EXPERIMENTAL INVESTIGATION ON THE PROPERTIES OF RECYCLED COARSE AGGREGATE CONCRETE

Abstract: Theaimofthisexperimentalworkistofindthe properties of recycled coarse aggregate. For this purpose, NaturalCoarseAggregate(NCA)isreplacedwithRecycled CoarseAggregate(RCA)10%,20%and30%forM25grade concrete mix respectively. The RCA is obtained from the demolishedwaste.Cementispartiallyreplacedwithsilica flume and GGBS 10%&20% each separately. This study summarizes the effect or influence of recycled coarse aggregateonworkabilityandmechanicalpropertiessuchas compressive strength, Rebound Hammer and Ultrasonic PulseVelocityforM25gradeofconcrete.

Keywords: - Recycled aggregate replacement of natural coarse aggregates, Silica fume and GGBS replacement of cement.

1. INTRODUCTION

AsthecementindustryreleasesasignificantamountofCO2 intotheatmosphere,sustainabilityofconstructionmaterials, particularlyconcrete,isthemostfrequentlydiscussedtopic worldwideatthemomentandwillcontinuetobesointhe future. There are two distinct phases in which cement production results in the emission of CO2 into the atmosphere.Oneisaccomplishedthroughthecalcinationof calciumcarbonates,andtheotherisaccomplishedthrough theburningofcoalsasasourceofenergyfortheproduction ofcement.

Whilecementonlymakesupasmallportionoftheconcrete's volume, the coarse and fine aggregates make up the majority roughly 75 to 80 percent. As a result of rapid industrialization and urbanization, there is an annual increaseinthedemandforaggregatesandcementusedin concrete around the world. However, there are troubling indicationsofalackofnaturalaggregatessources,whichmay result in future shortages. On the other hand, a lot of constructionanddemolition(C&D)wasteismadewhennew buildingsarebuiltandoldonesaretakendown,whichcauses problemswithlandfillsallovertheworld.

Globally,theconstructionanddemolitionindustriesusealot of natural resources and dump a lot of construction and

demolition debris in landfills. Not only are these methods harmful tothe environment,but theyare also regardedas unsustainable. Quarrying activities harm the environment andoveruseofaggregatesinconcreteproductionresultsin overexploitationofnaturalaggregates.RecycledAggregates (RA)asaviablesourceofstructuralmaterialhaverekindled interest as a result. Reused totals, acquired from neighborhood development and destructionsquander, not just lessens the utilization of essential regular assets yet additionallyworksonthemanageabilitybydecreasingthe utilizationofsignificantlandfillspace.

Cementuseisrisingasaresultofinfrastructureexpansion andrapidindustrialization.Theproductionofcementusesa lotofenergyandreleasescarbondioxide,whichpollutesthe environment.Asaresult,utilizingPozzolanamaterialsforthe preparationofconcreteandreducingcementconsumption are two potential solutions to these issues. According to previousresearch,usingFlyAsh,SilicaFume,Matakaoline, GroundGranulatedBlastFurnaceSlag,andRiceHuskAshas apartialsubstituteforcementresultsindecreasedcement consumption as well as increased concrete strength and durability.

To protect regular assets,various examinations have been performed by involving reused total in concrete, yet it generallybroughtaboutlowerlevelofsubstantialqualities. This was because the cement paste and the recycled aggregateswerenotabletoformastrongbondbecausethere wasstillmortaronthesurface.

2.LITERATURE REVIEW

2.1 Experimental investigation on Recycled Aggregate Concrete Made with Silica Fume

Experimented with the characteristics of cement mortar containing silica fume particles and recycled aggregates, resulting in stronger blended mortars after seven and 28 days.Themicrostructureanalysisrevealedthat,inaddition toservingasafillertoenhancethemicrostructureandan activator of the pozzolanic reaction, 20% silica fume was usedasapartialreplacementforcementon20%recycled aggregates.

2.2 Study on properties of concrete using GGBS & recycled aggregates.

Ggbs Ground granulated impact heater slag utilized in concreteasconcretesubstitutionwhichisconcretesaving, energy saving, cost saving and besides cause ecological financial

•Impact heater slag is non-metallic side-effect delivered duringthetimespentironmaking.

• Blast furnace slag is not corrosive to steel embedded in concretemadewithblastfurnaceslagcementoraggregates becauseitisslightlyalkalineandhasapHinsolutionrange of8-10.

•PortlandcementandGGBSarecombinedtomakeconcrete structuresthatarelong-lasting.

2.3 Study on Recycled Aggregate

Commercialrecycledaggregateswithreplacementratesof 0%,25%,50%,and100%fornaturalaggregates.At28days, 100%recycledaggregateconcrete'scompressivestrength was12.2%lowerthanthatofnaturalaggregateconcrete.At a 20 percent replacement level of natural aggregate, the valuesofrecycledaggregateconcreteimprovedsignificantly after90days.

3.MATERIALS AND METHODOLOGY

3.1 SILICA FUME

Microsilica,alsoknownassilicafume,isabyproductof making ferrosilicon alloys or silicon metal. It is a fine powdersubstancethatrangesinsizefrom0.1to5microns and is mostly composed of amorphous silicon dioxide (SiO2).Duetoitshighsurfacearea-to-volumeratioandhigh reactivity,silicafumeisanexcellentpozzolanicmaterial.

Inconcretemixtures,silicafumeisfrequentlyutilizedas aadditionalcementitiousmaterial.SilicaFumereactswith thecalciumhydroxideproducedduringcementhydrationto formadditionalcalciumsilicatehydrate(C-S-H)gelwhen addedtoconcrete.Thisenhancestheconcrete’sdurability, strength and resistance to chemical attack. Concrete’s permeabilityisalsoreducedbysilicafume,makingitmore resistant to water penetration and the harmful effects of freeze-thawcycles.

Silica Fume isutilized notonlyin concrete but alsoin ceramics,rubbercompounds,refractorymaterials,other

S.NO PROPERTIES VALUE

1 SIZE,MICRON 0.1

2 SPECIFICGRAVITY 2.2

3 BULKDENSITY 576Kg/m3

4 SURACEAREA 20,000m2/Kg

Ground granulated blast furnace slag (GGBS) is a byproduct of the production of iron that, when added to concreteimprovesitsworkability,strengthanddurability. Ironore,limestoneandcokeareheatedtoapproximately 1500 degrees Celsius in order to produce this substance. The process of GGBS does not directly form in a blast furnace.Theproductionofironresultsinbyproductslike moltenironandslag.Aluminaandsilica,insmallamounts, aswellasoxide,makeupthemoltenslag.

Thegranulationoftheslagoccursasitcools.Inorderto accomplishthis,itispermittedtotravelthroughwaterof highpressure.Theparticlesquenchasaresult,producing granuleswitha diameteroflessthan5millimeters.After that,itisdriedandgroundinaspinningballmillintoafine powder, which is a spinning ball mill into a fine powder, whichiscallergroundgranulatedblastfurnaceslag.

3 3 METHODOLOGY

Paststudies.Concretetestsareconductedtodetermine whether silica flume and ggbs20% are utilized in proportion Prior to beginning the work, the research consistedofareviewofpreviouslypublishedtothecement content. PPC class 53, natural sand as fine aggregate, natural aggregate as coarse aggregate, and recycle aggregatesof20%wereallusedinthistest.Anominal M25designwithawater-to-cementratioof0.45anda ratioof1.0:10:2.0wasusedtotestthesamples.After seven days of curing, the first set was tested, and the secondsetwastestedafter28days.

4 RESULT AND DICUSSION

4.1 compressive test

Inlightofthistest,onecaneitheracknowledgeordismiss a substantial establishment. The quality of the materials used, the mix design, and quality control during concrete production all affect compressive strength as a concrete property.Themostcommontestpatternisacube15cmx 15cmx15cm,dependingonthecode.

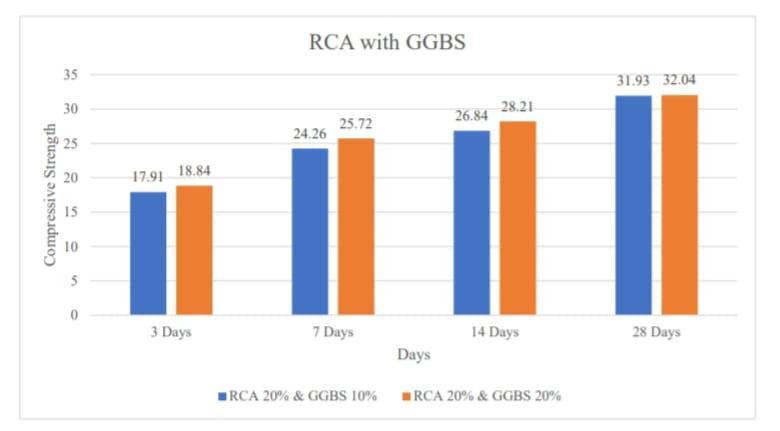

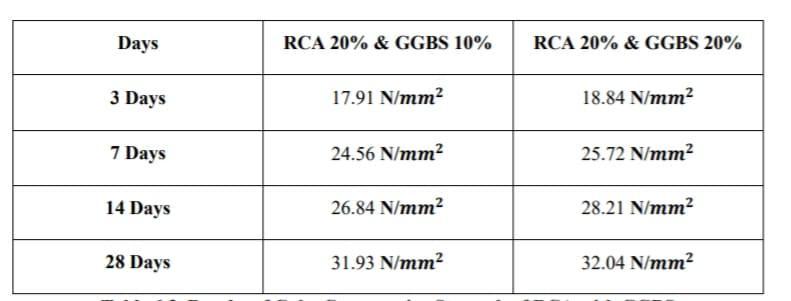

4.2 COMPRESSION TEST RESULT

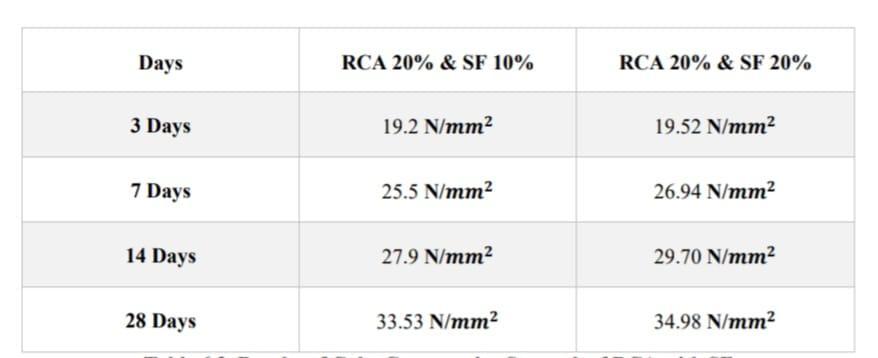

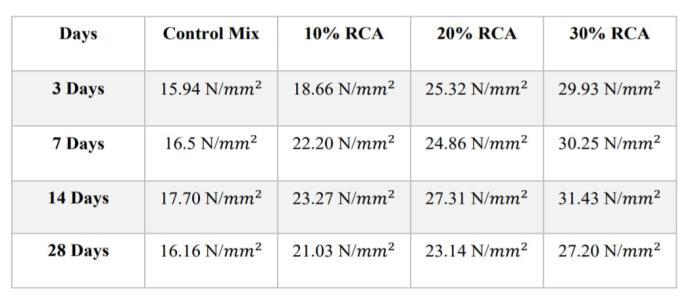

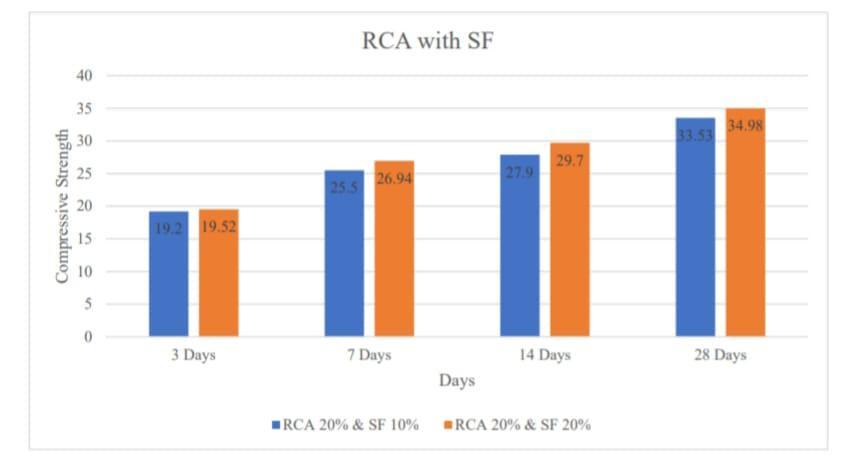

Table No 4.1 Compression strength of control Mix & RCA

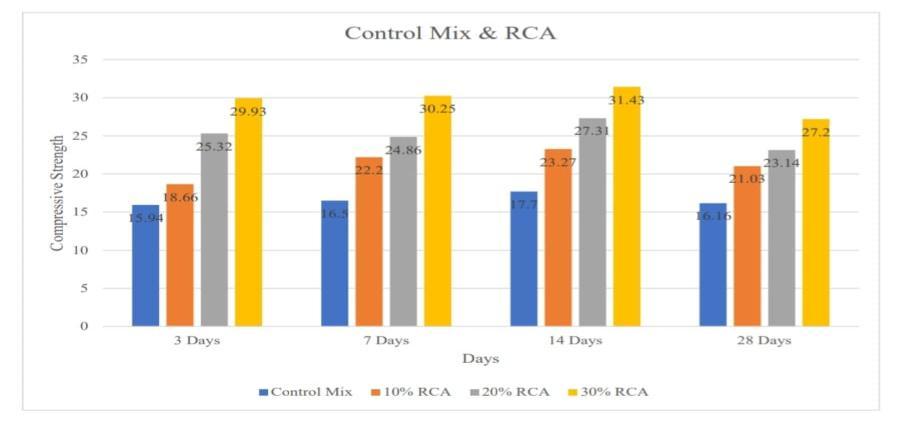

Graph No:4.1 Compression strength results for control Mix & RCA

5.0 CONCLUSION

1.Thecompressivestrengthdecreasedasthepercentageof recycledcoarseaggregateincreasedtomorethan20%,but this effect is unaffected when recycled coarse aggregate replacesnaturalaggregatesupto20%.

2.Asaresult,recycledaggregatesand10%and20%ofGGBS andSilicaFumeareutilized.

3.When10%and20%ofthecementarereplacedwitheach, respectively, silica fume has a greater positive impact on compressivestrengththanGGBS.

REFERENCES

1.References Vyas, C.M., and D.R. Bhatt published an articletitled"UseofRecycledCoarseAggregateinConcrete" intheJanuary2013issueofIJSR,aninternationaljournalof scientificresearch.

2.RyuJ.S.2002.Atrialconcentrateontheimpactofreused total on substantial properties, magazine of substantial examination.54(1):7-12.

3.Alireza N. G., Suraya A. , Farah Nora A.A. , Mohamad A. M.(2010). " Contribution of GGBS to Concrete and Mortar Properties:ReviewNo.

4NationalLaboratoryofCivilEngineering(LNEC),Portugal, by Arlindo Goncalves, Ana Esteves, and Manuel Vieria (1990). Impact of recycled concrete aggregate on the durabilityofconcrete2001.M.Anwar,T.Miyagawa,andM.

GaweeshMakinguseofsilicafumeasasubstituteforcement in concrete. in the proceedings of the first international conferenceonecological buildingstructuresheldin2001. pp.671-684.

6. Saurav(2012)"Useofnanotechnologyinbuilding materials" Worldwide Diary of Designing Exploration and Applications" Vol. 2, Volume 5, Number 5,SeptemberOctober2012,pages1077-1082"InfluenceofGGBSandSilica FumeonConcretePerformance,"byM.Nili,A.Ehsani,andK. Shabani(2010).

8.Bjornstrom J., Martinelli A., Matic A., Borjesson L. furthermore, I.Panas (2004) "Speeding up impacts of colloidal Silica Smoke for advantageous calcium-silicatehydrate development in concrete", Substance Physical scienceLetters,392,242-248.

9. Heasam Odoh, Andrew, and Faiz Uddin Ahmed B "Effectof Silica Fumeonthe PropertiesofConcretesWith RecycledCoarseAggregates" MohsenTadayon,Hamed, MostafaKhanzadiMohamedandSepehri."InfluenceofGGBS Particles on Mechanical Properties and Permeability of Concrete,"bySeperi(2010).

11."Methods of test for aggregates for concrete," IS 2386 (Parts1and3):1963

12."Methodoftestforstrengthofconcrete,"accordingtoIS 516:1959

13.Shetty'sConcreteTechnologyS.Chandpublications,first editionofM.S.,1982.

14.IS456-2000.Forpractice,aclearandreinforcedconcrete code.NewDelhi'sBureauofIndianStandards

15.IS 383-1970. specification for natural coarse and fine aggregate for concrete. New Delhi's Bureau of Indian Standards

16.IS 10262:2019. Guidelines for the proportioning of concretemixNewDelhi'sBureauofIndianStandards

17.IS12269:1987.requirementsfor53gradeOPCcement. NewDelhi'sBureauofIndianStandards

18.SW.ASTabsh.Abdelfatah,"Impactofreusedsubstantial totalsonstrengthpropertiesofcement",Developmentand BuildingMaterials,vol.23,1163-1167,2009.

19.MC. Rao, SK. SV. Bhattacharyya Barai. “ Concrete propertiesareaffected byfield-recycledcoarseaggregate, accordingtoMaterialsandStructures,vol.44,205-211,2011

20.BRE.“Recycledaggregates,”Wikipedia,London,United Kingdom,BuildingResearchEstablishment,1998.

21.BCSJ. “ Recycled aggregate concrete and a proposed standardfortheiruse,”CommitteeonDisposalandReuseof ConstructionWaste,BCSJ,Tokyo,Japan,1977.