Analysis of various sensors to measure the physical parameters of the oil stored in Oil Tank for Oil and gas Industries in Oman

1Lecturer, Electrical Engineering University of Technology and Applied Sciences, Nizwa, Sultanate of Oman

2 Lecturer, Electrical Engineering University of Technology and Applied Sciences, Nizwa, Sultanate of Oman

3 Lecturer, Electrical Engineering University of Technology and Applied Sciences, Nizwa, Sultanate of Oman

4 Technician, Electrical Engineering University of Technology and Applied Sciences, Nizwa, Sultanate of Oman

5 Technician, Electrical Engineering University of Technology and Applied Sciences, Nizwa, Sultanate of Oman

Abstract - Oil and gas industries play a vital role in improving the economy of Oman. Oman government pays major attention in improving the production and safety measures in oil and gas industries. As oil is flammable, it is important to measure various internal and external parameters of oil when it is stored in a tank. Having a smart monitoring system with suitable sensors will have safe environment and enhanced production. In this paper various sensors thatcanbe usedfor oiland gas industriesis discussed and the proposed sensor technology that is efficient than the existing models is suggested.

Key Words: Sensors,OilandgasIndustries

1. INTRODUCTION

OilisthemainsourceofresourceinOman.Omanhaslarge numberofoilfieldsandisawell-knowncountryintermof exportingoiltovariousneighbouringcountries. Oilandgas industriesarenormallylocatedoutsidetheresidentialareas consideringsafetyandalsodependsonthelocationwhere the oil is explored. There are so many internal process associatedwithoilwhenitcomestodomesticusage.Each processissignificantlyshouldbehandledwithutmostsafety asoilishazardousinnature[1]

Itisveryimportanttomeasurevariousfactorsofoilandthe storagetankwhenitisstoredforprocessingordelivering for domestic usage. Modern technology has immense research interest in developing smart sensors with safety measuretoenableparametermeasurementatoptimalcost andsafety.

Varioussensorsthatarecurrentlyunderusageisdiscussed inthispaperandanefficientsensorthatcanbeusedforoil and gas industries with cost, simplicity and efficiency is suggestedinthispaper.

2. SENSOR TECHNOLOGIES

Asoilishighlyhazardousitisa difficulttasttochoosethe sensorswithhighefficiencyandoptimalperformance.Inthis paperimprovessensormodelsarediscussed.

Sensorsneededfortheoilstoragetanks

2.1. Pressure sensor

ItisaSubmersiblepressuresensorrangingfrom 0–0.2 barformeasuringthelevelofa2meter oilstoragetank.This typeofthepressuresensorcanbe installeddirectly intoa storagetankcontainingfueloil.Itissuesaoutptsignalof420mAwith0.1%accuracy[2]

2.2 Multi-spot thermometer

Theaveragetemperatureoftheoilcanbemeasuredusing these multi spot thermometers. The standard measuring elementsareaccordingtoEN60751.Min.150mmfromfoot ofthesensortotheheadspot[3]

In oil and gas industries accurate and reliable oil flow measurement is required for estimating the cost of distributionand generation The mostly used type of flow metersarePositivedisplacementflowmeters.Inrecentdays differentialpressureflowmetersarewidelyusedtomeasure theoilflow[4]

and gasoline and liquid mixtures like Y-grade natural gas liquids(NGL),butcanalsobeusedtomeasurethedensityof crudeoil.Thetypicalinstallationisinasingle-phaseliquid stream, but densitometers can be used to measure singlephasegasorvapor.Thispaperaddressesonlycontinuous, on-lineliquiddensitymeasurement[6]

Gas sensors are essential for personal safety and environmentalprotection.Thesesensorsaremainlyusedto detect and measure actual levels of methane, hydrogen sulphide, carbon monoxide, oxygen along with 50 other gases.Thissensorhas auto-calibrationfunctionthatallows for precious calibration of the gas levels This sensor can storethevaluesandcouldtransferdatatoacomputer[5].

Surface tension is the major property of any liquid in contact with the gas. Interfacial tension stands of the propertythatexistsbetweenvariousformsofliquidtosolid, solidtosolidorsolidtoair.

The cohesive energy is measured with respect to the InterfacialTension.Byusingthismeasurementthepractical imbalanceofforcesthatexistbetweenmoleculesatanytype of interfacecanbeestimated

The imbalance of force is created due to the contact of twodifferentphasesofsubstances.Asaresult accumulation offreeenergyattheinterfacetakesplace.Thisaccumulated energyiscalledsurfacefreeenergyandcanbecalculatedto increasethesurfaceareaoftheinterface[7]

Excessenergyexistsatanytypeofinterface.Ifoneofthe phases is the gas phase of a liquid being tested, the measurementisnormallyreferredtoasSurfaceTension(ST). Ifthesurfaceinvestigatedistheinterfaceoftwoimmiscible liquids, the measurement is normally referred to as interfacialtension(IFT).

2.7 Oil Viscosity

Itisimportanttomeasurethelevelofflowingoilstream. Adensitometeriscanmeasurecontinuously inon-linethe measurethedensityofaflowingstream.Intheoilandgas industry, a densitometer is normally used to measure the densityofliquidhydrocarbonfinishedproductslikepropane

OilViscosityisoneoftheimportantparametersmeasured becauseofitsimportancetoanalyzetheconditionoftheoil and lubrication. There are two ways to measure the oil’s viscosity. One measurement technique is based on its kinematicviscosityoritsabsoluteviscosity[8].

Oilviscosityismeasuredeasilyusingthecapillarytube viscometer.Itconsistsofametalrodthatisinsertedintothe twobeakersthataresimilartoeachother.Theactualforce requiredforstirringthegearoilwillbemuchmoregreater thantheactualforcerequiredtostirtheturbineoil.

Basedonthisobservation,itmightbetemptingtosaythat thegearoilrequiresmoreforcetostirbecauseithasahigher viscosity than the turbine oil. However, it is the oil’s resistancetoflowandshearduetointernalfrictionthatis beingmeasuredinthisexample,soitismorecorrecttosay that the gear oil has a higher absolute viscosity than the turbineoilbecausemoreforceisrequiredtostirthegearoil.

2.9.

AcidityorbasicityofaliquidismeasuredwithPhvalues. Phvalueoftheoilplaysasignificantroletoknowthequality of oil with respect to chemical reactivity and its effect on environment[9].

the amount of oil inside thetank. The measurement could helpthemotortodrivefromonetanktoanothertankwhen thelevelofoilfallsbelowsomesafevalues.

Also it is possible to estimate the amount of oil transferred for billing purpose and to know the supply quantity[10]

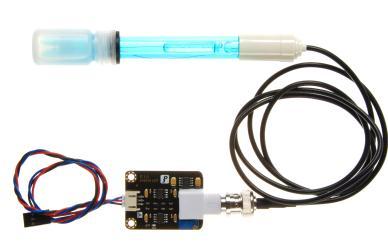

ArduinocompatiblePhSensorsasindicatedinthefigure abovecanabletomeasurethePhValueoftheoilaccurately andsendsthevaluetotheArduinoforfurthercomputations.

Astheoilpresentinsidethestoragetanksarenotcapable ofviewedfromoutsidealevelsensorisinneedtomeasure

Since oil is highly flammable it is essential to have a noncontactablesensortoavoidfireaccidents.Ultrasonicsensors canabletomeasurethelevelwithouthavinganycontactwith theoil.

2.11 Environmental sensor

The BME680 is the one of the type of gas sensor that measures high-linearity and high-accuracy gas, pressure, humidityandtemperaturesensors.Thissensorismadefor usage in mobile applications due to its small size and low powerconsumption.TheBME680hasvariousadvantagesdependingonthevariousoperatingmodeunderoptimized consumption, longer-term stability and higher EMC robustness.MBE680canmeasuretheairqualityforpersonal measurement and the gas sensor within the BME680 can detectalargerangeofgaseslikevolatileorganiccompounds (VOC).

The following are the Possible use cases that can be measuredusingthissensor:

Personalairqualitytracker

Airqualitymapping

Airqualityinsidecars&publictransport

Enhancedcontextawareness

Accuratestep&calorietracker

QuickGPS-fix&improvednavigation

Indicatoroftoohigh/lowhumidity

Airquality&well-beingindicator

Sleep/recoverytracker

ItisawellknowfactthatGreenhouseEffec ismeltingthe Earth ice core every day there by creating dangerous icebergs. By measuring the exact concentration of CO2(CarbonDioxide),itispossiblettoreducetheCO2andto protectourEarth.

InoilandgasfileditisveryimportanttomeasuretheCO2 level that comes out of the gas tank to avoid any fire accidents. Oil and gas when stored in a closed tanks are subjected to emission of gases due to changes in environmentaltemperatureandgaspressureofthestorage tank.

It is obvious andcompulsory to measure the CO2level comingoutofthisstoragetanktosafeguardtheplantfrom anyexcessemissionsthatcancausesmokesorburns.

ThisisthefirstCO2sensorthataremadeforcompatible with theArduinomarket.Theoutputvoltageofthissensor decreasesastheconcentrationoftheCO2increases.Thereis apotentiometerdesignedalongwiththissensorboardtoset thethresholdofvoltage.Themeasurementworkssslongas theCO2concentrationishighenough(thevoltageislower thanthethreshold),adigitalsignal(ON/OFF)willbesentto theArduinosensorpin.

The CO2 sensor is basically a MG-811 sensor module which is highly sensitive to CO2 emissions. This sensor is madewith lesssensitivetoalcoholandCO,lowhumidity& temperaturedependency.

Onboardheatingcircuitbringsthebesttemperaturefor the sensor to function. Internal power boosting to 6V for heatingsensorbestperformance.

This sensor has an onboard conditioning circuit for amplifyingoutputsignal.

ToeasethedifficultyofusingthisCO2sensor,aGravity Interface is adapted to allow plug play. The Arduino IO expansion shield is the best match for this CO2 senor connectingtoyourArduinomicrocontroller.

ThisisanelectrochemicalArduino-basedCO2sensor,itis suitableforqualitativeanalysis.ThereareotherInfraredCO2 sensors,whichcouldmakeaquantitativeanalysis.

3. CONCLUSIONS

Inthispapervarioussensorsthatarerequiredtobeusedin oilandgasindustriesarediscussed.Itisveryimportantto measuretheinternalandexternaloilqualityparameters.As oilishighlyflammableliquidutmostattentionisrequiredin selectingpropersensortooperatesafeandtogiveaccurate results. The sensors discussed here are made with latest technologies and can able to operate safely as per the climaticconditioninOilandgasindustriesinOman.

ACKNOWLEDGEMENT

ThisprojectisfundedbyOmanResearchcouncilTRCOman and the project is a real time project carried over at UniversityofTechnologyandAppliedSciencesNizwa.

REFERENCES

[1] PanYi,XiaoLizhiandZhangYuanzhong,"RemoterealtimeMonitoringSystemforOilandGasWellBasedon WirelessSensorNetworks",2010

[2] Stig Petersen, Paula Doyle, Svein Vatland, Christian SalbuAasland,TrondMichaelAndersenandDagSjong Requirements. DriversandAnalysisofWirelessSensor NetworkSolutionsfortheOil&GasIndustry,2007,IEEE

[3] Kazem Sohraby, Daniel Minoli and Taieb Znati. Wireless sensor networks: technology, protocols, and applications. Published by John Wiley & Sons, Inc., Hoboken,NewJersey,2007ISBN:978-0-471-74300-2

[4] Summarized Version published in Ozean Journal of AppliedSciences6(2),2013.ISSN1943-2429,Pages39 – 43. Ozean publication REFEREN CES Alex Talevski, SimonCarlsenandStigPetersen.ResearchChallengesin ApplyingIntelligentWirelessSensorsintheOil,Gasand ResourcesIndustries,7thIEEEInternationalConference onIndustrialInformatics(INDIN2009)

[5] He, J.; Yang, S.; Gan, C.; He, J.; Yang, S.; Gan, C. Unsupervised Fault Diagnosis of a Gear Transmission Chain

[6] UsingaDeepBeliefNetwork.Sensors2017,17,1564.

[7] Gkerekos,C.;Lazakis,I.;Theotokatos,G.ShipMachinery ConditionMonitoringUsingPerformanceData

[8] throughSupervisedLearning;UniversityofStrathclyde Publishing:Glasgow,Scotland,2017;pp.105–111.

[9] ISBN9781909522169

[10] Marichal,G.N.;Hernández,A.;Acosta,L.;González,E.J.A Neuro-FuzzySystemforExtractingEnvironment

BIOGRAPHY

Dr.D.Vimalakeerthy is working as Lecturer at University of Technology and Applied Sciences Nizwa.Hehas22yearsofteaching experience and involved in real timeresearchactivities.