Advancing Digital Twin through the Integration of new AI Algorithms

Usman Ibrahim Musa1, Sukanta Ghosh2

Usman Ibrahim Musa1, Sukanta Ghosh2

1,2

School of Computer Applications, Lovely Professional University, Punjab, India.Abstract - This research paper explores the integrationofAI algorithms to advance the technology of digital twins. Digital twin is a virtual representation of a physicalobject,process,or system that enables real-time monitoring andanalysis, which has the potential to transform various industries. However, despite its potential, the technology faces several challenges, such as data management, scalability, and accuracy. This paper proposes the use of AI algorithms to address these challenges and improve the performance of digital twin technology. The proposedAIalgorithmscanhelpovercomethe challenges faced by digital twin technology, making it more scalable, accurate, and efficient. This paper provides a valuable contribution to the field of digital twin technology and offers insights into its potential applications and challenges.

Key Words: DigitalTwin,AI,Algorithms.

1. INTRODUCTION

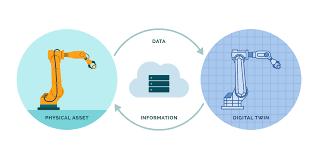

This research focuses on the topic named “Digital Twin”. Digital-Twinissimplyavirtualrepresentationofaphysical systemorobjectthatallowsforsimulationandanalysisof realworldscenarios[1][2][3].Accordingtothedefinitionof theDigitalTwingivenbyaresearcher;Digitaltwincanbe defined as a virtual representation of a physical asset enabled through data and simulators for real-time prediction, optimization, monitoring, controlling, and improveddecisionmaking[1].

Nowadays,theuseofthisDigital-Twinispopularinmany industriessuchasmanufacturing,aerospace,andhealthcare. And it has also led to important improvements in quality, efficiency,andcost-effectivenessinsuchindustries[1][2].A peer-reviewed research recently published on smart manufacturingandwhereitreviewstherecentdevelopment ofDigitalTwintechnologiesinmanufacturingsystems,and researchissuesofDigitalTwin-drivensmartmanufacturing inthecontextofIndustry4.0.[2].Inlightoftheforegoing, oneofthemostsignificantchallengesistheintegrationof new AI algorithms to advance the Digital Twin. The AI algorithmswearetalkingaboutworkandenablemachines tolearnandmakedecisionsbasedonthegivendatawhich has played a role to the development and integration of smartsystems thatcanpredictand respond to real-world challenges [3]. With that being said, the integration of AI algorithms into digital twins in this research has the potential toenhancetheircapabilities,makingthemmore accurateandeffective.

There are several applications of the Digital Twin which include Manufacturing, Healthcare, and Aerospace as mentionedearlier,theproposedAIalgorithmsthatwillbeof greathelpinenhancingtheDigitalTwinsintheseindustries are available further in this research. The purpose of this research paper is to explore the advancements in digital twins through the integration of new AI algorithms. The paper will examine the current state of digital twins, the challenges faced in their development, and the potential benefitsofintegratingnewAIalgorithms.Thepaperwillalso explorethetypesofAIalgorithmsthatcanbeintegratedinto digitaltwinsandtheirapplications.

We will begin by discussing the definition of digital twins and their current state in this research. Furthermore, the paperwillalsoprovideanoverviewofthedifferenttypesof digitaltwinsandtheirapplicationsinvariousindustries,and itwillthenexplorethechallengesfacedinthedevelopment ofdigitaltwins,suchastheneedforaccuratedataandthe complexityofthemodelsandhowtoovercomethemwith thehelpofthenewalgorithms.Thepaperwillalsodiscuss thepotentialbenefitsofthedigitaltwin.Wehavecollected some research questions on this topic to make it more readableandaccurate,theseresearchquestionsarefurther explained in the next section. A photo by Data Center KnowledgeispresentedbelowontheconceptoftheDigital Twin.

Research Questions

1. WhatisDigitalTwinandhowitworks?

2. WhatistherelationshipbetweenAIandDigitalTwin andthebenefitsofcombiningthetwo?

3. WhatarethepossibletoolsforcreatingAI-enabled DigitalTwins?

4. What are the current challenges in Digital Twin TechnologyandhowcanAIbeusedtoaddressthose challenges?

5. Whatistheresearchgapexistingintheintegration ofAIandDigitalTwintechnology?

1. What is Digital Twin and how it works?

Asdefinedbymostoftheresearchers,Digital-Twin refers to a virtual representation of a physical object that allowsforsimulationandanalysisofreal-worldscenarios[1] [2]. On the other hand, a Digital twin can be defined as a virtual representationofa physical assetenabled through dataandsimulatorsforreal-timeoptimization,prediction, monitoring,andcontrolling[2][3].

Thissectionofthisstudywillexplainhowthedigitaltwin workinabasicwaythatwillbeeasytounderstand.Firstand foremost, imagine you have an identical twin brother or sisterwhichyoulookalike,youhavethesameDNA,andyou werebornatthesametime.However,youaretwoseparate individualswithyourownexperiencesandexpertise.Inthis case,adigitaltwiniskindoflikeyourtwin,butforaphysical objectorsystem.Let'sassumeyouhaveacar,adigitaltwin ofyourcarisavirtualmodelthat'screatedusingcomputer software where it looks and behaves like your car, but it exists entirelyinthedigital world [4]. Thatdigital twin of yourcarcanbeusedtomonitorandanalysehowyourcaris performing.Therewillbesensorsattachedtoyourcarthat cancollectdataonseveralthingslikeitsfuelconsumption, speed,andenginetemperatureandthedatacanbefedinto the digital twin, which can then simulate how your car is functioninginreal-time[4][5].Thisisveryusefulbecauseit allows you to identify potential problems before they becomeserious,oneexampleis,ifthedigitaltwinshowsthat theengineisrunningtoohot,youcantakeyourcarinfor maintenancebeforeitbreaksdownonthesideoftheroad.

The Digital Twin on the other hand, is a term that distinguishes itself from the digital model and digital shadow. Despite being a key enabler for digital transformation in manufacturing, there is no common understandingofthetermDTinliterature,andliteratureon thehighestdevelopmentstage.However,thedigitaltwinisa key building block for smart factory and manufacturing undertheIndustry4.0paradigm[7].Itisadigitalmodelfor emulatingorreproducingthefunctionsoractionsofareal manufacturingsystem[8].DTiscreatedduringthedesign stage of a complex manufacturing system and is usable throughoutitslifecycle[7].Itssevenbasicelementsinclude controller,executor,processor,buffer,flowingentity,virtual

service node, and logistics path of a DMS for formally representingamanufacturingsystemandcreatingitsvirtual model.Adigitaltwinrepresentsanorganicwholeofphysical assets and their digitized representation that mutually communicate and co-evolve through bidirectional interactions. The entities, behaviours, and relations in the physical world are digitized holistically to create highfidelityvirtualmodels.Virtualmodelsdependonreal-world data from the physical world to formulate their real-time parameters, boundary conditions, and dynamics. DT has emerged over the past decade in the domains of manufacturing,production,andoperations[8].Itfacilitates learningthroughmodelling,simulation,andanalysisandhas been used in the PDCA cycle for production management includingdesign,operation,andimprovementofproduction systems[8].Monitoreddatafromphysicalartefactstodigital processesisanessentialcomponentofDTwhichgenerates newknowledge.Additionally,well-definedservicescanbe supported by DT such as monitoring, maintenance, management, optimization, and safety [7] [8]. DT is attracting attention from bothacademiaandindustryand hasbeenclassifiedasoneofthetop10technologicaltrends withstrategicvaluesforthreeyearsfrom2017to2019by Gartner.LockheedMartinlistedDTasoneofthesixgamechangingtechnologiesforthedefenceindustry.Digitaltwins are also used in manufacturing and engineering. A digital twinofafactoryorabridgecanbeusedtosimulatedifferent scenarios and test how the system will behave under different conditions [5]. This can help engineers identify potentialdesignflawsandoptimizetheperformance.

2. What is the relationship between AI and Digital Twin and the benefits of combining the two?

The integration of artificial intelligence (AI) into Digital Twins can greatly enhance their capabilities and expand their beneficial applications. AI can open up entirely new areasofapplicationforDigitalTwins,includingcross-phase industrial transfer learning [9]. One way in which AI enhancesthecapabilitiesofDigitalTwinsisthroughtransfer learning [10]. Transfer learning involves transferring knowledgefromonelifecyclephasetoanothertoreducethe amountofdataortimeneededtotrainamachinelearning algorithm.WithAI,DigitalTwinscanusereal-timedatato forecast the future of physical counterparts, thus significantlyimprovingpredictivemaintenanceandreducing downtime[10].Furthermore,AIfacilitatesthedevelopment of new models and technology systems in the domain of intelligent manufacturing, particularly in cross-phase industrial transfer learning use cases [10][9]. The implementation of AI in Digital Twins allows for optimization,adaptation,andreconfigurationofindustrial automation systems, which can lead to significant improvementsinefficiencyandcostsavings[11].Moreover, the intelligent Digital Twin architecture can be a possible implementation of AI-enhanced industrial automation systems,providing the four fundamental sub-processes of

intelligence - observation, analysis, reasoning, and action [11].Toachievethis,anartificialintelligencecomponentis connectedwiththeindustrialautomationsystem'scontrol unit and other entities through a series of standardized interfacesfordataandinformationexchange[10][11].With the integration of AI into Digital Twins, algorithms can be fine-tuned once real data becomes available, significantly speedingupcommissioningandreducingtheprobabilityof costly modifications [9]. Overall, equipping Digital Twins withAI functionalitiescangreatly expandtheir scopeand usefulnessforindustrialautomationsystems.

ThecombinationofAIandDigitalTwintechnologycanlead tonewandinnovativesolutionsfordisasterresponseand emergency management. AI can enable the collection and analysis of situational data from multiple sources in near real-time, including remote sensing, social sensing, and crowdsourcing technologies. This can enhance data collection, analysis, and decision-making in disaster situations and humanitarian crises [12]. Moreover, integratingheterogeneousdatausingAIcanprovidecritical insights needed by responders and relief actors [12]. The proposedDisasterCityDigitalTwinvisionofferssignificant

contributionsandimplicationsforresearchandpracticeof AI and city management in disasters, promoting interdisciplinaryconvergenceinthefieldofICTfordisaster response and emergency management [12] [13]. This integration can also introduce autonomy for in-situ selfmaintenance and autonomous repair capability [13]. By combiningAIandDigitalTwintechnology,itispossibleto enhance the performance of disaster response and emergency management, providing valuable information thatcaninformfutureresearch[12].

3. What are the possible tools for creating AI-enabled Digital Twins?

There is no one technology that can be used to execute digitaltwin;rather,varioustechnologies,includingAI,IoT, and communication technologies, are combined. Each technologicalcomponentmaybeimplementedusingawide range of techniques. Only tools that support component integration, AI, and machine learning are included in this section. Table 1 summarizesafewofthecommonlyusedAI technologiesthatmaygiveassistanceatvariousphasesof digitaltwinning.

4. What are the current challenges in Digital Twin Technology and how can AI be used to address those Challenges?

Digital twin technology is an emergent field that has seen recent growth and attention in case studies. Despite its potential,digitaltwintechnologyfacessignificantchallenges initsgrowthandimplementation,whichmustbeaddressed forittobesuccessfullyintegratedintovariousdomains.The challenges associated with digital twin technology are significantandincludealackofpredictiveability,theinfancy of digital twins, complexity and scale of cyber-physical systems, and the need for manual construction of digital systems and definition of system components [21]. Nevertheless, digital twin technology offers the ability to providedeepinsightsintotheinnerworkingsofanysystem,

including the interaction between different parts of the systemandthefuturebehavioroftheirphysicalcounterpart inawaythatisactionablefortheirusersandstakeholders [22]. The development of industrial software solutions to virtual commissioning has greatly improved the accuracy and user-friendliness of off-line programming robotic systems and verifying control logic [21 [22]. In addition, there is an increasing trend toward the widespread implementation of digital twin technology in several domains, such as industrial, automotive, medicine, smart cities,etc.[22].Toovercomethechallengesassociatedwith digitaltwintechnologyandfacilitateitsimplementation,itis important to have a comprehensive understanding of the technology challenges, limitations, and trends as well as a domain-specific revision of applications. Therefore, a systematicliteraturereviewaimstopresentsuchaviewon

the digital twin technology and its implementation challengesandlimitsinvariousdomains[22].Forinstance, research toward the development of a metal additive manufacturing(AM)digitaltwincanbeorganizedlogically into a hierarchy of four levels of increasing complexity, whichrequiresdeepintegrationofkeyenablingtechnologies such as surrogate modeling, in-situ sensing, hardware controlsystems,andintelligentcontrolpolicies.Ultimately, digitaltwinsareconsideredashiftawayfromcostlyphysical testing and can provide a new perspective into cyberphysicalsystemtestingduetothecouplingbetweendigital andphysicalworlds[22][21].

ArtificialIntelligence(AI)isapromisingapproachto address the challenges in Digital Twin technology. AIenhanced interaction in DTS is presented in detail in the paper, and it is shown that predictive control through AIenhancedDTSimprovesreal-timeinteraction[23].AIisalso an effective approach to improve the intelligence of the physical shop-floor, and can be used to create virtual counterpartsofrobotmanufacturingsystemsthroughdigital twinsimulationandcommunicationtechnologies[23][21]. The intelligent scheduler for work cell scheduling can be safely trained on these virtual systems using Deep Reinforcement Learning (DRL) algorithms, which can incorporateAIintheindustrialcontrolprocess.TheuseofAI indigitaltwintechnologycanprovidemodernsolutionsto thegrowing needsof digitalizationinmanufacturing[21]. System-leveldigitaltwinningcanbeexpandedtocomplex manufacturing systems with deep neural networks to overcomethechallengesinDigitalTwintechnology.Virtual commissioningusinglarge-scalesimulations,promptsystem indicators,andcomputationtechnologiescanestablishalifelikedigitalmanufacturingplatform[21].Moreover,adatadrivenapproachthatutilizesdigitaltransformationmethods can automate smart manufacturing systems, while integrating a smart agent into industrial platforms can expandtheusageofthesystem-level.Virtualcommissioning canacceleratethetraining,testing,andvalidationofsmart control systems, providing a step towards system-level digital twinning. Furthermore, AI-driven robotic manufacturingcellscanbedevelopedthroughtheideation of a platform optimization tool as a concept of digital engineering [21] [23]. Therefore, AI can play a significant roleinovercomingthechallengesinDigitalTwintechnology andrevolutionizemanufacturingprocesses.

5. What is the research gap existing in the integration of AI and Digital Twin technology?

Digital Twin technology has recently been proposed and finds broad applications in industries such as the manufacturing,healthcareandaerospace.Thecombination ofwirelesscommunications,artificialintelligence(AI),and cloudcomputingprovidesanovelframeworkforfuturistic mobile agent systems. The digital twin builds a mirror integratedmulti-physicsofthephysicalsysteminthedigital

space[24].However,thecommunicationframeworkforDT has not been clearly defined and discussed. The article describesthebasicDTcommunicationmodelsandpresents open research issues [24]. The proposed Digital Twin paradigmincludesfourcomponents:multi-datasensingfor data collection, data integration and analytics, multi-actor game-theoretic decision-making, and dynamic network analysis[25].AI-enabledremotesensing,socialsensing,and crowdsourcingtechnologiesareimportantelementsofthe Digital Twin for near-real-time gathering and analysis of disasterandcrisissituations[25].TheadvancesinAIhave broughtopportunitiestogather,store,andanalyzevarious typesofdatarelatedtoadisastercity,andintegratingICT andAItechniquesintoadigitaltwinparadigmispossiblefor Disaster City Digital Twin [24] [25]. Edge computing technology is introduced to build an intelligent traffic perceptionsystembasedonedgecomputingcombinedwith digital twins. Some technological solutions for monitoring construction work have recently become available and appliedcommercially[26].

2. METHODOLOGY

All of the methodologies utilized in this research will be presented in full in this section, along with appropriate analyses and graphics. We gathered the algorithms from manysources,andallofthestagesandapproacheswillbe detailedinthispart.

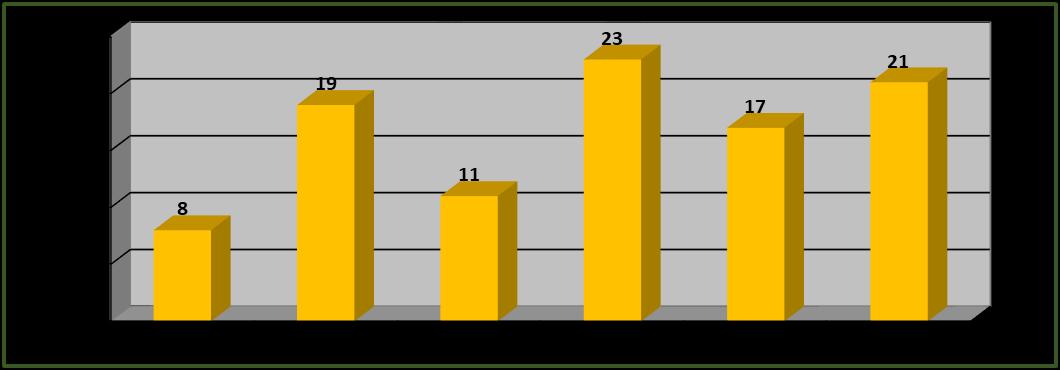

i. Data Sources: This paper's literature is made up of multiple research publications and articles from various sources.Figure3depictsavisualorgraphicalillustrationof the data sources used in this study, as well as their correspondingpercentages.Inaddition,asshownin Table 2, wecreatedatableofthedatabasesandtheircorresponding URLsthatwereallemployedinthisresearch.

Sources URLs

Researchgate https://www.researchgate.net/ IEEEXplore

https://www.ieeexplore.ieee.org/ Elsevier https://www.elsevier.com/ Academia https://www.academia.edu/ Springer https://www.springer.com/

ii. Exploration Criteria: It is evident that this research necessitatesathoroughexaminationofearliersourcesfrom boththedigitaltwinandartificialintelligencedomains;so, wegatheredallreferencesandcalculatedtheproportionof articles utilized in this research for each and every year. Figure 5 depictsagraphicaldepictionofthesame,withall percentagesclearlyindicated.Despitethefactthatcertain paperswererepresentedas"others,"whichsignifiesthey areancientpapersandmakeuplessthan1%ofthepaper. For example, the majority of the publication's date from 2015to2023,withonepapereachfrom1999,2003,and 1988.Thesepapersarecollectivelyreferredtoas"others."

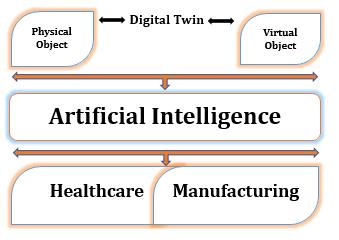

AI Developments in Digital Twin for Industries

Asdiscussedpreviouslyrightintheintroductionpartofthis paper,digitaltwinhasawiderangeofapplicationsuchas manufacturing,healthcareetc.Additionally,theAIhasbeen veryusefultotheseareaswheredigitaltwinworks,theAI enhanced the working of the digital twin in those areas efficiently and effectively. This section will discuss thoroughlyontheAIdevelopmentsinthedigitaltwinfor variousindustriesasfollows;

i. Digitaltwintechnologyhasbeengainingattentioninthe manufacturing industry as it offers a powerful way to optimize processes and improve efficiency [25]. The

integration of AI in digital twin technology has further enhanceditscapabilities,allowingittolearnfrompastdata andmakepredictionsforthefuture.Asstatedbythepaper [11],thathealthcareindustryisanotherareawheredigital twin technology, combined with AI, has the potential to improvepatientoutcomessignificantly.Digitaltwinscanbe createdforindividualpatients,whichcanhelpdoctorstailor treatments and medication plans to suit each patient's uniqueneeds. Table 3 showsthesame.

ii. As a result of extensive research conducted in this researchfor digital twinin healthcareindustries,wehave compiledacomprehensivelistofseveralAIdevelopments thathavebeenimplementedbyvariousresearchers.Inorder to provide a clear and concise overview of these advancements,wehaveprepared Table 4,whichpresentsa detailed analysis of the various applications of AI, digital twin use cases, the AI approach utilized for each, and corresponding references for further exploration. This compilationservesasavaluableresourceforindividualsand organizations seeking to enhance their knowledge and understanding of the latest developments in digital twin technology.

References Applications and Digital Twin Use-Cases

[27]

forManufacturing

Developmentfaultdiagnosisistheapplicationandthedigital twinusecaseisshopfloor

[33] Usedforqualityimprovementforproductassemblyandthe digitaltwinusecaseisforremotelaserwelding.

[34]

ForForecastwork-in-processtime,thedigitaltwinusecaseis shopfloor.

[35] Used for multi life cycle process forecast and AGV fault diagnosis, the digital twin use case is Automated guided vehicles(AGVs)

[36] For product quality, the digital twin use case was CNC bendingmachine.

[37] Theapplicationwasforcollaborativedatamanagementand AM defect analysis, the use case for digital twin is project MANUELA.

[28]

Jobschedulingoptimizationandoptimalresourceallocation. Theusecaseisshopfloorofaircraftengine.

[29] Resource management and product quality control, digital twinusecaseissatelliteassemblyshopfloor.

[30] Productdesignandprocessoptimization.Forshopfloor.

[38] Performanceoptimizationfordew-pointcooler

AI Approach

Deep neural networks with transfer learning.

ConvolutionalNeuralNetworks(CNN)

Multiplelinearregressionmodels

TheAIapproachusedwasDeepLearning

TheArtificialNeuralNetworks(ANNs)

DeepLearning

Geneticalgorithmandevolutionalgorithm

GeneticalgorithmandPSO

MachineLearningandDeepLearning

Multi-objectevolutionaryoptimizationand feed-forwardneuralnetwork

[31] Processplanningandoptimization,thedigitaltwinusecaseis formarinedieselengine

[32] Process control and scheduling optimization for robots manufacturingcell.

[39] RobotOptimizationforavoidingobstacles.

Mathematical and Statistics Big Data Analytics

DeepReinforcementLearning

Antcolonyoptimization

Table 4. AIDevelopmentsinDigitalTwinforHealthcare

References Applications and Digital Twin Use-Cases

[48]

[49]

[50]

[40]

[51]

Application was crack state estimation and fatigue life predictionforaircraft.

TheapplicationwasforDamageDetection,thedidgitaltwin usecaseifBottom-setgillinet

Plasmaradiationdetection.Thedigitaltwinusecasewasa bolometer.

Degradationofwindinginsulationandshortcircuitsforfaults inmotor.DigitaltwinusecasewasforElectricVehicleMotor.

Expertfaultdiagnosisforaircraftengine

AI Approach

ProbabilisticModels

ArtificialNeuralNetworks(ANNs)

Fuzzylogic

FuzzyLogicandArtificialNeuralNetworks (ANNs)

ArtificialNeuralNetworks(ANNs)

[54] Shipspeedloss- predictionduetomarinefouling.Usedfor ship. DeepLearning

[53]

[44]

Faultdiagnosisforphotovoltaicenergyconversion

Gearboxprognosisandfaultdetectionforwindturbine

[45] The application was capacity fade and power fade for the battery’saginglevelprediction,thedigitaltwinusecasewas lithiumandlead-acidbatterysystem.

[46]

[41]

Cuttingtoolfaultandlifepredictionwithdigitaltwinusecase ofCNCmachinetool(CNCMT)

Theapplicationwasfaultpredictionandmaintenanceinshaft bearing,theusecasewasanaeroengine

Usedtheholisticfaultdiagnosisapproach

NeuralNetworks

The approach used was particle swarm optimization

Bayesianmodelandregressionmodel.

NeuralNetworkandDeepLearning

[42] Spacecraftstructurallifepredictionforspacecraft. DynamicBayesianNetworkwasused

[43]

Faultpredictionandoptimization,thedigitaltwinusecase wasCNCmachineTool(CNCMT)

[47] Trackassetdegradationandfaultsdetection.Thedigitaltwin usecasewasthegearbox,rotatingshaftbearing,andaircraft turbofanengines

[52]

Dynamically detect structural damage or degradation and adoptstrategy.UsedforUAV.

ThissectionaboveexplainsafewAIadvancesinthehealth industriescreatedbyvariousresearchers. Table 4. Displays the numerous applications, digital twin use cases, the AI techniqueforthesame,andtherelevantreferencesforeach.

MachineLearning

GenerativeAdversarialNetworks(GANs)

Static-condensation reduced-basiselement method, and Bayesian state estimation

3. PROPOSED AI ALGORITHMS

Inthissection,wepresenttoyouacomprehensiveoverview ofthelatestAIalgorithmsthatcouldgreatlyenhanceDigital Twin technologies. In today's digital era, the use of AI algorithmsisbecomingincreasinglycommonastheyhave thepotentialtovastlyimprovetheaccuracyandefficiencyof

digitaltwintechnologies.Wehavecompiledalistofsomeof the most recent and innovative AI algorithms being used today,andwehavesummarizedtheirapplicationsandkey featuresin Table 5 below.Ourgoalistoprovideyouwith usefulinsightsintothelatestadvancementsindigitaltwin technologies,andtoshowyouhowthesetechnologiesare transformingvariousindustries.

Itisimportanttostayup-to-datewiththelatesttrendsand technologies, especially in a world that is constantly changing and evolving. That is why we believe that this information could prove to be immensely valuable. By

providing an in-depth understanding of the latest AI algorithmsbeingusedindigitaltwintechnologies,wehope toempowerthereadertomakeinformeddecisionsandtake advantage of the opportunities that arise. And is these AI algorithms continue to evolve, we believe that they will revolutionize the way industries operate. The impact of digitaltwintechnologiesisalreadybeingfeltacrossvarious industries, from healthcare to manufacturing to transportation. With the help of AI algorithms, these technologies will continue to improve, leading to greater efficiency,accuracy,andproductivity.

Algorithm Features

Synthetic Data Generation, Data Augmentation

Description

Impact to Digital Twin Generative Adversarial Networks(GANs)

GANs are a type of neural network that can generatenewdatasamplesthataresimilartothe ones in the training data. They can be used to train Digital Twin or to generate synthetic data fortestingandvalidation

Improves training and validation of Digital Twins through synthetic data generation and augmentation

Recurrent Neural Networks(RNNs)

Sequential data processing, timedependentdata

RNNs are a type of neural network that can processsequentialdata,suchastimeseriesdata or natural language text. They can be used to improve the accuracy of Digital Twins that involvetime-dependentdata,suchassimulations ofweatherpatternsorfinancialmarkettrends.

ImprovesaccuracyofDigital Twins that involve timedependentdatabyenabling better sequential data processingandanalysis.

Reinforcement Learning Learning through interactions, prediction improvement

BayesianNetworks Probabilistic graphical model, complex relationship representation

DeepLearning Neural network with multiple layers, data analysis,learning

Reinforcement Learning is a type of machine learning algorithm that enables agents to learn through interactions with their environment. It can be used to improve the accuracy of Digital Twins by training the model to make better predictionsbasedonthedataavailable.

Bayesian Networks are a type of probabilistic graphical model that can represent complex relationships between variables. They can be usedtoimprovetheaccuracyofDigitalTwinsby enabling them to model complex systems with multipleinteractingvariables.

Deep Learning is a subset of machine learning thatusesneuralnetworkswithmultiplelayersto analyze and learn from data. It can be used to improve the accuracy and efficiency of Digital Twinsbyenablingthemtoprocesslargeamounts ofdataandmakemoreaccuratepredictions.

ImprovesaccuracyofDigital Twins by enabling better predictionthroughlearning from interactions with the environment.

ImprovesaccuracyofDigital Twins by enabling better representation and modeling of complex systems with multiple interactingvariables.

Improves accuracy and efficiency of Digital Twins byenablinglarge-scaledata analysis and better predictions.

Convolutional Neural Networks (CNNs)

Image and video processing, pattern recognition

CNNs are a type of neural network that is particularly effective at image and video processing. They can be used to improve the accuracyofDigitalTwinsthatinvolvevisualdata, suchassimulationsofmanufacturingprocesses ortrafficflows.

ImprovesaccuracyofDigital Twins that involve visual data by enabling better pattern recognition and imageprocessing.

Evolutionary Algorithms Optimization, parametersearch

Evolutionary Algorithms are a family of optimizationalgorithmsthatareinspiredbythe principles of biological evolution. They can be usedtooptimizeDigital Twinsbysearchingfor the best parameters or configurations that producethedesiredresults.

Improves optimization of Digital Twins by enabling betterparametersearchand configuration for the desiredresults.

FuzzyLogic

Uncertainty and imprecision handling

Fuzzy Logic is a mathematical framework that can deal with uncertainty and imprecision in data. It can be used to improve the accuracy of Digital Twins that involve incomplete or ambiguous data, such as simulations of human behaviororsocialsystems.

ImprovesaccuracyofDigital Twins that involve incomplete or ambiguous data by enabling better handlingofuncertaintyand imprecisionindata.

Deep Reinforcement Learning

Learning through interactions, prediction improvement, complex behavior learning

4. FUTURE DIRECTION

DeepReinforcementLearningisacombinationof Reinforcement Learning and Deep Learning. It can be used to improve the accuracy of Digital Twins by training agents to learn complex behaviors through trial-and-error interactions withtheirenvironment.

Looking ahead, we see several promising directions for future research. First, there is a need to develop more sophisticated AI algorithms that can handle complex and heterogeneousdatafrommultiplesources.Second,thereisa needtointegrateAIwithotheremergingtechnologiessuch as block chain, Iota, and edge computing to enable more robust and secure digital twins. Third, there is a need to explore the ethical and social implications of using AI in digital twins, particularly in sensitive domains such as healthcare.

5. CONCLUSION

Ourresearchhashighlightedthepotentialofintegratingnew AI algorithms to improve digital twin technology, particularly in industries such as manufacturing and healthcare.ByleveragingtheproposedAIalgorithms,wecan enhance the accuracy, efficiency, and predictive power of digital twins, leading to better decision-making and optimization of operations. We have discussed various AI applications in digital twin technology and provided examples of successful implementations in real-world scenarios.However,thereisstillmuchworktobedonein termsofexploringthefullcapabilitiesofAIfordigitaltwins andaddressingthechallengesassociatedwithdataquality, scalability,andinterpretability.

REFERENCES

[1] A. Rasheed, O. San and T. Kvamsdal, "Digital Twin: Values, Challenges and Enablers From a Modeling Perspective," in IEEE Access, vol. 8, pp. 21980-22012, 2020,doi:10.1109/ACCESS.2020.2970143

ImprovesaccuracyofDigital Twins by enabling better prediction and learning of complex

[2] Lu, Y., Liu, C., Kevin, I., Wang, K., Huang, H., & Xu, X. (2020). Digital Twin-driven smart manufacturing: Connotation,referencemodel,applicationsandresearch issues. Robotics and Computer-Integrated Manufacturing, 61, 101837. Doi: https://doi.org/10.1016/j.rcim.2019.101837

[3] M., Virtually Intelligent Product Systems: Digital and Physical Twins, in Complex Systems Engineering: TheoryandPractice,S.Flumerfelt,etal.,Editors.2019, AmericanInstituteofAeronauticsandAstronautics.p. 175-200.

[4] Z. Wang et al., "Mobility Digital Twin: Concept, Architecture, Case Study, and Future Challenges," in IEEEInternetofThingsJournal,vol.9,no.18,pp.1745217467, 15 Sept.15, 2022, doi: 10.1109/JIOT.2022.3156028.

[5] ChiaraCimino,ElisaNegri,LucaFumagalli,“Reviewof digitaltwinapplicationsinmanufacturing”,Computers in Industry, Volume 113, 2019, 103130, ISSN 01663615,https://doi.org/10.1016/j.compind.2019.103130

[6] https://ch.mathworks.com/products/matlab.html

[7] Qinglin Qi, et al. “Enabling technologies and tools for digitaltwin”,JournalofManufacturingSystems,Volume 58, Part B, 2021, Pages 3-21, ISSN 0278-6125, https://doi.org/10.1016/j.jmsy.2019.10.001.

[8] Sacks, R., Brilakis, I., Pikas, E., Xie, H., & Girolami, M. (2020). Construction with digital twin information systems. Data-Centric Engineering, 1, E14. doi:10.1017/dce.2020.16

[9] Benjamin Maschler, et al. “Transfer learning as an enabler of the intelligent digital twin”, Procedia CIRP, Volume 100, 2021,Pages 127-132, ISSN 2212-8271, https://doi.org/10.1016/j.procir.2021.05.020

[10] Kaur, M.J., Mishra, V.P., Maheshwari, P. (2020). The ConvergenceofDigitalTwin,IoT,andMachineLearning: Transforming Data into Action. In: Farsi, M., Daneshkhah,A.,Hosseinian-Far,A.,Jahankhani,H.(eds) DigitalTwinTechnologiesandSmartCities.Internetof Things.Springer,Cham.https://doi.org/10.1007/978-3030-18732-3_1

[11] NasserJazdi,etal.“RealizationofAI-enhancedindustrial automation systems using intelligent Digital Twins”, ProcediaCIRP,Volume97,2021,Pages396-400,ISSN 2212-8271, https://doi.org/10.1016/j.procir.2020.05.257

[12] ChaoFan,etal.“DisasterCityDigitalTwin:Avisionfor integratingartificialandhumanintelligencefordisaster management”, International Journal of Information Management, Volume 56, 2021, 102049, ISSN 02684012,https://doi.org/10.1016/j.ijinfomgt.2019.102049

[13] SamirKhan,etal.“Ontherequirementsofdigitaltwindriven autonomous maintenance”, Annual Reviews in Control,Volume50,2020,Pages13-28,ISSN1367-5788, https://doi.org/10.1016/j.arcontrol.2020.08.003.

[14] M.Abadi,P.Barham,J.Chen,Z.Chen,A.Davis,J.Dean,M. Devin,S.Ghemawat,G.Irving,M.Isard,andM.Kudlur, ``TensorFlow: A system for large-scale machine learning,''inProc.12thUSENIXSymp.OperatingSyst. DesignImplement.(OSDI),2016,pp.265_283.

[15] F.SeideandA.Agarwal,``CNTK:Microsoft'sopen-source deep-learningtoolkit,''inProc.22ndACMSIGKDDInt. Conf.Knowl.DiscoveryDataMining,Aug.2016,p.2135.

[16] Y. Jia, E. Shelhamer, J. Donahue, S. Karayev, J. Long, R. Girshick, S. Guadarrama, and T. Darrell, ``Caffe: Convolutionalarchitectureforfastfeatureembedding,'' inProc.22ndACMInt.Conf.Multimedia,Nov.2014,pp. 675_678.

[17] A. Gulli and S. Pal, Deep LearningWith Keras. Birmingham,U.K.:Packt,2017.

[18] M.Hall,E.Frank,G.Holmes,B.Pfahringer,P.Reutemann, andI.H.Witten,``TheWEKAdataminingsoftware:An update,''ACMSIGKDDExplor.Newslett.,vol.11,no.1, pp.10_18,2009.

[19] G. Brockman, V. Cheung, L. Pettersson, J. Schneider, J. Schulman, J. Tang, and W. Zaremba, ``OpenAI gym,'' 2016, arXiv:1606.01540. [Online]. Available: http://arxiv.org/abs/1606.01540

[20] Y. Duan, X. Chen, R. Houthooft, J. Schulman, and P. Abbeel,``Benchmarkingdeepreinforcementlearningfor continuous control,'' in Proc. Int. Conf. Mach. Learn., 2016,pp.1329_1338.

[21] Kaishu Xia, et al. “A digital twin to train deep reinforcementlearningagentforsmartmanufacturing plants: Environment, interfaces and intelligence”, Journal of Manufacturing Systems, Volume 58, Part B, 2021, Pages 210-230, ISSN 0278-6125, https://doi.org/10.1016/j.jmsy.2020.06.012.

[22] Botín-Sanabria, et al. “Digital Twin Technology ChallengesandApplications:AComprehensiveReview”. Remote Sens. 2022, 14, 1335. https://doi.org/10.3390/rs14061335

[23] XinMa,etal.“Artificialintelligenceenhancedinteraction indigitaltwinshop-floor”,ProcediaCIRP,Volume100, 2021, Pages 858-863, ISSN 2212-8271, https://doi.org/10.1016/j.procir.2021.05.031

[24] Computer Science > Networking and Internet Architecture.https://arxiv.org/abs/2105.07182 Accessed2023-03-23

[25] ChaoFan,etal.“DisasterCityDigitalTwin:Avisionfor integratingartificialandhumanintelligencefordisaster managemen”t, International Journal of Information Management, Volume 56, 2021, 102049, ISSN 02684012,https://doi.org/10.1016/j.ijinfomgt.2019.102049

[26] Sacks, R., Brilakis, I., Pikas, E., Xie, H., & Girolami, M. (2020). Construction with digital twin information systems. Data-Centric Engineering, 1, E14. doi:10.1017/dce.2020.16

[27] Y.Xu,Y.Sun,X.Liu,andY.Zheng,``Adigital-twin-assisted fault diagnosis using deep transfer learning,'' IEEE Access,vol.7,pp.19990_19999,2019.

[28] H. Zhang, G. Zhang, and Q.Yan, ``Digital twin-driven cyber-physicalproductionsystemtowardssmartshop_oor,''J.AmbientIntell. HumanizedComput.,vol.10,no. 11,pp.4439_4453,Nov.2019.

[29] C.Zhuang,J.Liu,andH.Xiong,``Digitaltwin-basedsmart productionmanagementandcontrolframeworkforthe complexproductassemblyshop-_oor,''Int.J.Adv.Manuf. Technol.,vol.96,nos.1_4,pp.1149_1163,Apr.2018.

[30] F. Tao, J. Cheng, Q. Qi, M. Zhang, H. Zhang, and F. Sui, ``Digitaltwindrivenproductdesign,manufacturingand servicewithbigdata,''Int.J.Adv.Manuf.Technol.,vol. 94,nos.9_12,pp.3563_3576,Feb.2018.

[31] J.Liu,H.Zhou,G.Tian,X.Liu,andX.Jing,``Digitaltwinbasedprocessreuseandevaluationapproachforsmart processplanning,''Int.J.Adv.Manuf.Technol.,vol.100, nos.5_8,pp.1619_1634,Feb.2019.

[32] K. Xia, C. Sacco, M. Kirkpatrick, C. Saidy, L. Nguyen, A. Kircaliali, and R. Harik, ``A digital twin to train deep reinforcementlearningagentforsmartmanufacturing plants: Environment, interfaces and intelligence,'' J. Manuf.Syst.,Jul.2020.

[33] P. Franciosa, M. Sokolov, S. Sinha, T. Sun, and D. Ceglarek, ``Deep learning enhanced digital twin for remote laser welding of aluminium structures,'' CIRP Ann.Manuf.Technol.,vol.69,no.1,2020.

[34] W. Wang, Y. Zhang, and R. Y. Zhong, ``A proactive materialhandlingmethodforCPSenabledshop-_oor,'' Robot. Comput.-Integr.Manuf.,vol.61,Feb. 2020, Art. no.101849.

[35] Y.Wang,S.Wang,B.Yang,L.Zhu,andF.Liu,``Bigdata driven hierarchical digital twin predictive remanufacturing paradigm: Architecture, control mechanism,applicationscenarioandbene_ts,''J.Cleaner Prod.,vol.248,Mar.2020,Art.no.119299.

[36] S. Zhang, C. Kang, Z. Liu, J.Wu, and C. Ma, ``A product qualitymonitormodelwiththedigitaltwinmodeland the stacked auto encoder,'' IEEE Access, vol. 8, pp. 113826_113836,2020.

[37] C.Liu,L.LeRoux,C.Körner,O.Tabaste,F.Lacan,andS. Bigot, ``Digital twin-enabled collaborative data management for metal additive manufacturing systems,''J.Manuf.Syst.,May2020.

[38] Y.GolizadehAkhlaghi,A.Badiei,X.Zhao,K.Aslansefat,X. Xiao,S.Shittu,andX.Ma,``Aconstraintmulti-objective evolutionaryoptimizationofastate-of-the-artdewpoint cooler using digital twins,'' Energy Convers. Manage., vol.211,May2020,Art.no.112772

[39] R.Bansal,M.A.Khanesar,andD.Branson,``Antcolony optimization algorithm for industrial robot programminginadigitaltwin,''inProc.25thInt.Conf. Autom.Comput.(ICAC),Sep.2019,pp.1_5.

[40] S.Venkatesan,K.Manickavasagam,N.Tengenkai,andN. Vijayalakshmi, ``Health monitoring and prognosis of electricvehiclemotorusingintelligent-digitaltwin,''IET Electr.PowerAppl.,vol.13,no.9,pp.1328_1335,Sep. 2019.

[41] Z. Liu, W. Chen, C. Zhang, C. Yang, and H. Chu, ``Data super-networkfaultpredictionmodelandmaintenance strategyformechanicalproductbasedondigitaltwin,'' IEEEAccess,vol.7,pp.177284_177296,2019.

[42] Y.Ye,Q.Yang,F.Yang,Y.Huo,andS.Meng,``Digital twinforthestructuralhealthmanagementofreusable spacecraft:Acasestudy,'' Eng. Fract. Mech.,vol.234, Jul.2020,Art.no.107076.

[43] W.Luo,T.Hu,C.Zhang,andY.Wei,``DigitaltwinforCNC machinetool:Modelingandusingstrategy,''J.Ambient Intell. Humanized Com- put., vol. 10, no. 3, pp. 1129_1140,Mar.2019.

[44] F.Tao,M.Zhang,Y.Liu,andA.Y.C.Nee,``Digitaltwin drivenprognosticsandhealthmanagementforcomplex equipment,''CIRPAnn.,vol.67,no.1,pp.169_172,2018.

[45] W.Li,M.Rentemeister,J.Badeda,D.Jöst,D.Schulte,and D. U. Sauer, ``Digital twin for battery systems: Cloud batterymanagementsystemwithonlinestate-of-charge andstate-of-healthestimation,''J.EnergyStorage,vol. 30,Aug.2020,Art.no.101557.

[46] W. Luo, T. Hu, Y. Ye, C. Zhang, and Y. Wei, ``A hybrid predictivemaintenanceapproachforCNCmachinetool drivenbydigitaltwin,''Robot.Comput.-Integr.Manuf., vol.65,Oct.2020,Art.no.101974.

[47] W.Booyse,D.N.Wilke,andS.Heyns,``Deepdigitaltwins fordetection,diagnosticsandprognostics,''Mech.Syst. SignalProcess.,vol.140,Jun.2020,Art.no.106612.

[48] P.E.Leser,J.E.Warner,W.P.Leser,G.F.Bomarito,J.A. Newman,andJ.D.Hochhalter,``Adigitaltwinfeasibility study(PartII):Nondeterministicpredictionsoffatigue life using in-situ diagnostics and prognostics,'' Eng. Fract.Mech.,vol.229,Apr.2020,Art.no.106903

[49] H.Kim,C.Jin,M.Kim,andK.Kim,``Damagedetectionof bottom-setgillnetusingarti_cialneuralnetwork,''Ocean Eng.,vol.208,Jul.2020,Art.no.107423.

[50] A. Piros, L. Trautmann, and E. Baka, ``Error handling method for digital twin-based plasma radiation detection,''FusionEng.Design,vol.156,Jul.2020,Art. no.111592.

[51] H.Zhang,Q.Yan,andZ.Wen,``Informationmodelingfor cyber-physicalproductionsystembasedondigitaltwin and automationml,'' Int. J. Adv. Manuf. Technol., pp. 1_19,Mar.2020.

[52] M.G.Kapteyn,D.J.Knezevic,D.B.P.Huynh,M.Tran,and K.E.Willcox,``Data-drivenphysics-baseddigitaltwins via a library of component-based reduced-order models,''Int.J.Numer.MethodsEng.,Jun.2020

[53] P.Jain,J.Poon,J.P.Singh,C.Spanos,S.R.Sanders,andS. K.Panda,``Adigitaltwinapproachforfaultdiagnosisin distributed photovoltaic systems,'' IEEE Trans. Power Electron.,vol.35,no.1,pp.940_956,Jan.2020.

[54] A.Coraddu,L.Oneto,F.Baldi,F.Cipollini,M.Atlar,andS. Savio,``Data-drivenshipdigitaltwinforestimatingthe speedloss caused bythe marine fouling,''OceanEng., vol.186,Aug.2019,Art.no.106063