An Experimental Study on Stabilization of Soil by Using Quarry Dust and Egg Shell Powder

Abstract - Soil is the foundation for any civil engineering structures.it is required to bear the loads without failure. In some places soil may be weak which cannot resist the oncoming loads in such cases soil stabilization is needed, the clay often is weak has no stability in heavy loading. The study involves replacing a varying percentage of soil with quarry dust and introducing eggshell powder for enhancing the properties and obtained the optimum mix proportion.

In this experimental study we use eggshell powder and quarry dust to enhance the properties of soil, the test were carried out using various percentages of quarry dust like 8%, 16%, 24% and 32% as soil replacement and where max density value gained eggshell powder is added with a percentage of variation 4%, 8%, 12%and 16% to the weight of soil. The most appropriate percentage of quarry dust replacement and eggshell powder addition for black cotton soil and red soil was determined, which can be used to stabilize these soils for construction purposes. This experimental study provides valuable information for researchers and engineers in the field of soil stabilization.

The study was carried out through a series of laboratory tests, including sieve analysis Atterberg limits, compaction, unconfined compressive strength and California bearing ratio (CBR) tests.

Key Words: Red soil, Black cotton soil, sieve analysis, atterberg limits, compaction, unconfined compressive Strength, California bearing ratio

1.0 INTRODUCTION:-

Soilstabilizationistheprocessofalteringthepropertiesof soil to improve its strength, Durability and resistance to deformation It involves various techniques and methods thataimtoenhancethesoil'sabilitytosupportstructures and withstand external forces such as traffic Loads, environmental changes, and natural disasters The need for soil stabilization arises when the natural soil is not strong enough to support the intended use, such as building foundations, Roads, airports, and different infrastructureprojects.Soilstabilizationmaybedonewith theaidofusingaddingdifferentmaterialstothesoil,such

ascement,lime,flyash,orchemicaladditives.Thetypeof stabilizer used depends on the soil's characteristics, the desired engineering properties, and the project's requirements.

Therearevariousmethodsofsoilstabilization,whichcan be broadly categorized into mechanical, chemical, and physical methods. Mechanical methods involve adding materialssuchasgravel,sand,orgeo-textilestothesoilto improve its stability. Chemical methods involve the addition of substances such as lime, cement, or fly ash to the soil to alter its chemical and physical properties. Physical methods involve the use of techniques such as compaction, grouting, or freezing to improve the soil's strengthandstability.

Soil stabilization offers many benefits, including reducing construction costs, improving the performance of structures, and enhancing the safety and reliability of the infrastructure.Italsominimizestheenvironmentalimpact byreducingtheneedforexcavationandtransportationof soil materials, which results in fewer greenhouse gas emissionsandenergyconsumption.

2.0 OBJECTIVE OF THIS STUDY:-

This study aims to investigate the effectiveness of using quarry dust and eggshell powder as stabilizers for black cottonsoilandredsoil.

3.0 LITERATURE REVIEW:-

Lime stabilization: - In a study conducted by Mohammedetal.(2019)inNigeria,varyingpercentagesof lime (2%, 4%, 6%, and 8%) were added to black cotton soil. The study found that the addition of lime improved the soil's strength, with the highest strength achieved at 6%limecontent.

Bitumen stabilization:- In a study by Masu et al. (2020) in Nigeria, varying percentages of bitumen (2%, 4%,and6%)hadbeenintroducedtoblackcottonsoil.The study found that the addition of bitumen improved the soil's stability, with the highest stability achieved at 6% bitumencontent.

Organic stabilization:- A study by Karim et al. (2019) inBangladesh investigated theuseofricehusk ash(RHA) and cow dung ash (CDA) in stabilizing black cotton soil. Thestudyfoundthatamixtureof8%RHAand2Awasthe most effective in improving the soil's strength and durability.

Geogrid reinforcement:-InastudybyEl-Badawyetal. (2018) in Egypt, varying percentages of geogrid (0.25%, 0.5%,0.75%,and1%)wereaddedtoblackcottonsoil.The study found that the addition of geogrid improved the soil's strength and stability, with the highest strength achievedata1%geogridcontent.

Quarry dust:-InastudybyAbduetal.(2021)inNigeria, varying percentages of quarry dust (0%, 2.5%, 5%, 7.5%, and 10%) were added to black cotton soil. The an experimentalstudyfoundthattheadditionofquarrydust improved the soil's strength, with the highest strength achievedata7.5%quarrydustcontent.

4.0 MATERIAL USED:-

Quarry dust:- Quarry dust is a waste material that is generated from the stone crushing industry, in this experimental study we collected the quarry dust from donabandanearkanchikacherla,AndhraPradesh,India.

Eggshell powder:-Egg shell powder is a waste material obtained from hotels and school Canteen. ESP was received after the outer cover has been cleaned mechanically. It was kept in an open atmosphere for 1 week, the dried eggshell grinded to make it fine powder andsievefrom90-micronsieve.

Black cotton soil:- The black cotton soil used in this study was collected from perakalapadu village close to Kanchikacherla, Andhra Pradesh, India. The general properties of the soil were studied in the laboratory. The soil was tested for sieve analysis, specific gravity, liquid limit, plastic limit, optimum moisture content, maximum dry density, unconfined compressive strength and Californiabearingratio.

5 Optimum moisture content (I.S.2720part VII:1974)

6 Maximumdry density (I.S.2720part VII:1974). 1.47%

7 Unconfined compressive strength (I.S2720part 10:1973). 1.89 kg/cm2

8 California bearingratio (IS:2720( Part16)–1987) 8.87%

Red soil:-

The red soil used in this study was collected from west Ibrahimpatnam, Andhra Pradesh, India. The general properties of the soil were studied in the laboratory. The soil was tested for sieve analysis, specific gravity, liquid limit, plastic limit, optimum moisture content, maximum dry density, unconfined compressive strength and Californiabearingratio.

S.no Properties I.S code value 1 Sieveanalysis I.Scode (1498:1970) Sandy

part v:1985) 40%

4 Plasticlimit (I.S.2720part v:1985) 23%

5 METHODOLOGY:-

The clayey and red soil was replaced with four different percentage of quarry dust which were 8% 16% 24% and 32%bytheweightofsoil,wherewegetthemaximumdry density of soil of that percentage of quarry dust replaced

tothesoilandweagainaddeggshellpowderwithvarying percentage of 4% 8% 12% and 16% to weight of soil, the varioustestareconductedarelistedbelow.

1) Sieveanalysis 5)UCS

2) Specificgravity 6)CBR

3) Compactiontest

4) Atterberglimit.

i)Liquidlimit

ii)Plasticlimit.

5.1

analysis:-

Particle Size Distribution:-

GrainsizeanalysishasbeencarriedoutaspertheI.S.code of practice (I.S.1498:1970).As per the I. S code the given blackcottonsoilisclassifiedassandysoil.

relationship, Optimum moisture content (OMC) and Maximum dry density (MDD) were determined, Similarly compaction tests were conducted with different percentagesofquarrydustreplacedsuchas0%,8%,16%, 24%, and 32% where get the maximum density value gained eggshell powder is added with a percentage of various 4% 8% 12% and 16% to the weight of soil and correspondingOMCandMDDweredetermined

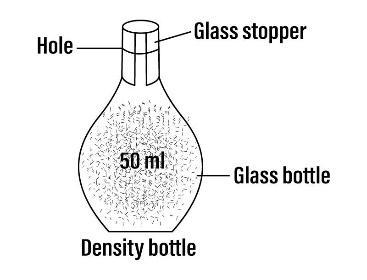

Determination of Specific Gravity:-

The specific gravity of black cotton soil was determined according to IS: 2720 (part III, section-1) 1980. The specificgravityofblackcottondeterminedas2.66.

Compaction test result value at various percentage Replacement of BCS by quarry dust.

Compaction test:-

The moisture content, dry density relationships were found by using compaction tests as per IS: 2720 (part7) 1980.Forthistest,separately mixedblack cottonsoiland red soil with required amount of water and wet samples was compacted in proctor mould either in three or five equal layer using standard proctor rammer of 2.6 kg or modified proctor rammer of 4.5 kg. The moisture content

dust for Various

by

Compaction test result value for Optimum Replacement of BCS by quarry dust+ Addition of ESP by various percentages.

Optimum Replacement of BCS by quarry dust+ Addition of ESP by various percentages

Liquid limit:-

The liquid limit of black cotton soil and red soil was determinedaccordingtoI.S:2720(partV1985).Theliquid limit of black cotton soil was found to be 40% and liquid limitofredsoilfound37%thereweretestalsoconducted withthereplacementandintroductionofquarrydustand egg shell powder with respective to compaction test results.

Plastic Limit:-

The plastic limit of black cotton soil and red soil was determined according to IS: 2720 (part V 1985). The plastic limit of black cotton soil was found to be 23% and red soil 20% there were test also conducted with the replacementandintroductionofquarrydustandeggshell powderwithrespectivetocompactiontestresults.

Liquid Limit result value at various percentage Replacement of BCS by quarry dust.

Plastic Limit Plastic Limit result value at various percentage Replacement of BCS by quarry dust.

Plastic Limit result value for Optimum Replacement of BCS by quarry dust+ Addition of ESP by various percentages.

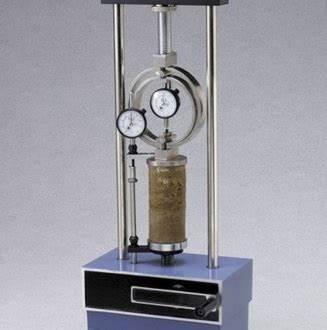

Unconfined compressive strength:-

TheblackcottonsoilandredsoilUnconfinedcompressive strength is the load per unit area at which an unconfined cylindrical specimen of soil will fail in compression test. The unconfined compressive test has been carried out as per I.S code of practice (I.S 2720 part 10:1973). There were test also conducted with the replacement and introduction of quarry dust and eggshell powder with respectivetocompactiontestresults.

California bearing ratio:-

The California Bearing Ratio (CBR) test is a standardized laboratorytestusedtodeterminetherelativestrengthofa material such as soil, aggregate, or pavement subgrade. These test measures the pressure required to penetrate a soilsamplewitha standard pistonata standardrate,and then compares the result to the pressure required to penetrate a standard material (typically crushed rock or gravel) under the same conditions. The ratio of the pressure required for the soil sample to the pressure required for the standard material is known as the California Bearing Ratio, and it provides an indication of thestrengthandbearingcapacityofthesoil.TheCBRtest is commonly used in civil engineering and road construction to design and evaluate pavement subgrades andbasecourses.

CBR result value at various percentage Replacement of BCS by quarry dust.

CBR result value for Optimum Replacement of BCS by quarry dust+ Addition of ESP by various percentages.

Optimum Replacement of BCS by quarry dust+ Addition of ESP by various percentages.

6.0

Sieve analysis:-

Particle Size Distribution:-

GrainsizeanalysishasbeencarriedoutaspertheI.S.code of practice (I.S.1498:1970).As per the I. S code the given redsoilisclassifiedassandysoil.

Determination of Specific Gravity:-

The specific gravity of red soil was determined according to IS: 2720 (part III, section-1) 1980. The specific gravity ofredsoilwasfoundtobe2.55.

Compaction:-

Compaction test result value at various percentage Replacement of Red soil by quarry dust.

Liquid Limit result value for Optimum Replacement of Red soil by quarry dust+ Addition of ESP by various

Optimum Replacement of Red soil by quarry dust+ Addition of ESP by various percentages.

Plastic

result value for Optimum Replacement of Red soil by quarry dust+ Addition of ESP by various

California bearing ratio:-

CBR result value at various percentage Replacement of Red soil by quarry dust. Red soil in % and replacement of quarry dust in % CBR

Unconfined compressive strength:-

UCS result value at various percentage Replacement of Red soil by quarry dust.

CBR result value for Optimum Replacement of Red soil by quarry dust+ Addition of ESP by various percentages.

Optimum Replacement of Red soil by quarry dust+ Addition of ESP by various percentages CBR Soil84%+quarrydust

UCS result value for Optimum Replacement of Red soil by quarry dust+ Addition of ESP by various percentages. Optimum Replacement of Red soil by quarry dust+ Addition of ESP by various percentages. UCS kg/cm2

Soil76%+quarry dust16%+16%ESP 11.91%

CONCLUSION:-

The effectiveness of utilization of the quarry dust and egg shell powder as a stabilizer which improving the properties of black cotton soil and redsoil.

The combination of quarry dust and egg shell powder is more effective than the addition of

quarry dust or egg shell powder along for the improvementofpropertiesofsoil.

The optimum mix proportion was found to be 76%soil+24%quarrydust+8%Eggshellpowder forBlackcottonsoil

Liquidlimitvalueisincreasedby40%

Plasticlimitvalueisincreasedby49%

For this optimum mix proportion MDD is increases by 19.04%and OMC is increased by 4.69%

TheCBRvalueisincreasedby39.45%

TheUCSvalueisincreasedby60%.

The optimum mix proportion was found to be 84% soil+16%of quarry dust+12% of eggshell powderforRedsoil.

Liquidlimitvalueisincreasedby43.51%

Plasticlimitvalueisincreasedby56%

For this optimum mix proportion MDD is increases by 14.11% and OMC is decreased by 15.94%

TheCBRvalueisincreasedby36.90%

TheUCSvalueisincreasedby46%.

REFERENCES:-

ASTM D2487-17, "Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)," ASTM International,WestConshohocken,PA,2017.

ASTMD422-63(2007),"StandardTestMethodfor Particle-Size Analysis of Soils," ASTM International,WestConshohocken,PA,2007.

Mitchell, J. K. (1993). Fundamentals of soil behavior(2nded.).NewYork:Wiley.

Bell, F. G. (1996). Lime stabilization of clay minerals and soils. Engineering Geology, 42(4), 223-237.

Holtz, R. D., & Kovacs, W. D. (1981). An introduction to geotechnical engineering (2nd ed.).NewYork:PrenticeHall.

Mitchell, J. K., & Soga, K. (2005). Fundamentals of soilbehavior(3rded.).NewYork:Wiley.

Kaloush, K. E., & Gress, D. L. (2003). Stabilization ofsoilswithclassCflyash.JournalofMaterialsin CivilEngineering,15(5),474-482.

O'Neil,W.R.,&Smith,R.J.(1995).Stabilizationof soilswithlimeandflyash.JournalofGeotechnical Engineering,121(9),659-663.

Little, D. N., & Hills, M. J. (1997). Stabilization of soft soils with lime columns. Journal of GeotechnicalandGeoenvironmentalEngineering, 123(11),1006-1016.