Chemical properties of Fly ash

1.1 IndianstandardInstitutiondefinesBitumen

other hand, large quantities of scrap tyres are being generatedeveryyearglobally.

1.2

1.5 Classification of Rubber based on size: In most of the researches performed, usually three broad categories of rubber have been considered: Chipped rubber, Crumb rubberandGroundrubber.

a. Shreddedorchippedrubbertoreplacethegravel. To produce this rubber, it is needed to shred the Tyres in two stages. By the end of the stage one, the rubber has length of 300-430 mm and width of100-230mm.inthesecondstageitsdimension changesto100-150mmbycutting.Ifshreddingis further continued, particles of about 130-75 mm dimensions are produced and are called “shreddedparticles”.

AdvantagesofFlyashinconcretethetechnicalbenefitsof using fly ash in concrete are numerous. The various advantages found by different investigators in India are summarizedbelow:

SuperiorPozzolanicaction Reducedwaterdemand(for fly ash low carbon content and high fineness) Improved workability More effective action of water reducing admixtures Reducedsegregationandbleeding

1.4 BINARY BLENDED CONCRETE:

Cement mixtures containing Ordinary Portland Cement (OPC) and at least one supplementary cementitious material(SCM)iscalledblendedcements.Binarycements contain OPC and one SCM. Concrete made with such binarycementiscalledBinaryBlendedConcrete.9Inthis study,thetermBinaryBlendedConcreteisusedtoreferto concrete made with binary blended cement containing OrdinaryPortlandCement(OPC)and20%ClassFFlyash.

1.5 CRUMB RUBBER: Sand has by now become the most widelyconsumednaturalresourceontheplanet,nextonly to fresh water. Especially in Asia and Arab states the hungeroftheconstructionindustryis evergrowing. Once sand is used in concrete, the components are bound forever and are no longer available as resources. On the

b. Crumbrubberthatreplacessand,ismanufactured by special mills in which big rubbers change into smallertornparticles.Inthisprocedure,different sizes of rubber particles may be produced depending on the kind of mills used and the temperature generated. In a simple method, particles are made with a higher irregularity in therangeof0.425-4.75mm.

1.5.1 Effect on physical properties One of the main issues relatingtotheuseofchippedorcrumbrubberaggregateis theincreasedtendencytowardssegregationandbleeding.

1.5.2 Effect on strength properties as rubber has lower stiffness compared to aggregates, presence of rubber particles in concrete reduces concrete massstiffness and lowersitsloadbearingcapacity.

1.6 FIBRES: Fibreisasmallpieceofreinforcing

Materialpossessingcertaincharacteristicproperties.

Fibres can be of any shape and size. Fibres are often described by a convenient parameter called aspect ratio. The aspect ratio of a fibre is the ratio of its length to its diameter

Natural fibres: Natural fibres are fibres made or extractedfromplant,animal andmineralsources. Naturalfibressuchascellulose,jute,sisalandcoir areusedinconcrete.Naturalfibresarearesource that can be utilized in concrete to enhance its strength and are abundantly available in tropical regions.

Artificial fibres: Artificial fibres are man-made fibres.Artificial fibressuch assteel,glass,carbon, nylonasbestosandpolypropylenefibresareused in concrete. The most commonly used artificial fibresaresteelfibres.

1.7 COCONUT FIBRES:

Coconutfibresareagriculturalwasteproductsobtainedin the processing of coconut oil and are available in large quantitiesinthetropicalregionsoftheworld,especiallyin Africa,AsiaandAmerica.Coconutfibresarenotcommonly usedintheconstructionindustrybutareoftendumpedas agriculturalwastes.

1.8 FIBRE REINFORCED CONCRETE:

Fibre reinforced concrete is a concrete mix containing water, cement, aggregate and discontinuous fibres of various shapes and sizes. Plain concrete possesses a very low tensile strength, limited ductility and little resistance to cracking. Internal micro-cracks are inherently present in the concrete and its poor tensile strength is due to the propagation of such micro-cracks, eventually leading to brittlefractureoftheconcrete.

1.9 NEED FOR THE PROJECT:

The replacement of sand with crumb rubber may tend to marthefreshpropertiesofconcreteas indicated bysome researchers. Therefore, significant quantity of cement is often replaced with admixtures to enhance the fresh properties of concrete and reduce heat generation. The use of Fly ash in concrete is well established and widespread; it is not only economical but also improves the fresh and hardened properties of concrete. It also

helps to solve the problem of storage and disposal of the ash.

1.10 OBJECTIVES OF THE PRESENT STUDY

To study the influence of addition of coconut fibres as reinforcement, by weight of cement, on strength properties of binary blended concrete. To study the influence of crumb rubber in various percentages of sand replacement, by volume, on strength properties of coconut fibre reinforced binaryblendedconcrete.

Toformacomparativestudyofthepropertiesofcoconut fibre reinforced binary blended concrete and rubberizedcoconutfibrereinforcedbinaryblended concrete.

1.11 SCOPE OF THE PRESENT STUDY:

The present investigation is carried out to study the strength properties of binary blended concrete of M30 grade with 20% replacement of cement with Fly ash (by weight),0%,5%,10%,15%and20%replacementofsand with Crumb rubber (by volume) and addition of 0.1%, 0.2%and0.3%Coconutfibre byweightofcement.

1.12 SUMMARY:

In this chapter, use of admixtures in concrete, Pozzolanic materials, Fly ash and its advantages on addition to concrete,Crumbrubberanditsbenefitsinconcrete,useof fibres in concrete, Coconut fibres, Fibre reinforced concretearediscussed

2. LITERATURE REVIEW

2.1 GENERAL: This chapter deals with the review of literature related to the properties of concrete made with Crumb rubber as sand replacement, effect of Fly ash and Coconutfibreonpropertiesofconcrete.

2.1.1 LITERATURE REVIEW

Literature Review on Coconut Fibre

Noor Md. Sadiqul Hasan et al. (2012): Studied the physical and mechanical properties of concrete produced using chopped coconut fibres incorporatingdifferentvolumepercentageoffibres 1.0, 3.0, 5.0 and 7.0 subjected to static loading. The mix proportion of 1:2:3 was adopted with water cementratioof0.4.

Pravin V Domke (2012): studied the effect of partial replacement of cement by rice husk ash (RHA) and addition of coconut fibre (COIR) on the compressive, split tensile and flexural strengths of concrete.Itwasobservedthat12.5%RHA+2%COIR gives maximum compressive strength which was

close to that of normal concrete. Maximum flexural strength wasobservedat20%RHA+2%COIRwhich was 21.11% more than that of normal concrete. Maximum split tensile strength was observed from themixof15%RHA+3%COIR.

Olonade et al. (2013): Studied the development of compressive strength and modulus of rupture of coconutfibrereinforcedconcreteatdifferentcuring ages. Concrete of mix ratio 1:2:4 was used containing coconut fibre of 0, 1, 2, 3 and 4% 16 by weight of cement. Compressive strength and modulus of rupture of CFRC specimens were determinedatcuringagesof7,21,28and56days.

J. Sahaya Ruben et al. (2014): Investigated the compressive strength of coconut fibre reinforced concrete. In this experiment M25 grade concrete was used. Coir fibres were chopped to lengths of 20mm,25mmand30mmandsubjectedtochemical treatments. Compressive strength test was carried outon concretecontaining different percentagesof fibres(0.5%,0.75%and1.0%)byweightofcement. Theresultsshowedthatthemaximumcompressive strength is achieved using 25mm length coconut fibreswith0.75%additionoffibres.

Bhupendra Kumar et al. (2015): Compared the workability and compressive strength of flyash based coconut fibre reinforced concrete and plain cement concrete of M40 grade. The fly ash was replaced with the cement as 10, 20, and 30% and coconut fibres are added additionally by weight of cementintheproportionsof0,1,1.5,2,2.5and3%. The diameter of coconut fibre varied between 0.25 to1.0cmandlengthtakenwas4cm.

2.1.2 Literature Review on Crumb Rubber

Piti Sukontasukkul (2008): Investigated the thermal and sound properties of crumb rubber concrete panels. The mix proportion for the control specimen(nocrumbrubber)wassetat1:1.64:1.55 and crumb rubber was used to replace fine aggregate at 10%, 20% and 30%. The results showed that by replacing fine aggregate with 17 crumb rubber at 10 to 30%, the unit weight of concrete can be reduced from 14 % up to 28%. Also, rubberized concrete exhibited superior thermalandsoundpropertiesthanplainconcrete.

Piti Sukontasukkul et al. (2009): studied the mechanical and physical properties of lightweight concrete obtained by replacing fine aggregate partially with crumb rubber. The mix proportion forthecontrolspecimen(nocrumbrubber)wasset at 1:1.64:1.55 and crumb rubber was used to replacefineaggregateat10%,20%and30%

Yogender Antil et al. (2012): Studiedtheuseof crumb rubber in concrete to replace sand partially. The study was conducted on M30 grade concrete mix withcrumbrubberreplacingsandbyvolumeat5%, 10%, 15% and 20%. Specimens were cast for compressive strength and tested at 7 days and 28 days curing periods for plain concrete and rubberizedconcrete.

Parveen et al. (2013): Studiedtheuseofrubberwasteas partial replacement of fine aggregate to produce rubberized concrete in M30 mix. Specimens with different partial replacements of crumb rubber (0, 5, 10, 15 and 20%) by volume of fine aggregate were cast and tested for compressive strength, flexural strength, split tensile strength and stress strainbahavaiour.

S. Selvakumar et al. (2015): Studied the effectiveness of rubber as substitute for fine aggregate. Concrete mix design in this experiment was designed as per the guidelines in IS 10262-2009. All the samples were prepared using design mix. M30 grade of concretewasusedfortheinvestigation.

2.3 CRITICAL APPRAISAL OF LITERATURE REVIEW

TheincreaseincementreplacementbyFlyashproduces a better workable concrete. The optimum usage of Fly ash content replacing cement in concrete is 20%.

Addition of coconut fibre to concrete increases the compressive strengthtoa certainamount of fibres. Higher amount of coconut fibres in concrete decreasesthecompressivestrengthofconcrete.

2.4 SUMMARY:

In this chapter, the literature review of papers on properties of Coconut Fibre Reinforced Concrete andRubberizedConcretewasdone.Thereviewsof the above papers suggest that Crumb rubber, Coconut fibre and Fly ashhave significant effect on thepropertiesoffreshandhardenedconcrete.

3. EXPERIMENTAL PROGRAM

3.1 GENERAL:

In the present experimental program, standard cubes (150mm x 150mm x 150mm), standard beams (100mm x 100mm x 500mm), standard cylinders (150mm Ø, height 300mm) were casted and tested for finding the Compressive strength, Impact resistance and Split Tensile strength propertiesof Plain Concrete, PlainCoconutFibre Reinforced Binary Blended Concrete and Rubberized CoconutFibreReinforcedBinaryBlendedConcrete.Before castingofspecimens,themixesweretestedforproperties offreshconcrete.

3.2 MATERIALS:

ThematerialsusedinthisexperimentalstudyareCement, Fine aggregate, Coarse aggregate, Water, Fly ash, Crumb rubberandCoconutfiber.

3.2.1 Cement:

OrdinaryPortlandcement(Ultratechcement)of53grades confirming to IS: 12269-1987 was used. It was tested for its physical properties as per IS 4031 (part II)- 1988 and chemical properties as per IS: 12269. The details of the testresultsaregiveninTable3.1andTable3.2.

3.2.2 Fine Aggregate:

Locally available sand is used as fine aggregate in the presentinvestigation.Thesandisfreefromclayeymatter, salt and organic impurities. The sand is tested for various propertieslikespecificgravity,sieveanalysis,bulkdensity etc.,andinaccordancewithIS2386-1963.

3.2.3 Coarse Aggregate: Machinecrushedangulargranite of 20mm nominal size from the local source is used as coarse aggregate. It is free from impurities such as dust, clay particles and organic matter etc. The physical properties of coarse aggregate were investigated in accordance with IS 2386 -1963. The details of test results aregiveninTable3.5andTable3.6.

3.2.4 Water: Locally available water is used for mixing and curing which is potable and is free from injurious amounts of oils, acids, alkalis, salts, sugar, organic materials or other substances that may be deleterious to concreteorsteel.

3.2.5 Fly Ash: The fly ash obtained from a local fly ash brick manufacturing plant in Hyderabad,T elangana is usedinthepresentexperimentalwork.

3.2.6 Crumb Rubber: Crumb rubber used in the study was procured from a local workshop that recycles waste tyre rubber by grinding it mechanically to make crumb rubber. It is free from impurities such as dust, clay particlesandorganicmatteretc.

ThechemicalcompositionofFlyashisrichinsilica content which reacts with calcium hydroxide to form C-SHgel.Thisgel isresponsibleforthestrengthof mortar or concrete.

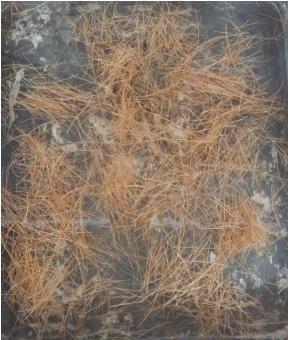

3.2.7 Coconut fibres: Coconut fibres were obtained from a local coir factory that extracts coir from coconut husks. Thecoconutfibreswerecleanedand choppedtomaintain auniformlengthof40mm.

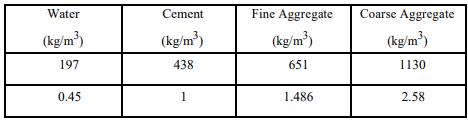

3.3 CONCRETE MIX DESIGN: The concrete mix of M30 grade was designed as per IS 10262-2009 using the properties of cement and aggregate. For each mix of Rubberized concrete, the concrete mix was modified by replacing the amount of sand to be replaced by crumb rubberforthemix

3.4 PREPARATION OF TEST SPECIMENS

3.4.1 Mixing: Mixing of ingredients is done manually. Thorough mixing by hand, using spades is adopted. Initially,OrdinaryPortlandCementandFlyashwasmixed thoroughly and then added to the mix of fine aggregate and coarse aggregate. Crumb rubber and river sand were weighedaccuratelyandmixedwellbeforemixingwiththe coarseaggregate.

3.4.2 Testing of fresh properties of concrete

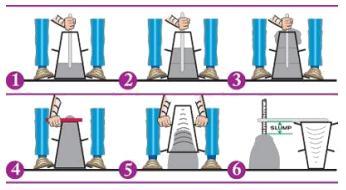

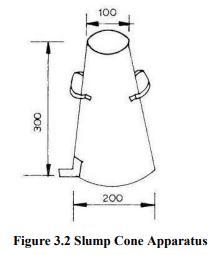

3.4.3 Slump Cone Test: Slump test is used to determine the workability of fresh concrete. Slump test as per IS 1199-1959 is followed. The apparatus used for doing slumptestareslumpconeandtampingrod.

Methodology: About 6 liter of concrete is needed to perform the test, sampled normally. The base plate and inside of mould is thoroughly cleaned and oiled. The base plate is placed on level stable ground and the slump cone centrally on the base plate and hold down firmly. The mould is then filled in four layers with freshly mixed concrete,eachapproximatelytoone-fourthoftheheightof themould.

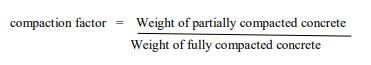

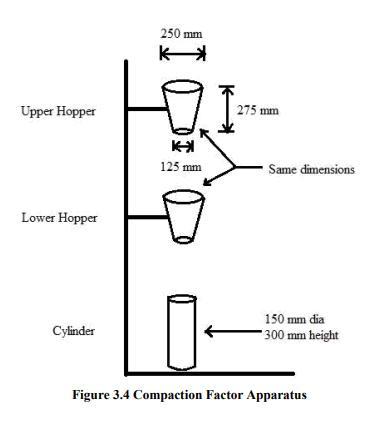

3.4.4 Compaction factor test: Compactionfactor offresh concrete is done to determine the workability of fresh concrete by compacting factor test as per IS 1199-1959. TheapparatususedisCompactionfactorapparatus.

Methodology: Both the hoppers and the cylinder of Compaction factor apparatus are cleaned thoroughly the oiledinside.

3.4.5 Testing of Specimens: Atimeschedulefortestingof specimens is maintained to ensure that proper testing on the due date and time. The cast specimens are tested as per standard procedures, immediately after they are removed from curing pond and wiped off the surface water.Thetestresultsaretabulatedcarefully.

3.4.6 Description of Compression Testing Machine: The Compression Testing Machine used for testing the cube specimens is of standard make. The capacity of the testing machine is 200 Tones or 2000 KN. The machine has a facility to control the rate of loading with a control valve. The machine has an ideal gauge on which the load appliedcanbereaddirectly

Methodology: The specimens are removed from the curing pond just before testing on the specified due date and time and cleaned to wipe off the surface water. The cubespecimenisplacedon thelowerplatensuchthatthe load is applied centrally on the faces other than top and bottomfacesofcasting.

3.4.7 Test arrangement for determination of Split Tensile Strength: Though concrete is not expected to resistdirecttension,thedeterminationofTensilestrength ofconcreteisnecessarytodeterminetheloadatwhichthe concrete member may crack, since cracking is a tensile failure.

Methodology: Both the hoppers and the cylinder of Compaction factor apparatus are cleaned thoroughly and oiledinside.Thetrapdoorsofboththehoppersareclosed and the cylinder is placed in position. The sample of concreteisplacedintheupperhopperuptothebrim.The trap door is opened so that the concrete falls into the lowerhopper.

3.4.5 Casting of Specimens: The cast iron Moulds are cleaned of dust particles and applied with oil on all sides before concrete are poured in the moulds. The mould of size 150mm x 150mm for cubes, 100mm x 100mm x 500mm for beam specimens, mould of diameter 150mm andheight300mmforthecylinderspecimens.

3.4.4 Curing of Specimens: Thespecimensareleft inthe mould is undisturbed at room temperature for about 24 hoursaftercasting.Thespecimensarethenremovedfrom the moulds and immediately transferred to the curing pondcontainingcleanandfreshwater.

Methodology: Before testing, diameter, length of specimen is determined to nearest 0.2mm. Center one of the plywood strips along the center of lower platen. The specimenisplacedontheplywoodstrip.

The appearance of concrete and any unusual features in the type of failure is carefully observed. Splitting strength ofspecimeniscomputedtonearestof0.05N/mm2.

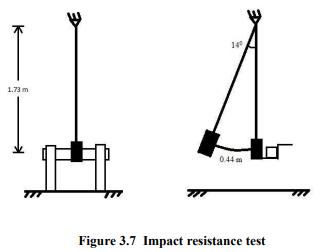

3.4.8 Test arrangement for determination of Impact

Resistance: TestforImpactResistancewascarriedouton plain concrete mix and optimum concrete mix. Three specimensofsize100mmx100mmx500mmwerecasted for each mix. These specimens were tested by Modified Chirpy Method. The length of the pendulum of Modified Chirpy apparatus is 1.65m and the striker is a steel cylinder of 15 kilograms attached to the end of the pendulum.

Methodology: The specimens are removed from the curing pond just before testing on the specified due date andtimeandcleanedtowipeoffthesurfacewater

3.8 COARSE AGGREGATE PROPERTIES: The crushed coarse aggregate of 20 mm maximum size angular obtained from the local crushing plant at Hyderabad is used in the present study. The physical properties of the coarse aggregate like specific gravity, bulk density, gradation and fineness modulus was found in accordance withIS2386.

3.9 TYPICAL OXIDE COMPOSITION OF FLY ASH: The following Table shown below gives the typical oxide composition of Fly ash which is used in the present investigation.

3.10 CRUMB RUBBER PROPERTIES: Crumb rubber is obtained from local tyre rubber recycling workshop. The physical properties like specific gravity, bulk density, gradation fineness modulus were determined in accordancewithIS2386.

3.11 WATER IMPORTANCE: This is the least expensive but most important ingredient in concrete. The water, which is used for making concrete, should be clean and freefromharmfulimpuritiessuchasoil,alkali,acidetc.In general, the water fit for drinking should be used for makingconcrete.

3.12 SUMMARY: In this chapter, the study of materials used,theirproperties,mixingproceduresoftheconcretes, the phases of experimental program and the procedures fortestingoffreshandhardenedconcreteswasdiscussed. The resultsof the experimental programdiscussedinthis chapteristabulatedandstudiedinthenextchapter.

4. CONCLUSIONS:

The workability of fresh binary blended concrete decreased with the increase in sand replacement withcrumbrubberandadditionofcoconutfibres.

3.5 TESTS CONDUCTE: Tests are carried for control mix (PlainConcrete),BinaryblendedCoconutfibreReinforced Concrete containing 20% Fly ash and with varying percentages of crumb rubber as sand replacement and varyingcoconutfibreasadditiontocementmix.

3.6 CEMENT PROPERTIES: In the present investigation, Ordinary Portland Cement of 53 Grade (Ultra Tech) is used. Care is taken that it is freshly produced and from a singleproducer.Thecementthenproducedwastestedfor physicalpropertiesinaccordancewithIS4031.

3.7 FINE AGGREGATE PROPERTIES: Fine aggregate is natural sandobtainedlocally.The physical propertieslike specific gravity, bulk density, gradation and fineness modulus were determined in accordance with IS 2386. Fineness modulus was found based on sieve analysis resultsforfineaggregate.Weightofthesampletakenwas 1000grams.

Replacement of river sand with crumb rubber ranging from 0% to 20% decreases the compressivestrengthofconcrete.

Split Tensile strength of concrete mix also decreases with increase in replacement of sand withcrumbrubber.

The impact resistance of optimum mix is 21% morethethatofplainconcreteforfirstcrackand 24%forfailure.

The compressive strength and split tensile strengthforallthefibrereinforcedmixesincrease upto 0.2%addition of coconut fibres and decreasedthereafter.

5. REFERENCES

Piti Sukontasukkul (2008), “Use of crumb rubber to improve thermal and sound properties of precast concrete panel”, Construction and Building Materials23(2009)1084-1092.

Piti Sukontasukkul and somyot Wiwatpattanapon (2009), “Moderate Lightweight Concrete Mixed Recycled Crumb Rubber”, Thammasat Int. J. Sc. Tech.,Volume14,No.1,January-March2009.

Yogender Antil, Er. Vivek Verma, Er, Bhupinder Singh (2012), “Rubberized Concrete Made with Crumb Rubber”, International Journal of Science andResearch,ISSN(Online):2319-7064.

Noor Md. Sadiqul Hasan, Habibur Rahman Sobuz, Md. Shiblee Sayed and Md. Saiful Islam (2012), “The Use of Coconut Fibre in the Production of Structural Lightweight Concrete”, Journal of AppliedSciences12(9):831-839,2012.

Pravin V Domke (2012), “Improvement In The Strength Of Concrete By Using Industrial And Agricultural Waste”, IOSR Journal of Engineering, Volume2(4)pp:755-759,April2012.

Olonade, Kolawole Adisa, Alake, Adewae Doyinsala and Morakinyo, Abiola Gabriel (2013), “Strength development and crack pattern of coconut fibre reinforced concrete (CFRC)”, Civil and Environmental Research, Volume 4, 2013, Special Issue for International Congress on Materials & Structural Stability, Rabat, Morocco, 27-30November2013.

Parveen, Sachin Dass, Ankit Sharma (2013), “Rubberized Concrete: Needs of Good Environment (Overview)”, International Journal of Emerging Technology and Advanced Engineering,Volume3,Issue3,March2013.

J. Sahaya Ruben, Dr. G. Baskar (2014), “Experimental Study of Coir Fiber as Concrete Reinforcement Material in Cement Based Composites”,International Journal of Engineering Research and Applications, Volume 4, Issue 1 (Version3),pp.128-131,January2014.52

S. Selvakumar, R. Venkatakrishnaiah (2015), “Strength Properties of Concrete Using Crumb Rubber with Partial Replacement of Fine Aggregate”, International Journal of Innovative ResearchinScience,EngineeringandTechnology, Volume4,Issue3,March2015.

Bhupendra Kumar, Dr. S S Kuswah, Dr. Amit Viswakarma (2015), “Effect of Coconut Fiber and

Fly Ash on Concrete”, International Journal of Science Technology & Engineering, Volume 2, Issue3,September2015.

IS 12269-1987 “Specifications for 53 Grade Ordinary Portland Cement”, Bureau of Indian Standards, New Delhi. 12. IS 2386-1963 “Method of Test for Aggregate for Concrete”, Bureau of IndianStandards,NewDelhi.

IS 456-2000 “Code of Practice for Plain and ReinforcedConcrete”,BureauofIndianStandards NewDelhi.

IS 516-1959 “Method of Tests for Strength of Concrete”,BureauofIndianStandards,NewDelhi.

15. IS 383-1970 “Specifications for Coarse and Fine Aggregate from Natural Source of concrete”, BureauofIndianStandardsNewDelhi

IS 10262-1982 “Recommended Guidelines for ConcreteMixDesign”,BureauofIndianStandards, NewDelhi.

UNDER THE GUIDENCE OF: ABHIRAM SIR, FACULTY OF HITSCOLLEGE

P. LAXMI PRASHANTH (21C91D8722), R. ABHILASH (21C91D8716), M. Tech (Highway Engineering), Civil Engineering Department.

HOLYMARI INSTITUTE OF TECHNOLOGY AND SCIENCE