Multipurpose Solar Powered Agribot

B.Tech Students, Dept. of EEE, PMIST, Thanjavur 4 Associate Professor Department of Electrical and Electronics Engineering, Periyar Maniammai Institute of Science and Technology, Thanjavur, Tamil Nadu, IndiaABSTRACT: The biggest problems faced by farmers, especially in rural areas, are low productivity rates and less exposure to appropriate technologies inthe agriculture sector. Hence, additional support is required to carry out certain tasks on agricultural land. There are many modern methods and machines available in the market, but all farmers cannot afford to buy them. In this paper, a multi-purpose solarpowered Agribot for supportingagriculture purposes has been designed. This robot has four modes of operation:1. Ploughing 2. Seed sowing 3. Soil moisture monitoring 4. Weed removal. The robot is instructed to carry out these processes with details about the total land surface dimensions as well as the distance between plants. The variables are sent as SMS by the user to the GSM Module. A PIC Microcontroller receives the information. For the ploughing operation, the rotating blade and Plough will be activated. During the seed sowing mode, the robot starts to drop the seed by first loosening the soil and then covering the seed and then followed by dropping the seeds and covering the seed with loosened soil. Solar Panel has been provided to recharge these batteries. During the Weedremoving mode, a spinning blade removes the unwanted plants in between the sown seeds. During the soil moisture monitoring mode, sensors determine the exact moisture content of the land. Accordingly, it will switch the ON the water pump kept in the agriculture field. This highly costeffective robot can be shared by a large group of farmers

Keywords: weedremover,soilmoisturemonitoringrobot, weeding mechanism, seed sowing mechanism, ploughing mechanism

1. INTRODUCTION

ThebaseoftheIndianeconomyismainlydependentonthe Agriculturesector.Foodproductionhasalwaysbeenonthe rise.Butsometimesduetoalackofappropriatesupervision andaswellasnaturalcalamities,hugeportionsofcultivated cropsareaffectedwhichleadstolesserproductionthereby raisingthesellingpriceduetohigherdemand.Thereshould be sufficient labourers in the field. But, nowadays, Landownersarestartingtoselltheirpropertybecausethey arenotgettinglabourersfordoingsomework. Incasethey get labourers, they charge very high wages. Many landownerscouldnotaffordsuchpayinghighwages.

Theconventionalmethodofagricultureisusuallyverytimeconsuming and highly labour dependent. There are many modernmethodstodosomeagriculturalactivities.Butthey have a very high initial investment, most farmers cannot affordtopaythehighprice.So,tosimplifythefarmer’swork someagriculturerobotscanbeusedinsteadofthehuman labourer. The idea is to make agriculture robots that can performthetaskofthelabourernamelyploughing,seeding, weedremoving,andwaterpouring.So,thelabourproblem intheagriculturalsectorcanbereduced.Mobilephonesare used by a huge number of people globally. Here, used a mobile phone is the interface between the robot and the user. The GSM(Global Systemfor Mobilecommunication) supportswirelesscommunication.Thefarmercansendthe appropriateinstructionstotheGSMmodulewhichisfixedin therobot.

Inthispaper,Agribothasfourmodesofoperation:

1.Ploughing2.Seedsowing3.Soilmoisturemonitoring4. Weedremoval. Forploughingmode,acurvedtoolisused.it can do burrowing as well as closing the seeds with soil. During the seed-sowing mode, three control variables are given as input. Distance between the seeds is very important.Propergerminationandfurthergrowthrequire thecorrectspacing.Duringsoilmoisturemonitoringmode,a soil moisture sensor is used to determine the amount of moisturecontentinthesoil.Accordingtothemoisturelevel, therobotwillturnON/OFFthewaterpumpkeptnearbyin theagriculturefield.Theyieldofthecropmainlydependson themoistureinthesoilratherthantheavailablenutrientsin thesoil.Ithelpsbiologicallywelltogrowcropseffectively. Anotherbigproblemfacedbythefarmersisthegrowthof weeds.Weedsaretheunwantedcropsgrowninbetweenthe seeded crops. This occurs mainly due to more fertilizer contentintheagriculturalland.So,suchtypesofunwanted crops should be removed to grow seeded crops. Weeds should be removed in the earlier stage itself to get more yieldfromtheagriculturefield.

TheMicrocontrolleristheheartofthisrobot.Herea PICmicrocontroller(PIC16F877A)isusedwhichisan8-bit microcontroller.Thisrobotwilloperateinopenatmospheric conditions. So, Solar Panel is placed on top of the agribot. Whichisusedtorechargethe12Vbatteriesused.Thishighly cost-effectiverobotcanbeusedbyalargegroupoffarmers andforhugeagriculturallands.Itcanbeeasilyoperatedand

user-friendly. By implementing such technologies in agriculture,theyieldofthecropscanbeincreased.

2. PROPOSED SYSTEMS

In this paper, we deal with the use of automation androbotics.ThisAgribothasfourmodesofoperation.For seedsowingoperation,thelengthandno.ofcolumnstobe sownseedsinthelandaretheagriculturaltwovariablesand the distance between seeds is another variable. The proposedrobotautomaticallydropstheseedsandcoversof soilafterplantingaseedinasequence,tillitreachestheend of the proposed area. This robot is controlled by a smartphoneusingGSMandPICcontrollertoautomatethe entire function. The microcontroller is programmed to controlagriculturalpurposeslikeopeningthesoil,dropping the seed in the soil, and putting the soil back We are also programmingthePICtosendthereporttotheremoteplace throughtheGSMmodule.Thereportcanalsobemonitored onamobilephoneanywhereintheworld.Thus,themain problem faced by the farmers that lack manpower can be manpowerledbytherobot.Asoilmoisturesensorisplaced todeterminethemoistureleveloftheland.Accordingtoit turnON/OFFthewaterpumpplacedintheagricultureland. Forremovingtheweedintheagriculturalland,weedcutting mechanismisprovidedhere.Ithasaspinningbladethatis used to cut down unwanted crops. This proposed work is donetoprovidebetterresultsinthefieldofagriculture.

3. METHODOLOGY

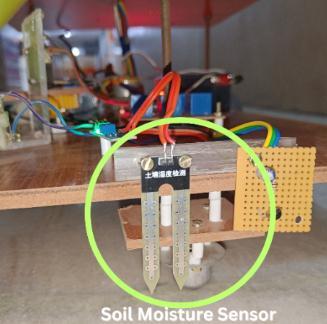

Thispaperfocusesondesigningarobotthatisused for various agricultural activities like ploughing, seed sowing,soilmoisturemonitoring,andweedremoval.Using GSMtechnology,thevariablesaresentintheformofanSMS totherobot.ThePICmicrocontrollerreceivesthevariables fromtheGSMmodulesanddoestheprogrammedsequences. SMS (Short Message/Messaging Service) is only sent after theGSMconnectstothecellularnetwork.Itcanbeknownby thetextdisplayedontheLCD“ENTERTHEDISTANCE”.For each mode of operation, the activating mechanisms were different.Thishardwareoftherobotconsistsofaploughing toolwhereashovelisusedtodigandloosenthesoil.Forthe seed-sowingmechanismwherethefunnel-shapedcontainer isusedtostoretheseedsandawoodenplateisusedtoopen thebottomofthefunneltodroptheseedintotheland.Here a limit switch is used to limit the position of the wooden plate.Forsoilmoisturemonitoring,asoilmoisturesensoris usedtomonitorthemoisturelevelofthesoilandsentthe datatothemicrocontrolleraccordinglyitwillturnON/OFF thewaterpump.Ifthemoisturelevelisveryhighmeansit turnsOFFthewaterpumpandviceversa.Forweedremoval, afan-shapedbladeisplacedundertherobottoremovethe weeds.Usersgetthecompletionstatusaftereachoperation. Here,theGSMmoduletransmitsandreceivesdatausingAT (ATtention) commands. This robot could be used by the farmerstomaketheirworkevenmoreproductive.

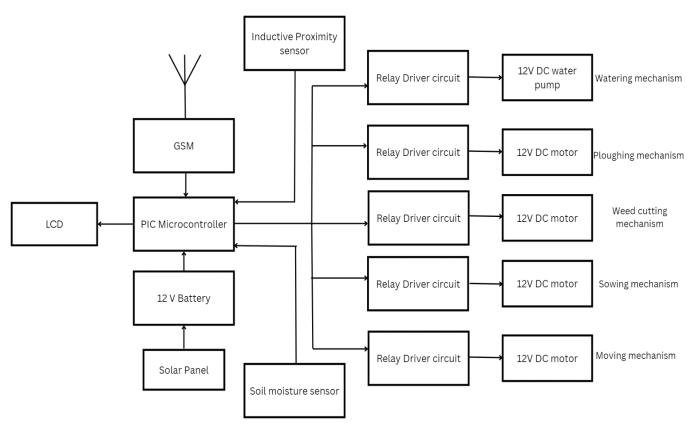

4. BLOCK DIAGRAM

The block diagram of the Agribot is shown in Figure 1. It consists of a PIC 16F877A microcontroller, two sensors namely an Inductive proximity sensor and soil moisture sensor, a Solar panel with 12V rechargeable batteries, an LCDforshowingthedatasentbytheusers,aGSMmodule withanantennafortransmittingandreceivingthedatato theusersandtotallyfiverelaydrivecircuitusedforwatering mechanism, seed sowing mechanism. The ploughing mechanism, weed-cutting mechanism, and robot moving mechanism.

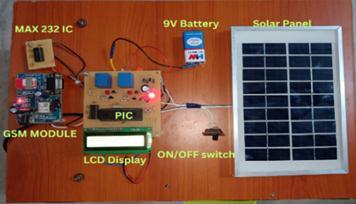

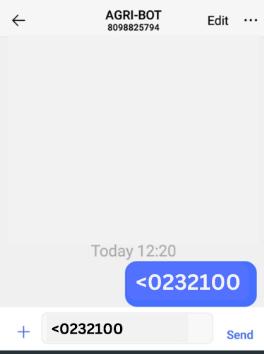

Thetopview,sideviewand bottomviewofthehardware set-up are shown in Fig 2, Fig 3, and Fig 4. Here 12V DC powersupplyisused.Whenthepowersupplyisswitched ON, it will start to process the robot with the PIC microcontroller, according to the program written. The program used here is written using Embedded C and it is implementedinMPLABIDEsoftware.Thefirstprocessisto detectthesignalintheGSMmoduleoftherobot.Tostartthe entireperformanceoftherobotisgiventhroughSMS. When the GSM module receives the input signal, the Red-LED blinksslowly.NowitisreadytoreceivetheSMSfromthe user.WhentheLCDdisplays“ENTERTHEDISTANCE”,the SMSissentbytheuserfromthemobilephonetoactivatethe robot’sfunctioning.ThisSMSisintheformofasequenceof 7-digitnumbers.SolarPanel isusedheretopowerupthe 12VBattery.Aninductiveproximitysensorisusedforthis robottocalculatethedistancebyit.Asoilmoisturesensoris alsousedheretomonitorthemoisturecontentinthesoil.

Modes of operation: Thisrobotcanperform4operations namelyploughing,seedsowing,soilmoisturechecking,and weedremoval.

Mode 1: Ploughing: Farmers prepare the land before cultivating the crops. The Ground is well-loosened and prepared for proper germination. When this mode is selected,itbroughttheploughstructuredownandloosens thesoilforeffectivegermination.Thetotaldimensionsofthe landweregiventhroughtheSMS.

microcontroller,theplastic-likestructurewillgodowntodig thesoil.Itworksaccordingtotheinstructionsgiveninthe program. After finishing the work, it will go back to its originalposition.

Mode 2: Seed Sowing

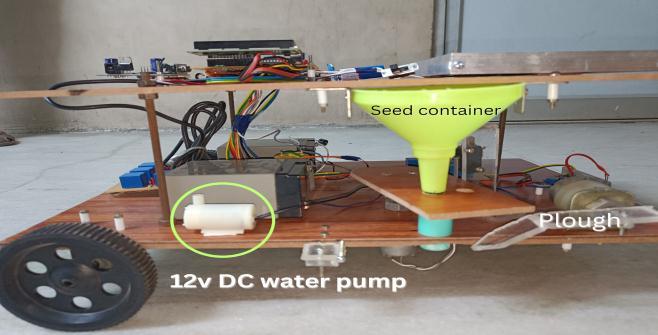

Fig. 5. shows the arrangement of the mechanism used for thisrobot.Here,a12V10RPMmotorisusedtocontrolthat mechanism.2channelrelaysareusedtocontroltheforward and reverse positions. Whenever it gets a signal from the

Fig-6 Seedsowingmechanism

AWoodendisc(diameter:50mm)isprovidedtosupportthe droppingofseeds.Theseedsarestoredinafunnel-shaped containerabovethewoodendisc. Thefunnelhasaholein thebottomthroughwhichtheseedsdroponeaftertheother. Intherigiddisc,thereisahole(diameter:10mm).Thedisc rotatestilltherobotreachesthelocationwheretheseedhas to be dropped. The limit switch is used to control the movement of the wooden disc. For better germination, placingtheseedcorrectlyonthelandisveryimportant.This mode is very useful for farmers to save their time and be productive.

Mode 3: Soil moisture checking

Fig-7 Soilmoisturemonitoring

Asafarmer,themoistureofthelandshouldbeconstantly monitored,providingwateratrighttimeandnotwastingthe waterisimportant.Ifthesoilmoistureoptionisselected,it willstarttomovearoundtheseed-plantedareasandcheck the moisture level and send that value to the user. If the watermoisturelevelishighitwillONthewaterpumpand viceversa.

Mode 4: Weed removing

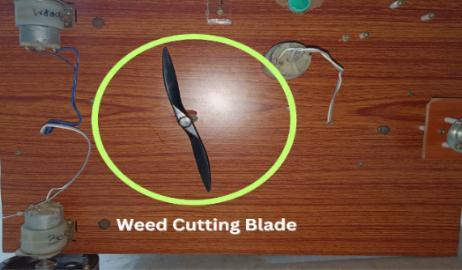

Weedcontrolisveryimportantinagriculturalland.Because itreducestheefficientgrowthofthecropandinterfereswith harvesting.Weedshouldberemovedintheinitialstageitself togetahighercropyield.Theprocessofremovingweeds

fromagriculturallandiscalledweeding.Theweedremoval mechanismconsistsofarotarybladethatwillcutdownthe unwantedcropsgrownontheland.Here,the12VDCmotor isusedtodrivetheblade.Thiswholemechanismisplaced onthebottomsideoftherobotforefficientcuttingofweeds.

‘w’variabledenotesthemodeofoperation.

1unitisapprox.equaltoonerotationoftherobotwheel anditisequalto10cm

Table-2: Modes of Operation

SMS variables Modes of Operation

1 Ploughing

2 SeedSowing

3 Soilmoisturemonitoring

4 Weedremoval

Measuring the distance

Robothastobeinstructedaboutthedistancewhereitneeds todroptheseeds.Aninductiveproximitysensorisusedto measurethedistance.Thissensorisplacedontherearleft wheel.Asthewheelrolls,thepositionoffournutsissensed bythesensortocalculatethedistance.

Experimental methods:

(i) Ploughing

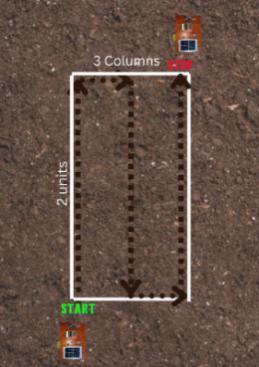

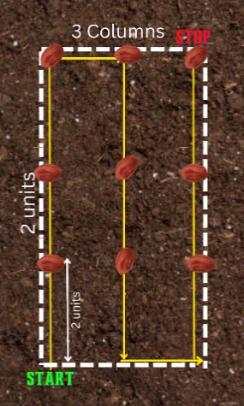

TheTotaldimensionofthelandisrepresentedas the2-unitlengthand3-unitbreadth. So,theSMSissentin the format of <0232100>. Hence, the first two digits representthedistancebetweentheseeds.Forselectingthe Ploughingoption,theVariable‘w’isrepresentedby1inthe message.

Fournutsareplacedontherimoftheleftrearwheel.Asthe sensor senses every nut, the controller automatically calculatesthedistancemovedbytherobot.TheRobotcanbe programmed to be stopped as per the requirement as required.Onefullrotationofthewheelcanmovetherobot approx.15cm.

6. RESULTS AND DISCUSSION

Table-1:

‘x’variabledenotesthedistancebetweentheseedsthat aretobesown.

‘y’variabledenotesthenumberofcolumnsinthelandin whichtheseedswillbesown.

‘z’variabledenotesthetotallengthofthelandinunits.

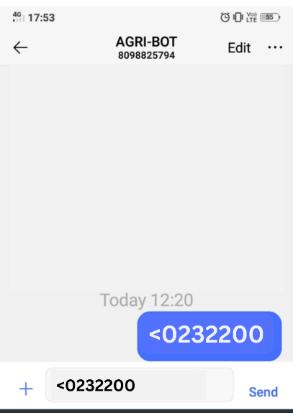

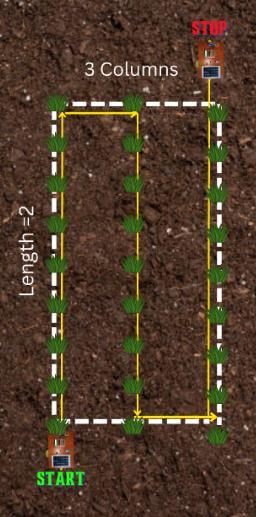

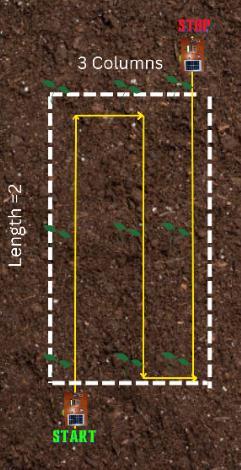

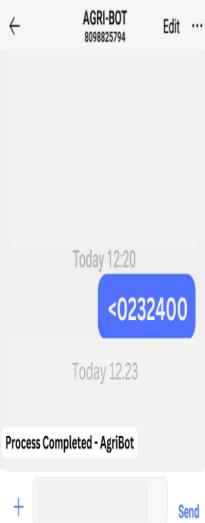

Figure10showsthescreenshotoftheSMSsentbytheuser forthePloughingoperationintheformatmentionedinTable 1.Figure11showsthediagrammaticrepresentationofthe land.Inthisfigure,theWhitecolourlinerepresentsthearea thatisploughed.Therouteoftherobotisrepresentedina

dark brown colour. The entire process is explained in the followingsteps

STEP 1: The first step of the programmed sequence is to receivethevaluesfromtheuserthroughGSMintheformof SMS.Thisisthentransmittedtothemicrocontroller.

STEP 2: Based on the variables given by the user, the Distancetobetravelledbytherobotinthefirstcolumnis supported by a proximity sensor which allows the wheel rotation in the forward rotation. When it completes the length given by the user it stops and turns right and continuestheploughingprocessinthenextcolumn.

STEP 3: Duringthisprocess,theploughingshovelremains down and in addition to cleaning unwanted plants, the rotating blade also rotates to cut down them. The rotary bladeiskeptinthebasementoftherobot.A12VDCmotoris usedforthepurpose.

STEP 1:TheShovellowersdownandloosensthesoiland thewheelsrotateandtherobotmovesforward.

STEP 2: It stops after moving through the distance mentioned (the distance between the dropping of two seeds).

STEP 3: AWoodendisc(diameter:50mm)isprovidedto support the dropping of seeds. The seeds are stored in a funnel-shapedcontainerabovethewoodendisc.Thefunnel hasaholeinthebottomthroughwhichtheseedsdropone aftertheother.Intherigiddisc,thereisahole(diameter:10 mm). The disc rotates till the robot reaches the location wherethelastseedhastobedropped.Thelimitswitchis usedtocontrolthelimitofthewoodendisc.

STEP 4: Whiletherobotmovesforwarddroppingseedafter seedthedugpitisclosedusingthesoil-closingshovel.

STEP 5:Aftertherobotreachestheendpointcoveringthe entirelengthgiventhroughtheSMS,itautomaticallyturns rightandstops.Theseedsaresownatequaldistancesinthe field.

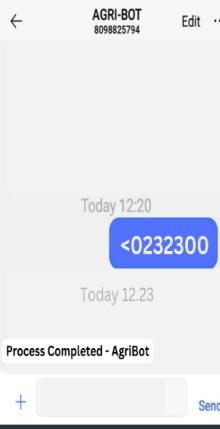

STEP 6:Aftercompletingtheentireoperation,therobotwill automaticallystopanddisplaythevalue0000intheLCD displayandsendanSMSaswellasshowninFig.14.

Fig-12: Ploughing completed SMS

STEP 4: Atlast,theAgribotwillsendthemessage“Process completed–AgriBot”totheuseroncetheprocessisfinished asshowninFigure12

(ii) Seed Sowing

Fig-13: Screenshot of SMS (Seed sowing)

Fig.13showsthescreenshotoftheSMSsentfromtheuser’s mobilephone.AftersendingtheSMStotheGSMmodule,the GSMmodulewillreceivetheSMScontentandtransmitthat input variable to the microcontroller and it starts the process. The process sequence is explained in the below steps.

STEP 7:Finally,theshovelgoesbacktoitsoriginalposition. Fig15showstheoutputofthelandwithsownseeds.

(iii) Soil moisture monitoring

Intheagriculturefield,aWaterpumpisusedtosupply thewholeland.Sometimesduetoheat,themoisturelevelof soilwillgodown.Byusingthissoilmoisturecheckingmode, thisproblemcaneliminate.Forselectingthisoperation,the variable‘w’shouldbegiven‘3’

CASE 1: SOIL MOISTURE LEVEL IS LOW

Whenthemoisturelevelofthesoilisdetectedtobelow by the moisture sensor, Microcontroller will turn ON the water pump in the agricultural land by using a relay connectedtoit.Thewaterpumpprovidedhereisa12VDC waterpumppoweredbya9Vbattery.

STEP 1:ASMSissentbytheuseralongwiththedetailsof thelandareathathastobemonitored.

STEP 2: The GSM sends the variable received by it to the microcontroller.

STEP 3: Soil moisture sensor continuously monitors the moisturecontentofthesoilbymovingforwardintheseed sownarea.

STEP 4: After it detects the low moisture level, The robot automaticallyswitchesonthewaterpump.

STEP 5: “Processcompleted-Agribot”isshownfinallyinthe SMSafteritcompletestheentireprogrammedsequences.

CASE II: SOIL MOISTURE LEVEL IS HIGH

Fig-16: SMS screenshot of Soil moisture monitoring

TheSMSissentintheformatof<0232300asshownin fig16.Here,‘02’representsthedistancebetweentheseeds sown,‘3’representsno.ofcolumns,‘2’representsthelength oftheland,and‘3’representsthesoilmoisturemonitoring mode. SMS received by the GSM is sent to the microcontroller and starts the sequence of operations as mentioned below. During the day time due to high temperatures,thelandcaneasilybedried.So,itisnecessary tocheckthelandduringtheeveningtime.

STEP 1:SMSsentbytheuseralongwiththedetailsofthat areaneedtobemonitored

STEP 2: GSM sent the variable received by it to the microcontroller.

STEP 3: soil moisture sensor continuously monitors the moisturelevelcontentbymovingintheseedsownarea.

STEP 4: After it detects the high moisture level, it automaticallyswitchesoffthewaterpump.

(iv) Weed removal

STEP 1:SMSwithcontrolvariablesissentbytheusershown infig.18

STEP 2:AfterreceivingtheSMSfromtheGSMitwillforward ittothePICmicrocontroller.

STEP 3:Inthebottomoftherobotithasarotarybladefixed, whichrotatesandwillcutdownallweeds.Thesebladesalso workduringploughing.

STEP 4:Afterfinishingalltheworktherobotwillstopatthe endlocationshowninfig.17

STEP 5:Aftercompletingalloperations,anSMSwillbesent byAgribottotheuser.

6. CONCLUSION

Inthispaper,Arobothasbeenproposedtoperformspecific agricultural activities namely ploughing, seed sowing, weeding, and soil moisture monitoring. The robot is designed to perform these activities using program sequences.Itdropstheseedwithoutwastinganyofthemat equaldistancesasmentionedbytheuser.TheGSMmodule isusedasaninterfacebetweentheuserandtherobot.Land dimensionsaregiventotherobotusingthemobilephone. Alltheactivitiesarecarriedoutaccordingtotheinstructions givenbytheuser.Therobothasbeentestedsuccessfullyand performedallmentionedactivities.Thisrobotwillbevery helpfultothefarmerswhocannotaffordtopayhighwages tothelabourers.Hence,largegroupsoffarmerscanusethis cost-effectiverobotforhugeagriculturallands.Thisproject may be improved with more agricultural activities. Spike wheelscanbeplacedformoremechanicalstrength.Also,the UsageofIoTandmachinelearningalgorithmsinthisproject canbedoneasafullyautonomousrobot.Otherfeaturessuch asdetectingtypesofweedsanddiseasesandthepercentage ofthegrowthofthevegetablescanbeincluded.

REFERENCES

[1] Abdulrahman,MangeshKoli,UmeshKori,Ahmadakbar, et al proposed (2017) “Seed Sowing Robot”-

InternationalJournalofComputerScienceTrendsand Technology(IJCST)–Volume5Issue2,Mar-Apr2017

[2] RetheepRaj,AjayAravind,AkshayV.S,MariyaChandy, Sharun N.D, et al proposed (2019) “A Seed Planting Robot with Two Control Variables”- Trends in ElectronicsandInformatics(ICOEI2019)

[3] PankajKumar,G.Ashoketalproposed(2020)“Design andfabricationofsmartseedsowingrobot”-Materials Today:Proceedings

[4] TanmayNagdeve,PranayJangde,HrushikeshTandulkar, SushobhitDhara,Neema Ukani,SaurabhChakoleetal proposed (2020) “Design of Automated Seed Sowing Robot for BT Cotton Seed”-Inventive Research in ComputingApplications(ICIRCA-2020)

[5] AlbertFrancisA,AravindhR,AjithM,BarathKumarMet al proposed (2017) “Weed removing machine for agriculture” -International Journal of Engineering Sciences&ResearchTechnology

[6] Beza Negash Getu, Hussain A. Attia et al proposed (2015)“AutomaticControlofAgriculturalPumpsBased onSoilMoistureSensing”-IEEE(2015)