STUDY AND IMPLEMENTATION OF LAST PLANNER SYSTEM (LPS) IN CONSTRUCTION PROJECTS

Shamal S. Chavan1 , Prof. A.V. Hankare2

1PG Student (M. Tech Construction and Management)

2Assistant Professor (Civil Engineering Department)

1-2 Tatyasaheb Kore Institute of Engineering and Technology, Warananagar, Maharashtra (India) ***

Abstract - Lean construction is a relatively new construction management philosophy which has evolved from Lean manufacturing principles. Lean construction along with its various tools like the Pull Approach, Just in Time, Continuous Improvement, Last Planner System, etc. has gathered a lot of impetus in the developed nations. The challenge now lies in implementing it in the developing countries. The Last Planner System (LPS) is well-documented in the literature, and has sometimes been used to represent lean construction or lean project management. LPS aims to achieve reliable workflow by encouraging foremen to have a sense of ownership of the project programme and to build-in their commitment into it. Lean Construction methodis consideredthe core principle behindthe Identificationand Elimination ofvarious wastes inconstruction

Key Words: Lean construction, Lean Principles, Last Planner, Labour activities, Target works

1.INTRODUCTION

Assuchwhenwetalkofconstruction,theimmediatecharacteristicsthatgoinourmindareuniqueness,complicacyandend resultinclination.Inordertoexecuteanactivity,thefirstandforemoststepisthethoughtofansweringhow,whenandmost importantly“bywhom”.Thoughmodernconstructionshavestartedtoimprovetheconstructionpracticeandproceduresby meansofmechanization,alargepartofanyactivityisdependentontheconstructionworkers,whomwewillhereinafterrefer toas‘Labours’throughoutthispaper.Lackofskilledlabourandlowproductivitymayseemtobetheimmediatecauseof wastageoflabourresource.Thisissignificantmainlyinthefinishingactivitiesofanybuildingproject,sincetheappearanceand afeelingofgoodaestheticismindorientedwhichcanbewellorganizedonlywiththehelpoflabours.Asitsnameindicates,in LPSthedecisionmakingisgiventothe‘lastplanner’orforeman,sothathecanaddindetailsandcommittowhatcanactually beachievedinthecomingweek(Ballard,2000).

1.1 Last Planner System

Lean Construction Institute created the Last Planner System in 1992. LPS is a production system, according to the Lean Construction Institute This was developed to provide a predictable workflow and to serve as a quick learning tool for construction performance, projections, documentation, and project handover. LPS is a bottom-up method to project management,asopposedtothetop-downstrategyusedinstandardprojectmanagement.Controlisdelegatedtolower-rank workerswhoactuallyoperateonthesite,ratherthanseniormanagement,inLPS.

Workisbrokendownintosmallerpackagesandactivitiesinconventionalmanagement,andprecisetimedurationswere assignedtothecompletionofthetasksusingthecriticalpathtechnique.TheCPMtechniqueincorporatesfloatfornon-critical tasks,allowingtheseactivitiestobedelayedwithoutaffectingtheoverallprojectduration.However,thebiggestshortcomingof CPM is that it ignores the time necessary for information and material flow. However, given the dynamic nature of the construction sector, the display of information and material flow becomes critical. The LPS can be used to aid with this representation.

LastPlannerisinchargeoftheconnections,talks,andcommitmentsthatmakeaprogrammepossible&inavarietyofone-off productionsettingssoftware, productionplanningchoicesmustbemadejointlyatthelowestpossiblelevel One-of-a-kind productionincludesplanning,shipbuilding,yachtfit-out,andconstruction.LPSalsoworksonnewproductdevelopmentand designwithmodifications.

LastPlannerisa25-year-oldshort-termprojectplanningsystemthatwasinitiallyusedinengineeringconstruction.It continuestomakemajoradvancesinthesafetyofprojectsandprogrammes.Predictability,productivity,deliveryspeeds,profit, and project team members emotions of well-being LPS provides a practical solution to manage project-based production cooperatively,allowingissuestobediscoveredandmanagedbeforetheybecomemajorproblemsOn-siteissuesarereduced, increasingthelikelihoodthatwork will flowsmoothlyandprojectswill befinishedonschedule.Itservesasacriticallink

betweenthelogisticsandconstructionteams.Asaresult,anincreasingnumberofbusinessesareincorporatingitintotheir usualprojectdeliverystrategy.

LastPlanner,forexample,encouragesdetailedcommunicationbetweentradeforemenandsitemanagementinthebuilding industryandbeforethesituationbecomesseriousThesediscussionsboostthelikelihoodofworkflowingandemphasizethe importanceofpersonaltiesandpeerpressureintheprocess.

1.2 Purpose of study

Theconstructionbusinessisoneoftoday'semergingindustriesthathasasignificantinfluenceonanycountry'seconomy. Thebuildingindustrycontributessignificantlytotheeconomy'scompetitivenessandgrowth.Amodern,efficientinfrastructure is a key driver of productivity, and the construction industry has a major role in delivering the built infrastructure in an innovativeandcost-effectiveway.

The four M's are material, money, manpower,and machinery, with time being the essence of the building business. In construction, good project management requires a zealous pursuit of the most effective use of personnel, materials, and equipment.WemustinvestigatetheviabilityoftheLastPlannerSystemintheIndianconstructionsectorinordertoimprove constructionmanagementperformance.

Itiswidelyacknowledgedthatconstructionmanagementhasanumberofpracticalissuesthatneedtobeaddressedorbetter understood.Thepersonorgroupinchargeofproductionunitmanagement,ortheaccomplishmentofindividualassignmentsat theoperationallevel,isknownasthe"lastplanner"(Ballard,1994).Itwascreatedtoimprovetheefficiencyofplanningand controlbymakingprogramsmorepredictable,increasingthelikelihoodofcompletingprojectsonschedule.Thismethodclaims tomakethejobeasiertocompleteMakeassignmentsavailable,promoteshort-termplanning,andreducewasteandnon-valueaddingactivityto make programs more predictable.Furthermore, itallows forthecollaborativeadministrationof thefull network ofconnectionsandinteractionsrequiredforeffectiveprogrammecoordination,productionplanning,andproject delivery.Asaresult,thetechnique'sefficacymustbetestedinthelocalbuildingsector.

1.3 Objectives

1 TostudyconceptofLastPlannerSystem.

2.ToidentifytheWorkPackagesi.e.,activitiesdeciding,materialandlabourrequiredetc.thatmaybeneededwithinthe workperiod.

3.Toconsultwithstakeholdersinordertocompletetheworkwithinthetimeconstraint.

4.Tocreateweeklyworkactivitiesthataregoingtobecompletedbeforedeliveryoftheassignedwork.

5.Toapplyweeklyworkplanningondecidedactivities.

6.Tocheckthelabourproductivity,timeandcostminimization.

1.4 Methodology

1 Collectionofinformationthroughliteraturereview.

2 LearningtheLeanconstruction.

3.TostudyLPSprinciplesandexaminethecomponentsofit.

4 TocollectthenecessarydatafromthecasestudytakenfromtheKolhapurregion.

5.Tomakeweeklyconstraintanalysisofgivencasestudybasedondatacollected.

6 ToanalyseandapplyimpactofLPS.

2. LAST PLANNER SYSTEM & IMPLEMENTATION METHODOLOGY

2.1 Introduction

Thisstrategypromisestomakeprogrammesmorepredictablebyutilisingshort-termplanning,reducingwasteandnonvalue-addedactivity,andpreparingassignmentsforwork.Itwascreatedtoimprovetheaccuracyofplanningandcontrolby makingprogrammesmorepredictable,therebyincreasingthelikelihoodofcompletingtheprojectonschedule.AbdullahO. Alsehaimi (Abdullah O. Alsehaimi) LPS is built on panoptic collaboration between diverse consultants, contractors, and subcontractors who commit to more detailed coordination of their efforts in order to determine the most practicable implementationtechniques.Inaddition,thefinalandmostdetailedscheduleplanisdevelopedbasedonpreviousexperiences with reference to what caused deviations between planned and actual execution It detects all of the necessary tasks and

restrictionsforaparticularjobandensuresthatalloftheprerequisitesarefulfilledandanyconstraintsareeliminatedbeforethe taskbegins.

Theindividualorgroupthatmakesassignmentstoleademployeesisknownasthe"lastplanners"inLPS.(Ballard).Last plannersarethosewhoareinvolvedintheactualexecutionofthejob;theyarealsoactivelyinvolvedindesigningthework scheduleandensuringthattasksarecompletedpriortothestartoftheactivity.Thefinalplanner'sresponsibilitiesinclude ensuringthattheworkflowinthebuildingprocessisefficientandthatthejobiscompletedatanideallevel.

Asobservedfromthestudylastplannerprinciplescanbelistedas-

•Asyoucomeclosertocompletingthetask,youshouldplanwithmoredepth.

•Preparetheplansincollaborationwiththosewhowillreallybedoingthetask.

•Asagroup,analyseandremovethelimitsonthescheduledtasks.Commitmentsthatcanberelieduponshouldbemade.

•Takenotesontheworkbreakdownsthathappened.

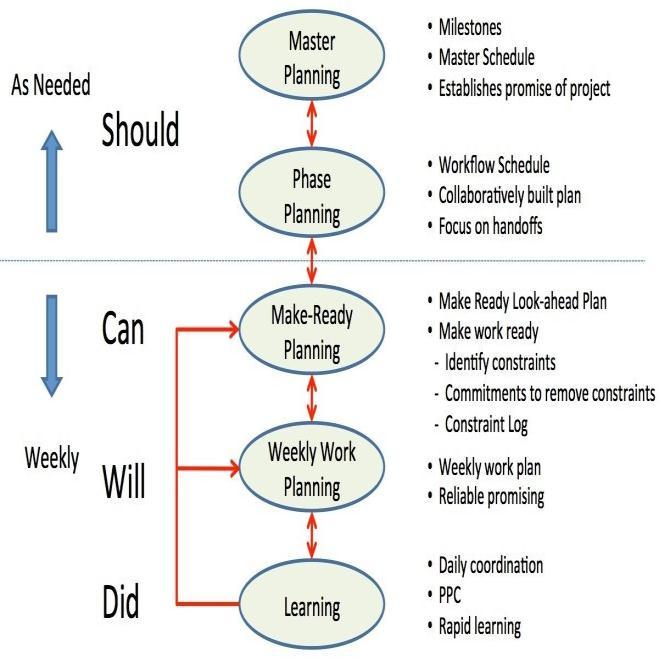

2.2 Components of Last Planner System

1. MasterPlanning

2. PhaseScheduling

3. Look-aheadPlanning

4. WeeklyWorkPlan(WWP)

5. PercentagePlanComplete(PPC)

2.2.1

Master Planning

It represents the project's significant milestones. The project's overall timetable is contained in master planning. The milestonedatesarecalculatedbyworkingbackwardsfromtheprojectcompletiondatetotheprojectstartdate.Itbringsallof theimportantcomponentstogethertoexaminetheirinterdependenciesandagreeontheappropriatesequenceofactions.The goal of this plan is to develop planning and execution methods, as well as to assess the viability of existing resources in completingtheplanwithinthetimeframeset,andtoidentifykeymilestonesforcustomersandowners.

2.2.2 Phase Scheduling

PhaseschedulingisastepintheLPSprocessthatinvolvesusingapullmechanismtocreateatimetableforeachphaseofthe project.Thesephasesarebasedonthemasterschedule'smilestonesandserveasthefoundationfortheschedule'sappearance. Eachstepisplannedbackwardsfromthemilestones,highlightingthecriteriaaswellasconditionsthatmustbemetinorderto gofromoneactivitytothenext.Phaseschedulingalsodeterminesthelevelofcollaborationneededtoallownumeroustasksto runconcurrently.Attheconclusionoftheprocedure,durationsforeachactivityaredeterminedtocheckwhetherthereisany floatbetweenthecalculatedstartdateasperthemasterscheduleandthepossiblestartdate.Ifanyfloatremainsafterthewhole phaseschedulehasbeenprepared,itiseitherusedtopostponethestartofthephasebyspendingmoretimeinearlierworkorit isgiventoactivitiesthatarepossiblychangeableandinvolvegreateruncertainty.

2.2.3 Look-ahead Planning

Themostsignificantfeatureofthefinalplannermethodislookforwardplanning.Thedraftingofalook-aheadprogrammeis usuallydoneoveraperiodof4-6weeks.Theseschedulesgiveyouaheads-uponactionsthatareduetobefinishedorbegun withinthattimeperiod.Lookaheadplanning'smajorgoalistoidentifyandeliminaterestrictionsthatmustbeaddressedprior to the start of an activity. Contract design, material procurement, labour needs, and precursor work are all examples of constraints.Tasksaremadeworkreadyandcanbeputinworkablebacklogsaftertheindicatedlimitationsareeliminated.Look aheadplanningisimportantbecauseitbridgesthegapbetweenlong-andshort-termplanning.It'saplanningloopthatconverts whatshouldbedoneintowhatwillbedone.Asaresult,itgivesoperationalinformationthatarerequiredforobligations

2.2.4 Weekly Work Plan (WWP)

Inthelastplannersystem,WWPisanelementofshort-termplanning.It'saone-weekoperationalassignmentleveltimetable andcollaborativemanagementplanthat'sbasedoncommitments.Itcontainsallactionsandactivitiesthatmustbebeguninthat specificweekandcompletedbythecompletiondatesspecifiedinthelookaheadplan.Onlywork-readyqualityassignmentsare included in WWP, which includes activities with all limitations eliminated, enough resource availability, necessary work accomplished,andsoon.Thegoalofweeklymeetingsistoimprovecommunication,discusstheprogressofthepreviousplan, planforthecurrentweek,andinvestigatetaskinterdependency.Fortheproject'seffectiveadvancement,thereisatwo-way transmissionofinformationbetweentopmanagementandthefinalplanners.Thisisthestageinwhichthelastplannersareheld accountableforthepromisestheymadeduringthesubsequentscheduleplanning.

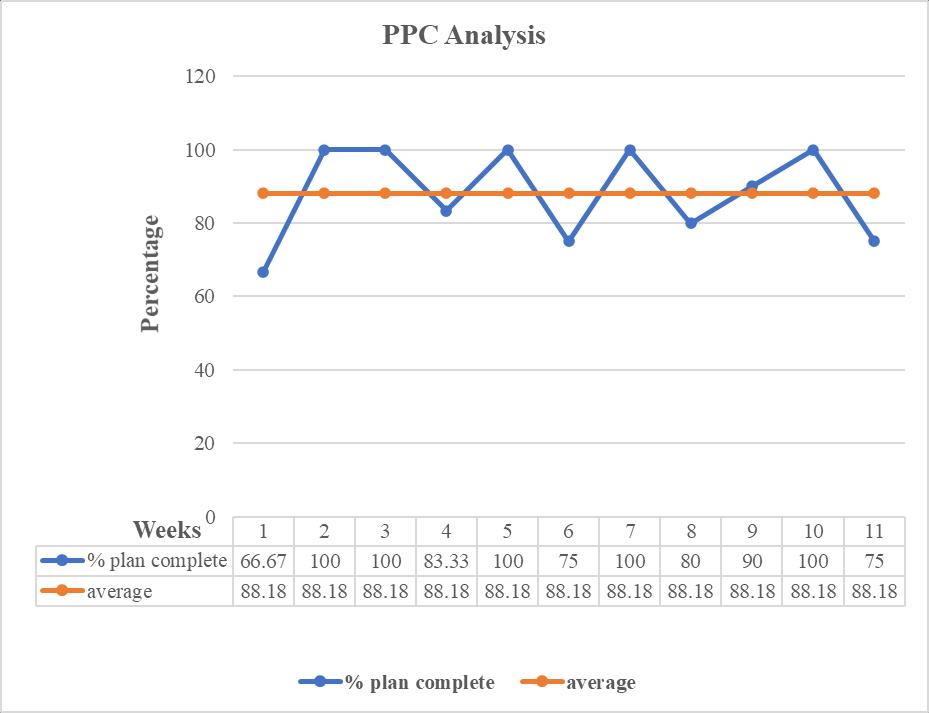

2.2.5 Percentage Plan Complete (PPC)

Inthelastplannersystem,PPCisthelearningphase.PPCisusedtodeterminetheWWP'sdependability.PPCiscomputedby dividingthetotalnumberoftasksaccomplishedbythetotalnumberoftasksplannedforaspecifictimeperiod(1week).PPC measurementisthefirststeptowardbetterplanningsinceitidentifiesthereasonsforactivitynon-completionandidentifiesthe corecauses.Followingthat,stepsaredonetopreventthesereasonsofnon-compliancefromoccurringagain.Thisassessment servesasafoundationforlong-termprogressthroughthedecreaseofdifficulties.ThisPPCapproachisusedtokeeptrackofa project'sprogress.

2.3 Last Planner System tools

Theauthorhasparticularlynotedthatthetoolsdescribedbelow,includingastablesandcharts,wouldbeessentialfor effectiveimplementationofLPStheoryonbuildingprojectsinordertogetthebestpotentialoutcomes.Aspreviouslysaid,LPSis acomponentofshort-termplanning,anditisseparatedintofiveelements.WWPandPPCaretherealoperationalassignment levelportionsintheimplementationprocess,outofthesefivesections.InWWP,restrictionsareanalysed,andlastplanners makecommitmentsforthefutureweek.ThefollowingtoolsmustbeusedinpractiseforaccurateWWPanalysis

2.3.1 Weekly Constraints analysis board

Table-1

Constraints CNC(Causesofnoncompliance)

CA(Correctiveactions taken)

Constraints foundinWWP Non-complianceiscaused byexternalcircumstances orpersons.

Correctiveactions performedtoalleviateor eliminaterestrictions

Thisconstraintsanalysisboardillustratestherestrictionsthatareseenasroadblockstocompletingspecifictasks.Because thisboardcontainsalistofrecognisedrestrictions,itaidstheprojectmanagerincategorisingthemasactionsornoactions.Asa result,projectmanagersmayfocustheirattentionontasksthatcanbeimplemented.Inaddition,theCNCcolumnexplicitly definestheindividualorexternalcircumstancesresponsibleforthefailuretocompletetheobligation,aswellasthecorrective actiontakentoeliminatethesamerestrictions.Withthistool,theprojectmanagermayreadilydeterminewhetherornotthe remedialactionconductedwasjustified

Constraintsmaybeclassifiedintoseveralcategoriestosimplifytheanalysisprocessevenfurther,asindicatedintable:

Table-2: Constraintcategories

Constraint category Example

Directives

Designdocuments,specifications,andwork assignments,amongotherthings.

Workthatis requiredinadvance Workthatmustbecompletedbeforemovingonto thenextactivity.

Resources Labor,equipment,andsupplies,tonameafew.

2.3.2 Pareto chart of causes of variation

Chart-1: Paretochart

Thisgraphdepicts thehierarchical order ofcauses observed in buildingprojectsbased onthe number of occurrences, startingwiththereasonthathasoccurredthemosttimesinacertainperiodandprogressingtothecausethathasoccurredthe fewesttimes.Thisassiststheprojectmanagerinidentifyingthefactorsthatrecurandobstructtheproject'sdevelopment.With theaidofthisgraphic,onemayquicklyidentifythemostinfluentialreasonsandconcentratetheireffortsonremovingthem.

2.3.3 Commitment monitoring board

Table-3: Commitmentmonitoringboard

3. CASE STUDY (DATA COLLECTION & ANALYSIS)

3.1 Introduction

1.Sitelocation-ShivajiPark,Kolhapur

2.Name-ElixaPark

3.Wing-D

4.Buildername-Mr.AjaysinhV.Desai

Theconstructionofa(G+15)residentialstructureisthesubjectofthiscasestudy.Becausethecasestudywasjusttwoand halfmonthslong,allfourphasesofthelastplannersystemcouldnotbeimplemented.Followingaone-weektrialperiodfor weekly work planning, the creation of a look-ahead planbegan. The initial master plan and phase schedule were created, howeverduetotheshorttimeframeofthecasestudy,itwasnotabletousethepullapproachtocreatethephaseschedule.It wasnotpossibletoupdatethelook-aheadplanonaweeklybasissinceitisacourseofpractisethattakesalongtimetomaster. Thismustbeviewedasaflawinthework.

Oncertainoftheactivities,theLastPlannerSystemisusedontherealbuildingsite.ThebuildingoperationsincludedRCC constructionofthreestoreysandbrickwork.Kolhapurwasthelocationoftheconstructionsite.

Thedetailsofbuildingareasunder,

DWingResidentialBuildingG+15

Address=Kolhapur

TotalArea=631sq.m

Built-upArea=631sq.m

Beam=122m3/floor

Column=20m3/floor

Slab=80m3/floor

• Rates of Labour

1Carpenter=Rs450/8hr

1Helper=Rs350/8hr

1Skilled=Rs350/8hr

1Unskilled=Rs300/8hr

1Mason=Rs500/8hr

1Malemazdoor=Rs350/8hr

1Femalemazdoor=Rs300hr

• Rates of Material

Aggregate=Rs.1800perbrass

RiverSand=Rs.7000perbrass

CrushedSand=Rs.3700perbrass

Cement=Rs.340perbag

Bricks=Rs.11perpiece

3.2 9 Weeks Look Ahead Plan

The table below depicts the 9-week look-ahead plan from the case study. It represents the constraints that have been observedaswellasthepeoplewhoareinchargeofremovingsuchconstraints.

1.RCC

1.1-COLUMN

1.1.1-Reinforcement

1.1.2-Shuttering

1.1.3-Casting

1.2-BEAM

1.2.1-Reinforcement

1.3-SLAB

1.3.1-Shuttering

1.3.2-Reinforcement

1.3.3-Casting

1. Material (for 9 weeks 5th to 7th floor)

1.1RMC:660m3

1.2-Aggregate:6m3

1.3-Riversand:6m3

1.4-CrushedSand:6m3

1.5-Cement:500bags

1.6-Steel:27000kg (Approx..1.5kgpersqft)

2. Men

2.1-Carpenter-7,helper-10,

2.2-Skilled worker-8,unskilled worker-10

2.3-SlabCastinggang5mason, forpump8malemazdoor

3. Cost

3.1RMC-₹2970000/-

3.2-Aggregate-₹26400/-

3.3-RiverSand-₹70400/-

3.4-CrushedSand-₹52800/-

3.5-CementBags-₹123200/-

3.6.Steel-₹460900/-

3.7. Construction Cost₹4888000/(Approx.₹1900/-per sq meter)

Men and MaterialManager

(Mr. Aniruddha Shinde)

RCC-Supervisor

(Mr. Sagar Patil)

2.Brick work

2.1 Prop Removal andsitecleaning

2.2. Soaking and stakingofbricks

2.3.

1.1-Bricks-45000nos.

2. Men

2.1-Mason-8,male mazdoor-15.

3. Cost

3.1-Bricks-₹495000/-

3.2- Construction Cost₹288000/-

Men and MaterialManager

(Mr. Aniruddha Shinde)

RCC-Supervisor

(Mr.SagarPatil)

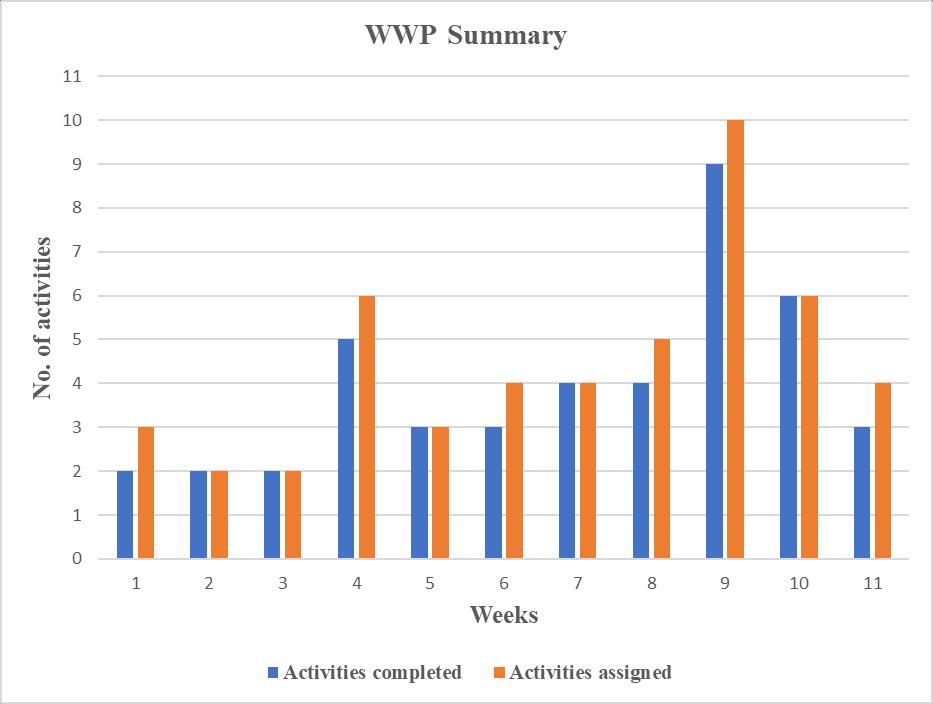

3.3 Weekly Work Planning (WWP)

Thissectionprovidesdetailsofweeklyplanningdonethroughouttheperiodofcasestudy.WWPinthiscasestudyconsiders detailedrequirementsofmanpower,materialandprerequisitesneededforthefulfillmentofupcomingweekwork.

WEEK 1-

Table-5: Week1

WEEK 4Table-8: Week4

WEEK 5Table-9: Week5

WEEK 6Table-10: Week6

WEEK 7Table-11: Week7

WEEK 8Table-12:Week8

WEEK 9Table-13: Week9

WEEK 10Table-14: Week10

WEEK 11 –Table-15:

3.4 Percentage Plan Complete (PPC) Analysis

Anine-weeklook-aheadplanwascreatedatthestartofthiscasestudy.However,actualimplementationdemonstratesthat thelook-aheadanticipatedatthestartoftheprojecttook11weekstocomplete.Thistableexplainsthe11-weekPPCanalysis fromthecasestudy.Itshowshowmanyactivitiesfromallocatedactivitiesweredoneperweekandtheprimaryreasonsfor delays.

3.5 Overall Cost and Time Saving

AfterapplicationofLastPlannerSystem,reductionincostisasfollows-

1.Material

a) Steel=Rs.189000/-(Fluctuation7perkg)

b) Cement=Rs.20000/-/-(Fluctuation20perkg)

InitialCostofSteelwasRs.60perkgandforcementbagwasRs.340perbag.Butinviewofmanager,therewasapossibility ofpricehikeanditwasobservedasoneoftheconstraintinlookaheadplanandthepredictionwastrue,pricehikewasbyRs.7 perkgofsteelandRs.20perbagofcementbag.

2.Men

a) Labour=Rs.38500/-

b) Supervisorandmanager=Rs.42000/-

BytheimplementationofLPS,therewastimereductionby3daysforperfloorconstructionwhichresultedincostsavingas mentionedabove

OverallCostreductionusingLPS=189000+20000+38500+42000 =Rs.289500/-

3.6 Concluding remark

Inorderforlastplannerstoachievetheappropriatedegreeofplanreliability,projectcoordinatorsmustembracetheLast Plannersystem'sobjectives,particularlythelookaheadphase,whichiscommittedtogettingtasksreadyforassignmentand balancingloadandcapacity.Lastplanners,fortheirpart,mustfollowtheLastPlannerstandardsand,insomecases,usetheLPS system'sPPClearningtoolconsistentlyandeffectively.

Comparison between without LPS and with LPS

Without LPS With LPS

1) Time-78months

Projectstarts-January2017

Probablypossession-June 2023

WithoutusingLPS,thetime periodofconstructionwas increasedby78months.

Timeperiodincreasedby 216%

2) Cost-

Atthebeginningofproject, theestimatedcostofproject was78Cr.

Butbecauseofdelayin construction,thecostof projectincreasedby112Cr.

Costincreasesby143.59%

1) Time-36months

Projectstarts-January2017

Probablypossession-December 2019

ByusingLPS,thetimeperiod willbedecreasedby36 months.

2) Cost-

Atthebeginningofproject,the estimatedcostofprojectwas 78Cr.butincreasedby112Cr. Hence,byusingLPSthecost canbesavedby34Cr.

4. CONCLUSION

4.1 Conclusion

LPS has proven to be a veryeffective technique in terms of planning, improved participantcoordination,collaborative management,andinformationflow.TheresultsofthisliteraturereviewrevealthatLPStrainingisnecessaryforcomplete implementationsincetheparticipant'sworkidentitymustbecompatiblewithhispreviousintendedworkpractise.Accordingto thefindings,LPSisunlikelytohaveahigherimpactwhenusedforashorteramountoftime;however,combininglook-ahead schedules,WWP,andPPCassessmentswiththelearningprocesswouldimproveworkflowoveralongerperiodoftimeby creatinganexperiencelearningcycle.

UnderstandingthecausesofvariationobservedintheLPSlearningphaseandtakingappropriateactionagainstthesecauses using risk assessment matrixes, excel spreadsheets, time buffers, information flow software's, social subcontracts, action research,andothertoolswillimproveLPSeffectiveness.

TheadoptionofLPSwoulddiminishthepowerofautonomybydelegatingchoicestotheengagedplayersintheprocess, hencetopmanagementplaysacriticalroleinitssuccessfulimplementation.Thisresearchaidsinunderstandingthetheory underlyingtheLastPlannerSystem,aswellasthemainimplementationaspects,roadblockstocompleteadoption,andwellknownadvantagesoftheLastPlannerSystem.

4.2 Barriers

Mostcommonbarriersobservedfromstudyare-

InadequacyindependablecommitmentsduringLPSimplementation.

Stubbornattitudei.e.,resistancetochange

PartialimplementationofLPS.

FaultypresentationofPPCcomponents

LackofLPSimplementationtrainingorahazyunderstandingofsystemcomponents

Afraidofdelegationofauthority,uppermanagementisunsupportive.

Insufficientuseofdatagatheredduringinstallation

Lackoflong-termvision,ahostileworkclimate,oralackofteamwork.

REFERENCES

[1] AhiakwoOgrabe,OlokeDavidetal.(2013),“AcasestudyofLastPlannerSystemimplementation inNigeria”,Proceedings IGLC-21,July2013,Fortaleza,Brazil,pp.699-707

[2] AlarcónLuisF.,SalvatierraJoséL.(2014),“Usinglastplannerindicatorstoidentifyearlysignsofprojectperformance”, ProceedingsIGLC-22,June2014|Oslo,Norway,pp547-558

[3] Aslesen, S. and Tommelein, I.D. (2016). “What “makes” the Last Planner? A Typology of Behavioral Patterns of Last Planners.”In:Proc.24thAnn.Conf.oftheInt’l.GroupforLeanConstruction,Boston,MA,USA,sect.7pp.43-52

[4] BhatlaAnkit,PradhanBuluetal(2016),“IdentifyingWastesinConstructionProcessanImplementingtheLastPlanner SysteminIndia”,KICEMJournalofConstructionEngineeringandProjectManagementOnlineISSN2233-9582,pp11-19

[5] Brioso Xavier, Humero Antonio et al (2016), “Comparing Point-to-point Precedence Relations and Location-Based Management System in Last Planner System: A housing project of highly repetitive processes case study”, Procedia Engineering164,pp12–19

[6] DanielEmmanuel,PasquireChristine(2015),Exploringtheimplementationofthelastplanner® systemthroughiglc community:twentyoneyearsofexperience”,154ProceedingsIGLC-23,July2015|Perth,Australia,pp153-162

[7] DaveBhargav,KoskelaLauri(2015),“Exploringtherecurrentproblemsinthelastplannerimplementationonconstruction projects”,ProceedingsoftheIndianLeanConstructionConference(ILCC2015).pp1-9

[8] SamadGhali,EmdanatSamir(2017),“Lastplannersystem–theneedfornewMetrics”,ProceedingsIGLCHeraklion,Greece, pp637-644

[9] HamzehFarook,ZankoulEmileetal(2016),“RemovingConstraintstoMakeTasksReadyinWeeklyWorkPlanning”, ProcediaEngineering164,pp68–74

[10] HussainMannan,AsraFatimaetal(2015),“Asystematicapproachofconstructionmanagementbasedonlastplanner systemanditsimplementionintheconstructionindustry”,IJRET:InternationalJournalofResearchinEngineeringand Technolog,4(1),pp2321-7308

[11] Kalsaas,B.T.,Skaar,J.andThorstensen,R.T.,2015.Pullvs.pushinconstructionworkinformedbyLastPlanner.In:Proc. 23rdAnn.Conf.oftheInt’l.GroupforLeanConstruction.Perth.Australia,pp.1-10

[12] KemmerSergio,BiottoClarissa(2016),“Implementinglastplannerinthecontextofsocialhousingretrofit”,In:Proc. 24thAnn.Conf.oftheInt’l.GroupforLeanConstruction,Boston,MA,USA,sect.6pp.83–92.

[13] Lagos Camilo, Herrera Rodrigo et al(2017), “Contributions of information technologies to last planner system implementation”,In:LC32017VolumeII–Proceedingsofthe25thAnnualConferenceoftheInternationalGroupforLean Construction(IGLC),Walsh,K.,Sacks,R.,Brilakis,I.(eds.),Heraklion,Greece,pp.87–94.

[14] Paz, A., and Oscar, V. (2016).“Last Planner System: Implementation, Evaluation and Comparison of Results in the ConstructionofaSocialHousingProjectinChile.”Proc.24thAnn.Conf.oftheInt’l.GroupforLeanConstruction,Boston, MA,USA,sect.6pp.153–162

[15] PellicerEugenio,CerveróFernandoetal(2015),“Thelastplannersystemofconstructionplanningandcontrolasa teachingandlearningtool”,ProceedingsofINTED2015Conference2nd-4thMarch2015,Madrid,Spain,pp4877-4884

[16] VitaliyPriven,RafaelSacks(2016),“ImpactsoftheSocialSubcontractandLastPlannerSystemInterventionsonthe Trade-CrewWorkflowsofMultistoryResidentialConstructionProjects”,J.Constr.Eng.Manage.,2016,142(7):04016013

[17] OlubukolaTokede(2016),“LastPlannerSystem-fromtheorytoImplementation”,10thICES2016constengg.,quality surveyingandproductmanagement,pp305-318

[18] WaliaBanpreetSuri,N.etal(2017),“ImplementationOflastplannersystemandchallengesencounteredinanindian residentialconstructionproject”,InternationalResearchJournalofEngineeringandTechnology(IRJET),4(6),pp28812888

[19] ZaeriF.,CoxJ.etal(2016),“ImplementationoftheLPSusinganexcelspreadsheetAcasestudyfromtheNewZealand constructionindustry”,ConstructionInnovationVol.17No.3,2017pp.324-339