Compressive Strength of Different Grades of SCC Mix With 0.5% Of PEG 400 Self Curing Compound

1Associate Professor, Department of Civil Engineering, Rajeev Gandhi Memorial College of Engineering and Technology (Autonomous), Nandyal, India

2,3,4,5,6,Student, Department of Civil Engineering, Rajeev Gandhi Memorial College of Engineering and Technology (Autonomous), Nandyal, India ***

Abstract –For achieving the desired quality of SCC, proper curing is essential. But in practice achieving proper curing is difficult due to dependency on humans. Also requires water daily during the curing period. Hence researchers are using self curing compound. The effect of Self Curing Compound PEG 400 on compressive strength of different grades of SCC Mix is not investigated as per the literature cited. The present investigation finds the effect of PEG 400 self curing compound on compressive strength of SCC Mixes

The Nan-Su mix design is used. The workability properties Slump Flow, J-Ring satisfy EFNARC Guidelines, but V- Funnel and L Box values does not satisfy EFNARC Guidelines. For M25 and M30 grades compressive strength obtained is more than the target mean strength. For all grades compressive strength obtained is more than the characteristic compressive strength of concrete.

Key Words: SelfCompactingConcrete(SCC), GGBS,PEG 400 Self Curing Compound, Nan-Su Mix Design, EFNARC Guidelines, Slump Flow Test, J-Ring Test, V-Funnel Test andL-BoxTest.

1. INTRODUCTION

For achieving the desired quality of SCC, proper curing is essential. But in practice achieving proper curing is difficultduetodependencyonhuman.Alsorequireswater daily during the curing period. Hence researchers are using self curing compound. The effect of Self Curing Compound on compressive strength of different grades of SCCMixisnotinvestigatedaspertheliteraturecited.The present investigation finds the effect of PEG 400 self curingcompoundoncompressivestrengthofSCCMixes.

TheNan-Sumixdesignisused MasterGleniumSKY8233 super plasticizer is used. Mix grades M20 to M40 are consideredininvestigation.

2. EXPERIMENTAL INVESTIGATION

2.1 Materials Used

i. OPC53Grade(Zuaricompany)

ii. GGBS

iii. FineAggregate

iv. Coarse Aggregate-12.5 mm(70%) and 20 mm(30%)

v. MasterGleniumSky8233(SuperPlasticizer)

vi. PEG400(SelfCuringCompound)

2.11 Materials Properties

ThepropertiesofmaterialsareshowninTable1,2&3.

2.21 Nan-Su Mix Design

The steps used in Nan-Su Mix Design for M35 Grade are givenbelow.

Step 1: Calculation of Coarse and Fine aggregate contents:

( ) =899924kg/m3 (1)

( ) = 739800 kg/ m3

(2) Where,

Wfa:contentoffineaggregatesinSCC(kg/m3),

Wca :contentofcoarseaggregatesinSCC(kg/m3),

fa:unitvolumeweightoflooselypiledsaturatedsurfacedryfineaggregatesinair(kg/m3),=1545205kg/m3

ca:unitvolumeweightoflooselypiledsaturatedsurfacedrycoarseaggregatesinair(kg/m3),=1376.13kg/m3

PF:PackingFactor=1.12(Assumed)

: volume ratio of fine aggregates (sand) to total aggregates, =52%(Assumed)

Table 5: Workability Properties

Step 2: Calculation of Cement Content:

=313.649kg/m3 (3)

Where, C=Cementcontent(kg/m3);

f’c = designed compressive strength (psi). =6273 psi (4325 MPa Target Mean Strength Obtained from IS: 10262-2019)

Step 3: Calculation of mixing water content required by cement: (4)

W wc =120.755kg/m3 C C

Where,

Wwc =waterrequiredbycement(kg/m3), =thewater/cementratio =0.385(AfterTrialmixes)

Step 4: Calculation of SP dosage

DosageofSPusedWsp =n%×C (5)

Where,

n%=DosageofSP=0.8%(Fixedaftertrials)

AmountofwaterinSP

Wwsp=(1-m%)Wsp=1.255kg/m3 (6)

Where,

m%=AmountofbindersanditssolidcontentofSPtaken as50% W

Step 5: Calculation GGBS content:

=

0.149m3 (7)

Where, w =densityofwater, Gca,Gfa,Gc,Gw arespecificgravityofcoarseaggregates, fineaggregates,Cement,andwaterrespectively, (W/G)=WatertoGGBSratio(Assumed) Va =aircontentinSCC(%).

The modified formula2 (8) for calculating WG is used.

(8)

using14litresofconcrete.LBoxtestisconductedbyusing 17 litres of concrete. Fresh properties are determined for themixes.TheresultsareasshowinTable5. SlumpFlow and T50 Slump Flow results are conforming to EFNARC guidelinesfor SCC andotherresultsare notconfirming to EFNARCguidelines

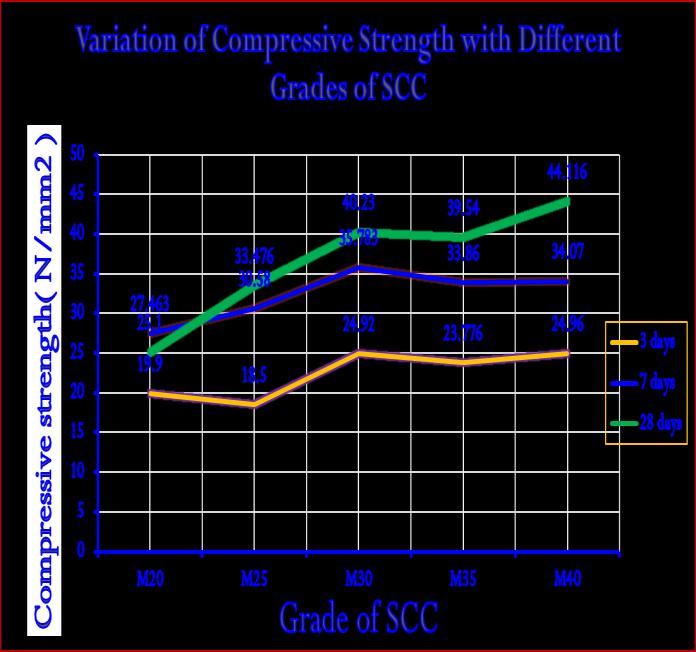

5. COMPRESSIVE STRENGTH OF MIXES

The compressive strength of different grades of concrete for 3,7 and 28 days is determined after curing in air at room temperature and the results are shown in Table 6 and also shown in Fig 1. For grades M25 and M30 compressive strength is more than the target mean strength.Forallgradesthecompressivestrengthobtained ismorethanthecharacteristiccompressivestrength.

Where,GG,SpecificGravityofGGBS

and =0.385is assumed, andVPG obtainedfrom Eq.(7)

WG = 202.235kg/m3 (9)

MixingwatercontentrequiredforGGBSpasteisobtained fromEq(10)

WWG= ×WG =77.860kg/m3 (10)

Step 6: Calculation of mixing water content in SCC:

The mixing water needed by SCC is calculated from Eq. (11).

Ww =Wwc +WWG -Wwsp =197.361kg/m3 (11)

Step 7: Calculation of PEG 400 Self Curing Compound:

PEG400SelfCuringCompoundof0.5%byweightof CementitiousmaterialsiscalculatedfromEs.(12)

WPEG = .005x(C+WG)=0.005 x( 313.649+202.235) = 2579 kg/m3 (12)

3. MIX DESIGN

Concrete grades M20 to M40 are designed as per above Nan-Su mix design Target mean strength as per IS 10262:2019 is used for the mixes in Eq. 3 in place of f’c Based on trial mixes W/C ratio and SP dosage is fixed to satisfy EFNARC guidelines. The SCC mix proportions for differentgradesofSCCareshowninTable4.

4. WORKABILITY TESTS

SlumpflowtestandthenJ-Ringtestisconductedinorder byusing6litresofconcrete. Vfunneltestisconducted by

6. CONCLUSIONS

1. For grades M25 and M30 compressive strength is morethanthetargetmeanstrength(IS:10262=2019).

2. For all the grades compressive strength obtained is more than the characteristic compressive strength of concrete.

3. Slump flow and T50 slump flow test results are conformingtoEFNARCguidelinesforSCC.

REFERENCES

1. C. Krishnama Raju et. al. (2022) investigated on “Compressive Strength of Different Grades of SCC Mix using Portland Slag Cement (75% ), GGBS(25%) and Replacing 20% Fine Aggregate with Copper Slag” , International Research Journal of Engineering and Technology(IRJET), Vol. 9, Issue 04, April 2022 pp: 3535-3539,p-ISSN:2397-0072.

2. G. Asif Hussain et.al (2020), “Properties of M60 High PerformanceSelfCompactingConcretebyusingBlends of Different Sizes of Coarse Aggregate”, National Virtutal Conference on Recent Trends in Civil Engineering -2020 (RTCE’20),September 2020 pp 3136,ISBN:978-81-942685-2-9.

3. Gajireddy Nandini et. al. (2020), “An Experimental Study On Physical Properties Of Self Curing Concrete by using Polyethylene Glycol”, International Journal of Research,vol.07,Issue02,p-ISSN:2348-6848.

4. J. Vengadesh Marshall Raman et. al. (2017), “Partial Replacement of Cement With GGBS in Self Compacting Concrete for Sustainable Construction” , SSRG International Journal of Civil Engineering,(SSRG-IJCE), Vol.04,Issue.03,March2017,ISSN:2348-8352.

5. B. Chandraiah, et. al. (2017) “Variation Of Compressive Strength And Split Tensile Strength Of M40 Self Compacting Concrete With Different Sizes Of Coarse Aggregate”, International Journal of Engineering Technology Science and Research (IJETSR), Vol. 4, Issue 8, August 2017, pp.279-285

6. Bhavani, et. al. (2016), ” Effect on Mechanical Properties of M25 SCC with Variation of Class - F Fly Ash & GGBS”. International Journal of ChemTech Research, Vol. 11, No. 07, 2018, pp. 70-77, DOI= http://dx.doi.org/10.20902/IJCTR.2018.110709

7. M.V.Jagannadha Kumar et. al. (2012), “Strength Characterstics Of Self-Curing Concrete”, International Journal of Research in Engineering and Technology, Vol :01Issue:01,Sep-2012,ISSN:2319-1163.

8. S. Venkateswara Rao, M.V. Seshagiri Rao, P. Rathish (2010), ”Effect of Size of Aggregate and Fines on StandardandHighStrengthSelfCompactingConcrete”, JournalofAppliedSciencesResearch,pp.433-442

9. Nan Su, Kung-Chung Hsu and His-Wen Chai (2001) proposed a ” Simple Mix Design Method for Self Compacting Concrete” Journal of Cement Concrete Research,Vol.31,No.12,pp.1799-1807.,Dec.2001.