Review Paper on Experimental Investigation of Permeable Fins

Viraj K. Warang1 , Bhalchandra S. Parkar2 , Shriram A. Sawant3 , Prasad P. Adivrekar4 , Aniket S. Pendse51,2,3,4U.G. Students, Dept. Of Mechanical Engineering, S.S.P.M’s College of Engineering, Mumbai University, Maharashtra, India 5Professor, Dept. of Mechanical Engineering, S.S.P.M' s College of Engineering, Mumbai University, Maharashtra, India

***

Abstract – The primary objective of this study is to quantify and compare the convective heat transfer improvement of perforated fin assemblies with different fin spacing, perforation angle, perforation diameter, perforation spacing, and heater input. The variables for this natural convection cooling with fin surfaces are orientation and geometry. In this study, steady-state heat transfer from solid and perforated fin assemblies is measured. In this study, we specify an optimized fin configuration for various fin shape parameters and their impact on heat transfer results. The results obtained are in good agreement, showing similar trends and good agreement for heat transfer under natural convection. From all the results it can be concluded that the heat transfer coefficient of the fin with the maximum number of perforations and the perforations in the middle of the fin gives the best results. A rib arrangement with triangular perforations with a 90 degree slope is best suited for horizontal rectangular rib arrangement for natural conventions, followed by circular, rectangular, and non-perforated ribs. The perforation geometry of the fins has a great effect on convective heat transfer.

Key Words: Permeable fins, Heat transfer rate, perforated fins, Natural Convection, Fin arrays

1. INTRODUCTION

Convectionisthemodeofheattransferbetweenasurfaceandaliquidmovingoverit.Energytransferinconvectionis primarilyduetothebulkmotionoffluidparticles,butmolecularconductionwithinthefluiditselfalsocontributestosome extent.Ifthismotionisprimarilyduetodensitychangesassociatedwithtemperaturegradientswithinthefluid,themodeof heat transfer is said to be due to free or natural convection. On the other hand, fluid motion is mainly generated by superimposedvelocityfields(fans,blowers,pumps,etc.),andenergytransportissaidtobeduetoforcedconvection.

Weknowthatremovingheatfromasystemisveryimportant,sosystemsemployheatsinkstoextractheatfromthe systembyexchangingtheextractedheatwithanotherfluidorenvironment.Increase.AccordingtoNewton’sLawofCooling, thiscanbedoneintwoways:

i. Increasingheatsinksurfacearea

ii. Increasingheattransfercoefficient

Increasingtheheattransferraterequiresinstallingapumporfan,orreplacingtheexistingonewithalargerone,butthis approachmayormaynotbepractical.Insomecases.Alternatively,extendedsurfacescalledfinsmadeofahighlyconductive materialsuchasaluminiumcanbeattachedtothesurfacetoincreasethesurfacearea.Suchribbedsurfacesarecommonly usedinpracticetoimproveheattransfer,oftenincreasingtheheattransferratethroughthesurfacemanytimes.

Areviewoftheliteraturerevealsthatperforatedfinassemblieshavebeentriedusingsquare,triangular,andcircular perforatedfinassembliestoimproveheatexchange.Itcanbeseenthatfornaturalconvection,theheattransfercoefficient dependsontheorientationandshapechangeofthefinassembly.

2. REVIEW

2.1

Pramod R. Dabhade

Thispaperinvestigatesthetrialexaminationofnaturalconvectionheattransferfromhorizontalrectangularfinsarraywith blindholes.Theeffectofsurfaceareaoffinsarraywereidentifiedasthemaincontrollingparametersfortheheattransfer augmentation.Heattransfercoefficientwasfoundtobeincreasedwiththeincreaseinthediameteroftheperforatedfins.Three

finarrayblocksofaluminumwith4mm,6mm&8mmperforationdiameterand6mmfinspacingwereexperimentallytested atvariousinputpowers40W,60W,80W,100W,120W.Anotherparameterbeingvariousinclinations(0-90)ofthefins.

Fromthisstudyweconcludedasthesurfaceareaincreasestheheattransfercoefficientincreases.Convectionheattransfer coefficientincreaseswiththeincreaseinfininclinationfrom0-90.Forthegiveninput,heatexchangecoefficientofarraywith blindholesishigherthantherelatingsolidone.[1]

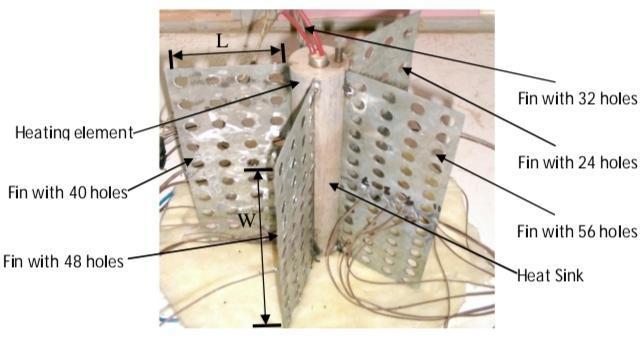

The experimentation on heat exchange through fins with circular holes is examined in this work. In this study, the rectangularflatfinsarealteredbycircularholesbeingdrilledintothem.Thegoalofthestudywastobetterunderstandhowheat moves through a rectangular fin plate with circular holes acting as heat sinks naturally. The initial fin had 24 circular perforations(holes),andeachsubsequentfinhadeightmore,foratotalof56perforationsbythetimethefifthfinwaspresent. Therewere614rowsand4columnsoftheseholes.

Itwasconcludedfromthisthatthetemperaturereductionfortheperforatedfinswasgreaterthanforthenon-perforatedfins. Also,itisinferredfromthisstudythatthefinswiththemostperforationshavethemostastonishingconvectiveheattransfer coefficient.Accordingtotheinvestigation,theperforatedfinswithahighernumberofperforationshadahigherheattransfer coefficientthanthosewithfewerperforations.[2]

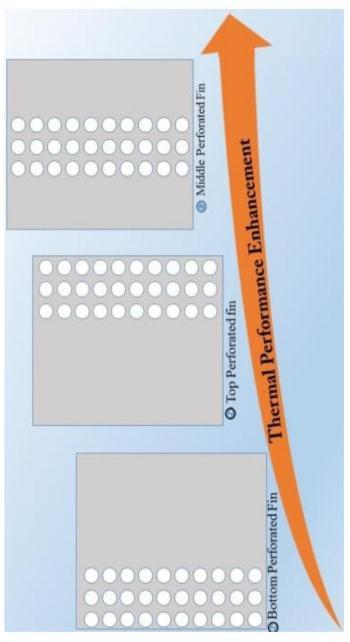

Thisstudyexaminestheenhancementofnaturalconvectionheattransferinrectangularplate-finswithperforationsatthe top,middle,andbottom.Thegoaloftheinvestigationwastodeterminehowperforations,perforationdiameters,andperforation placementsaffectedthethermalperformanceofsolidfinsduringconditionsofnaturalconvectionheattransfer.Sixdifferent aluminium fin arrangement options make up the setup. Three different combinations use rectangular plane fins with perforationsthatare3mm,5mm,and7mmindiameter.Theremainingthreevariantsplacedamatrixwiththreecolumnsand tenrows,totalingthirtycircularperforations,atthebottom,top,andmiddleoftheflatplatefin.

Eachfinhasanoutsidesizeof110mminlength,1mminthickness,and100mminbreadth.Allthetestedfinsarereceiving a steady heat flux in the meantime.Findingsshowed that regardlessof the diameter, the perforations at thecentre of the perforated fins produce the greatest gain in thermal performance. Also, regardless of the perforations placements, it was discoveredthat3mmperforationsperformedbetterthermallythan5mm&7mmperforations.[3]

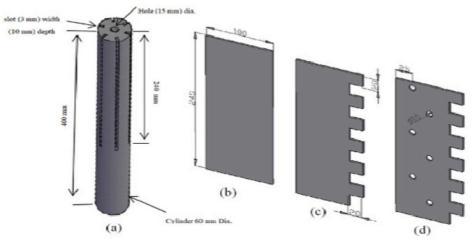

2.4 Maha A. Hussein

Inthepaper,weinvestigatetheinfluenceofthenewlyproposedtilefingeometryonthethermalperformanceinheatsinks undernaturalconvectionconditions.Ithas6finsanditsmaterialisaluminum.Eachribis3mmthick,240mmlongand100mm wide.Thesesixfinswereattachedthroughlongitudinalslotsaroundthecylindricalheatsink.Thefirsttypeoffinsetwasflat(fin 1),thesecondtypewasasquarerim(fin2)andthelasttypehadacircularholeandasquarefinrim(fin3).Theparameters consideredinthisstudywere:

1. Drillholesbychangingtheshape,position,diameter,arrangementandnumberofholes.

2. Cutthepartsbychangingtheshape,numberandpositiontobecut.

3. Ribmaterial,thickness,direction,weightandlength.

The power values delivered were 37.5 V, 50 V, 62.5 V,and 75 V for all fin settings. Different values of heat loss were 4.02395%,2.6044%and2.3212%forfin(1),fin(2)andfin(3)respectively.Thetestedfin(3)wasfoundtodissipate6.8%and 12.9%moreheatthanfins(2)and(1)respectively.Theaverageeffectsoftheinvestigatedfinswere2.9,3.1and3.3forfins(1), (2)and(3),respectively.Efficienciesofallproposedfingeometrieswereabove90%.[4]

2.5 Akhilesh Kumar Singh

Thispaperexaminestheinvestigationoftheeffectofincreaseinperforationdiameterandangleofinclinationonthenatural convection heat transfer from rectangular fin array.In this paper, the natural convectionheat transfer under steadystate

conditionfromthesolidfinarrayandtheperforatedfinarrayswith4mmfinspacing,finperforationdiameter(4,6and8mm)& fininclinationangle(0,30,45,60and90)wereanalyzed&compared.

Experimentationwascarriedoutonconfigurationwith10fins.Dimensionsoffinandbaseplatemadeofaluminummaterial aretakenas(75*27*2mm)and(76*75*2mm)respectively.Heatinputwasprovidedas15W,25W,35W,45W.Resultimplies thattheenhancementintheheattransfercoefficientwasachievedwiththeincreaseinthefinperforationdiameter.Withthe variationinfininclinationanglefrom0to90alsotheheattransferwasenhanced.[5]

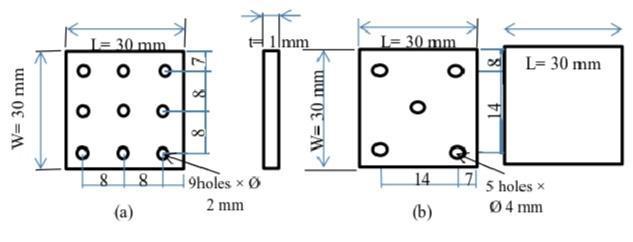

2.6 Basima S. Khalaf

Inthispaper,experimentsweredonetoinvestigatethenaturalandforcedconvectionofheattransferalongaflat surfaceequippedwithvarioustypesofrectangularaluminumfins(solidandperforated).Selectedribwithdimensions(30mm high x 30 mm wide x 1 mm thick). Perforated ribs have different distributed holes (2mm for 9 holes, 4mm for 5 holes). Aluminumisusedfortheribsandfloormaterial.Naturalconvectionmodesofheattransferalongperforatedandnon-perforated finswereanalyzedinsteadystate.

Theeffectsofthenumber,sizeandarrangementofperforatedlamellaewereinvestigated.Ahigherheattransferrateis observedwithanincreasednumberofcircularholes,andefficiencyisalsoimprovedduetothereducedweightofthefins.A numerical analysis was also performed to examine this temperature distribution and used in a simulation program (SOLDWORKS).Goodagreementwasfoundwhencomparingexperimentalandtheoreticalstudies.Someobservationsfromthis studycanbesummarizedasfollows:

1. Thetemperaturedifferencebetweenthebaseandtipoftheperforatedfinwaslargerthanthatofthenon-perforated fin.

2. Theheattransfercoefficientofperforatedfinsdependsonthedimensionsoftheholesandthewidthofthefins.

3. Theheattransfercoefficientincreasedasthenumberofholesincreased.[6]

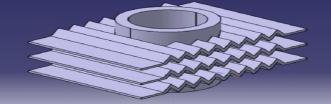

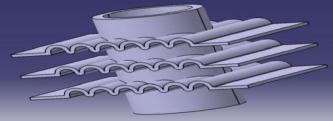

2.7 Rashin Nath K.K

Inthiswork,theynumericallyinvestigatetheeffectofdifferentfingeometriesontheoverallheattransferfromanair-cooled finassemblymountedonacylindricalsurface.Inthispaper,theheattransferandheattransfercoefficientofthreefinmodels (rectangular,wavyandzigzag)werestudied.ThestructurewasmodeledwithCATIAV5softwareandthermallyanalyzedusing ANSYSFluentsoftware.AcylinderwiththreeribsusedforCFDanalysis.Thealuminumslatdimensionsareassumedtobe220x 150x1mm.Theouterdiameterofthecylinderis72mm.70mminnerdiameter,1mmthickness.Thelengthofthecylinderis 80mm.

Next,wecomparedtheheattransfercoefficientsofdifferentgeometries.Atlowspeeds,flatfinswerefoundtohavehigher heattransfercoefficientsandheattransfercoefficients.Theheattransfercoefficientsofthezigzagandwavefinsincreasedwith increasingvehiclespeedcomparedtotheflatfins.Thedevelopmentofacurvedzigzagshapecancreatevorticesbetweenthe twofins,creatingturbulenceandincreasingheattransfer.[7]

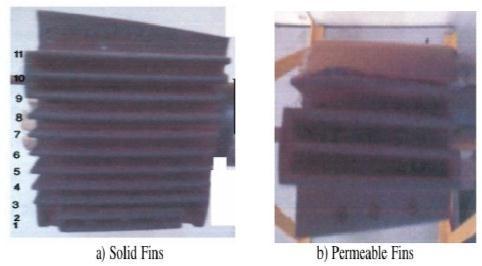

2.8 Ashok Tukaram Pise

AshokTukaramPiseconductedexperimentforcomparingtheheattransfercoefficientsofsolidandpermeablefins.The permeableribsareformedbyalteringthesolidrectangularribsbydrillingthreeholesperrib,inclinedathalftheriblengthof thetwo-wheelcylinderblock.Solid,permeableribblockswerekeptinanisolatedchamberandtheefficacyofeachribinthese blockswascalculated.

Anenginecylinderblockwithsolidpermeablefinswastestedatvariouspowerinputs(i.e.75W,60W,45W,30W,15W).We foundthatthepermeablefinsimprovedtheaverageheattransfercoefficientoftheblockbyabout5.63%,increasingtheaverage heattransfercoefficientby42.3%comparedtothesolidfins,andreducingthematerialcostby30%.[8]

2.9 Mahathir Mohammad

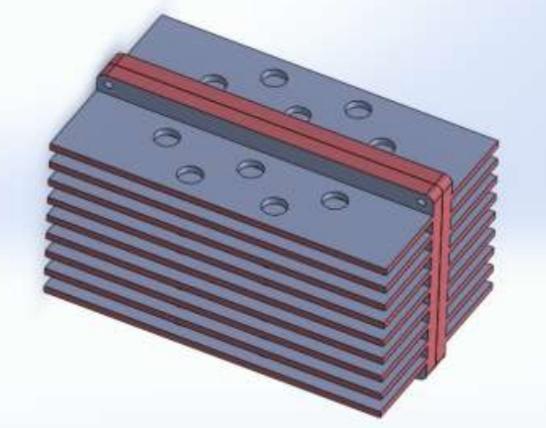

Thisexperimentalstudywasconductedtoinvestigatetheeffectofextendedsurfaceperforationshapeorgeometryon forcedconvectionheattransfer,findingtheheattransferpropertiesofvariousperforatedfinstorevealtheoptimalperforation

geometryforplanarheatsinks.Studieshaveshownthatthetemperaturedropalongperforatedribswasgreaterthanwithout perforations.Fortheheatsinkweusedasolidaluminumblock190mmlong,120mmwideand7mmthick.Theribwas120mm long,85mmwideand4mmthick.Eachfinisspaced38mmapartforevenheatdistribution.Tominimizeheatlossfromthe baseplateandfinplate,thefinplatewasplaced3mminsidethebaseplateandwasalsosolderedtothebaseplateandfinsto reduceheatloss.Theparametersstudiedweretemperaturedistributionandheattransfercoefficient.Theaverageincreasein convectiveheattransfercoefficientat150Wis78.98%fortrianglesandfinswithoutholes,whichisgreaterthanforrectangles (74.36%)andcircles(41.42%).Asimilaritycanbeseenfor100Wpowerconsumption,withtriangularperforatedfinsexhibiting thehighesttemperaturedifferenceat54.59%,followedbyrectangularat38.0%andcircularat33.04%.

From this study it can be concluded that, Fin holes and hole geometry had a significant impact on the temperature distributionacrossthefin,whichaffectsthefin’sperformance.Atriangularperforatedshapegivesthebestresults,followedby rectangularandcircular.[9]

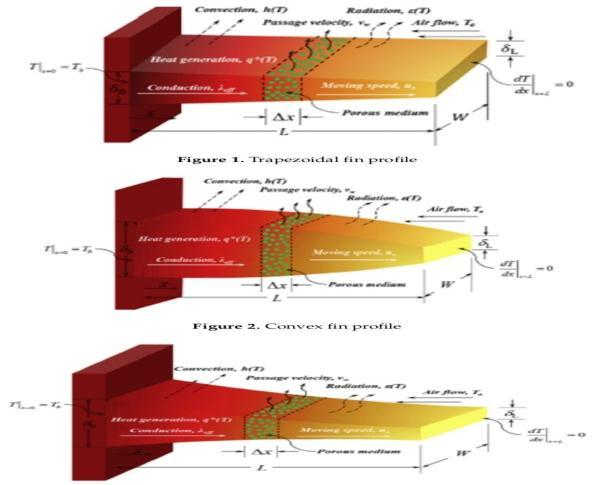

2.10 G. M. Sobamowo

Inthisstudy,investigationonthethermalresponsesofmovingirregularporousfinswithtrapezoidal,concave,andconvex profilesofcopper,aluminum,siliconnitridesandstainless-steelmaterialswereexamined.Thedevelopedthermalmodelis solvedusingdifferentialtransformmethod(DTM).

Intheparametricstudiescarriedout,theeffectofphysicalparameterssuchasconvective-conductive,convectiveradioactiveterm,internalheatgeneration,porosity, surfaceemissivity,powerindexofheattransfercoefficient,Pecletnumber andDarcynumberonthethermalbehavioroffinswereexaminedanddiscussed. Thecomparativeanalysiscarriedoutonthe effectofmaterialsonnon-dimensionaltemperaturedistributionrevealsthatcopperobtainsthehighesttemperaturewhilethe stainless steel gets the lowest. More-so, the fins with concave geometry gives the highest volume adjusted efficiency with increaseinPecletnumberwhilethatwithconvexprofilehastheleast.

Theconclusionsmadefromtheexperimentationsareclearthattheseresultoutputsareessentialandwouldbeusefulinthe futuredesignoffinswithoptimumsizereductionandhighefficiency.[10]

TABLE -1:ComparisonofParameters

NAME OF AUTHOR MODIFICATIONS PARAMETERS STUDIED

Pramod R. Dabhade [1]

Rectangularfins withBlindholes

Surface area of fins

Heattransferrateis maximumin perforatedfinswith Blindholesas comparedtofins withcompleteholes. (i.e.,heattransfer rateisdepends uponthesurface areaoffins.

Wadhah Hussein [2]

Rectangularfins platewith circular perforations (completeholes)

No. of perforations24,32,40,48,56

Dia. of perforations - 12 mm

(i.e.variationin no.of perforationswith constant diameter)

Temperaturedrop inperforatedfinsis higherthannonperforatedfins. Heattransferrate increaseswithno.of holesincreases.

Rectangularfins withperforations having perforated positionslike bottom,middle, top.

Perforations

diameter - 3,5,7

No. of perforations

(holes) - 30

(i.e.,variationsin dia.of perforationswith constantno.of holes)

Perforations

positions –(Top, Middle,Bottom)

Fin dimensions –

Length - 110mm,

Width - 100mm

Thickness - 1mm

Perforations positionedatthe middleofthefin regardlessofthe dia.givesmaximum improvementinthe thermal performance.

Finswith rectangularedge, andfinswith circular perforationswith arectangular edge

Material –Aluminium

Fin dimensionsLength-24cm

Width-10cm

Thickness-3mm

Heatsinkwith circularperforations witharectangular finedgegives maximum performance,heat dissipation,and minimumfins weightandcost.

Hole patternZigzag

Hole size

Fin dimensions –

Length - 75mm

Width - 27mm

Thickness - 2 mm

Effect of perforations diameter&fin inclination

Increaseinheat transfercoefficient withtheincreasein diameterofholes. Alsoheattransfer rateincreaseswhen thefininclinationis variedfrom0°to 90°.

Squarefinswith circular perforations

Fin dimensionsLength - 30mm

Width - 30mm

Thickness - 1mm

1] 9holes

*dia.2mm

2] 5holes

*dia.4mm

Thetemperature differencebetween baseandtipof perforatedfinsis greaterthanfor thoseofnonperforatedfins.

Finswith different geometries (rectangular, zigzag,wavy)

Heat transfer & heat transfer coefficient of conventional, zigzag&wavyfin models.

Heattransferrateof conventionalfins aregreaterforlow velocityw.r.t.thatof zigzag&wavy. Zigzag&wavyfins canbepreferred overconventional finsforhigherspeed vehiclesasit inducesgreater turbulenceandthus greaterheat transferrate.

Rectangularfins withcircular perforationsin applicationfor2wheelercylinder block.

Fin dimensions -

Length -110mm

Width - 66mm

Thickness - 5mm

Perforations

(hole) diameter -5mm

Forthesameheat transfer,the materialremoved bymassin permeablefinsis about10-30%. Therefore,reduction inmaterialcostis 30%.

Circular, rectangular& triangular perforatedfins

Fin dimensions -

Length -120mm

Width -85mm

Thickness -4 mm

Heattransfer coefficientincreases mostfortriangular perforations followedbycircular, rectangularandno perforations. Perforationshapes offinsshowsa significanteffectin conventionheat transfer.

Finswith trapezoidal, concave&convex profilesof copper, aluminium,and stainlesssteel

Effect of different materials with different profiles onheat transferrate

Copperobtainsthe highesttemperature whilethestainless steelgetsthelowest. Finswithconcave geometrygivesthe highestvolume adjustedefficiency whileconvexprofile hastheleast.

3. CONCLUSION

From the above, we can obtain a basic understanding of various parameters such as fin shape and orientation when structuringaheatsink.Theheattransfercoefficientincreaseswiththenumberofperforationsandthesizeoftheperforations.It hasalsobeenobservedthataholeinthecenterofthefingivestheoptimumheattransfercoefficient.

Moreover,itiswelljustifiedthattriangularperforatedfinsgivehigherheattransfercoefficients,followedbycircular rectanglesthanregular(non-perforated)fins.Theperforationgeometryofthefinshasagreatinfluenceontheconvective heattransfer.Theperformanceofperforatedfinarraysisverygoodcomparedtoregularfinarrays.

Aliteraturereviewthereforeprovidespreliminaryevidencethatperforatedfinheatsinksaremostcommonlyused forpracticalheattransferapplicationscomparedtoplatefinheatsinks.Thisextensivestudywillhelpfutureheatsink designstudies.

REFRENCES

[1]PramodR.Dabhade,Prof.N.S.Payaghana,"AReviewPaperonHeatTransferRateofFinswithBlindHolesinNatural Convection"(IJERT)Volume&Issue:Volume08,Issue08(August2019)ISSN(Online):2278-018

[2] Wadhah Hussein Abdul Razzaq Al- Doori, "ENHANCEMENT OF NATURAL CONVECTION HEAT TRANSFER FROM RECTANGULARFINSBYCIRCULARPERFORATIONS"(IJAME)ISSN:2229-8648(Print);ISSN:2180-1606(Online);Volume4, pp.428-436,July-December2011

[3]OsamahRaadSkheelAl-khafaji,NizarF.O.Al-Muhsen,"ASSOCIATEDEFFECTOFPERFORATIONPOSITIONANDDIAMETER ONTHERMALPERFORMANCEOFPLANEFINUNDERNATURALCONVECTIONENVIRONMENT"Publishedonline27August 202082:5(2020)101–108|www.jurnalteknologi.utm.my|eISSN2180–3722

[4]MahaA.Hussein,VinousM.Hameed,"Animplementationstudyonaheatsinkwithdifferentfinconfigurationsunder naturalconvectiveconditions"CaseStudiesinThermalEngineering30(2022)101774

[5]AkhileshKumarSingh,RajivVarshney,"Experimentalinvestigationonrectangularfinswithholesinnaturalconvection"© 2017IJEDR|Volume5,Issue4|ISSN:2321-9939

[6]BasimaS.Khalaf,AhmedK.Muhammad,"ExperimentalandNumericalInvestigationofHeatTransferEnhancementUsing CircularPerforatedFinset"al2020IOPConf.Ser.:Mater.Sci.Eng.870012168

[7]RashinNath.KK,JayeeK.Varghese,"DesignModificationandAnalysisofTwoWheelerEngineCoolingFin"(IJERMCE)Vol2, Issue7,July2017ISSN(Online)2456-1290

[8]AshokTukaramPise,UmeshVandeoraoAwasarmol,"INVESTIGATIONOFENHANCEMENTOFNATURALCONVECTION HEATTRANSFERFROMENGINECYLINDERWITHPERMEABLEFINS"(IJMET),ISSN0976–6359(Online)Volume1Number1, July-Aug(2010)

[9] Mahathir Mohammad, Md. Ponir Hossain Talukder, Kazi Afzalur Rahman, Monowar Wadud Hridoy, "EXPERIMENTAL INVESTIGATION ON THE EFFECT OF DIFFERENT PERFORATION GEOMETRY OF VERTICAL FINS UNDER FORCED CONVECTIONHEATTRANSFER"(ICMERE)11–13December,2019

[10] G. M. Sobamowo, O. M. Kamiyo, M. O. Salami, A. A. Yinusa, "Exploration of the effects of fin geometry and material propertiesonthermalperformanceofconvective-radiativemovingfins"Vol.2(2019),Issue3,pp.14–29ISSN:2617-9709 (Online)

[11] Abdullah, H. Al. and Mohammed Q. A., "Enhancement of natural convection heat transfer from a fin by triangular perforationsofbasesparallelandtowardItsbase",TheArabianJournalforScienceandEngineering(2009),34(2B):531-544.

[12] Al-Essa, A.H. and Al-Hussien, F.M.S. 2004, "The effect of orientation of square perforations on the heat transfer enhancementfromafinsubjectedtonaturalconvection",HeatandMassTransfer,40:509-515.

[13]Bayram,S.andAlparslanD.,"Performanceanalysisofaheatexchangerhavingperforatedsquarefins"AppliedThermal Engineering(2008),6:621-632.

[14]Chung,B.T.F.andIyer,J.R.,"Optimumdesignoflongitudinalrectangularfinsandcylindricalspineswithvariableheat transfercoefficient"HeatTransferEngineering(1993),14:31-42.

[15]Elshafei,E.A.M.,"Natural convectionheattransferfroma heatsink withhollow/perforatedcircularpinfins" Energy (2010),35:2870-2877.

[16]Kutscher,C.F.,"Heatexchangeeffectivenessandpressuredropforairflowthroughperforatedplateswithandwithout crosswind"JournalofHeatTransfer(1994),116:391-399.

[17]BassamA/KAbuHijleh,“Naturalconvectionheattransferfromacylinderwithhighconductivitypermeablefins”,ASMEJ. HeatTransfer,vol-125,Apr-2003

[18]BogdanI. Povel,AbdulmajeedA. Mohamad, “An experimental and numericalstudy on heat transfer enhancement for gas heat exchangers fitted with porousmedia” International Journal ofHeat andMass Transfer 47 (2004), pp. 49394952

[19]WaleedAl-Salami,AmerAl-Damook,H.M.Thompson,"ANumericalInvestigationoftheThermal-HydraulicCharacteristics ofPerforatedPlate-FinHeatSinks",InternationalJournalofThermalSciences,121(2017)266-277

[20]KarimaBoukhadiaa,HouariAmeura,DjamelSahelc,MohamedBozitb,"EffectofthePerforationDesignontheFluidFlow andHeatTransferCharacteristicsofaPlateFinHeatExchanger",InternationalJournalofThermalSciences,126(2018)172–180.

[21] Kale S., Bhatkar V., “A Review of Electronic Equipments Cooling Through Rectangular Fin Array By Using Natural Convection”,InternationalJournalofCurrentEngineeringandScientificResearch,Volume2,Issue2,2015,pp.93-97.

[22]SamarthA.,KaleN.,“AReviewofThermalAnalysisofCylindricalPerforatedFinsinStaggeredArrangement",International JournalofResearchinScienceandEngineering,Volume1,Issue6,pp.80-88.

[23]KanaskarA.A.,KriplaniV.M.,WalkeP.V.,“AReviewofHeatTransferEnhancementfromHeatSinkUsingPerforatedFins”, Volume3,Issue6,2015,ISSNNo.2309-4893,pp.726-730.

[24]BarhatteS. H.,Chopade M.R.,Kapatkar V. N.,“Experimental and Computational AnalysisAndOptimization ForHeat Transfer Through Fins With Different Types of Notch”, Journal of Engineering Research and Studies, vol.2, Issue 1, 2011, pp.133-138

[25]Ehteshum,Mehedi,etal.,"ThermalandHydraulicPerformanceAnalysisofRectangularFinArrayswithPerforationSize andNumber",ProcediaEngineering105,2015,184-191.

[26]Ismail,MdFarhad,etal.,"NUMERICALinvestigationofturbulentheatconvectionfromsolidandlongitudinallyperforated rectangularfins",ProcediaEngineering56,2013,497-502.

[27]M.R.Shaeri,M.Yaghoubi,"Numericalanalysisofturbulentconvectionheattransferfromanarrayofperforatedfins", InternationalJournalofHeatandFluidFlow,2009,218-228.

[28]Al-Damook,Amer,etal.,"Computationaldesignandoptimisationofpinfinheatsinkswithrectangularperforations", AppliedThermalEngineering,(2016)

[29]NoamanSalam,KhanRahmatullah,Faizanurrahman,SalmanAh,AnsariTohid,TariqueKhan,"HeatTransferEnhancement ThroughPerforatedFin"IOSRJournalofMechanicalandCivilEngineering(IOSR-JMCE)e-ISSN:2278-1684,p-ISSN:2320-334X, PP.72-78

[30]MohamadI.Al-Widyan,AmjadAl-Shaarawi,"NumericalInvestigationofHeatTransferEnhancementforaPerforatedFin inNaturalConvection",InternationalJournalofEngineeringResearchandApplications(IJERA)ISSN:2248-9622,Vol.2,Issue 1,pp.175-184