SELF CURING CONCRETE

1Assistant professor, Department of Civil Engineering, Gayatri Vidya Parishad College for Degree and PG Courses(A), Rushikonda, Visakhapatnam, Andhra Pradesh, India.

2,3,4,5,6 B.Tech, Department of Civil Engineering, Gayatri Vidya Parishad College for Degree and PG Courses(A), Rushikonda, Visakhapatnam, Andhra Pradesh, India. ***

Abstract –Inthepresentworld conservation of water is one of the mainchallengefor humankind. The construction industry consumes a global average of 30%of fresh water. Inorder to reduce the water usage, Self-curing agents are being utilized in response tothe current water scarcity crisis affecting the construction sector. This research explores the effects of using Spinaciaoleracea as a self-curing agent in concrete to meet this challenge. Dosages of 0.2%,0.4%,0.6% and 0.8% (by weight of cement) of selfcuring agent is being added to concreteand the cubes casted using selfcuring concrete is comparedwith regular-cured concrete. The specimens were cured for different periods (3,7, 28 and 56 days). Our goal was to analyze the behavior (compressive strength and flexuralstrength) of the produced concrete.

Key Words: Self-curingconcrete,Regular-curedconcrete,Spinaciaoleracea,Compressivestrength,Flexuralstrength.

1. INTRODUCTION

Self-curingconcreteisamaterialwiththeuniqueabilitytoreducewaterlossandincreasethecapacityofconcretetoheal itself. The use of self-curing agents in concrete is becoming more popular due to the numerous advantages it has over traditionalcuringmethods.Self-curingagentscanbeaddedtothemixduringbatchingorappliedaftercastingasasurface treatment. Self-curing agents work by releasing internal water, which helps maintain a moist environment for hydration and reduces shrinkage cracks. The purpose of this project report is to look into the properties and applications of selfcuring concrete, specifically its strength. The report will also compare the compressive strength and flexural strength of self-curingconcretetothatofconventionalcuringmethods.

2. LITERATURE REVIEW

Malathy et al (2017) Conducted experimental work on the new and hardened properties of organic selfcuring concrete with30%flyashaspartofa cementsubstitute.Inthiswork mostlyfocusesonthe actionofinternallycuredconcreteof M20,M30andM40byutilizingnaturallyavailablevegetativematerialslikeSpinaciaoleracea(SP),Calatropisgigantean(CG) andchemical admixturelike polyethyleneglycol(PEG)at0.6%,0.24%and0.3%(byweightofcement)respectively.Selfcuringconcretewiththeseidealvalueshadastrengthactivityindexmorethan1at28daysandgot1.15at58thisisdue to pozzolonic action of fly powder at later ages. This study concentrates on the study of concrete performance in aggressiveenvironments,andallsuchtestshavebeenpositivecomparedtostandardconcrete.Fromthepointofviewof durability,theweightlossis15%,10%and5%lessthanregularconcreteforidealvaluesofSP,PEGandCGrespectively. Thereasonbehindthisisthatthecube'sporestructureistightanddoesnotenableadditionalacidintake.Finally,itwas concludedthatthevegetativematerialsaddedalongwithpolyethyleneglycolasself-curingagentsexecutegoodstrength, workability and durability characteristics in fly ash mixed concrete, and also these synthetic materials are used in pavements,RCCrelatedworks,overheadtanksandpre-stressedconcretestructurestoaccomplishlongtermstrengthand highperformance

Vaisakh et al(2018) The primary goal of this research was examine the various properties of M50 grade self- curing concrete by using poly ethylene glycol(PEG-400) as internal curing agent. The impact of PEG content on quality pointers like compressive, split tensile and elasticity modulus and durability markers like electrical resistivity, water sorptivity, chloridepermeability,andwatersorptivitywereconcentratedbydifferingpercentageofPEG400from0to2%with0.5% ofspan.AsthePEGcontentincreased,thereisanincreasingtrendinthemechanicalpropertiesduetohydrationreaching its completeness up to a PEG content of 1.5 %. In terms of compressive, tensile and elasticity modulus, the specimens exhibited less strength beyond 1.5 %. Moreover, with increasing PEG content to 1.5 %, water absorption decreases and then increases. Watersorptivityand permeabilitytothe chloridealsoshow similar trends.Concrete resistivityincreases withPEGcontentincreaseto1.5%anddecreaseswithfurtherPEGincrease.

Daud Mohamad et al (2017) This paper exhibits the impact of using baby diapers polymer as an internal curing admixtureinselfcuringconcrete.Inthisprocess,babydiaperpowderwasusedindifferentproportions(1%,2%,3%,5 %and10%)ofcementweight.Varioustestsarecarriedoutusing100mm*100mm*100mmcubemouldsonthenewand solidifying characteristics of concrete. Hardened concrete characteristics are performed at room temperature at 3, 7, 28 and 90 days of air curing. With expanding the level of infant diapers flowability of concrete is expanded got maximum slump at 10%. Eventually it is found that at 1% diaper polymer concrete got optimum values in terms of compressive strength.Duetothepolymerinsidetheconcrete,theconcretethathasahigherpercentageofpolymershadabsorbedlarge amountsofwatercomparedwiththefewerpolymers.

Chaitanya et al (2019)Astudyisbeingconductedtoreportontheuseofpre-saturatedlightweightaggregates(LECA)to resistself-desiccationandautogenousshrinkage.Inthisstudy,thepropertiesofconcretewithM30gradeareinvestigated using various dosages of LECA (0%, 10%, 15%, and 20% by volume) as a selfcuring agent for water retention. They are primarily concerned with compressive, split, and flexure qualities and are unconcerned with fresh and durability attributes. Finally, the study indicated that the consolidated properties of concrete are increased by up to 15% of LECA. The compressive, split tensile, and flexure strengths are increased by 1.67%, 1.29%, and 2.47%, respectively, at 15% LECA.

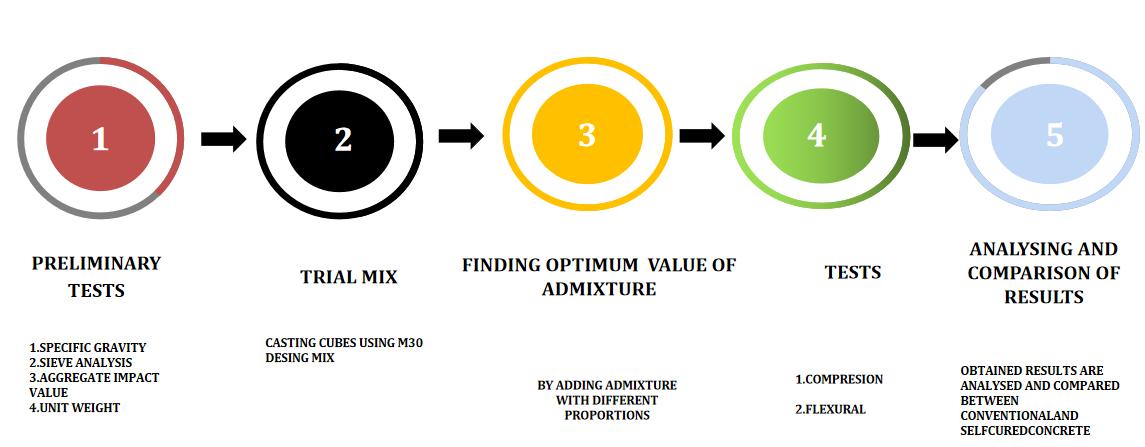

3. EXPERIMENTAL PROGRAM

3.1 Materials

Throughout the investigation, ordinary Portland cement OPC 53 Grade conforming to IS: 12269 was used. Concrete was preparedusinglocallyavailablebluegranitemetal.Weusedlocallyavailablehardbluegranitemetal,wellgraded20mmand downsize.Asfineaggregates,riversandpassedthrougha4.75mmsieveaccordingtoIS383specificationsandconfirmedto zoneII.

Table -1: Preliminary tests

Preliminary tests

3.2 Self-Curing Agents

When compared to conventional concrete, concrete with a curing agent produced better results with Spinacia oleracea, curing agent was used in different concrete mix proportions with varying amounts of curing agent and compressive strength was tested. Polyethylene glycol is a commerciallyavailable curing agent with a molecular weight of 190 to 210. Thespecificgravityrangesbetween1.12-1.13.Thehydroxylvaluerangesfrom535to590(mgKOH/g),andthepHranges from 5 to 7.Spinaciaoleracea, also known as Palak, is a type of green that is widely consumed as a food product. After thoroughlygrindingthefiltrateextractofSpinaciaoleraceaasshowninthefig-1,acuringagentwasprepared.IthasapH of 6.59. This extract base is added during the concrete preparation process, when water is added to the dry ingredients. Fresh concrete is placed and compacted in the same way standard concrete, but without curing.The chemical structure reveals the presence of (-O-) and (-OH) functional groups. As a result, the Spinacia oleracea used as an internal curing agenthashydroxylandetherfunctionalgroups,asevidencedbyFourierTransformInfrared(FTIR)results.

3.3 Proportioning of the Mix

ThemixdesignforconcreteM30gradeisbasedontheIS10262:2019code.Thedosageofcuringagentswasoptimizedand found to be 0.6% by weight of cement, with strength studies showing promising results.As a result, those proportions wereusedtocreateconcretesamplesforstrengthtesting.

3.3.1 Mix DesignProcedure

Theconcretemixdesignisaprocessofselectingthesuitableingredientsofconcreteanddeterminingtheirmostoptimum proportion which would produce, as economically as possible, concrete that satisfies a certain compressive strength and desiredworkability.

[1] Stipulations for proportioning:

a)Gradedesignation :M30

b)Typeofcement :OPC53gradeconfirmingtoIS12269

c)Exposurecondition :Moderate

d)Maximumnominalsizeofaggregate :20mm

e)Cementcontent :380Kg/m3

f)Watercementratio :0.45

g)Workability :25mmto50mm(slump)

h)Methodofconcreteplacing :Normal

i)DegreeofSupervision :Good

j)Typeofaggregate :Crushedangularaggregate

[2] Test data for materials:

a)Cementused :OPC53gradeconfirmingtoIS12269

b)Specificgravityofcement :3.15

c)Specificgravityofcoarseaggregate

i.For20mm :2.74

d)Specificgravityoffineaggregate :2.65

FineaggregateconfirmingtogradingZone-IIoftable4ofIS383

[3] Target strength for mix proportioning:

f1ck=fck+1.65S

Where,

f1ck =targetmeanstrengthat28days

fck=characteristiccompressivestrengthat28days

S =standarddeviation

Fromtable1ofIS10262-2019,standarddeviation(s)=5.0N/mm2

f1ck =30+1.65(5)=38.25N/mm2

[4] Selection of water cement ratio:

Fromtable5ofIS456,maximumwatercementratio=0.45forverysevereexposurecondition

[5] Selection of cement content:

Fromtable5ofIS456,MinimumcementcontentforM30gradeconcrete=320Kg/m3 .

380Kg/m3>320Kg/m3 , HenceOK.

[6] Selection of water content:

Fromtable2ofIS10262:2019,Maximumwatercontentfor20mmaggregate=186litres.

Watercontent=0.45xcementcontent =0.45x380 =171litres.<186litres HenceOK.

[7] Proportion of volume of coarse aggregate and fine aggregate:

From table 3 of IS 10262:2009, volume of coarse aggregate corresponding to 20mm size aggregate and fine aggregate (ZoneII)forwater-cementratioof0.5=0.62.

Inthepresentcasewater-cementratiois0.45.

Hence from IS 10262:2009 we can find the volume of coarse aggregate corresponding to 20mm size aggregate and fine aggregate(ZoneII)forwater-cementratioof0.45as0.63

Volumeofcoarseaggregateforwater-cementratioof0.45=0.63

Volumeoffineaggregate=1-0.63=0.37

[8] Mix Calculations:

Volumeofconcrete =1m3

d)Volumeofallinaggregate(d)=1-(0.120+0.17)=0.71m

e)Massofcoarseaggregate =d×volumeofcoarseaggregate×specificgravityofcoarseaggregate×1000 =0.71×0.63×2.74×1000=122560Kg

f)Massoffineaggregate

=d×volumeoffineaggregate×specificgravityoffineaggregate×1000 =0.71×0.37×2.65×1000 =696.155Kg

[9] Mix proportions:

a)Cement =380Kg/m3

b)Water =171Litres

c)Fineaggregate =696.155Kg/m

d)Coarseaggregate =1225.60Kg/m

MixProportions is Water:cement:fineaggregate:coarseaggregate

5. RESULTS AND DISCUSSIONS

5.1 Optimum Dosage of Bio Admixture

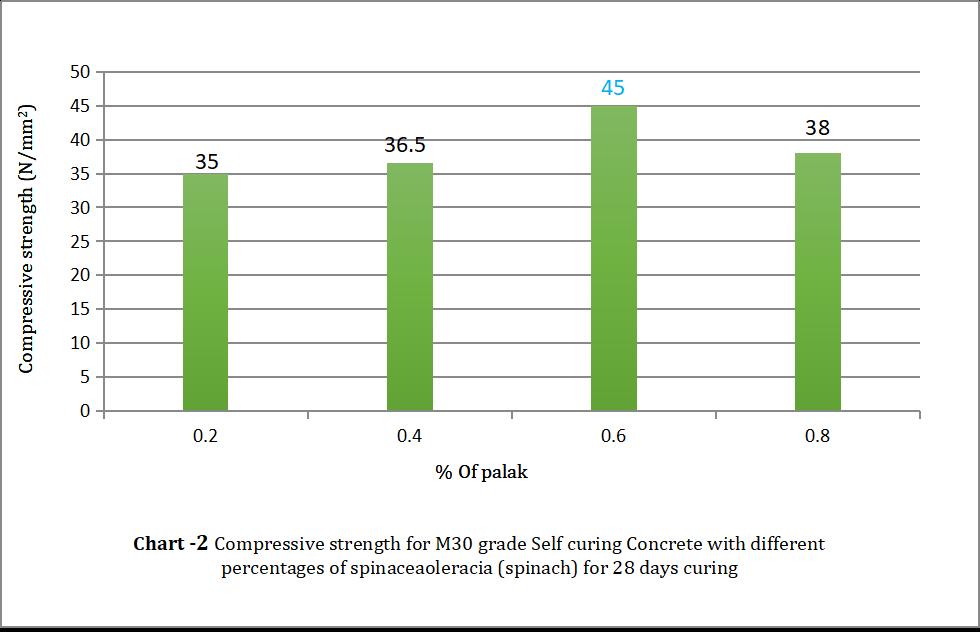

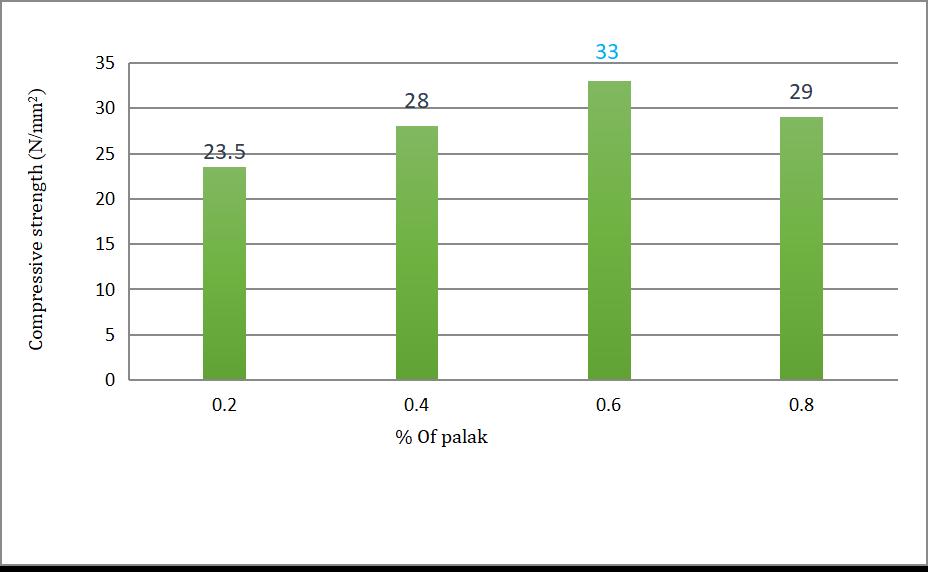

Thecompressivestrengthofconcreteimprovedwiththeriseofadmixtureupto0.6%ofAdmixture(toweightofcement), andanyadditionalincreaseinadmixturecontentloweredthestrengthofconcrete,sotheidealpercentageof admixtureis 0.6%.

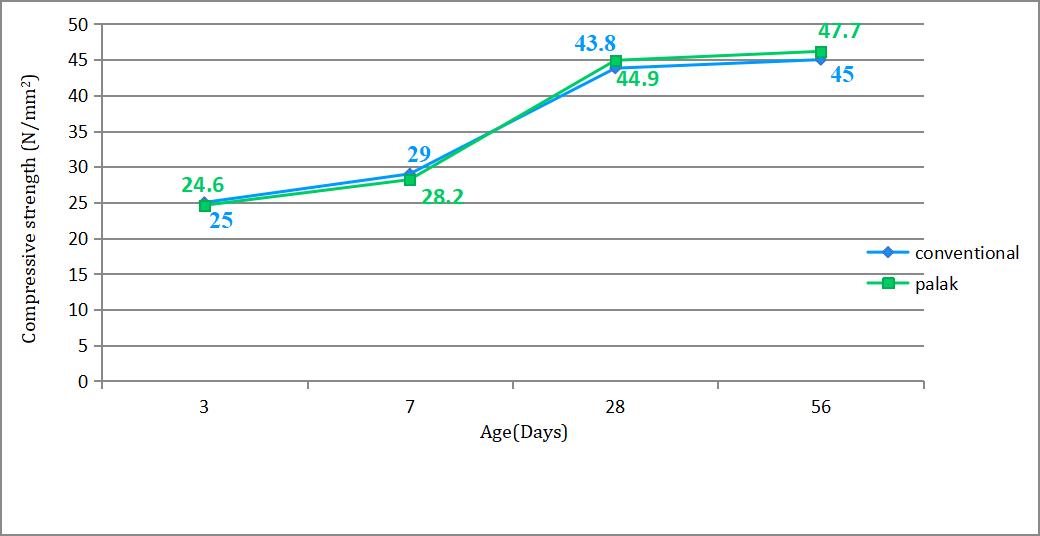

5.2 Compressive Strength

It is observed that selfcuring concrete attaining higher compressivestrength after28days of curing, when compared toconventionalcuredconcrete.

Itisobservedthatinselfcuringconcretethereisanincreaseof1.1%and2.7%ofcompressivestrengthat28and56days ofselfcuring,whencomparedtoconventionalconcrete.

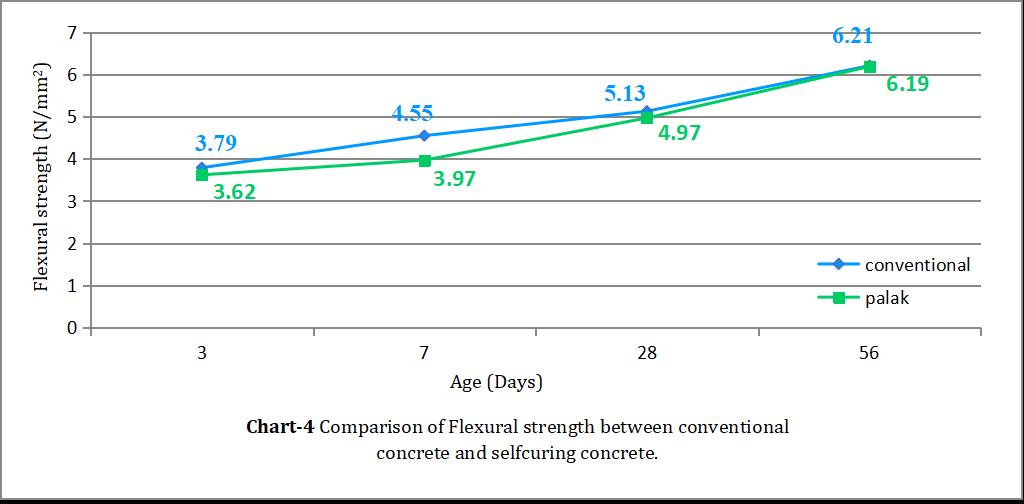

5.3 Flexural Strength

ItisobservedthatselfcuringconcreteattaininglowerFlexuralstrength,whencomparedtoconventionalcuredconcrete. Itisobservedthatinselfcuringconcretethereisadecreaseof0.17%,0.58%,0.16%,and0.02%ofFlexuralstrengthat3, 7,28and56daysofselfcuring,whencomparedtoconventionalconcrete

6. CONCLUSION

[1]TheoptimumpercentageofspinaciaoleraceaformaximumcompressivestrengthofM30gradeselfcuringconcreteis 0.6%byweightofcement.

[2] When compared to conventional cured concrete, selfcuring concrete achieves higher compressive strength after 28 daysofcuring.

[3]Itisconcludedthatself-curingconcretehaslowerflexuralstrengththanconventionallycuredconcretebuttheflexural strength of selfcuring concrete is greater than design flexural strength of rigid pavements as per IS:456 which is 4.33 N/mm2 forM30gradeconcrete.

[4]Thesebiomaterialsarebothcosteffectiveandenvironmentallyfriendly ,theycanbeusedinconcreteroadpavements withouttheneedforadditionalwatercuringmaintenanceandinareaswherewaterisscarce.

7. REFERENCES

[1] M.Geetha and Dr.R.Malathy (2017) “Strength Development Of Self Curing Concrete With Respect To Age Using Bio MaterialsAsAdmixtures”,IndianConcreteInstitute,JOURNAL,Vol17,January-March2017,No.4

[2] M.Geetha and Dr.R.Malathy “Strength And Durability Properties Of Different Grade Concrete By Using Polymeric Materials AsSelfCuringAgents”,JournalOfInternationalScienceAndTechnology,ISSN:0975-5462,Vol3,Issue1.

[3] M. ManojKumar and D.Maruthachalam (2013) “Experimental Investigation on Self-curing Concrete”, International JournalofAdvancedScientificandTechnicalResearch,Issue3volume2,March-April2013,ISSN2249-9954.

[4]El-Dieb“Self-curingconcrete”Waterretention,hydrationandmoisturetransport“ConstructionandBuildingMaterials” 21pp.1282-1287,2007

[5] M.S.Shetty“CONTRETETECHNOLOGY”,3rdEdition,S.Chand&CompanyLimited,Delhi,1992

8. BIOGRAPHIES

P.Pallavi AssistantProfessor, DepartmentofCivilEngineering

Gayatri Vidya Parishad For Degree And P.G Courses (A), Rushikonda, Visakhapatnam,A.P,India

CH.Rakesh

B.Tech

DepartmentofCivilEngineering

Gayatri Vidya Parishad For Degree And P.G Courses (A), Rushikonda, Visakhapatnam,A.P,India.

G.RaviTeja

B.Tech

DepartmentofCivilEngineering

Gayatri Vidya Parishad For Degree And P.G Courses (A), Rushikonda, Visakhapatnam,A.P,India

K.SaranTeja

B.Tech

DepartmentofCivilEngineering

Gayatri Vidya Parishad For Degree And P.G Courses (A), Rushikonda, Visakhapatnam,A.P,India

B.MohanVineethKrishna

B.Tech

DepartmentofCivilEngineering

Gayatri Vidya Parishad For Degree And P.G Courses (A), Rushikonda, Visakhapatnam,A.P,India

S.Venkatesh

B.Tech

DepartmentofCivilEngineering

Gayatri Vidya Parishad For Degree And P.G Courses (A), Rushikonda, Visakhapatnam,A.P,India