Intravenous Therapy Supervising And Handling Using IoT

AVINASH K 1, AKASH S 2, RAJA M 3 , Mr. K. ARUNGANESH 4

1,2,3 B.Tech., Students Dept. of EEE, PMIST, Thanjavur. 4 Assistant Professor

Department of Electrical and Electronics Engineering, Periyar Maniammai Institute of Science and Technology, Thanjavur, Tamil Nadu, India

Abstract: An automatic Intravenous Fluid Administration and handling using IoT saline level monitoring consists of Load cell sensors which are used to measure the level of Intravenous fluid in the container whether it is Full or Low with warning status. The detection of the load is in Analog format. The output obtained from the sensor is displayed in the LCD display. When the level of saline goes below a threshold level, the alarm sound will be produced. Thus, the flow rate can also be controlled by the doctor using IoT as well as automatically with the help of input sensors placed for patients and displayed graphically in LabVIEW software.

KEYWORD: IoT, Solenoid Actuators, Heartbeat sensor, LabVIEW

I. INTRODUCTION

Modern problems always require modern solutions A Lifesavingsystem.Thispaperproposesaproof-of-concept system that uses no pain, level sensing with a lesser power-consuming computing platform to deliver continuousinfiltrationmonitoring around the IV catheter site. This kind of system could be able todetectaninfiltration non-invasively monitoring for known symptoms: swelling of soft tissue and increased skin firmness; these symptoms can be sensed by measuring skin stretch and local bioimpedance. This project was designed in order to help the nurses and caretakers as it is considered as automation application The nurses can able to handle a large number of patients inanhourlymannerwhenthisprojectisimplemented.

Adequate hydration via a saline drip is essential duringsurgery,butrecentreportssuggestthatgettingthe balance of salt and water just right could have an importantimpactonpatientrecovery

This Intravenous Drug administration includes various drugs namely saline, plasma, blood and all the other haemolyticdiagnosis.itisnecessarytofindthereasonsfor the intravenous infusion process so as to analyse the presence of any underlying diseases may affect the patients during the infusion process like respiratory issues, anaemia, feel nausea over time. The Intravenous fluid plays an important role in maintaining a good blood flowandliquidmovementafterthepatientisidentifiedas

weak. The IV fluid reduces the complication of water retention on the underlying tissues causing unwanted issues on the body of the patient The nurses who are working over time should have to care themselves so our project gives every minute details in perfect to the last patientifthepatientsareinalargernumbers,itrequiresa lot of nurses and care takers to be in the times of emergencyasweallknowthatintheyear2020theCOVID 19affectedtheentireglobecausingalargenoofcasualty. thus, it is necessary to hold a larger work strength to handle that much of people with less work power. If we use a network of this project, we can able to monitor all thepatient’sdatainasinglewindowasitcanbebeneficial fora large number ofpatientsintheabsenceora smaller number of nurses to patient ratio. The LabVIEW is very helpful for people with less technical knowledge So, This project can be easily acknowledged by everyone around theglobewithoutanybarriertothecommunication

Due to the increase in the population, there is a need for improvement in health care. As the salinebottlegoesbelowthethresholdlevel,itisnecessary to change the saline bottle. So new idea called LabVIEWbased Saline Level Monitoring System is emerged. The main objective of system is to provide authentic, accessible, easy and economic system for saline level monitoring. The saline is inserted into blood by considering certain characteristics like heart rate, blood pressure,bodytemperature,pulserateandbodyweightof patient.So,nursesdonotneedtogotopatient’sbedevery timebecausetheycancheck amountofFluidinjectedinto each patient via this system. This system is a low-cost systemandcomfortableforanurse Thus,itwasplacedin ruralvillagesandremotelyvillagescanhavethissystemto cope up the upcoming issues. Initially, this might be inferred as an event. But the consequences are harmful. WhentheIVbottle Thus,Thus,Uniquehealthmonitoring systems have been developed with less human interference which will be available at low cost in remote areas as well as highly populated areas. The system objective is to trouble-shoot the above-mentioned problem efficiently. By means of this the nurses can supervise the amount of IV fluid remains even from the control room. The Intravenous supervising and handling using IoT consists of load weighs the bottle fixed to the endinanAnalogformatanditcanbeconvertedusingADC

converter. It displays the output as whether the bottle is full , half and low and produces alarm to the nurses in duty.Whenthelevelofsalinegoesbelowathresholdlevel, thealarmsoundwillbeproduced.

II. PROPOSED SYSTEM

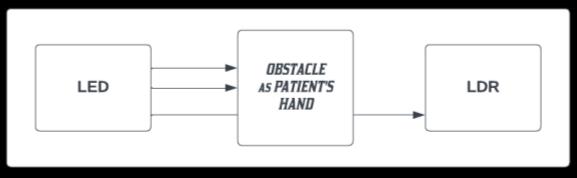

At first, it is necessary to change the saline bottle after it reachesthethresholdlevel.So,weconnectedanautomatic saline level monitoring consists of LOAD CELL sensors whichareusedtodetermineamountofIVfluid remainsin the container whether it is normal or abnormal with warningstatus.Secondly,wemonitorandcollectdatalike heartbeat, body temperature of the patient, oxygen saturation level in blood (SPO2), blood pressure. This system can automatically monitor the saline flow rate by using LOAD CELL and fed the data to microcontroller. Thus, the data are represented in form of Analog representation. Thus, the processed data from the microcontroller is transferred as output to LABVIEW, buzzer, LCD display Using LABVIEW, we can visualize the data to nurses or doctors and display the results in the form of flow rate, amount of IV Fluid in taken by the patient’s body in Analog units with the help of serial port in graphical format. Our system consists of Auto/Manual Mode. In Auto mode, the saline fluid flow will be controlled based on heart sensor & temperature automatically and it’s monitored in the cayenne app. Nurse/Doctorcanvarythebloodflowwithouttheneedto presenceinpersonwiththehelpofIoTaslikeasinoffline mode of operation. The solenoid valve is used to controls the blood flow to dialysis machine from human body. In oursystem,wehaveusedtotwosolenoidleveltocontrols the level of blood flow. If patient heart beat and temperature values are normal, two solenoid valves will be turned ON in the auto mode of operation. In case of patient heart rate or temperature is abnormal, the only one solenoid valve will be ON to reduce the saline flow level into human body. Every data is monitored a supervisedusingtheLabVIEWinagraphicalmeterformat as we can able to analyse patient’s vitals for every 30 seconds and are updated in the LabVIEW display All the dataaboutthevictimsarementionedintheregisterspace located in the bottom area of the LabVIEW in a Code format (e.g., L..H..SP…T…R.) Any Discrepancies in the measuring instruments can be easily identified by graphicalmethodThus,theIntravenousFluidisconnected to the patient’s body through the catheter needle in the dorsum region. The most common site for Intravenous Catheter is the antecubital fossa usually called as forearm (the back of the hand) which has a good blood flow and most suitable comparing to the other regions. Improper insertion of IV catheter in cannula causes a swollen red tissue under the epidermal regions obstruct the flow of blood through veins and became a site of infection. So, to overcometheseobstructionswedesignedawristhanging

band structure which holds on the catheter region identifies the swell by comparing the old hand area with theupdatedareausingLEDandLDRconcept.

III. METHODOLOGY

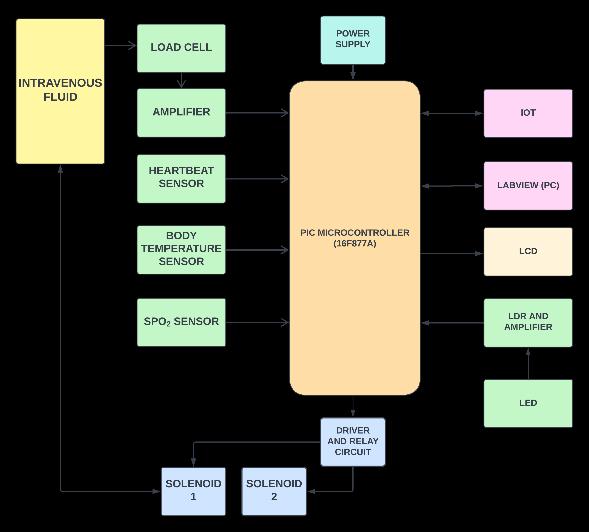

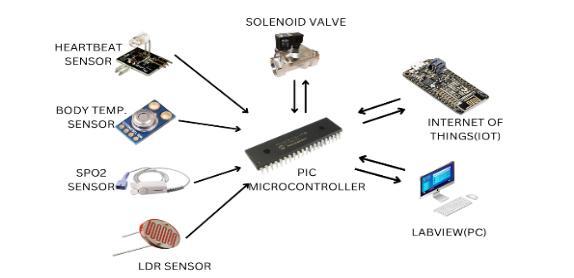

Intravenous Fluid Container is connected to the load cell which sends an amplified Analog signal about the amount present in terms of load(weight) to the microcontroller. Then the temperature sensor, SPO2 sensor, and Heartbeat sensor are all connected. the data from thesemodulesarecollected in the formof Analog in theprocessingunitandthesolenoidactuatorisconnected to thebottleandaLDRsensorinplacedinthewristofthe human hand for special purpose i.e., the detection of the hypodermicreactions.

Thus, all the data collected are processed and proceeded the output in form of digital signal to the LED, LabView software and the solenoid actuator is controlled byusingtheIoTserverinthehandydevicesofthenurses, doctorsandcanbeseenbythecaretakersalsoreducesthe riskofundesiredchanges

The status intravenous fluid volume used by patients divided into three categories namely: Safe: intravenousfluidcondition>10%;Standby:thecondition oftheinfusionliquid5%-10%andEmpty:0%conditionof intravenousfluids.

IV. GRAPHICAL REPRESENTATION

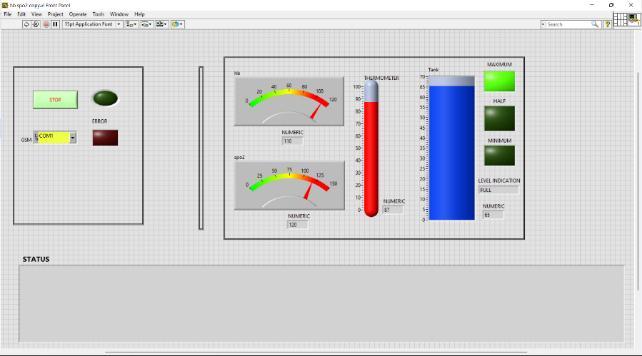

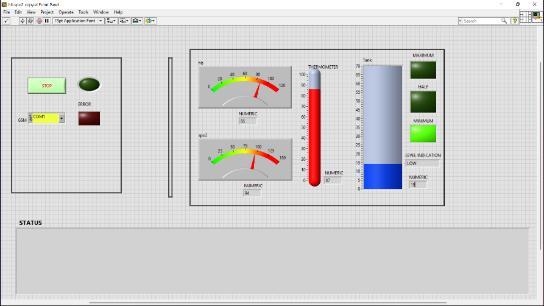

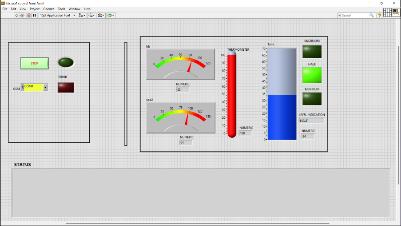

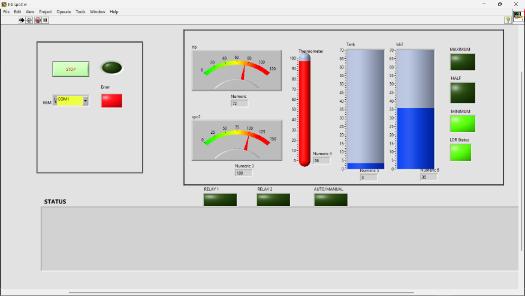

The Fig. represented below shows the outlook of the workingofIntravenousFluidsupervisingandHandlingby usingIoT.

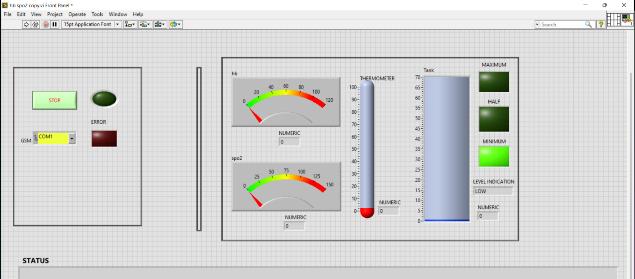

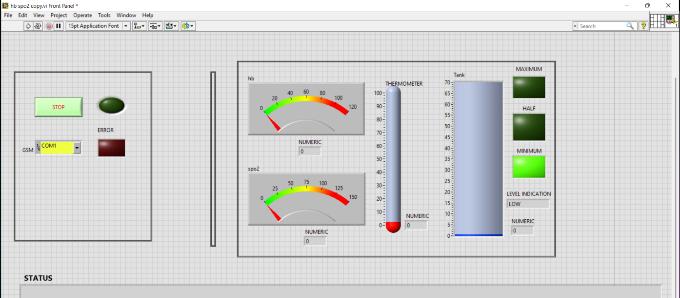

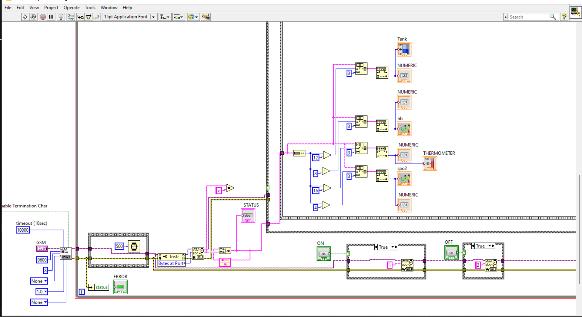

The Fig. represented next to this is the user Interface ofLabVIEWsoftware with themodulesloadedonform of blocks which is the simpler form of understanding in whichwecanabletosuperviseandhandlethestatus and the solenoid actuator using IoT control as well as the Manualcontrol.

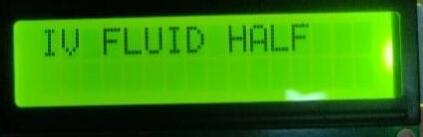

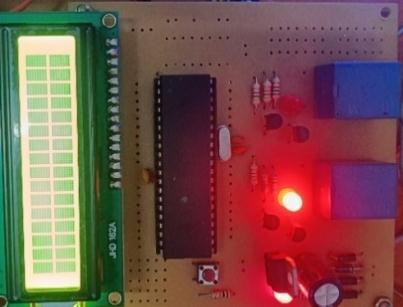

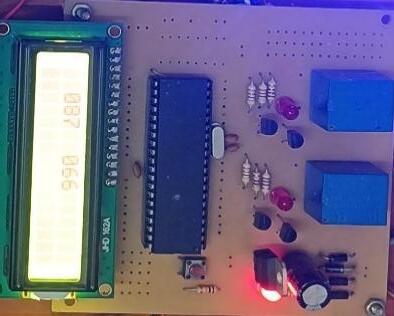

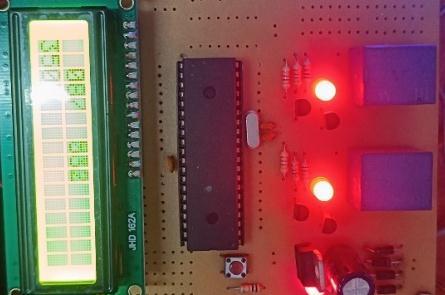

LCD OUTPUT

Thus, all the modules created in the LabVIEW interface areprogrammedby usingthelanguagecalled‘G’.TheFig. belowrepresentsthegraphicalblockdiagraminG.

Theoutputsareverifiedonthelcdscreenplacednearthe patient module and the buzzer and alarm are produced warningstatussignal

LABVIEW

OUTPUT

Thus, all the parameters were monitored and all thedata are recorded inside the microcontroller andthus data are processed and output is displayed in lcd display and the output is sent to PC using USB to UART and it display graphical output in the LABVIEW software as shownbelowinFig.5.9.

V. RESULT AND DISCUSSION

IV FLUID LEVEL

Theresultsarebasedontheseveralcombinations ofheartbeat,spO2,bodytemperature,IVfluidlevel

The above shown Fig.8 is the following parameters in

differentblocksasthedata beforetheUARTconnectedto thePC.

Thus, the Intravenous Fluid is connected to the patient’s body through the catheter needle in the dorsum region.ThemostcommonsiteforIntravenousCatheteris the antecubital fossa usually called the forearm (the back of the hand) which has a good blood flow and is most

suitable compared to the other regions. Improper insertionofanIVcatheterinthecannulacausesaswollen red tissue under the epidermal regions to obstruct the flowofbloodthroughveinsandbecameasiteofinfection.

So,toovercometheseobstructionswedesigneda wrist hanging band structure that holds on the catheter regionandidentifiestheswell bycomparingtheoldhand areawiththeupdatedareausingLEDandLDRconcepts.

SOLENOID ACTUATORS

There are two solenoid actuators S1 and S2 are usedinourproject.Thesetwosolenoidsareconnected in parallel with the IV Administration tubes to reduce the flowofIVdrugsenteringthepatient’sbody.

Itismainlyusedinthe haemodialysisprocessandICU .It playsavitalrolefortheIntravenousDrugtherapy.

The above shown Fig. are the representation of abnormalities in single parameters only. But the case is notalwaysthesameinwhichoneormoreparametersare shownatatime.

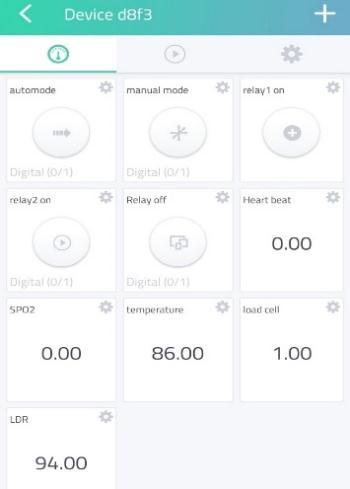

The designed interface with tools for the connected device in the server operated through the host device.Thesestatsareupdatedforeverycyclewithsome

delayduetonetworktraffic

In the IoT module, we used the ESP8266

Wi-FimodulewhichwasconnectedtotheMicrocontroller and the network connection of the host device. The IoT hascertainparametersnamely,

i. Automode

ii. Manualmode

iii. Temperaturevalue

iv. SPO2value

v. Loadcell

vi. Heartbeatvalue

vii. LDR

viii. RELAY1/RELAY2

Thus, Once the auto mode is activated, the Intravenousfluidflowsatthemaximumratewhichmeans that all the other parameters are at a safer level and no issuesaredetectedinthepatient’sbody.

FromtheaboveFig5.17,boththerelayR1andR2 are turned OFF which defines that more than two abnormalitieswerefoundfromthesensors.

VII. FUTURE SCOPE

Manual mode represents that the solenoid actuators are controlled by the nurses/ doctors who take carepatient’shealthinthereal-timeprocedureasitwasa usualday-to-dayone.Fig5.18representsthatrelay1and relay 2 are operated in alternate condition and reduces theflowofIntravenousFluid.

We can able to monitor the status of the parametersiii,iv,v,vi,andviiandcontroltheparameters a, ii, and iii by pressing the button switch in the interface ofthehostdevice.

VI. CONCLUSION

At last, from measuring all the data of patients throughthesensors,wecannowcometoaconclusionthat it is necessary to establish our project during the Intravenous Drug Administration to maintain a report of the patient about their body where we can able to point out the spike of any vitals during supervising using the data obtained from the National Instruments LabVIEW software.ThereisnocompulsionforadoctortobeinrealtimetomonitorthepatientasweincludedtheIoTmodule. wecanfindanyinformationandcancontrolthedrugflow rate through solenoid actuators which are really useful in efficient precise level flow in ml/sec. We also included a wrist band type LDR connected with LED to detect the bulge in the region the of IV injected by comparing the normal hand and the bulge hand using light dependent source. From this, it can be useful for any type of hand it may be thin, thick even neonates are taken care of by our system. This system is a mandatory blood leak detector (BLD) in a haemodialysis machine and is it is a lifesaving system. The healthcare technician takes immediate and appropriate action and prevents the patient from any major problem during blood leakage in haemodialysis. Well, it can be remotely operated reducing manual and manpower as well as Time-saving system. So, that it can Avoidaccidentsoccurredduringintravenoustherapy

This system is an efficiently economical project, but the only region where it needs Some more updating thing is the size. The size can be reduced by changing the power supply of the circuit from AC supply to DC supply by placing Lithium-ion batteries instead of transformers. Thus,usinglithium-ionbatteriesincreasesthelifespanof the device by increasing its safety in it. When this project is designed as a device, then the cost of the components andthematerialusedcanalsobereduced.Beforemaking itasaproduct,weshouldanalyzeallthefailureoccurring during the operation of the product apart from failure a certain code should be given along with it. So, it makes this project an easily available product on the market. If anyissuesarisein theproduct,thenit shouldbeserviced through the installed controller by activating several commandsinit.

REFERENCES

[1]. T.Nicola Giaquinto et al “ Real-time drip infusion monitoring through a computer vision system”IEEE2020

[2]. ShaojunJiang etal“Alowpowercircuitformedical dripinfusionmonitoringsystem”- IEEE2020

[3]. Muhammad Raimi Rosdi et al “A Smart Infusion Pump System for Remote Management and MonitoringofIntravenous(IV)Drips”-IEEE2021

[4]. Natapol Phetsuk et al “Design, Development, and Fabrication of an Intravenous Infusion Monitoring Device”-IEEE2021

[5]. MohammedArfan etal“DesignandDevelopmentof IOTenabledIVinfusionratemonitoringandcontrol device for precision care and portability”-IEEE 2020

[6]. MeoVincentCayaetal“DesignandImplementation of an Intravenous Infusion Control and Monitoring System”-IEEE2019

[7]. Ananya madhav et al “An IoT based intravenous dripratecontrollingandmonitoringsystem”–IEEE 2021

[8]. Ramisha Rani K et al “Smart Drip Infusion Monitoring System for Instant Alert– Through nRF24L01”–IEEE2017

[9]. Sanjay. B, Sanju Vikasini. R.M, “IoT based drips monitoring at hospitals”, International Research Journal of Engineering and Technology (IR-JET), Vol.07Issue:04,pp.:2395-0072,2020.

[10]. Karthik Maddala, Prashanth Gummadi, Sravani Posina, Chandana Perepi, Jayanag Bayana, “IoT based smart saline bottle for health care”, International Research Journal of Engineering and Technology (IRJET), Vol. 07 Issue: 10, pp.: 23950072,2020