Strength Improvement in the Soil Using Waste Materials

Anchu Anil1 , Ms. Athira S Nair2

1PG Student, Dept. of Civil Engineering, Sarabhai institute of Science and Technology, Kerala, India

2Assistant Professor, Dept. of Civil Engineering, Sarabhai institute of Science and Technology, Kerala, India ***

Abstract - In construction industry ground improvement is an important factor, the stone column technique is one of the effective methods used for improving the soil parameters like consolidation and reduce the settlement. In this study, quarry waste which is a waste material from the quarry industry are used in constructing the column to improve the bearing capacity of the soil. The results obtained from model test are compared with aggregate as column. The geotextile uses this study, the ultimate load increasing and reduce the settlement. The stone column fully replacedby waste materials like quarry waste and the result compared byaggregate usingcolumns. In this study conducted by the model test arrangement. The natural materials like aggregate using in stone column is a comparative study of the waste material like quarry waste used in column. The aggregate result similar to the quarry waste. Then the quarry waste used for the columns in ground improvement.

Key Words: column, quarry waste, aggregate

1.INTRODUCTION

The rapid growth of population and infrastructure developments in construction industry has been very dynamic. Then the stone column techniques are the most effective method for improving the soil parameters like bearingcapacity.Stonedrainagebyimprovingstrengthand deformationpropertiesofthesoftsoil.Thecommonlyused material in stone column construction is crushed stone aggregate.Stonecolumnisusedinweakdepositstoincrease the load carrying capacity and reduce settlement of structural foundations. Stone column generally depends uponcircumferentialconfinementprovidedbynativesoilor theweakpeatdepositsovertheseveraldepositsbelowthe grounddeposits.Thelossorpoorgroundsurfaceconditions areresponsibleforthefailureunderfoundationssoitisvery important for ground surface that it should be treated by differentwayssoastoobtainthebetterresultandhelpsto improvethebettergroundsurfaceconditions.Ingeneral,the improvementofsoftclayusingstonecolumnsisduetothe followingpoints:

1.Theimplicationofastiffercolumnmaterial(suchasstone, gravel,etc.)insoftclay.

2. The densification of surrounding soft soil during the installationofthestonecolumn.

3. Thestonecolumnandgravelcolumnwillbeasdrainsand accelerate the drainage of water and accelerate consolidationprocessofsoftclay.

2. LITERATURE REVIEW

Theliteraturereviewsarelistedbelow:

Alexiew D et.al. (2005) conducted experiment is cylindrical test tank. The maximum load carrying capacitiesofstonecolumnwithdepthsof0.25L,0.5L are612.0N,663.2Nrespectivelyandcorresponding settlementis25mm.Theloadcarryingcapacityand stiffnessareincreasedbyusinglateralreinforcement ofcolumnusinggeo-textilecircularamountofload carrying capacity that was needed for each project Some additional tests were also conducted on columns covered by an ordinary gravel mattress reinforcedbygeotextile.Inaddition,stonecolumns withdiametersof63and92mmweretestedwitha length-to-diameterratioof5.

Jamal M et.al. (2014) iscarriedoutbytheusesto stonecolumntechniqueisconductedinsoftsoil.In thistechniquealwaysusedforisolatedfooting,large foundationandembankment.Granularanddrained materials are consolidation settlement can be primarily minimized. Being granular and freely drained material, consolidation settlement is accelerated and post construction settlement is minimized. Stone columns may have particular applicationinsoftsoilssuchasN.Cclay,siltandpeat, theyaregenerallyinsertedonvolumedisplacement basisexcavatingaholewithspecifieddiameterand desireddepth.

Golakiya H D & Lad M D (2015) iscarriedoutbythe usesofhighwayconstruction.Reinforcedearthwalls havebeensupportedoncohesivesoilshavingshear strengthsas200to400psf.Fortheseverysoftsoils, wall settlement has been on the order of 1 to 2 ft. Importantapplicationsofstonecolumnsalsoexistfor landslide stabilization and liquefaction problems involving bridge foundation and embankment support during earthquakes. The support of a Reinforcedearthretainingwallorabutmentonstone columns gives a very flexible, compatible type construction,capableofwithstandingrelativelylarge movements.

Hassan M I H et.al. (2017) is carried out by the physicalandmechanicalpropertiesofclaybrick.The percentage of quarry dust waste as a second raw material was 10% for obtained the best results in physicalandmechanicalproperties.Theresultsshow thedecreaseinthecompressivestrengthoffiredclay brick when the percentage of the waste increased. Furthermore,thedensitywasinthestandardrange (1879.2kg/m3).Asthebricksbecomemoreporousit will result tolightweight brick. The increase of the wastealsowill producehighsuctionbrick because the IRStestshowsitmore than1.5kg/m2.min.All the physical and mechanical properties were compliedwiththeBS3921:1985standard.

Dr. Rao H C & Prakash K S (2017) iscarriedoutby observedthatthestrengthcharacteristicsofquarry dustissameas sand. The specific gravityofall the crusher samples is lies in between 2 to 2.7 which fulfill the sand requirement. The sieve analysis is carried out for the collected quarry dust crusher sampleandsandwhichpossessthesandzone.From theexperimentalstudyitisconcludedthatthequarry dust can be used as a substitute for sand. It is identifiedthat40%replacementofsandbyquarry dust give good result in strength than normal concreteforM20andM30grade.Theresultspossess that 40% replacement of sand by the quarry dust induced higher compressive strength and the workability of concrete decreases as replacement increases.Thus,theenvironmentaleffectsandwaste canbesignificantlyreduced.

Castro J (2017) is carried out by a single stone column with three types of materials, including recycled crushed brick (CB), recycled crushed concrete(CC)andgravelasnaturalaggregateswas modeled.Theresultsoftherecycledaggregateindex tests demonstrated a poorer performance of these materialscomparedtothenaturalaggregate.Despite this,thebearingcapacityoftheclaybedreinforced withthefloatingcolumn,whichwasfilledwithCBor CC,wasapproximatelyfivetimesthebearingcapacity oftheunreinforcedclaybed.Moreover,theloading results showed that the floating stone columns constructedofatypeofaggregatedeliveredabetter performance in comparison with the columns constructed of a combination of several types of recycled aggregates together or a combination of naturalandrecycledaggregates.

Nazir R & Zukri A (2018) is carried out by the partialreplacementofcompressiblesoilwithmore competent and promising materials such as stone aggregate, sand, and other granular materials, presentsseveralbenefitsintheconstructionofstone columns. It also acts as reinforcing materials that

increase the overall strength and stiffness of soft soils.Untilnow,a numberofresearcheshavebeen accomplishedpertainingtostonecolumnbehaviour and performance with various materials used as columnfillers.Mostofthealternativematerialsused as stone column fillers or backfill materials can be producedfromwasteandrecycledmaterials.These materials have been established based on experiments, numerical analysis and physical modelling as conducted in a laboratory. Therefore, thefindingsneedtobefurtherverifiedinafull-scale environment, to develop design guidelines, specificationsandQAtesting,priortoimplementing any of these replacement materials to be conventionallyutilizedasstonecolumnfillers.Ifthis isfulfilled,thenthesematerialscouldofferexcellent and sustainable solutions by utilizing potential wastes effectively while reducing demands for primaryaggregates.Thesealternativematerialsfor stonecolumnfillersofferhighefficiencyapartfrom beingeconomical,asthematerialsarecheap,easily availableandenvironmentallyfriendly.

3. OBJECTIVES

Theobjectivesofthisprojectarelistedbelow:

• To study the settlement in soil using number of stone columns (1, 2) using stones placed at equal intervalsencasedwithoutgeotextile.

• To study the settlement in soil using number of stone columns (1, 2) using stones placed at equal intervalsencasedwithgeotextile.

• Todeterminethesettlementinsoilusingofnumber ofquarrywastecolumns(1,2)usingquarrywaste placedatequalintervalsencasedwithoutgeotextile.

• Todeterminethesettlementinsoilusingofnumber ofquarrywastecolumns(1,2)usingquarrywaste placedatequalintervalsencasedwithgeotextile.

4. SCOPE

Thescopesofthisprojectarelistedbelow:

• Thenumberofstonecolumnsvaryingtoinvestigate thisstudy.Forexample,7,8etc.columnsareused thisstudy.

• The spacing of the stone column varying to this study.

• Thepatternofthecolumnsplacedindifferentwise forthisstudy.

5. MATERIAL COLLECTION

5.1 SOIL

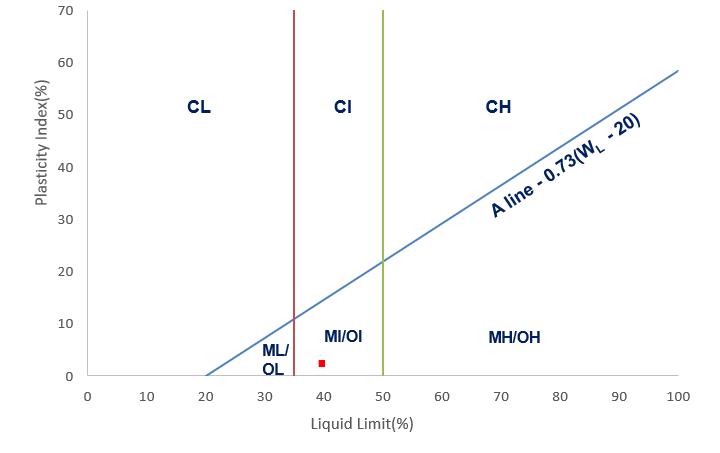

ThesoilfoundintheNeyyatinkara,Thiruvananthapuram regionfromthedepthupto1.5minsoillevel.Theliquidlimit is 39.50% and the plasticity index is 1.61 %. According to IndianStandardSoilClassificationSystem(ISSCS)basedon particlesizedistributionandtheplasticitycharacteristicsof thesoil,itisclassifiedastheOrganicSilt(MH).Thetable1 shows properties of soil. The figure 1 shows the plasticity chart.

5.3 QUARRY WASTE

Thequarrywasteisthebyproductofquarryindustry.Quarry waste consist of overburden, rock, or processed material, whichhasnoeconomic valueandisstoredtemporarilyor permanently at the extraction site. The table 3 shows the propertiesofquarrywaste.

5.2 AGGREGATE

Theaggregatewascollectedfromquarryindustry.TheStone column is generally constructed with the help of crushed aggregates,gravels,recycledaggregatesanddifferentsizesof aggregatessuchas20mmto70mmsizeofaggregatesusedin the formation of the stone column. The table 2 shows the propertiesofaggregate.

5.4 GEOTEXTILE

The geotextile are those fabrics used in geotechnical applications,suchasroadandrailwayembankments,earth dikesandcoastalprotectionstructures,designedtoperform one or more basic functions such as filtration, drainage, separationofsoillayers,reinforcementorstabilization.

6. RESULTS AND DISCUSSION

Inthispart,firstdataofloadingthecolumnmadeofdifferent materialscompared.Then,theoutputsoftheloadedcolumns, constructed of both natural and waste materials, are evaluatedandcomparedtogether.

6.1 Ultimate load

In thisstudy mainly focusedon two materials ultimate load.Thetwomaterialsultimateloadasgivenbelow.

6.1.1 Ultimate load from aggregate as column

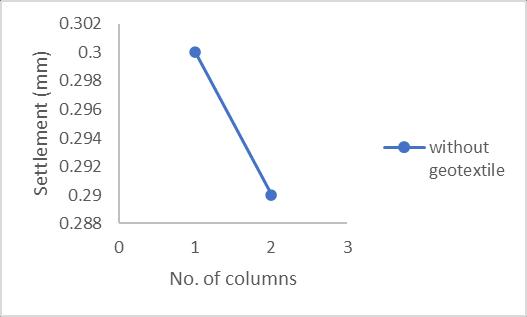

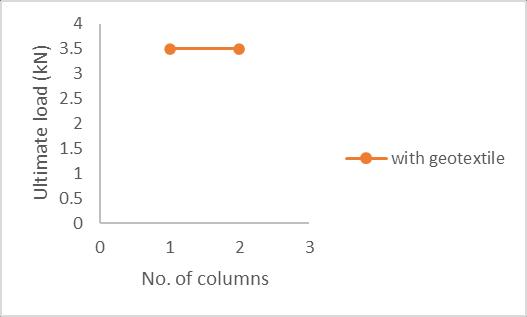

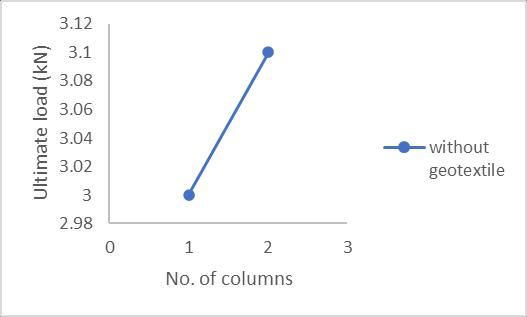

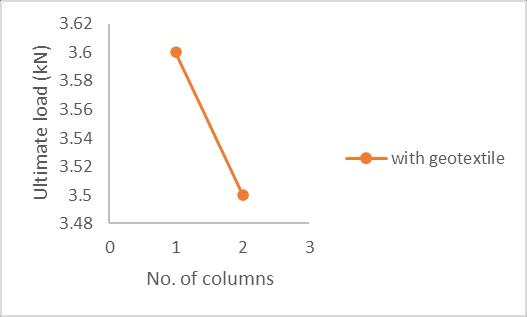

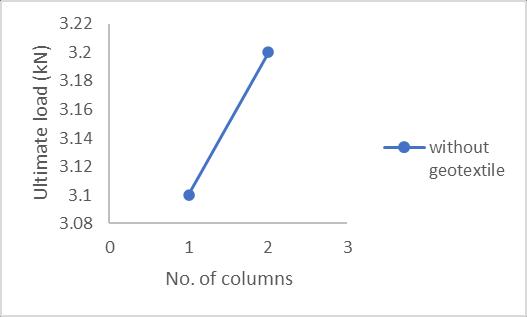

The below table 4 shows the ultimate load on aggregate usingwithandwithoutgeotextile.Inthisstudy,theultimate load for with geotextile is higher than that of without geotextile. The below figure 2 shows the ultimate load on withoutgeotextile.Thefigure3showstheultimateloadon withgeotextile.Usinggeotextile,theultimateloadincreasing andsettlementratereduced.

6.1.2

Thebelowtable5showstheultimateloadonquarrywaste using with and without geotextile. The figure 4 shows the ultimateloadonwithoutgeotextile.Andthefigure5shows theultimateloadonwithgeotextile.

In this study, mainly focused on two materials like aggregateandquarrywaste.

6.2.1

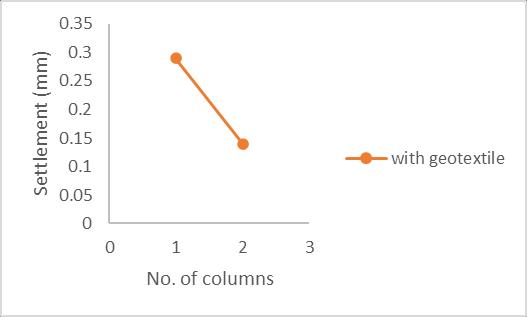

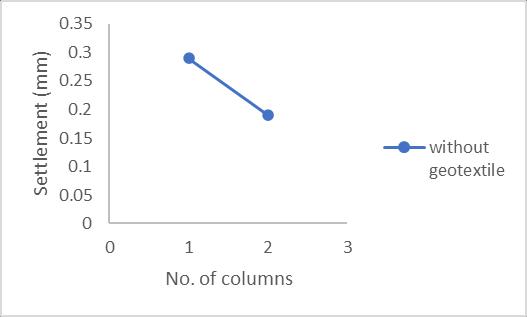

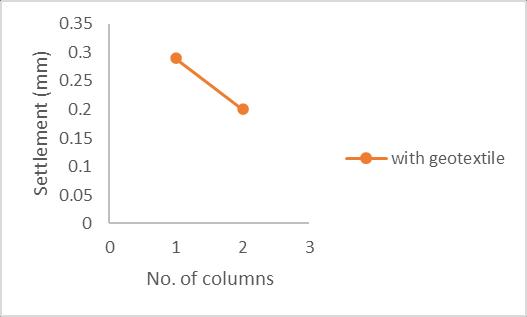

The table 6 shows the settlement on aggregate using with and without geotextile. The figure 6 shows the settlement without geotextile. The figure 7 shows the settlementwithgeotextile.

6.2.2 Settlement from quarry waste as column

Thetable7showsthesettlementonaggregateusing with andwithout geotextile. The figure8 shows the settlement withoutgeotextile.Thefigure9showsthesettlementwith geotextile.

Inultimateloadandsettlementgraphsclearlyknownthe number of columns increasing the corresponding load increasesandthecorrespondingsettlementratereeduces. Thecolumnsusedforthesoilstrengthcanbeincreases.The geotextileusedinthecolumns,thestrengthincreaseswith respect to the without geotextile. The geotextile used, the strengthimprovementinsoilanenobulgingeffect.

7. CONCLUSIONS

This chapter deals with the conclusion derived from the obtained results and discussion from this study. The soil improvement study for using stone column techniques as replacementofstonesinvariousmateriallikequarrywaste. Thesematerialsusinginsoiltodeterminethesettlementby test.Andtheresultswereobtainedandthecomparedalong thesematerials.Thesettlementratewasalsocomparedin everycase.Itisexpectedthatwiththeuseofwastematerial likequarrywasteinreplacementincolumntoimprovethe soilstrengthandtoreducethesettlementrate.

ACKNOWLEDGEMENT

It gives me a great pleasure to express my deep sense of gratitude to my guide Asst. Prof. Athira s Nair for her valuablesupportandencouragingtheproject.Oursincere thanks to Prof. R Jayachandran Nair, the Head of the Civil Engineering Department. We are also grateful to our Principal, Dr. Pavithran G and the college authorities for providingusthefacilitiesandexcellentamenities.

REFERENCES

[1] AbhishekVN,AnarghyaA,BulushiAlIandNayakNS (2018)“DevelopmentoflowcostsolardryerforOman conditions”, ResearchGate, Volume148,IssueG05

[2] Alexiew D, Brokemper D and Lothspeich S (2005) “Geotextile encased columns (GEC) load capacity, geotextile selection and pre design graphs”, International Research Journal of Engineering and Technology, Issue:05

[3] AuqbiST,MahamoodMRandSalimNM(2022),“The impact of different type of soft soil treated by stone columnoncreepbehavior”,IOPpublishing,Volume06.

[4] AyothiramanRandSoumya S(2018),“Modeltestson the use of tyre chips as aggregate in stone columns”, ResearchGate, Volume168,IssueGI3.

[5] AyothiramanR,MazumdarTandRolaniyaAK(2018), “Experimental study on bahaviour of encased stone column with tyre chipes as aggregate”, Journal of Geotechnical Engineering, ASCE, Volume 122(9), Issue 760-767.

[6] Bassioni, Gaafer, Hesham, Manar, Mastafa and Tareq (2015) “Soil improvement Techniques”, International Journal of Science and Engineering Research, Volume:6, Issue:12.

[7] DineshSandKirubakaranK(2019),”StabilizationofSoil byUseof WasteTyreRubber”, International Journal of Innovative Science, Engineering & Technology, and Volume:6,Issue:10.

[8] Dr. Rao H C and Prakash K S (2017) “Strength CharacteristicsofQuarryDustinReplacementofSand”, International Journal of Innovative Science, Engineering & Technology,andVolume:12,Issue:08.

[9] FattahMY,KolosovESand Kwa SF (2020),“Ground improvementusingstonecolumnconstructionencased with geogrid”,ResearchGate, Volume 10 (15),Page No. 15-24.

[10] Ganjian N, Kalantary F and Mehrannia N (2018) “Experimental study on soil improvement with stone columnsandgranularblankets” International Journalof Research in Advent Technology, Volume:07

[11] Golakiya H D and Lad M D (2015), “Ground improvement by using stone columns”, Journals of Engineering Technologies & Innovative Research, Volume:02,Issue11.

[12] Gopiprasath P, Lakshnimarayana V, Subathra P and SuriyaPA(2017),”StabilizationofSoftSoilUsingStone Column–TheReview”, ResearchGate,Volume:8.

[13] Haddad A and Shahverdi M (2019), “Evaluation of Recycled Materials as Aggregate of End Bearing and FloatingStoneColumns:aComparativeStudy”, Journal of Rehabilitation in Civil Engineering Volume 9-3,Issue 61-74.

[14] HasanS,SalimNMandSoudanyKA(2020),”Effectof replacing crushed stone in stone columns by waste material on soil improvement ratio”, ResearchGate, Volume:09.

[15] Hassan M I T, Ismail N, Kadir A A, Rahim A S A and SaraniNA(2017)“PhysicalandMechanicalProperties of Quarry Dust Waste Incorporated Into Fired Clay Brick” ScienceDirect Volume:18,Issue04.

[16] Jain P K, Kumar R and Soni S K (2019),”Settlement behaviourofsoftclaybedreinforcedwithstonecolumn undersustatinableloading”,ResearchGate,Volume:9, Issue:2.