Structural Behaviour of Ultra High Performance Fibre Reinforced Concrete

Abstract - Recent advancements in building materials technology have led to the creation of novel cementitious composites, such as Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). UHPFRC is a cementbased material with exceptional mechanical characteristics. UHPFRC is attractive for reinforcing applicationsbecausetoitssuperiormechanicalproperties overconventionalconcreteanditseaseofpreparationand application. Compared to typical concrete, Ultra-HighPerformance Fiber-Reinforced Concrete (UHPFRC) is a more durable concrete material. This current study explores the behaviour of compressive strength and load bearing capacity of ultra-high performance concrete (UHPC) with the addition of steel fibres, as well as silica fume and quartz powder to the concrete mix. Steel fibres are added to concrete in varying amounts (0 to 2%) by volume. The test results showed that UHPFRC produced thegreateststrengthcomparedtotraditionalconcrete.

Key words: Ultra-High Performance Fibre Reinforced Concrete (UHPFRC), silica fume, quartz powder, steel fibres

1. INTRODUCTION

Concretetechnologyhasadvancedinanewapproach to overcome the constraints of ordinary concrete, such as High-Performance Concrete (HPC). HPC is distinguished notonlybyitssuperiorstrength,butalsobyitsenhanced durability, resistance to a variety of external agents, and fast rate of hardening. The primary drawbacks include brittleness, low tensile strength, and poor resistance to fracture initiation and propagation [Tayeh et al., 2012]. Ultra-HighPerformanceConcrete(UHPC),oneofthemost recent innovations in concrete industry, blends highstrength concrete with fibers to overcome many of the issues with conventional concretes. In order to make a super plasticized concretethatisfiber-reinforcedand has higher homogeneity, fine sand is used in place of typical coarseparticles.

High performance concrete possesses the following performance characteristics: freeze-thaw resistance, scaling resistance, abrasion resistance, chloride

penetration, compressive strength, elastic modulus, minimum shrinkage, and creep. The first four are commonlyreferredtoasdurabilitycharacteristics.Binder components such as cement, silica fume, quartz powder, andfineaggregatessuchasriversandandquartzsandare combinedwithsteelfibreandasuperplasticizertocreate UHPC. It was developed in Europe and was first used in specialty applications requiring exceptional strength and corrosion resistance, such as earthquake buildings or marine applications. Lately, UHPC has seen significant application for narrow profiles requiring high strength, such as bridge spans and building facades, where the material's strength, wear resistance, less weight, and lowerlifecyclecostshavebeendecidingconsiderations.

2. LITERATURE REVIEW

Spyridon et al. (2020) investigated the possibility that UHPFRCisdesirableforreinforcingapplicationsduetoits superior mechanical properties compared to standard concrete,aswellasitseaseofpreparationandapplication. The strategy appears to be promising, since the performanceofthereinforcedportionsincreasedinevery example evaluated. Moreover, significant interface connection between concrete and UHPFRC was discovered,withminimalslipvalues.

Wei Fan et al. (2020) performedtheexperimentaltesting on fiber-reinforced ultra-high-performance concrete. Experimental data demonstrates that ultra-highperformance fiber-reinforced concrete (UHPFRC), one of themostinnovativeconcretematerials,providesexcellent strength, durability, impact resistance, and energyabsorption capacity. To assess the performance of UHPFRC-reinforced columns subjected to vehicle collisions,high-resolutionfiniteelement(FE)modelswere developed. The impact resistances of RC and UHPFRCreinforced columns were fully investigated using the suitablesimplifiedmodel.

The research conducted by Muhammad Safdar et al. (2018) on the flexural behaviour of reinforced concrete beams retrofitted with UHPFRC compares experimental resultsto3-Dfiniteelementanalysis.Thetestsweredone

on reinforced concrete beams that had been repaired in the tension and compression zones with UHPFRC of varying thicknesses. According to the research, UHPFRC improves the resistance and durability of repaired beams by increasing their stiffness and delaying the appearance oflocalizedfractures.

Tanarslan (2019) evaluated the UHPRFC as a laminated plate in order to acquire consistent results while utilising UHPRFC and enhance the efficacy of its use on site. In addition,multiplemethodsofapplyingUHPFRClaminates were investigated to determine which method enhanced theflexuralintegrityofRCbeamsthemost.Inlightofthis, seven specimens were reinforced using 50 mm thick UHPFRC laminates, one of which served as the control specimen and the remaining six as the under-reinforced testspecimens. Theload bearingcapacity oftheUHPFRCreinforced specimens improved by at least 32% and as muchas208%.

Tanarslan et al. (2019) analyzed the impacts of reinforced concrete (RC) beams using UHPFRC laminates. First, a preliminary analysis at the material scale was undertaken to assess the effect of fibre volume on the mechanicalcharacteristicsofUHPFRCandtoestablishthe optimalfibrereinforcementratioforlaminateproduction. In the second step, actual-sized laminates were subjected to material testing to assess their fundamental properties and analyse the size effect prior to their use as a reinforcement material. The last phase entailed fortifying flexurally weak RC beams with 30 mm thick UHPFRC laminatesusingtwodistinctbondingmethods:epoxyglue andmechanicalanchoring.

Itwashighlightedby Ramachandra Murthy et al. (2019) that RC beams were statically preloaded to about 70%, 80%,and90%ofthemaximumloadofcontrolbeams,The model accounts for the severity of any existing damage, the particular fracture energy and stress-crack opening correlations of concrete and UHPFRC, and the elastoplasticbehaviourofthereinforcingsteel.

Behaviour of ultra-high performance fibre reinforced concretecolumnssubjectedtoblastloadingwasexamined by Juechun Xu et al. (2018). Four UHPFRC columns measuring 0.2 m by 0.2 m by 2.5 m were subjected to different explosions at a standoff distance of 1.5 m. To determinehowthefourhighstrengthreinforcedconcrete (HSRC) columns would react under the same stress circumstances as the UHPFRC columns, blast tests were conducted on the HSRC columns. The failure mechanisms of flexural, shear, and concrete spalling, which constitute the three primary damage modes, were identified. In terms of blast loading resistance, UHPFRC columns outperformed HSRC columns, as indicated by post-blast fracture patterns, permanent deflections, and various levelsofdamage.

Lampropoulos et al. (2018) examined the fortifying of reinforced concrete beams with extremely high performance fibre reinforced concrete (UHPFRC). This research examines the behaviour of UHPFRC-reinforced reinforced concrete (RC) beams. To obtain extraordinary performanceconsiderablybeyondthatofnormalconcrete, an intense matrix and customised fibre and aggregate phases are required. A three-sided jacket with a 50 mm thickness, a 50 mm layer on the compressive side, and a 50mmlayeronthetensilesidewereproducedasmodels

3. EXPERIMENTAL PROGRAMME

3.1 Materials utilised in this work

Inthisinvestigation,gradeOPC53cementwasemployed. As fine aggregate, M sand that passed through an IS sieve of4.75mm wasutilised. Thisresearchmadeuseof20mm crushedstoneaggregatethatwaslocallyaccessible.

BarsofFe500-gradesteelwereutilisedforreinforcement. As a binding substance, silica fume and quartz powder were employed. The addition of steel fibres improves the flexuralbehaviour.ThesuperplasticizerconplastSP430is utilised. Regular potable water is utilised according to IS 456:2000

3.2 Material properties

The different materials employed in this study and the testing on their material properties were done in accordance with IS specifications. The materials used in this study are ordinary Portland cement with a specific gravity of 3.14, M sand as a fine aggregate with a specific gravityof2.65,andcrushed granitewitha particlesize of 20 mm as a coarse aggregate with a specific gravity of 2.85. The flexural reinforcement of each beam taken into considerationconsistsoftwosteelbars,oneoneachofthe tension and compression sides, each with a diameter of 8 mm. The use of 6 mm steel bars with 120 mm spacing is made for shear reinforcement. M30 grade concrete was takenforthisresearchwork.Theproposedmixdesignhas done as per the guidelines IS: 10262-1982 Material proportion for mix design of conventional concrete ; cement to fine aggregate to coarse aggregate mass proportions were 1:1.56:2.72 and the water to cement ratio was 0.45. Table 1 displays the proportion of UHPC materials.

3.3 Casting of specimen

Cubesofsizes150x150x150mmwereusedtoinvestigate the compressive strength of concrete. The size of beam specimen was 1.5mx0.15mx0.2m. The conventional RC beam labelled as CB and the beam consists of steel fibres as designated as (SFB) ; Cast RC beam specimens are illustratedinFigure1.

3.5 Compressive strength of specimens

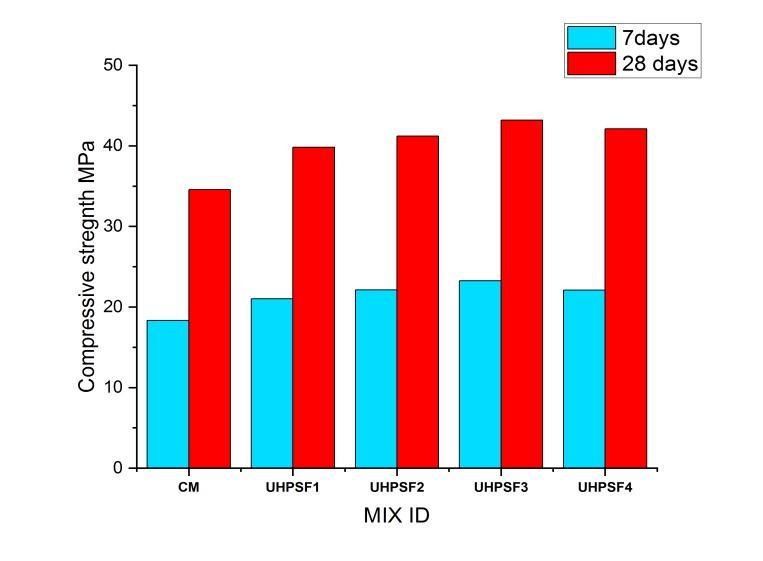

The compressive strength test was performed as per IS 516-1959 After7and28daysofcuring,cubespecimens' compressive strength was measured; the results are showninFigure2andTable2.After28daysofcuring,the control beam's compressive strength was 34.56 MPa. The specimen ID UHPSF3 produced the best results. In comparisontothecontrol mix,thestrengthwasraisedby 25%.

3.4 Testing of specimen

The comparison to be done with control beam and SFB. Thetwo-pointloadingconditionusedtotestallthebeams. A hydraulic jack was employed to provide the monotonic load, and a proving ring was utilised for accurate data collection. Load was applied to the beam progressively, witheachincreaseinforceequalto5kN.Thebeamswere stressed to their breaking points, and the loads at the on set of cracking and total collapse were recorded. Color coding the cracks helped to highlight the various failure patternsinthebeam.

3.6 Load carrying capacity of RC beam

Table 3 depicts the load carrying capability of control beams and other ultra-high performance steel fibre reinforced beams; Figure 3 depicts the ultimate load and first crack load of CB and SFB. CB's initial crack load and ultimate load were, respectively, 37 kN and 62 kN. The UHPSFB2 beam specimen achieved the greatest ultimate loadamongallotherbeamspecimens.

4. Conclusion

Onthebasisoftheexperimentalanalysis,thefollowing findingsmaybedrawn:

After 28 days of curing, the control beam's compressive strength was 34.56 MPa. The specimen ID UHPSF3 produced the greatest results. When compared to the control mix, it enhanced the strength by 25%. It was observed that the incorporation of fibrous elements improves mechanical performance, particularly flexural strength.

5. REFERENCES

1. A.Tayeh,B.A.Bakar,M.M.Johari,Y.L.Voo, (2012), Mechanical and permeability properties of the interface between normal concrete substrate and ultrahigh performance fiber concrete overlay Construction Building. Materials.,vol 36, pp.538548

2. A.P. Lampropoulos (2018) Strengthening of reinforced concrete beams using ultra high performance fibre reinforced concrete (UHPFRC)”, Engineering Structures, pp.370–384

3. A.Ramachandra Murthy (2019) Fatigue behaviour of damaged RC beams Strengthened with Ultra high performancefibreReinforcedConcrete”, International Journal of Fatigue,28

4. H.M. Tanarslan (2019) Flexural strengthening of RC beams with prefabricated ultra high performance fibre reinforced concrete laminates, Engineering Structures ,pp.337–348

5. H.M. Tanarslan and N. Alver (2019) Flexural strengthening of RC beams using UHPFRC laminates: Bonding techniques and rebar addition”, Construction and Building Materials,pp.45–55.

6. Juechun Xu (2018) Behaviour of ultra high performance fibre reinforced concrete columns subjectedtoblastloading”, Engineering Structures,pp. 97–107

7. Muhammad Safdar (2018) Flexural behavior of reinforced concrete beams repaired with ultra-high performance fiber reinforced concrete (UHPFRC), Composite Structures

8. Spyridon A. Paschalis (2020) Experimental and numerical study of the performance of ultra high performancefiberreinforcedconcretefortheflexural strengthening of full scale reinforced concrete members”, Construction and Building Materials, 2020, pp.351–366

9. Wei Fan (2020) Performance and sensitivity analysis ofUHPFRC-strengthenedbridgecolumnssubjectedto vehicle collisions, Engineering Structures, pp.251–268

10. IS: 456-2000; Plain and Reinforced Concrete-Code of Practice. Bureau of Indian Standards, New Delhi, India

11. IS516-1959:MethodofTestsforStrengthofConcrete Bureau of Indian Standards, New Delhi,India

12. IS:10262-1982,recommendedguidelinesforconcrete mix design, Bureau of Indian Standards, New Delhi,India.