International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 03 | Mar 2023 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 03 | Mar 2023 www.irjet.net p-ISSN:2395-0072

Abstract:

The most adaptable building material is concrete, which is created by combining cement, sand, and aggregate with water. After water, concrete is the material that is utilised the most globally. Concrete has a high fire resistance and durability. Yet, the design of the mix, the curing procedure, and the calibre of the materials employed all affect the quality and strength of the concrete. There are now many different kinds of high-strength materials available, including high-strength concrete, thanks to the development of new technologies and materials. The compressive strength of high-strength concrete is claimed to be much higher than that of regular concrete.

This study is mainly focused on the strength properties as well as the durability properties of silica fume based High strength concrete. In this study, SF is kept at a replacement level of 15% in the manufacture of HSC for three different mixes i.e. M60, M70 and M80. In this study, the strength properties viz., compressive strength of HSC was determined at an age of 7, 14 and 28 days of curing and the durability properties viz., Sorpitivity test were studied at 7, 14 and 28 days of curing.

Keywords: HighStrengthConcrete, Silicafume,Durabilityproperties,Sorpitivitytest

1) Introduction:

In place of normal concrete, high-strength concrete (HSC) is increasingly being employed in a numberofbuildingapplications[1] Thisisbecausetothe unique characteristics of HSC, such as its high compressive strength, improved durability, and reduced permeability.HSCwascreatedbytheuseofcutting-edge ingredients and procedures such as silica fume, fly ash, and superplasticizers, which increase the mechanical properties and durability of the concrete [2]. One benefit ofemployingHSCinsteadofordinaryconcreteistheuse of smaller cross-sections, which results in less material being utilised and cheaper prices. Moreover, the use of HSCmayresultinstructuralcomponentsthatarelighter and thinner, thereby increasing architectural expression anddesignflexibility [3]

In this instance, HSC has been used in place of regular concrete to replace the pozzolanic components. Silicafume,aby-productofthemanufactureofsiliconor ferro silicon, is the primary pozzolanic material used in this experiment [4]. Replacement of silica fume is kept at 15 For the successful and economical use of pozzolanic materials, the relationship between pozzolanic material and cement must be studied [5]. A construction made of concrete should be capable of housing humans for an extendedperiodoftimewithoutsacrificingthe

material's intrinsic properties [6]. Durability is the longterm need that tenants place on the structure [7]. The strengthanddurabilitytraits,specifically,Sorpitivity,are thesubjectofthecurrentinvestigation.

This investigation relates mainly to the production of high strength concrete (HSC) using SF (Silica Fume). In this study, the replacement level of SF kept at 15%. Based on the context of this project, the researchcomprisedthefollowingstages:

To develop a mixture proportioning process to manufacture High strength concrete replacing PortlandcementwithSilicafume(Microsilica).

To study compressive strength of SF based HSC after7,14and28daysofcuring.

To study the absorption rate of water (Sorpitivity test) by HSC after 7,14 and 28 days ofcuring.

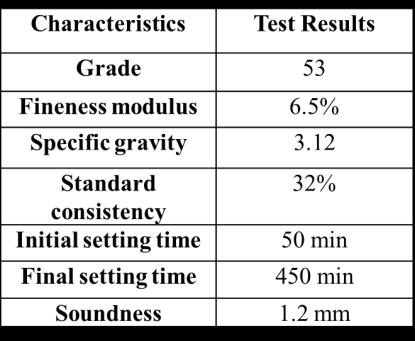

2.1 Cement:

ULTRATECH-53 grade ordinary Portland cement conformingtoIS:12269-2015wasusedinthisstudyfor

themanufactureofconcrete. Thephysical andchemical properties of OPC 53 grade are shown in table 1 and its specificgravityisnotedtobe3.15.

Mixing:Mixingaspermixdesign,thesilicafume is added at a percentage of 15% by replacing cement with silica fume for three different grades of concrete viz., M60, M70, and M80 gradesofconcrete.

Casting: For this research work, we proceeded with the casting of 36 cubes of size 100mm * 100mm*100mmand36cylindersofsize50mm * 100mm. These specimens are undergone various tests such as compressive strength and durabilitytestsnamelytheSorpitivitytest.

In this study, natural river sand was used as fine aggregate. The bulk specific gravity in oven-dry condition and water absorption of the sand is observed as 2.6 and 1% respectively. The Fineness modulus of sandisobservedas2.69

In this study, we used natural aggregates of crushed stone of size 10mm as coarse aggregates. The bulk specific gravity in over dry conditions and water absorption of the coarse aggregates of 10mm size are observedas2.6and0.3%respectively.

Thepozzolanicmaterialusedinthisstudyissilicafume. Silica fume known as micro silica is one of the byproducts of the manufacture of silicon or ferrosilicon metal. It is an amorphous silicon dioxide. In this, the cementisreplacedbysilicafumeat15%.

Inthisstudy,superplasticizerweused Poly-carboxylate ether which is used to reduce the water content in the manufactureofhigh-strengthconcrete.Thisisoneofthe essentiallyutilizedsuperplasticizersinconcretecement.

One of the main components while manufacturing highstrength concrete. In this research, weused potable and drinking water for casting and curing purposes as per theIS456-2000coalprovisions.

Curing: After completion of the casting, the specimens are left for curing. The curing duration may be varied for different tests of specimens. For the compressive strength test and Sorpitivity test, the curing duration is for 7 days,14days,and28days.

Mix proportions:

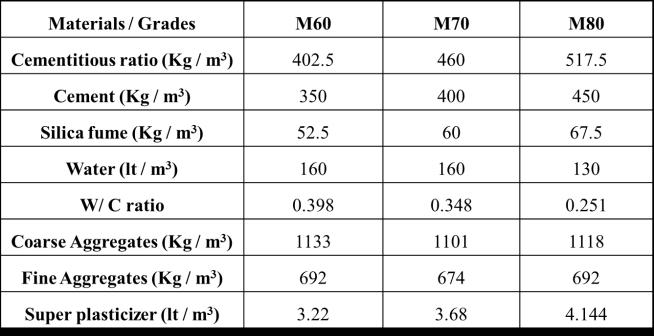

The main objective of this research work is to enhance the compressive strength and durability properties by adding blended materials such as silica fume. As per IS: 10262-2019guidelines,themixdesignisprepared.Here we used M60, M70, and M80 grade concrete shown in table 3, which shows the percentages of cement, fine aggregate, and coarse aggregate by 1:1.97:3.24, 1:1.53:2.48and1:1.685:2.75withwater/cementratioof 0.398,0.348and0.251eachrespectively.

4) Experimental setup:

Thecubesandcylindricalspecimenswerecured as designated above-mentioned conditions and tests were carried out as per IS: 516-1959 for the testing of strength,andIS1124(1974)fortheSorpitivitytest.

Thecubesofsize100mm* 100mm*100mmare testedunderthecompressiontesting machineasperIS: 516-1959 under saturated conditions by completely wrappingoutthemoisturecontentonthesurfaceperiod of 7 days, 14 days, and 28 days. The relation between cement and silica fume was done with a silica fume percentageof15%.

the rate of penetration of water into the concrete is calculated.

The Sorptivity rate is calculated by using the formula:

Sorpitivityrate,S= √

Where,S=Sorpitivityrate

=Changeinweights

A=Areaofthespecimen

=Densityofwater

t=timetakenforthelasttesting

The cylinders of size 100mm*50mm of grades M60,M70andM80arefirstlyovendriedaftercuringata surface period of 7 days, 14 days, and 28 days. Later these specimens are tested by applying epoxy resin to them as per the code IS 1124 (1974). Then these specimens’ weights are noted and then placed in the water for about thirty minutes after thirty minutes the specimens are removed from the water and then dried for30secondsandthenweighedandthetestisrepeated for about 6 to 8 trials where any two consecutive weights of specimens are equal. After obtaining the weightsofthespecimens,

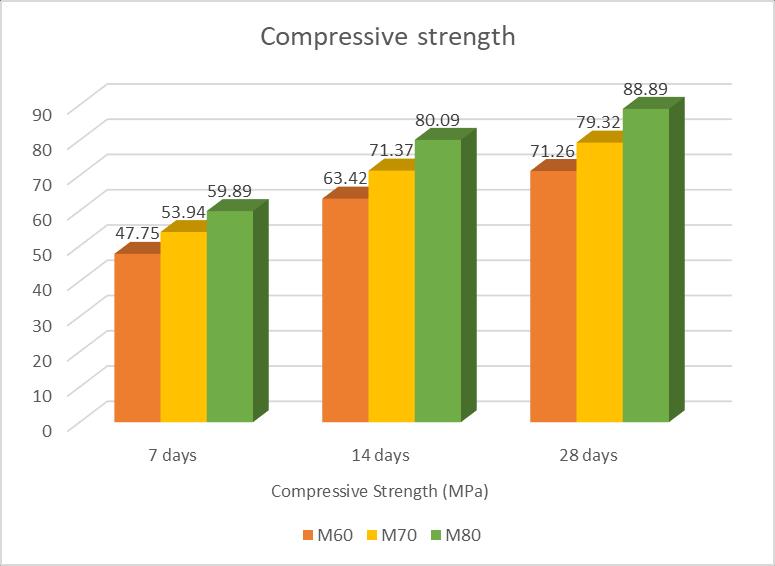

Thecompressivestrengthtestresultsareshown inchart1.ItisseenthatconcreteofgradeM60attained the minimum compressive strength values when compared to the other two mixes after 7 days, 14 days and 28 days of curing. The mixes of M70 and M80 have attained the maximum compressive strength values of

53.94 MPa and 59.89 MPa when compared to mixes of M60 (47.75 MPa) after 7 days of curing. The mixes of M70 and M80 have attained the maximum compressive strengthvaluesof71.37MPaand80.09MPawhen

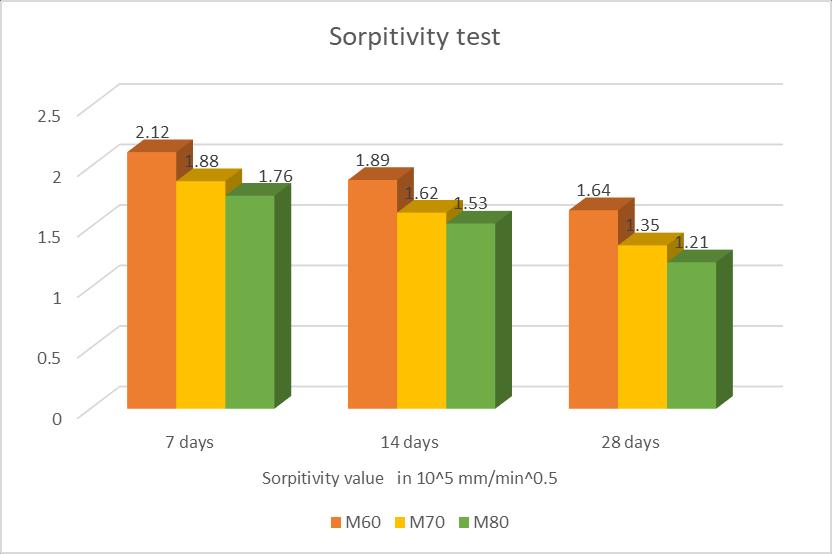

grade M60 has attained the maximum Sorpitivity value of1.89.ThemixesM70andM80attainedtheSorpitivity values 1.62 and 1.53 respectively which are less when compared to the mix M60 after 14 days of curing. Likewise, for the age of 28 days, the concrete mix of grade M60 has attained the maximum Sorpitivity value of1.64.ThemixesM70andM80attainedtheSorpitivity values 1.35 and 1.21 respectively which are less when comparedtothemixM60after28daysofcuring.

6) Conclusions:

Based on the test results, the following conclusions aredrawn:

Chart 1: Thecomparisonsofcompressivestrength valuesfordifferentgradesofconcreteatdifferentages.

compared to mixes of M60 (63.42 MPa) after 14 days of curing The mixes of M70 and M80 have attained the maximumcompressivestrengthvaluesof79.32MPaand 88.89MPawhencomparedtomixesofM60(71.26MPa) after28daysofcuring.

5.2

The Sorpitivity test results are shown in the chart 2.It isclearlyobservedthatconcrete mix of grade M80attainedthelessSorpitivity valueswhencompared tothoseoftheothertwomixesafter7,14and28daysof curing.

1. The increase in compressive strength has been observed in the mixes M60, M70 and M80 grades of concrete. It is clearly observed that as the grade of concrete is high then, the higher is thecompressivestrength.

2. As the age of curing increases, the compressive strengthalsoincreasesgradually.

3. As the grade of concrete increases, the Sorpitivityvaluedecreasesanditisseenthatas the curing period of concrete is increasing, the Sorpitivityvaluesaredecreasing.

7) References:

1. I.A.Sharaky,F.A.Megahed, M.H.Seleem, A.M.Badawy The infuence ofsilica fume, nano silica andmixing method onthestrength anddurabilityofconcrete.

2. Byung Wan Jo, Sumit Chakraborty, Seung-Tae Lee,andYunSungLee DurabilityStudyof Silica Fume-mortar exposed to the Combined Sulfate andChloride-richSolution.

3. Byung Wan Jo, Muhammad Ali Sikandar, Sumit Chakraborty, Zafar Baloch Investigation of the acid and sulfate resistance performances of hydrogen-richwater-basedmortars.

4. Riyadh A. I. Albattat, Zahra Jamshidzadeh, Ali AlasadiAssessmentofcompressivestrengthand durabilityofsilicafume-basedconcreteinacidic environment

The concrete mix of grade M60 has attained the maximumSorpitivityvalueof2.12after7daysofcuring. The mixes M70 and M80 attained the Sorpitivity values 1.88 and 1.76 respectively which are less when compared to the mix M60 after 7 days of curing. Likewise, for the age of 14 days, the concrete mix of

5. B. Krishna Kumari Bai and M. Kanta Rao the effect of fly ash, SF and its combinations on strengthanddurabilitypropertiesonHSC.