A BEHAVIORAL TESTING STUDY OF ULTRA HIGH PERFORMANCE CONCRETE

Anil Kumar1, Ibran khan2, Daud Chauhan31Lecturer in Civil Engineering Department, Swami Vivekanand Subharti University, Meerut, Uttar Pradesh, India

2Lecturer in Civil Engineering Department, Swami Vivekanand Subharti University, Meerut, Uttar Pradesh, India

3Lecturer in Civil Engineering Department, Swami Vivekanand Subharti University, Meerut, Uttar Pradesh, India ***

Abstract - Concrete is the most widely used building material developed in the last century. It hasa depressing powerbutnoconflict.InIS/456-2000cementconcreteis designatedwithits150mmcubicpressurewith28daysinN /mm2.Markseparationhasbeendoneasstandardconcrete forM-10toM-20,standardconcreteforM-25toM-55,high performanceconcreteforM-60toM-80andnowanewgrade hasbeendevelopedsuchasUltraHighPerformanceConcrete. High-performance concrete, lasts much longer than conventional concrete due to the strength and impermeabilityofchloridepenetration.Theconcretemixis madeofordinarywatermaterials,Portlandcement,andgood mixing and learning, but with admixtures that improve performance.WhenconcretestrengthisgreaterthanM-80it iscalledUltrahighperformanceconcrete.Alsocalledactive powderconcrete(RPC).Itisaductiletopmadeofamixture ofPortlandcement,silicasmoke,quartzflour,finesilicasand, awater-repellentagent,water,andmetalorlivingfibers.The materialprovidescompressivestrengthandflexuralstrength upto50Mpa.

If we talk about worldwide construction industry Reinforcedconcreteiswidelyusedmaterial.TheuseofUltra high-strength concrete has increased due to its obvious advantagessuchasincreaseddurability,chemicalresistance, soluble resistance, more low shrinkage and lower penetration.

Ultra-high-strength concrete is a safe material that enhancesthequalityofconcretewhenusedasacompressor. However,high-strengthconcreteshowsmorecrackingthan conventionalstrengthconcrete,andthustheshrinkageofthe structuredecreases.

UHPCdemonstratesunprecedenteddurabilityinstandard concrete, allowing metal dissolving in other applications. The use of UHPC allows the phase size to be reduced, utilizingadvancedmaterialsthatarenotassociatedwiththe rustandcorrosionthatisoftenassociatedwithconcreteand steelconstruction.Thisresistanceisdirectlyrelatedtothe long service life that can be achieved through the use of UHPC, making it an ideal asset for many construction applications,especiallybridgebuildings

Key Words - Ultra High Performance Concrete, chemical resistance, soluble resistance, unprecedented durability, low shrinkage and lower penetration

1.INTRODUCTION

UHPC(highperformanceconcrete)isabrandnewconcrete that exhibits very high mechanical properties than conventionalconcreteandhighconcreteperformance.The main features that distinguish UHPC from reinforced concrete are improved strength strength, durability, the addition of steel wires, and resistance to corrosion and corrosion. The mechanical features of UHPC allow for smaller,smaller,lightercomponentstobebuiltwhileenergy isstoredorupgraded.TheuseofUHPCislimitedtoafew architectural applications due to the high cost of building materialsandthelackofestablishedconstructionguidelines. As the construction of high-rise buildings and high-rise buildings grows around the world, the strength and durabilityofbuildingsisenhancedbytheuseofUltra-high strengthconcrete.Withsuchatrend,thedemandsofusing 100Mpa or Ultra-high-strength concrete over what is expectedto bewidespread.TheuseofUltrahigh-strength concretehasincreasedduetoitsobviousadvantagessuchas increaseddurability,chemicalresistance,solubleresistance, morelowshrinkageandlowerpenetration.

Ultra-high-strengthconcreteisasafematerialthatenhances thequalityofconcretewhenusedasacompressor.However, high-strength concrete shows more cracking than conventional strength concrete, and thus the shrinkage of thestructuredecreases.

CONTENT

Inthefollowingsection,theresultsobtainedfromtestingof fourteenspecimensofbeamscastedforflexureandshearis included in this experimental program is presented and discussed. The results recorded for each test included measurementsofload,deflection,bottomsteelstrainsand strainsatfourpointsonthebeamsurfaceatthecenterofthe span at various load stages. The things reported after observationareloadpropagation,crackpatternandfailureat ultimateload.

Thetestingofthebeamspecimensweregroupedintothree series. Series-1 consisted of total 10-beam :8-beams with dimension of 150mm*200mm by 1600mm made of a concretegradeof2-beamofM-30,2-beamofM-60,2-beam ofM-80and2-beamswithdimensionof150mm*300mmby 2100mm1-beamismadeofM-100and1-beamismadeof M-80andseries-2consistedof4-beamswithdimensionof 150mm*200mmby2000mm2-beamismadeofM-80

Mechanical properties of concrete from which the beam is made

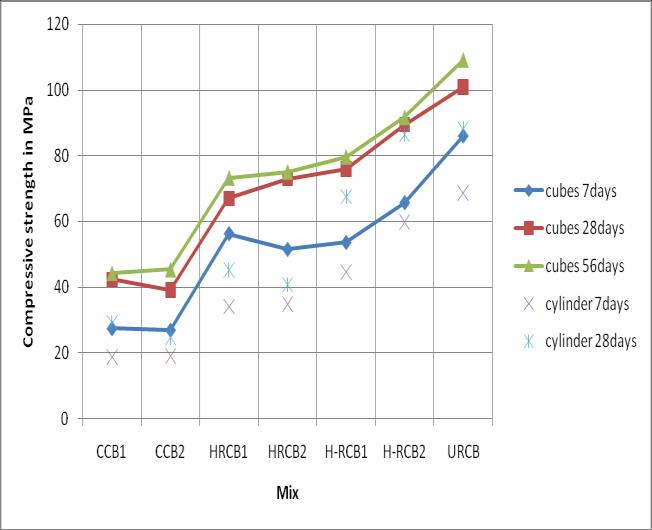

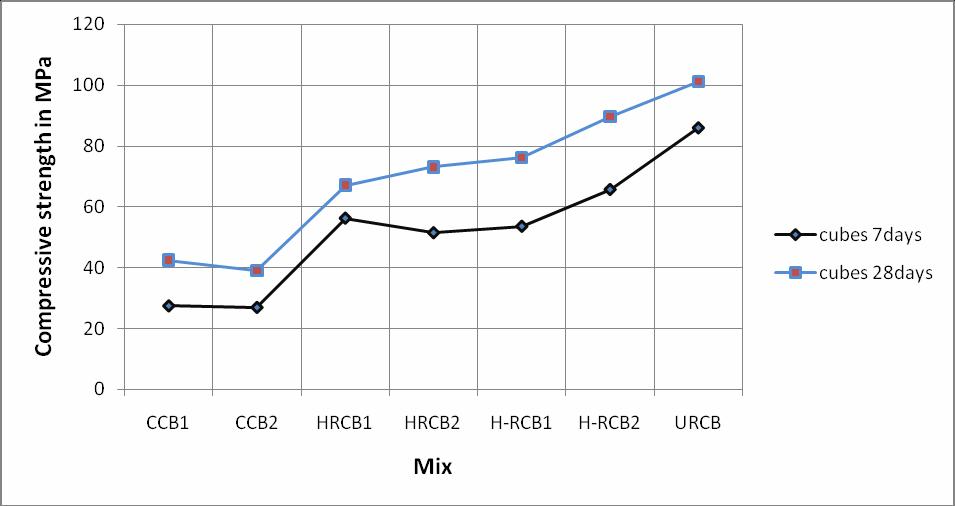

In this experiment, specimen was produced by using 100mm by 100mm mould for cube compressive strength testofultrahighstrengthconcretealongwiththeothermix isdoneandtheresultsareshowninthefollowingtable.

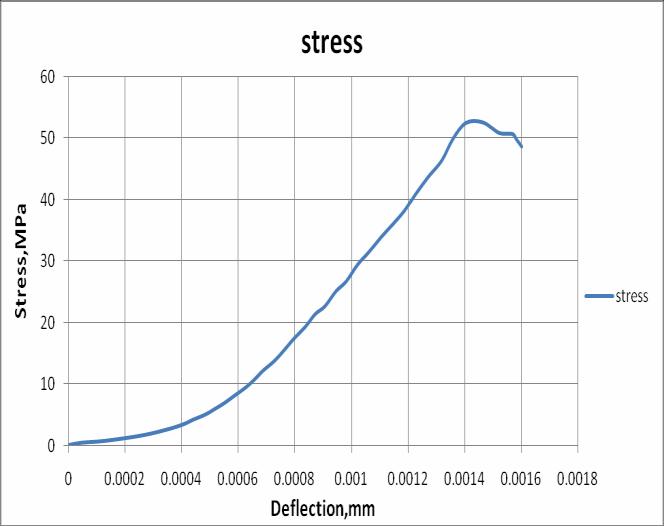

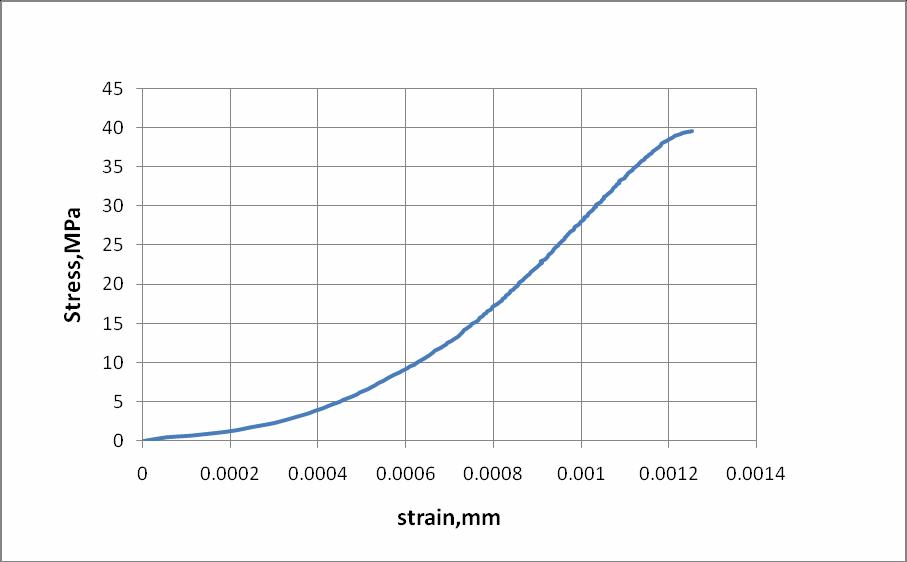

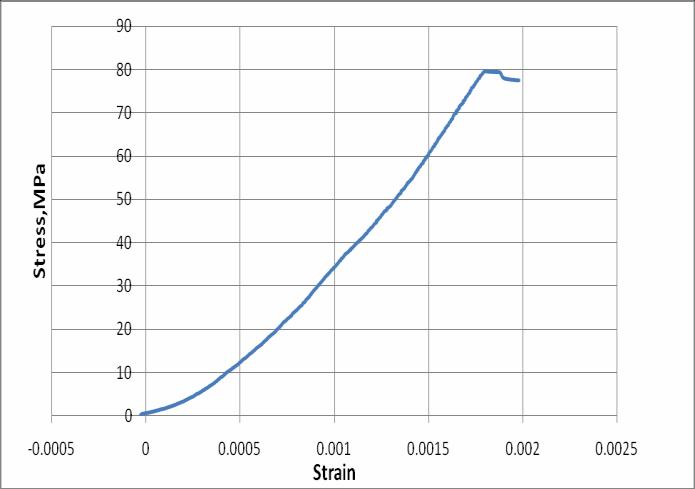

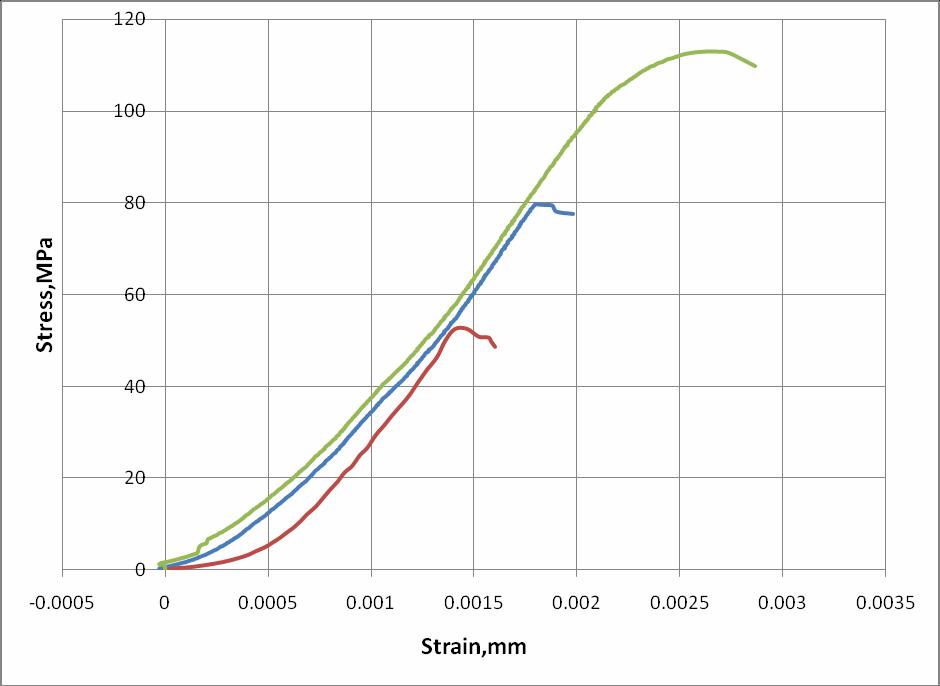

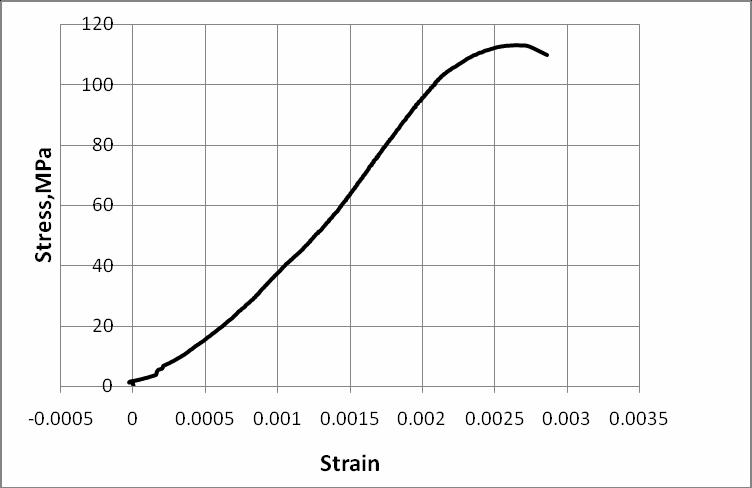

Thetablesandgraphsgivenbelowrepresentstheoutcomeof the mixes used. These values are results from test on new machineUTM-Heico,capacity300tonnes.Thecompressive stress-strainresponsesofdifferentconcretevariesbecause concrete is a heterogeneous material and the test method usedinsomespecimenaredifferenti.e.loadcontrolmode and displacement control mode. In load control mode the load capacity of IS-456-200 which is 140Kg / cm / min of cubes and 120 kg / cm / min of cylinder is accepted. The compressivefailureofUHPCwasfoundtobesimilartothe compressive failure of any fibre-reinforced concrete. In common terms, UHPC fails under compressive axial load through strong lateral expansion. Thislateral expansion is slightlyrestrictedbythetighteningoftheinnersteelplate, thus allowing more ductile failure than expected. As illustrated, fibres reinforced substantially enhance the toughness and ductility of concrete. If the materials were classical brittle,theloadingcurvewould belineartill peak loadanddropsharply,howevercementationsmaterialare not classical brittle, rather, their response is quasi-brittle, showing inconsistency with the line before reaching the maximumloadanddecreasinggraduallyafterthemaximum load. It can be also seen that with the decrease of water/cement ratio and the introduction of pozzolanic materials like fly ash and silica fumes strength tends to increase.

Plot of stress vs. strain of each mix are shown. From the graph,thestressversusstrainbehaviourofconcreteunder uniaxialcompressionisinitiallylinear,inthisstage,stressis proportional to strain and elastic strain is recovered at unloading. With the production of small fragments, the behavior becomes inconsistent and ineffective. As the sample attains the ultimate stress i.e. in the failure of the load, the pressure resists the decrease with increasing weight. For High strength and UHPC under uniaxial

compression, the ascending and descending branches are steepslopes.Theslopeoflinearportionofthecurveisthe modulusofelasticity.ThemodulusofelasticityofUHPCis significantlyhigherthannormalconcreteandhighstrength concrete.

CONCLUSION

1.UHPC is new technology of concrete that constitutes a breakthrough inconcrete mixdesign ischaracterized by a veryhighdensemicrostructureandveryhighcompressive strengthachieving.

2.ThestrongstrengthofUHPC,beforeandafterhardening cracks, is much higher than the strength from ordinary concrete

3.UHPC displays significantly improves visual assets comparedtoconventionalHPC.

REFERENCES

[1] Daud Chauhan1 , Mayankeshwar Singh2, Abhishek Tiwari3 “ACOMPREHENSIVEREVIEWONBEHAVIOUR OFCONCRETEONPARTIALREPLACEMENTOFCOARSE AGGREGATE WITH E-WASTE” International Research JournalofEngineeringandTechnology(IRJET)Volume: 09Issue:07|July2022

[2] Daud Chauhan et al/ IMPACT ON MECHANICAL BEHAVIOUR OF SILICAFUMEMORTAR ALONG WITH BACILLUSSPHAERICUSBACTRIA

[3] Paper no 4.ASTM C1437, “Standard Test Method for FlowofHydraulicCementMortar,”AmericanSocietyfor Testing and Materials Standard Practice C1437, Philadelphia,PA,2001.Pp.41–93

[4] Daud Chauhan et al/ STUDY OF BEHAVIOUR OF CONCRETE USING FOUNDRY SAND PARTIAL REPLACEMENTWITHFINEAGGREGATE

[5] www.cement.org/tech/cct_con_design_uhpc.asp

[6] www.ehow.com/how_4674791_make_ultra_highperfor mance.concrete.html

[7] www.hpcbridgeviews.com/:57/Article1.asp

[8] www.tfhrc.gov/structure/pubs/06103/06t103.pdf

BIOGRAPHIES (Optional not mandatory )

Er.AnilKumar

Lecturer in Civil Engineering Department, Swami Vivekanand SubhartiUniversity,Meerut,Uttar Pradesh,India

Er.IbranKhan

Lecturer in Civil Engineering Department, Swami Vivekanand SubhartiUniversity,Meerut,Uttar Pradesh,India

Er.DaudChauhan

Lecturer in Civil Engineering Department, Swami Vivekanand SubhartiUniversity,Meerut,Uttar Pradesh,India