Concrete Made Using Coconut Shell As A Coarse Aggregate

Motale Sanket Santosh1 , 1Lecturer Dept. of Civil Engineering Kai.Sau.Sunitatai Eknathrao Dhakane Polytechnic College, Shevgaon, DistrictAhmednagar, Maharashtra, India***

Abstract - There have been numerous experimentalstudies done to see if adding additional components to the concrete mix, whether they be synthetic, recycled, or natural resources, would improve the qualities of the concrete. The cost of building is the main determiningfactor.Mostbuildingprojects employ concrete, which is made of cement, sand, coarse aggregate, and water. In the modern era, natural resources like natural rocks and other materials are used to produce coarse aggregate. Coconut is widely used in India for a variety of uses, including industry and devotion.

When coconuts are used, their shell is left behind as a byproduct that can replace coarse material in construction projects.

Given that coconut shells are naturally strong and do not quickly decay when linked in concrete, In our experiment, coconut shell replaces 10% or 15% of the coarse concrete materials.

All cement, sand, aggregate, and concrete tests were carried out in accordance with IS regulation.

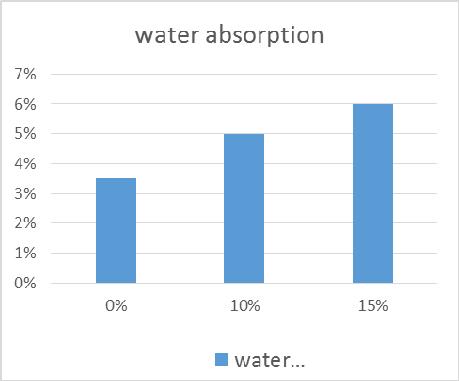

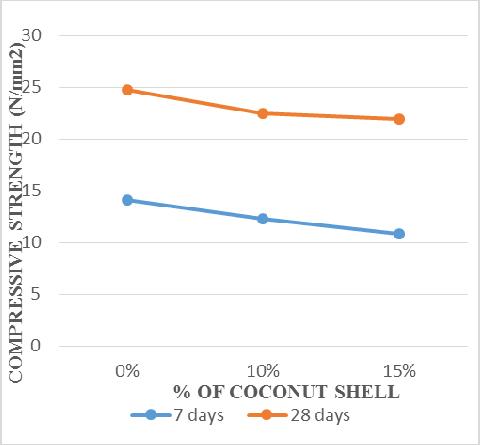

The compressive strength, water absorption, and cost of the concrete blocks made with coconut shells of grade M20 were all compared to conventional concrete of the same grade.

Key Words: Concrete, aggregate, strength, and coconut shells

1.INTRODUCTION

Now-a-days numerous engineers and scientists are in process to develop various natural as well as modernised approaches for the manufactureof construction materials especiallyconcrete.

They are also concerned about keeping its quality and strength, thus different materials are utilised in place of specific materials while creating concrete. Construction experts have long understood the advantages of adding a cementation binder to concrete during repair or constructiontoincreaseitsstrengthanddurabilityoverthe longterm.

There have been numerous experiments done to alter the qualities of soil by incorporating new elements, whether theybeorganic,recycled,orsynthetic.

In the majority of tropical nations, particularly in Asia, a largevolumeofagriculturalwastewasdumped.

Environmental and social problems will result from impropertrashdisposal.

So, by adding coconut shell to concrete, its engineering features are increased for better application in various constructionprojectsasneeded.

1.1 Necessity To Utilize Waste In Concrete:

Researchhasbeenconductedtomeetsociety'sdemandfor anefficientandcost-effectivewaytodisposeofgarbage.

• Recycling waste materials protects the environment by preservingnaturalresourcesandlandfillspace.

•Theconcretebuildingsastheyarenowcannotlast.

• Waste resources such as rubber tyres, e-waste, waste plastic, and waste water have all been the subject of experiments.

•Atthemoment,Indiaproduces960milliontonnesofsolid waste annually as a byproduct of agriculture, mining, municipalservices,andothersources.

•Onlyfromagriculturalsources,Indiahasgeneratedalmost 600milliontonnesofgarbage.

• The largest quantity of agricultural waste are sugarcane baggase, paddy and wheat straw and husk , jute fibres, groundnutshells,coconuthusketc.

•Eachyear,coconuttreesaregrownon12,280hectaresof land,yielding62.8billiontonnesofnuts.

•Acoconut'sshellmakesup15%ofitsoverallweight.

•Reportsfrom2018indicatethatIndiaproduces11.9million tonnesofcoconut.

1.78 million tonnes of coconut shells were therefore produced.

Because lignocelluloses are present in coconut shells, the processofdecompositionisextremelyslow.

So,wecanutiliseittocreateconcrete.

1.2 OBJECTIVES

1.Toresearchtheadvantagesofusingcoconutshellsin concrete.

2.Takestepstouseanalternativesubstanceasconcrete aggregate.

3.Tocomparethepricesofplainconcreteandconcrete withcoconutshellsadded,aswellastheresultsoftestson compressivestrength,waterabsorption,andslumpcone.

4. To make concrete constructions more resilient and effectiveoverthelongrun.

1.3 LITERATURE REVIEW

According to research by B.Damodhara Reddy, S.Aruna Jyothy, and Fawaz Shaik, coconut shell aggregate is a promising building material that also minimises environmentalpollution.

AccordingtoTomasU.GanironJr.,replacingthenecessary amount of coconut shell with concrete can generate a productwithadequatestrength.

Whencoconutshellwasadded,theconcrete'sstrengthwas increased,makingitstrongerthanothertypesofconcrete.

According to Vijay Kumar Shukla, Bharti Sharma, and Amarnath Gupta, coconut shell concrete can be utilised to manufacture lightweight concrete and is suitable for low strengthstructures.

2. METHODOLOGY

MaterialUsed :-

Cement - 53-grade Ordinary Portland Cement (OPC), which meets the standards of IS:12269-1987 regulations, was the cementusedintheexperiment.

It is made up of a combination of ferrites, aluminates, and calcium silicates (alite, belite), which are compounds that combinecalcium,silicon,aluminium,andironinwaysthatwill reactwithwater.

Table -1: PropertiesofCement

Also,theusageofGGBSforconcretematerialshelpstoreduce CO2emissionsandenvironmentaleffectwhilesavingenergy and natural resources during the cement manufacturing process.

Crushed Sand- A Quarry is where the crushed sand is produced.

In a plant or quarry, boulders, quarry stones, or bigger aggregatepiecesarecrushedintoparticlesthesizeofsand.

Becauseofitsstrongtextureandcubicalandangularshape, crushedsandispreferableforconcrete.

Incomparisontonaturalsand,ithaslessofanadverseeffect ontheenvironment.

Crushedsandhasaspecificgravityof2.73.

Coarse Aggregates- 10mm and 20mm crushed stone aggregateswereemployedinexperiments.

Water- Throughouttheexperiment,ordinarywaterfreeof salts,turbidity,andorganiccontentwasusedformixingand curing.

Coconut Shells- The experiment's coconut shells were exposedtothesunfor29to30daystodrythemoff.

We gathered coconut shells from the neighbourhood and temples.

MIXDESIGN

ConcreteMixDesignForM20GradeConcreteMixratiois1: 1.55:3.09

PREPARATION OF CUBE SPECIMENS:

This part described how to create and cure concrete compressiontestspecimens.

Inalabsettingwhereprecisemeasurementofthematerials' amountsandtestingconditionsisavailable,andwhenthe aggregates'maximumnominalsizeis20mm.

The approach is notably relevant to the making of preliminarycompressiontesttoevaluatethecompatibility oftheavailablematerialsortofindoptimalmixproportions.

Sampling Of Materials:-

Carefulsamplingmustbeusedtogetrepresentativesamples oftheconcretematerialstobeusedforthespecificconcrete buildingproject.

GGBS - Groundgranulatedblast-furnaceslag(GGBS)can boosttheabilitiestoavoidwaterpenetrationandchloride penetration, and it can improve the durability of concrete building.

Atinyfractionofcementtestsamplesmustbegatheredfrom eachofthesite'smanybags.

Aggregate test samples must be quartered from bigger batchesforcollection.

Preparation Of Materials -

Beforestartinganytesting,allmaterialsmustbebroughtto roomtemperature,preferablybetween27and30degrees Celsius.

Whenthecementsamplesarefirstbroughttothelab,they must be completely dry-mixed, either by hand or with a suitable machine, to guarantee the greatest blending and uniformityinthecomponents,whiletakingcaretoprevent theintroductionofextraneouselements.

Thecementmustbekeptinadryenvironment.

Foreachbatchofconcrete,aggregatesamplesmustbeofthe requiredgradeandmusthaveundergoneairdrying.

Proportioning:-

The proportioning of the components, including water in concretemixesusedtoassesshowacceptablethematerials are,mustbeidenticalineverywaytothematerialsthatwill beusedinthejob.

Thepercentage,byweightutilizedinthetestcubes,andthe unitweightsofthecomponentsmustbecomputedwhenthe proportionoftheelementsoftheconcreteistobeindicated onthesitebyvolume.

Weighing-

For each batch, the amounts of cement, each size of aggregate,andwatermustbecalculatedusingweightswith anaccuracyof0–1%ofthebatch'stotalweight.

MixingConcrete:-

Concretemustbemixedmanually,orideallyinalaboratory batchmixer,inordertopreventthelossofwaterorother ingredients.

MachineMixing:-

Whena powerloader replacesthe mixingdrum,all ofthe mixingwatermustbeaddedbeforethesolidmaterialsare placed into the skip: roughly one-half of the coarse aggregates,followedbythefineaggregates,thecement,and thentheremainingcoarseaggregatesontop.

Whenalltheelementsareinthedrum,themixingprocess mustlastatleast2minutesandcontinueuntilthefinished concreteisconsistentinappearance.

Workability:-

Immediatelyfollowingmixing,eachbatchofconcretemust undergooneoftheIScode-recommendedconsistencytests.

Theconcreteusedforconsistencytestingmaybere-mixed with the balance of the batch prior to creating the test specimens, provided that care is taken to ensure that no waterorotheringredientsarelost.

SizeOfTestSpecimen:-

Iftheaggregates'biggestnominalsizedoesnotexceed2cm, 10 cm cubes may be utilized in place of the specimen's required15*15*15cmcubicform.

The length of cylindrical test specimens must be twice as largeasthediameter.

Moulds:-

Metal moulds, ideally made of cast iron or steel, must be thickenoughtoavoiddeformation.

Whentheyarebuiltandpreparedforusage,thedimensions and internal faces must be correct to within the following tolerances. They are manufactured to make it easier to removethemouldedspecimenwithoutdamagingit.

Compaction:-

Thetestcubespecimensarecreatedasquicklyaspossible after mixing and in a manner that results in complete compaction of the concrete without segregation or undue laitance.

Three layers of concrete, each one about 5 cm thick, are pouredintothemould.

Eitherbyvibrationorbyhand,eachlayeriscompressed.

Atrowelisusedtofinishlevellingtheconcrete'ssurfacewith the top of the mould after the top layer has been compressed.

CompactingByVibration:-

Untiltherequiredconditionismet,eachlayerinthisprocess isvibratedusinganappropriatevibratingtable,anelectric orpneumatichammer,orvibrator.

Topreventsegregationfromoccurringinthemould,which results in poor strength when the cubes are crushed, precautionsmustbetaken.

Curing:-

The test sample is kept for 24 to 1 1/2 hours after the additionofwatertothedrycomponentsinanareafreefrom vibration,inmoistairwithatleast90%relativehumidity, andatatemperatureof27°to2°C.

Thespecimensare thenlabeled, pulledoutof the moulds, and kept immersed in clean, fresh water until they are retrievedforthetest.

3. CONCLUSIONS

According to the experimental findings, coconut shell concrete may be utilized in rural regions and locations wherecoconutsarereadilyavailable,aswellasinlocations wheretraditionalaggregateisexpensive.

Itisdeterminedthatusingcoconutshellsinplaceoftypical coarse aggregate in the manufacturing of concrete makes themamoreappropriatelightweightaggregate.

Moreover,itlowersbuildingcostsbyloweringthepriceof coarseaggregateandalsolowersenvironmentalpollution broughtonbycoconutshell.

Theslumpvalueofconventionalconcrete,measuredbythe slumpconetest,was110mm,whereastheslumpvaluesof coconutshellconcretefor10%and15%were80mmand60

mm, respectively. Coconut shell concrete's 28-day compressivestrengthwasdeterminedtobe22.5MPaand 21.9 MPa for 10% and 15% replacement by coconut shell aggregate,respectively,comparedtoconventionalconcrete's 28.74MPa.

We came to the conclusion that while we cannot use this concrete for large constructions, we can use it for smaller ones.

Future Aims

Coconut shells can be used in concrete as a partial replacementforcoarseaggregate.

Together with other unconventional aggregates like palm kernel shells, volcanic debris, etc., we may research the utilizationofcoconutshellaggregates.

REFERENCES

• S. A. Kakade, Dr. A. W. Dhawale (2015) “Light Weight AggregateConcreteByUsingCoconutShell”

• Sravika. V, G. Kalyan (2017) “A Study on the Partial ReplacementofCoarseandFineAggregatebyCoconutShell andQuarryDustMix”

• R. Ranjith (2017) “Study on Properties of Concrete with AgriculturalWaste”

• Manpreet Kaur and Jaspal Singh “Agricultural Waste UtilizationinCivilEngineering”

•AjimSShaikh,SagarBThorat,RahulVUnde,PrasadShirse (2015) “AdvanceConcrete-AggregatereplacedbyCoconut Shell”