CRITICAL LNG HAZARD SOLUTION

Ravi Kiran DasariAbstract

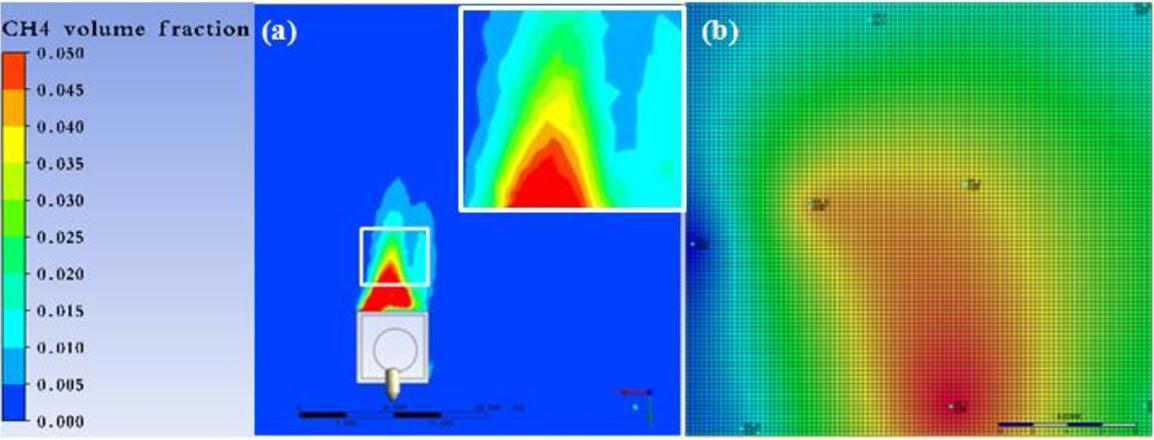

In this study, the main objective is to analyze different hazards and potential hazardous areas and investigate mitigation methods using computational fluid dynamics. The analysis focuses on the use of thermal radiant heat flux and temperature to evaluate the effectiveness of materials on both the LNG bunker and the cargo vessel. Additionally, the study considers the use of water curtains to prevent material stress cracking in case of LNG leakage as a potential mitigation method for the radiation hazard. The analysis is expected to provide insights into effective strategies for mitigating hazards associated with LNG storageandtransportation.

Keywords: Boil-off LNG vapor, Dispersion cloud, RPT (rapid phase transformation), bunkering, cryogenic

1. INTRODUCTION

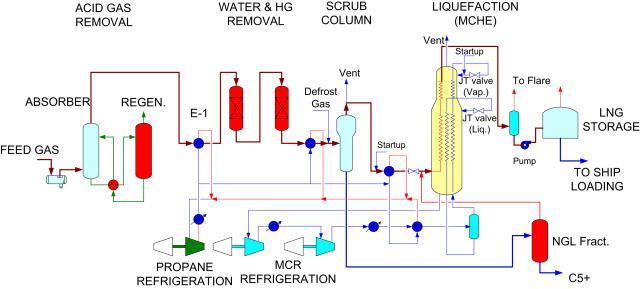

Natural gas is usually liquefied through a process called liquefaction, which involves cooling the gas to a very low temperature, around minus 260°F (minus 162°C), at ambient pressure through cold box or different refrigeration technologies. This process converts the naturalgasintoLNG(LiquefiedNaturalGas),whichisthen stored in specially insulated and refrigerated tanks for transportation. OneofthebenefitsofusingLNGisitshigh energy density, which makes it a very economical fuel for transportationandstorage.LNGtakesupto1/600thofthe volume of natural gas in its vapor state, making it much more efficient to transport and store. To use LNG for pipeline orasfuel gas,itis necessarytoconvertitback to its gaseous state through a process called regasification,

3. LNG HAZARD POOL FIRE DISCUSSION

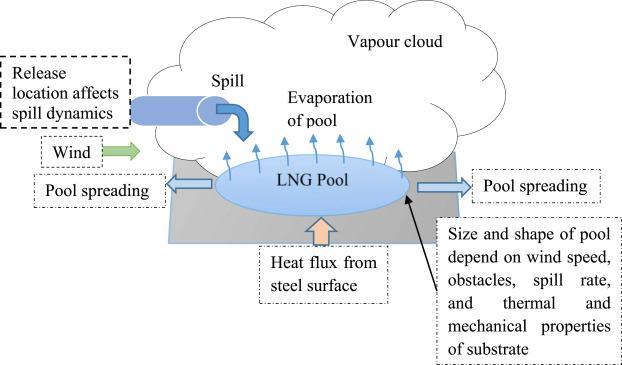

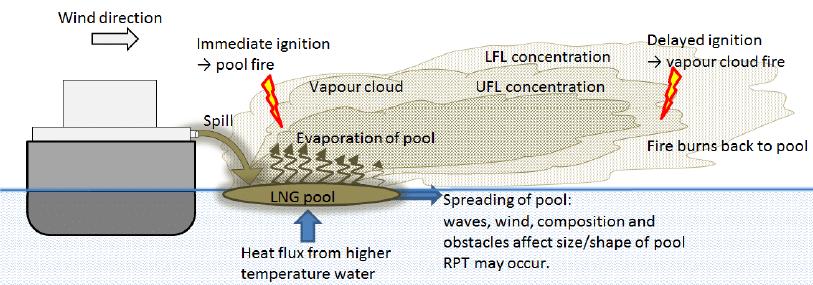

The boil-off LNG vapor, which can occur during ship-toship bunkering or any other handling of liquefied natural gas, is a significant hazard due to its cryogenic temperature and the fact that it initially behaves as a denser-than-air vapor. This means that if it is released, it can quickly spread and displace oxygen in the immediate area, creating a hazardous environment for workers and

whichinvolvesheatingtheLNGtoturnitbackintonatural gas.Onceregasified,thenaturalgascanbeusedforawide rangeofcommercial,industrial,andhouseholdpurposes.

2. ENVIRONMENTAL RISKS OF LNG

It is crucial to consider the potential environmental risks and adhere to the necessary regulations regarding the location of LNG tanks and pipelines. The primary concern is the risk of fire resulting from LNG vaporization and contactwithanignitionsource.However,thepossibilityof a large LNG release is highly unlikely, as the vapor cloud typicallycannotextendbeyond30miles.Additionally,LNG hasanexcellentsafetyrecord.

There are atmospheric emissions associated with LNG, such as CO2, SOX, and NOX, which come from combustion during power generation, in-plant heat, and LNG tanker propulsion units. Emissions can also come from LNG production and re-gasification plants and natural gas handling. It is critical to consider CO2 limitations in the feed and explore carbon capture technology. Small-scale LNGfeedtypicallycontains2%CO2,andminimalemission limitations must be followed to avoid environmental issueswithgreenhousegasemissions.

Another risk to consider is liquid effluents from transportation, mainly offshore LNG plants, where dischargeintothesea withpropertreatmentisnecessary. It is important to take marine life and the environment into consideration and follow necessary limitations. Sanitary waste is also a significant concern in every industry, and site-specific land expansion or dredging wastes must be taken into account, and necessary limitations must be followed. [10] [11]

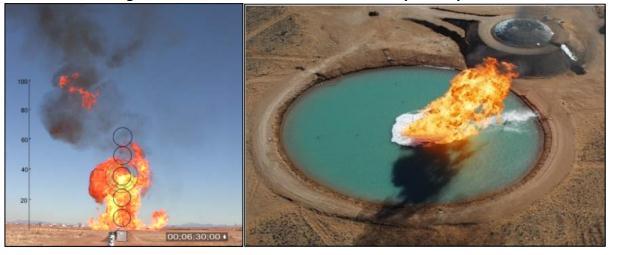

potentially leading to asphyxiation. As the vapor cloud is heated up by the surrounding environment, it will eventually disperse, but there is a risk of ignition and explosion if there is a source of ignition present. In addition, LNG pool fires can occur if the source ignites immediately or a flash fire burns back to the source, potentially causing thermal radiation damage to the surroundingarea[1][2][3] .RapidPhaseTransition(RPT)isa phenomenon that occurs when LNG is released from its

container into the atmosphere and undergoes a rapid phase change from a liquid to a gas state. This phase change results in a significant volume expansion, which can create high pressure and cause damage to the surrounding area. RPT can occur due to a number of factors,includinginadequateinsulation,equipmentfailure,

orhuman error.Toprevent RPT,it isimportantto ensure proper design and operation of LNG storage and handling facilities,aswellasregularmaintenanceandinspectionof equipment.Additionally,emergencyresponseplansshould beinplacetoquicklyaddressanyincidentsthatmayoccur [7]

It is important to note that incidents involving LNG vaporizingviolentlyuponcontactwithwater,resultingina physical explosion or "cold explosion," are rare and typicallyoccurduringthetransportationorstorageofLNG [13].AsfortheincidentattheTexasGulfCoastplant,while itdidcauseaspikeinglobalLNGprices,itwasnotcaused by a physical explosion, but rather a fire that occurred duringthemaintenanceofastoragetank.

WhatarethehazardsofLNGcargo?

Unwanted releases of LNG can lead to hazards such as asphyxiation, cryogenic burns, and cryogenic damage to the ship, as well as dispersion, fires, and explosions. Accurate modeling of the gas cloud resulting from a spill onlandiscrucialtopredictthehazardsassociatedwithit. Factors such as wind direction and speed, atmospheric stability, temperature, humidity, and topography can also affect the behavior and dispersion of the gas cloud. Therefore,acomprehensiveunderstandingofthephysical andmeteorologicalconditionsatthespillsiteisnecessary foraccuratemodelingandriskassessment.

Impoundment structures, also known as containment structures, are typically constructed around LNG storage tanks and pipelines in land-based LNG facilities. These structures are designed to contain and control the spread ofLNGinthe event ofa leak orrelease. Theyaretypically madeofconcreteorothermaterialsthatcanwithstandthe extremelycoldtemperaturesofLNG [8].Theimpoundment structure can hold the spilled LNG until it can be safely removed or transferred to another location. These safety systemsaredesignedtodetectandrespondtoanyleaksor spills that may occur in an LNG facility. Gas detectors can detect the presence of LNG vapors in the air, while fire detectors can detect any flames or heat sources. Temperature sensors can detect any changes in temperaturethatmayindicatealeakorotherproblem [4]

Oncethesesystemsdetectapotentialproblem,firefighting and vapor suppression systems are automatically

activated. Firefighting systems typically use water, foam, orotheragentstoextinguishanyfiresthatmaybreakout, while vapor suppression systems use water spray or mist todisperseLNGvaporsandpreventthemfromigniting [9] .

Overall, these safety systems are critical to ensuring the safe operation of LNG facilities and protecting nearby communities and the environment from the potential hazards associated with LNG. [6] Emergency shutdown devices are crucial for shutting down equipment and isolatingthesourceofaleakorrelease.Thesedevicescan be manual or automatic and are designed to prevent furtherescalationofanincident.Inaddition,LNGfacilities are required to have emergency response plans and trained personnel who can respond to incidents quickly andeffectively.

Regular maintenance and inspection of LNG facilities and equipment are also critical for ensuring their safe

operation.Thisincludesinspectingand testing emergency shutdown devices, fire and vapor suppression systems, and gas and fire detectors. Additionally, staff training and regularemergencyresponsedrillsarenecessarytoensure that personnel are prepared to respond appropriately in case of an emergency [11] The LNG facility operator is responsibleformaintainingthesafetyofthefacility,which involves developing and following detailed maintenance procedures to ensure the integrity of various safety

systems. These procedures may include regular inspections and testing of equipment, as well as preventative maintenance activities to identify and address potential issues before they become a problem. It's important for the operator to stay up-to-date on industry standards and best practices for LNG facility maintenance, and to train their employees on proper safety procedures to minimize the risk of incidents or accidents.

4. CONCLUSION/RECOMMENDATION

Computational fluid dynamics (CFD)[5]is used to determine the vapor dispersion modeling to predict the vapor exclusion zone.It’sbasicallyhydraulicmodelfortheLNGflowintotroughsortrenches.Expansionfoamapplicationisrecommendedfor LNGHazardMitigation.AlsoeffectiveuseofwatercurtainsisrecommendedinLNGVaporCloud.

REFERENCES

[1] SIGTTO (2009). Report on the Effects of Fire On LNG Carrier Containment Systems, Society of International Gas Tanker&TerminalOperators,March19,2009,WitherbySeamanvesselInternationalLtd,Scotland,UK

[2] Blanchat, T., Helmick, P., Jensen, R., Luketa, A., Deola, R., Suo-Anttila, S., Mercier, J., Miller, T., Ricks, A., Simpson, R., Demosthenous,B.,Tieszen,S.,andHightower,M.,(2010).ThePhoenixSeriesLargeScaleLNGPoolFireExperiments, SAND2010-8676,SandiaNationalLaboratories,Albuquerque,NM.

[3] Blanchat, T. (2011). LNG Carrier Tank Insulation Decomposition Experiments with Large Scale Pool Fire Boundary Conditions,SAND2011-1880,SandiaNationalLaboratories,Albuquerque,NM.

[4] Luketa,A. J. (2011), Recommendationson the Prediction of Thermal HazardDistances fromLarge Liquefied Natural GasPoolFiresonWaterforSolidFlameModels,SAND2011-9415,SandiaNationalLaboratories,Albuquerque,NM.

[5] Morrow,C.,CascadingDamagefromLNGPoolFire–PotentialforOverpressureorThermalDamagetoAdjacentCargo Tanks, SAND2011-9414, Sandia National Laboratories, Albuquerque, NM. Adaptive Research, (2008). CFD2000 - A general-purpose CFD program intended for complex scientific and engineering flow calculations), Keith Kevin O’Rourke.

[6] Kalan, R. J., Petti, J. P.(2010). LNG Cascading Damage Study Volume I: Fracture Testing Report, SAND2011-3342, SandiaNationallaboratories,Albuquerque,NM.

[7] Luketa,A.J.,(2005).AReviewofLarge-ScaleLNGSpills:ExperimentandModeling,SAND2005-2452J,SandiaNational Laboratories,Albuquerque,NM.

[8] Luketa,A.J.,M.M.Hightower,S.Attaway,(2008).BreachandSafetyAnalysisofSpillsoverWaterfromLargeLiquefied NaturalGasCarriers,SAND2008-3153,SandiaNationalLaboratories,Albuquerque,NM.

[9] Petti,J.P.,Wellman,G.W.,Villa,D.,Lopex,C.,Figueroa,V.G.,Heinstein,M.(2011),LNGCascadingDamageStudyVolume III:VesselStructuralandThermalAnalysisReport,SAND2011-6226,SandiaNationalLaboratories,Albuquerque,NM.

[10] Figueroa, V.G., Lopez, C., O’Rourke, K.K.,(2011). LNG Cascading Damage Study Volume II: Flow Analysis forSpills fromMOSSandMembraneLNGCargoTanks,SAND2011-9464.SandiaNationalLaboratories,Albuquerque,NM.

[11] GAO (2007). “Public Safety Consequences of a Terrorist Attack on a Tanker Carrying Liquefied Natural GasNeed Clarification,”GovernmentAccountabilityOfficereport,GAO-07-316,February2007.

[12]Hightower,M., etal.(2004).GuidanceonRisk AnalysisandSafetyImplicationsofa LargeLiquefiedNatural(LNG) SpillOverWater,SAND2004-6258.Albuquerque,NM:SandiaNationalLaboratories.

[13] Hightower, M., Luketa-Hanlin, A., Gritzo, L.A., Covan, J.M. (2006). Review of Independent Risk Assessment of the Proposed Cabrillo Liquefied Natural Gas Deepwater Port Project, SAND2005- 7339, Sandia National Laboratories, Albuquerque,NM