Evaluation of Strength Characteristics of Clayey Soil Using Shredded Rubber Tyre Chips and Rice Husk Ash

Ilyas Hussain Bhat1 , Sameer hussain mir2 , Mr Anoop Sharma31 M. Tech Scholar, Sri Sai College Of Engineering and Technology, Badhani Pathankot

2 Sameer hussain mir, M.Tech scholar Sri Sai College Of Engineering and Technology, Badhani Pathankot

3Assistant Professor, Sri Sai College Of Engineering and Technology, Badhani Pathankot ***

Abstract - soil being one of the most valuable materials used in different construction projects including multi-storied buildings, earth canals and earthen dams. Most of the failures of soil have been attributed to poor strength. Stabilization of soil by adding lime, cement, bitumen etc. are expensive and therefore require an economic replacement.

Shredded rubber tyre chips, is a new generation material, which have gained attraction towards the soil reinforcement. It can be obtained from waste rubber tyres almost 70% tyres are directly disposed into the enviroment.Itismanufacturedin the controlled conditions with special equipments to produce optimized size distribution which is its unique property.

Shredded rubber tyre chips are obtained from wastes rubber, which helps in soil stabilization of clayey soils, the performance of Shredded rubber tyre chips, is superior to all the other materials used in India. Hence, the utilization of Shredded rubber tyre chips for soil improvement will be a welcome development. In this thesis work, I studied the suitability of Shredded rubber tyre chipsasapossiblematerial to improve the strength of soils.

There was a sharp increase in UCS with addition of Shredded rubber tyre chips at all ages indicating the abnormalandhigh strength behavior of Shredded rubber tyre chips the compressive strength increases with addition of Shredded rubber tyre chips in comparison to without Shredded rubber tyre chips at all ages. The compressive strength was found to be maximum at 28 days with 10% Shredded rubber tyrechips The object of our present studies is to improve the various properties of clayey soil by mixing locally available material, hence Rice Husk Ash, which is locally and easily available material, selected to mix with clayey soil in different proportions. The admixture was collected from rice milling factory at budgam j&k.

Three proportions of SRTC used is 11%,13%,15%,17% by weight of dry soil and variation of Rice Husk Ash is 9%, 10%, 11% respectively. The analysis was done by conducting compaction, atterberg limits, compaction test, UCS and California bearing ratio tests. It was observed that Shredded rubber tyre chips and Rice husk ash had significant effect in the engineering properties of the soil. The results showed that the unconfined compression strength, Californiabearingratio

values had increased with increase in shredded rubber tyre chips content up to certain limit.

Key Words: shreddedrubbertyrechips,ricehuskash,ultra finesss. Clayey soil, atterberg limits, compaction test, UCS, CBR

1. INTRODUCTION

Soilistheuppermost-unconsolidatedmaterialoftheearth present naturally in the universe. It is formed by the decomposition of rocks under the influence of naturally occurringconditionssuchaswind,rain,snow,heat,etc.The characteristicsofsoilchangeaccordingtotopographyandits location.These soils show settlements, low shear strength andhighcompressibility.

Clayeysoilisoneofthetypesofsoilcomposedofverysmall particles, and usually it contains silicates of aluminum and/or iron and magnesium. Clayey soil swells in wet conditionandshrinksindrycondition.

The clayey soils being expansive in nature need to be stabilized in order to improve its various geotechnical parameters like strength, settlement control, shrinkage, swellingetc.whichcanbedonebynumerouswaysandhere I would be discussing the strength improvement by shreddedrubbertyrechipsandricehuskash.

1.1 materials

1.1.2 Clayey soil

Clayeysoilbeingoneofthetypesofsoiliscomposedofvery fineparticles,anditcontainssilicatesofaluminumoriron and magnesium. The flow of water is usually hindered by clayeysoil,meaningitslowlytakesupwaterandthenholds itforalongdurationoftime.VolumeofClayeysoilincreases inwetconditionanddecreasesindrycondition.

Clayeysoilsareoftenveryglueyandrolllikeplastic when theyareinwetcondition.Theycanretainmoretotalwater thanmostoftheothersoiltypes.Theyremainwetinwinter andsostockshouldbetakenoffthelandtoavoidpoaching (thecompactionofsoilsbyanimals’hooves).

Theyusuallytaketimeingainingtemperatureinthespring becausemoisturepresentinthemheatsupmoreslowlythan mineralmatter.Theyarenormallyrichinpotash,butlack phosphates .Clay soils usually have to be mixed with thelime. Over liming may not cause any problems like deficiency.Theclayeysoilsbeingexpansiveinnatureneedto be stabilized in order to improve its various geotechnical parameters like strength, settlement control, shrinkage , swellingetcwhichcanbedonebynumerouswaysandhereI wouldbediscussingthestrengthimprovementbyshredded rubbertyrechipsandricehuskash.

1.1.3 shredded rubber tyre chips

In civil engineering field, waste materials such as waste rubber tyres, have attracted attention to be used in soil reinforcement. Approximately 240 million tyres are being traded in each year, almost 70% or 170 million tyres are disposedofdirectlyintotheenvironment.Themostcommon disposal end point is privately and publicly owned stockpiles, which account for around 100 million tyres/,tubes annually. Approximately 28 million tyres are disposedofinlandfills,and38milliontyresarerandomly dumped on roadsides or in rural areas. While these estimatesalonearequitelarge,theydonotincludethehuge backlogofscraptiresfrompreviousyears.Thestockoftyres and tubes from past stockpiling has been estimated to be over 2.4 billion (GIA, 2013). In Western Australia around 48.5 million equivalent passenger unit (EPU) waste tyres/tubes were produced in 2009-2010 (Brindley et al., 2012). Consequently, waste tyres/tubes are occupying a considerable amount of valuable space in landfill sites, resulting in severe environmental consequence and an increasingneedfornewlandfillsites(Fig.3.2).Theobjective ofthisstudyistocontrolthepollutioncausedbydumpingof wasterubbertubetoalargeextent.Thisurgestheneedfor analternative,enviromentalfriendlywayoftubedisposal. The study presented in this work is part of an ongoing researchtoprovidegoodmeansofconsumingthemillionsof scrap tube that are taken for stock piling of used tubes. Therefore, reuse of waste tubes and tyres should be seriouslyconsidered.

This 75,000-tones tyre/tube dump near Madrid has presented Spanish authorities with a big problem (BBC NEWS,2016)

Therearesixmajortyreandtubedisposalendpointswhich are representative of the total disposal mix: landfills, stockpiles,randomdumps,retreads,asphaltmixtures,and energy feeds. The first three end points account for a significantportionofdisposedtires.Asphaltmixturesand energyfeedsrepresentthemosteconomicalandtechnically feasibleoptionsthatcouldabsorbasignificantportionofthe tyre and tube being disposed. There are also some applicationsofthewastetyresincivilengineeringsuchasin embankment construction or drainage layers in

landfills(Balunaini et al., 2014). However, considering the ongoingincreaseintheamountofwastetyreandtube,more studies are required to find other applications for theses wastes.

1.1.4 Rice husk ash

Rice milling generates a by-product known as husk. This surroundsthepaddygrain.Duringmillingofpaddy,about 78%ofweightisreceivedasrice,brokenriceandbran.Rest 22%oftheweightofpaddyisreceivedashusk.Thishuskis usedasfuelinthericemillstogeneratesteamfortheboiling process. This husk contains about 75% organic volatile matterandtheremaining25%oftheweightofthishuskis convertedintoashduringthefiringprocess,knownasRice HuskAsh(RH).ThisRHinturncontainsaround85%-90% amorphous silica. So for every 1000 kg of paddy milled, about220kg(22%)ofhuskisproduced,andwhenthishusk is burnt in the boilers, about 55 kg (25%) of RHA is generated.Thehuskgeneratedduringmillingismostlyused as a fuel in the boilers for processing paddy, producing energythroughdirectcombustionand/orbygasification. ThisRHAisagreatenvironmentalthreatcausingdamageto thelandandthesurroundingareainwhichitisdumped.

1.2 Mix proportions

Table-1:mix proportion of soil(s),rice husk ash (RHA) and shredded rubber tyre chips (SRTC)

S.NO DESIGNATION (S:RHA:SRTC)

1.3 Objectives

To calculate the consistency limits and compaction characteristicsofuntreatedclayeysoil.

TocalculatetheMDDandOMCValueofClayeysoilwith ShreddedrubbertyrechipsandRicehuskash.

TocalculatetheCBRValueofClayeysoilwithShredded rubbertyrechipsandRicehuskash

TocalculatetheUCSValueofClayeysoilwithShredded rubbertyrechipsandRicehuskash.

2.

2.1

Table-1 Variation ofLL, PL and PI for various proportions ofSoil,RHA and Shredded rubber tyre chips

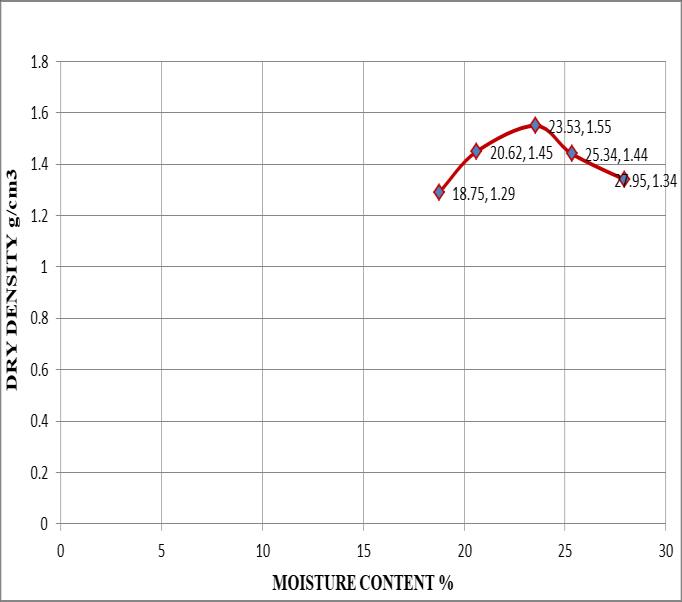

Fig 1:variationinthedrydensityandmoisturecontent

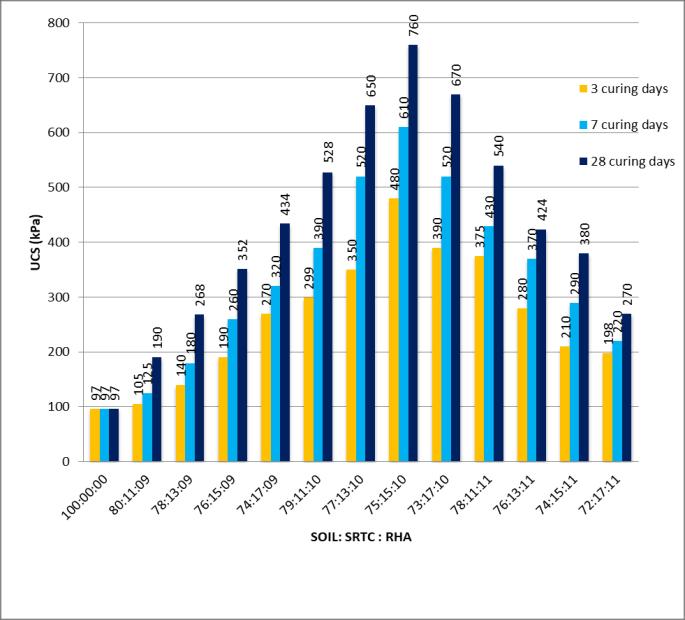

2.3 UCS

Thevalueofunconfinedcompressivestrengthfororiginal soilandsoilwithvariousmixproportionsofricehuskash andshreddedrubbertyrechipscalculatedfromUCStestis givenbelow:

Table-3:UCSValuesOf VariousMixProportionat DifferentCuringPeriods

Values of Various Mix Proportion

Table 2 MMD and OMC for soil-RHA-SRTC MIX

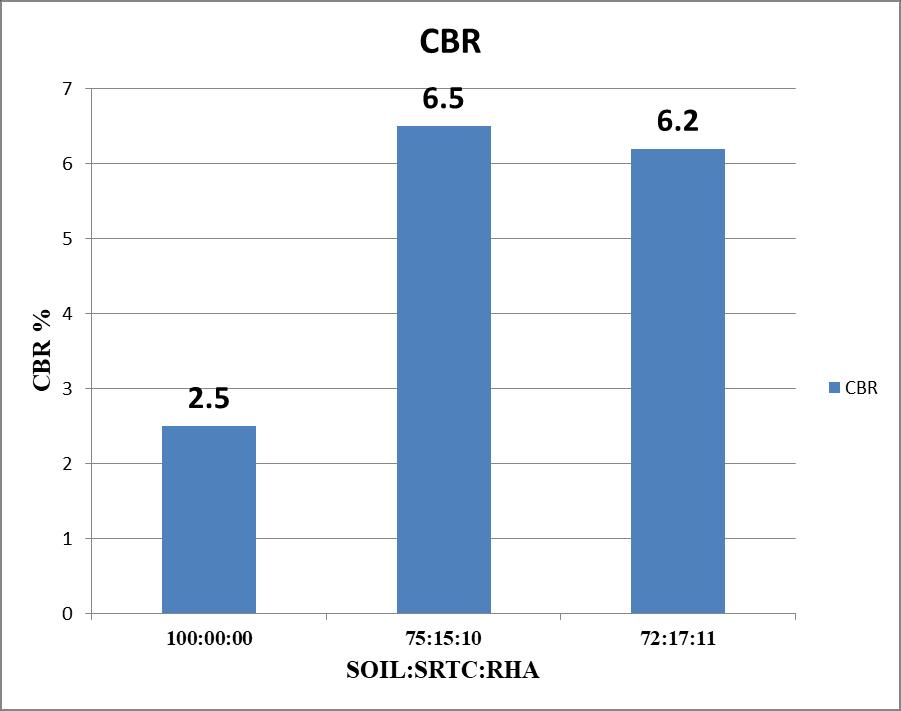

Californiabearingratio(CBR)valueofasoilorstabilizedsoil isacrucialparameterindepictingtheviabilityofthesoilfor engineeringuse.Itgivesusanideaaboutthestrengthand bearingabilityofthesoil.

ThevariationoftheCBRofsoilmixtureswithSRTCandRHA contentsaregiveninFig.4.9TheCBRgaveapeakvalueat 75:15:10(SOIL:SRTC:RHA).

It was noticed that, though, the value of the CBR showed increment with higher additive contents at higher compactive efforts, the compactive efforts do not have appreciableeffectonthevaluesoftheCBR.

Table-4:CaliforniaBearingRatioTest Results For SOIL:SRTC:RHA Mixes

3. CONCLUSIONS AND FUTURE SCOPE

3.1 conclusions

1. Theoptimummixisfoundtobe75%soil,15%SRTC and10%RHAonthebasisofconsistencylimittestand compactiontest.

2. The values of consistency limits for optimum mix (75:15:10) are found to be as follows, LL=47.5, PL=30.8,PI=16.7.

3. The MDD increases from 1.55 to 1.86 and OMC decreases from 23.53 to 16.45 with increase in percentageofricehuskashandshreddedrubbertyre chipsintothesoil.

4. The compressive strength of soil from UCS test increases from 97kpa (3days) with the addition of SRTC and RHA till it becomes maximum i.e. 480kpa (3day)foroptimummix(75:15:10)andthengoeson decreasing.Thesameincreasingpatternisobserved for7and28curingdays.

5. Theunconfinedcompressivestrengthalsoincreases withtheincreaseincuringdaysofoptimummix.

6. The increase in compressive strength is due to pozzolanic reaction taking place between lime and silicainpresenceofmoisture.

7. TheCBRvalueisalsofoundtoincreasefrom2.5with increaseinpercentagevalueof SRTCandRHA tillit attains maximum value i.e. 6.5 for optimum mix (75:15:10)&theincreaseinCBRisduetopozzolonic reaction.

3.2 Future Scope

1. Inthepresentstudyonlyupto25percentreplacement of shredded rubber tyre chips by soil has been considered.Theotherpercentagespercentneedtobe investigated.

2. Othertypesofwastemateriallikestonequarry,plastics, recycled aggregates, polythene bags etc. also need be triedtoknowtheeffectofvarioustypeofreinforcement.

3. DurabilityofRHAneedstobechecked,byconducting thetestsfordifferentcuringperiod.

4. Since the work is on expansive soil with addition of SRTC And RHA, so it shows effective results for the stabilizationofexpansivesoil.Inthefieldofstabilization ofsub grades,thereisa lot ofscopeforfurther work. Similarstabilizationcanalsobedonebyusingvarious othermaterialsavailable.

REFERENCES

1. Piyush V. Kolhe1, Rushikesh V. Langote (2017), “Performance of Black Cotton Soil Stabilized With Rubber TyreShreads”, JournalofGeotechnicalStudies Volume2Issue2.

2. Abarajithan. G, Rishab Kumar. P, Srikanth. R (2017), “FeasibilityofSoilStabilizationusingRiceHusk Ash and Coir Fibre”, International Journal of Engineering Research & Technology (IJERT), Vol. 6 Issue04,April-2017.

3. Rathan Raj R, Banupriya S &Dharani R (2016), “Stabilization of soil using Rice Husk Ash”International Journal of Computational Engineering Research (IJCER),ISSN(e):2250–3005||Volume,06||Issue,02 ||February–2016.

4. Phani Kumar Vaddi, D. Ganga, P. Swathi Priyadarsini, Ch. Naga Bharath (2015), “experimentalinvestigationoncaliforniabearingratio for mechanically stabilized expansive soil using waste rubber tyre chips”International Journal of Civil EngineeringandTechnology(IJCIET)Volume6,Issue 11, Nov 2015, pp. 97-110, Article ID: IJCIET_06_11_011.

5. UmarJan, Vinod K.Sonthwal,Ajay Kumar Duggal, Er. Jasvir S. Rattan, MohdIrfan (2015), “Soil Stabilization Using Shredded Rubber Tyre”,International Research Journal of Engineering and Technology (IRJET), Volume: 02 Issue: 09 | Dec2015, e-ISSN: 2395-0056, p-ISSN: 2395-0072.

6. AparnaRoy(2014), “SoilStabilizationusingRiceHusk Ash and Cement”International Journal of Civil Engineering Research. ISSN 2278-3652 Volume 5, Number 1 (2014), pp. 49-54 © Research India Publications,http://www.ripublication.com/ijcer.htm.

7. GhatgeSandeepHambirao ,Dr.P.G.Rakaraddi (2014), “Soil Stabilization Using Waste Shredded Rubber Tyre Chips”, IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684,pISSN: 2320-334X, Volume 11, Issue 1 Ver.V(Feb.2014), PP 20-27 www.iosrjournals.org.

8. Z. Ali Rahman, H. HasanAshari, A.R. Sahibin, L. TukimatandI.WanMohdRazi(2014),“EffectofRice Husk Ash Addition on Geotechnical Characteristics of Treated Residual Soil” American-EurasianJ.Agric.& Environ.Sci.”, 14(12):1368-1377,2014ISSN18186769 © IDOSI Publications, 2014 DOI: 10.5829/idosi.aejaes.2014.14.12.12462.

9. Mohammed Y. Fattah, Falah H. Rahil, Kawther Y.H.Al-Soudany(2013),“ImprovementofClayeySoil Characteristics Using Rice Husk Ash ”Journal of Civil EngineeringandUrbanism,Volume 3,Issue1: 12-18 (2013) ,(Received: December 25, 2012; Accepted: January28,2013;Published:February30,2013)

IS 2720 (Part V) (1985) ―Determination of Liquid&PlasticLimits

IS 2720 (Part VII) (1980) ―Determination of Moisturecontent&DryDensity