FEASIBILITY ASSESSMENT OF COW URINE BLENDED WITH PETROL TO REDUCE EMISSIONS

1,2,3,4,5,6,7(B.Tech In Mech Engg , Sri Krishnadevaraya University College Of Engg & Tech , Anantapuramu)

8S.LINGAMAIAH Asst.Prof , Dept Of Mech , Sri Krishnadevaraya University, Anantapuramu ***

Abstract - Now-A-DayspetrolIsTheMainFuelForMany Automobiles.Due To This The Emissions Are Also Greatly Produced Which Effects The Human & Environmental conditions. So Our Present Investigation Is To reduce The emissionsOfFuel(petrol)ByUsingCowUrine.TheElements Like Sodium (Na), Magnesium (Mg) , Calcium (Ca) , Pottasium(K)WhichAreFavourableToTheFuelProperties ArePresentInCowUrine.ByUsingTheseElementsWeCan reduce the emissions . The Cow Urine May Contain 90%95% Of Water Content Remaining 5% - 7% Containing Calcium,Chloride,Magnesium,Pottasium,Sodium,Sulphate, UricAcid,Lencocyte.ByAddingTheseConstituentsToFuel AtVariousProportionsToreduceTheemissions

Key Words: petrol, cow urine, sand bath technique, two strokeengine,bombcalorimeter,pollutioncheckingvehicle

1. INTRODUCTION

Air pollution is a complex mixture of gases, particulate matter,andotherpollutantsthatcanhaveharmfuleffectson humanhealthandtheenvironment.Inthecontextoftwostroke petrol engines, the most significant pollutants are hydrocarbons, carbon monoxide, nitrogen oxides, and particulatematter.

Hydrocarbons (HCs) are organic compounds that are producedduringincompletecombustionoffuel.Theyarea majorcontributortoairpollutionandcancauserespiratory problemsandotherhealthissues.Two-strokepetrolengines produce higher levels of hydrocarbons compared to fourstrokeenginesduetotheirdesignandoperation.

Carbonmonoxide(CO)isatoxicgasthatisproducedduring incompletecombustionoffuel.Itisacolorlessandodorless gas that can cause headaches, nausea, and other health problems. Two-stroke petrol engines also produce higher levelsofcarbonmonoxidecomparedtofour-strokeengines.

Nitrogen oxides (NOx) are a group of gases that are producedduringthecombustionoffuel.Theyareamajor contributor to air pollution and can cause respiratory problems and other health issues. Two-stroke engines producehigherlevelsofnitrogenoxidescomparedtofourstrokeenginesduetotheirhighercombustiontemperatures.

Particulatematter(PM)isamixtureoftinyparticlesthatare emitted from vehicle exhausts, industrial processes, and othersources.Theseparticlescanbeinhaleddeepintothe lungsandcancauserespiratoryproblems,heartdisease,and other health issues. Two-stroke petrol engines also emit higherlevelsofparticulatemattercomparedtofour-stroke enginesduetotheirlubricationsystem,whichusesoilthatis burnedalongwiththefuel.

Toreducetheseharmfulpollutants,severalmethodshave been developed, such as direct fuel injection, lean burn technology,catalyticconverters,exhaustgasrecirculation, clean fuel, and proper engine tuning and maintenance. By implementing these methods, the levels of hydrocarbons, carbon monoxide, nitrogen oxides, and particulate matter canbesignificantlyreduced,soatpresentweareblending cowurineresiduewithpetrolfor resultingin cleanerand healthierair.

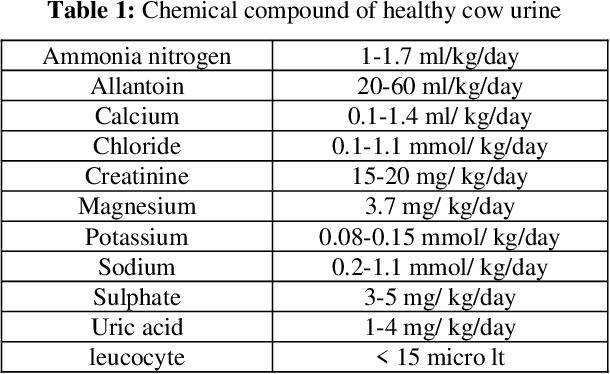

COWURINECOMPOSITION

CU contains95% water, 2.5% urea, minerals, 24 types of salts, hormones, and 2.5% enzymes. It also contains iron, calcium, phosphorus, carbonic acid, potash, nitrogen, ammonia,manganese,iron,sulfur,phosphates,potassium, urea,uricacid,aminoacids,enzymes,cytokineandlactose.

TheSodium,Pottasium,Calcium,AndMagnesiumAreVery Usefultodecreasethepollution

2. EXPERIMENTATION

The Processing Of Cow Urine Involves The Elimination Of 95 Percent Of Water From The Cow Urine Along With Uric Acids. Finally We Get Residual Mixture ContainingOfMagnesium,Calcium,Sodium,Pottasium An Some Other Elements. The Processing Is Done BySAND BATH

TECHNIQUE

TECHNIQUE

Thesandbathtechniqueisalaboratorymethodusedtoheat substancesindirectly.Insteadofdirectlyheatingasubstance withaflameorotherheatsource,thesubstanceisplacedin acontainerthatisthenimmersedinabathofsandthathas been heated to a desired temperature. The sand then transfersheattothecontainerandthesubstancewithinit.

Toperformthesandbathtechnique,acontainer,suchasa beaker or flask, is partially filled with the substance to be heated.Thecontaineris thenplacedina largercontainer, suchasametaltrayorceramicdish,thatisfilledwithsand. Thesandisheatedeitherinanovenoronahotplateuntilit reachesthedesiredtemperature.

Once the sand has reached the desired temperature, the containerwiththesubstanceisplacedinthesandbathand allowed to heat up. The sand will transfer heat to the container,andthesubstancewithinitwillgraduallyincrease in temperature. This method is particularly useful when workingwithtemperature-sensitivesubstances,asitallows formoregentleandgradualheatingthandirectheatingwith aflameorotherheatsource.

After the substance has been heated to the desired temperature,thecontainercanberemovedfromthesand bathandallowedtocool.Thesandcanbereusedforfuture sand baths, provided it has not been contaminated by the substancebeingheated.

In This Technique We Pour Cow Urine In A Beaker And Place It On A Sand Of 2 To 3 CmsThickness . When The Induction Heater Is On The Sand Receives Heat From The HeaterAndDeliversToTheBeakerContainingCowUrine .Then The Cow Urine Eliminates The Water In Form Of Evaporation.TheRemainingElementsAreSettleDownAt Thebottom.

Variousamountsofcowurineweretakenintobeakertoget someinformationabouttheextractionofresiduefromthat cowurine.

BeingheatedAftersometimeathinlayerwereformedon thetopofcowurine.

Aftertheheatingofcowurinewehavetocollecttheresidual extractedfromcowurine.

Wegotonly10gramsofcowurineresidueforthe500mlof cowurineatendofprocessing.

Theresidualitemconsistssodium,magnesium,potassium, andsomeotherelements.Thewaterandotheruricacidsare evaporatedduringheating

BLENDING

Blending refers to the process of mixing two or more substancestogethertocreateanewmixture.

In this experiment we are blending the cow urine residue with petrol. we take 200 ml of petrol and adding 2gms of residue.Buttheresiduetakeslongtimeover7to10daysfor dissolving.thebelowfigureshowsthedissolvingofresidue inpetrolfor7to10days.

CALORIFICVALUETESTING

Inthepropertiesofthefuelcalorificvalueplaysanvital role. Means a good fuel having high calorific value so we checkoursamplesforcheckingitscalorificvalue.sothatwe usebombcalorimeterforcheckingthevalues.

Abombcalorimeterisadeviceusedtomeasuretheheatof combustion of a substance by carrying out a controlled explosion of the substance in a closed chamber called a bomb. The bomb calorimeter consists of a steel container (thebomb)thatisfilledwithaknownamountofoxygenat highpressure.Thesubstancebeingtestedisplacedinside thebombandignitedbyanelectricspark.Asthesubstance burns,itreleasesheat,whichraisesthetemperatureofthe bombandthesurroundingwater.

Thechangeintemperatureofthewaterismeasuredwitha thermometer,andfromthis,theheatofcombustionofthe substance can be calculated using the principle of conservationofenergy.Thebombcalorimeterisanaccurate and precise method for measuring the energy content of fuelsandothersubstances,andiscommonlyusedinthefield ofcalorimetry.

Bombcalorimetersareusedinavarietyoffields,including biochemistry, food science, and materials science, to determinetheenergycontentofsubstancesandtostudythe behavior of materials under high-temperature and highpressureconditions.

Soforreducingthetimeofmixingweaddethanol

Wetookfoursamples

1.Normalpetrolof200ml

2. Petrol of 200 ml +2 gms of cow urine residue + 10 %ethanol

3. Petrol of 200 ml +2 gms of cow urine residue + 20%ethanol

4.Petrolof200ml+2gmsofcowurineresidue

Whenweadd ethanol tothesamplestheresidual amount gets dissolved with in less than couple of days. Also this ethanolhelpsthefueltoimproveitscharacteristics.

Thebombcalorimeterprovidesaprecisemeasurementof theheatofcombustionofasubstancebecauseitinvolvesa closed system in which all the heat produced by the combustionreactionisabsorbedbythewaterandthebomb. The heat of combustion can then be used to calculate the energy content of the substance, which is an important parameter in a variety of applications, such as fuel productionandfoodanalysis.

The heat absorbed by the water and the bomb (q) is calculatedusingtheformula:

q=Cp×m×ΔT

m=massofwater(inkg)

ΔT=tempdifferencebetweenintialandfinalstages

Cp=specificheatatconstantpressure

cv=q/mf

cv=calorificvalue

mf =massoffuel(inkg)

1.normalpetrol

ΔT=4.90degrees

M=1.2kg

Cp=4.2

q=Cp×m×ΔT

q=1.2*4.2*4.90

q=24.696Kj

cv=q/mf

cv=24.696/1\1000

cv=24,696kj/kg

2.petrol+cowurineresidue+10%ethanol

ΔT=4.89degrees

M=1.2kg

Cp=4.2

q=Cp×m×ΔT

q=1.2*4.2*4.89

q=24.645Kj

cv=q/mf

cv=24.645/1\1000

cv=24,645kj/kg

3.petrol+cowurineresidue+20%ethanol

ΔT=4.68degrees

M=1.2kg

Cp=4.2

q=Cp×m×ΔT

q=1.2*4.2*4.68

q=23.587Kj

cv=q/mf

cv=23.587/1\1000

cv=23,587kj/kg

4.petrol+cowurineresidue

ΔT=4.58degrees

M=1.2kg

Cp=4.2

q=Cp×m×ΔT

q=1.2*4.2*4.58

q=23.0832Kj

cv=q/mf

cv=23.0832/1\1000

cv=23,083.2kj/kg

Ingeneralthecalorificvalueofanormalpetrolishigher than our normal petrol sample because due to some in accuracywhiletesting.Sowetakeournormalpetrolsample asareferencepointtocompareothervalues.

Wegetthecloservalueforthesampleofhaving10%ethanol withthenormalpetrol.withthisweconcludethatsample containing10%ethanolisangoodfuel.

Aftercheckingthecalorificvalueforthesampleswehaveto check the emissions in exhaust for that we check our samplesontwostrokepetrolengine.

POLLUTIONCHECKING

Pollution checking is the main step in our experiment becausebasedonthiswehavetocomparetheemissionsof sampleswith normal petrol sample emissions. forthis we chooseantwostrokepetrolengine.

Pollutioncheckingistheprocessofmeasuringtheemissions fromavehicleoranyothersourcethatmaycontributetoair pollution. The main pollutants that are checked during pollution testing include carbon monoxide (CO), hydrocarbons(HC),nitrogenoxides(NOx),andparticulate matter(PM).

Thepollutioncheckingprocessmayvarydependingonthe country,region,orlocallawsandregulations.However,here are some general steps involved in the pollution checking process:

1. Preparation:Thevehicleor sourcebeingtestedis preparedfortestingbyensuringthattheengineis ingoodconditionandthatalltheemissionscontrol systemsareworkingproperly.

2. Testing: The emissions are measured using specialized equipment, which can include a dynamometer (to simulate driving conditions), a tailpipeprobe(tomeasureexhaustemissions),and othersensorsandanalyzers.

3. Dataanalysis:Theemissionsdatacollectedduring the testing is analyzed to determine the levels of pollutants that are being emitted. The results are compared against the local standards and regulations to determine whether the vehicle or sourceiscompliant.

4. Certification:Iftheemissionslevelsarewithinthe acceptablelimits,thevehicleorsourceiscertified as compliant. If the emissions levels are too high, the owner may be required to make repairs or modificationstoreduceemissionsandthenre-test thevehicleorsource.

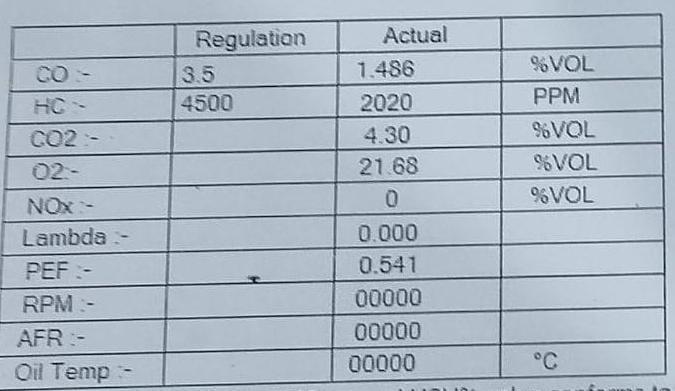

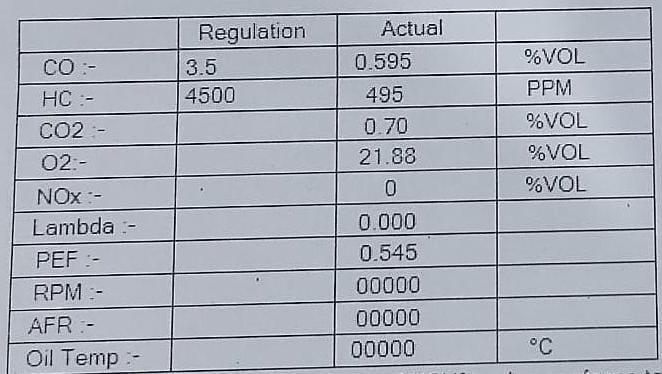

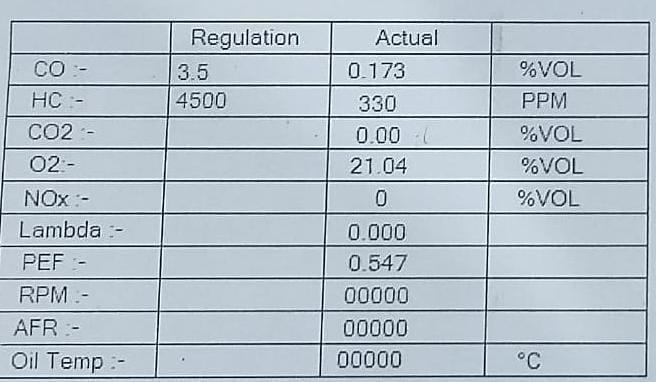

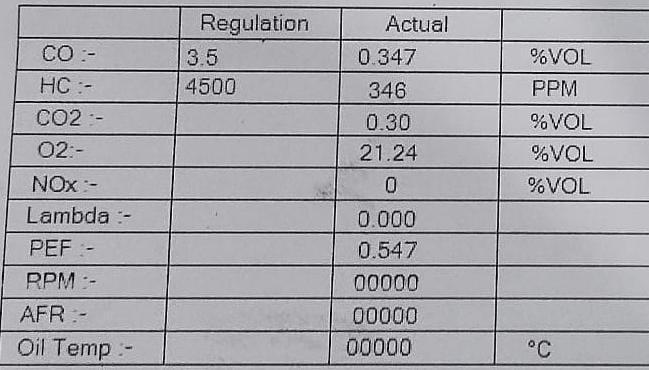

OBESERVATIONS FROM THE TESTS CONDUCTED ON SAMPLES

1.NORMALPETROL

So, when we compare all the samples with normal petrol sample we conclude that the sample having 10% ethanol produceoremitslessemissions.thecoandhcarereduced comparetonormalpetrolando2levelalsoslightlyincreased inthe10%ethanolsample.Oneofthemainparameterco2is notproducedinthe10%ethanolsample.

3. CONCLUSIONS

We conducted this experiment to reduce the emissions produced from the petrol engine. in some journal studies proven that the cow urine residue also increases the efficiency.buttheprocessingofcowurinetakeslongtime.it

isobservedthattheemissionsintwostrokepetrolengine wasreduced.

ACKNOWLEDGEMENT (Optional)

My sincere thanks to prof. P.VENKATA RAMANA Head of organic chemistry, sri krishnadevaraya university, ananthapuramu

REFERENCES

1. K. Ramachandran, M. Balasubramanian, and A. Rajagopal,"InvestigationontheUseofCattleUrine as a Fuel Additive in a Diesel Engine," Energy & Fuels,vol.24,no.5,pp.3245-3252,2010.

2. A.Shukla,S.Chakraborty,andR.Kumar,"Effectof Cow Urine on the Emission Characteristics of a Diesel Engine," International Journal of Green Energy,vol.9,no.6,pp.561-571,2012.

3. N. V. Murali Krishna, S. Suresh Kumar, and S. V. Prabhakar Rao, "Experimental Study on the Performance and Emission Characteristics of a SI EngineFuelledwithGasolineandCowUrineBlend," Fuel,vol.158,pp.873-879,2015.

4. S. Agarwal, A. R. Verma, and A. Sharma, "Effect of CowUrineandCowDungontheEmissionsfroma CI Engine Fuelled with Diesel," Fuel, vol. 190, pp. 295-305,2017.

5. R.Kumar,P.Kumar,andA.Kumar,"Experimental Analysis of Emissions and Performance Characteristics of Diesel Engine using Cow Urine and Diesel Blends," Journal of Mechanical Engineering Research and Developments, vol. 40, no.2,pp.247-254,2017.