COMPARATIVE STUDY OF ACTUAL AND CRASHED SCHEDULE OF BUILDING USING MSP

Sanjay Jagadeshwara E1, Dr. Nagaraj P S21Mtech Student (Construction Technology), University Visvesvaraya College of Engineering, Bangalore University, Bengaluru

2Professor, Civil Engineering Dept. University Visvesvaraya College of Engineering, Bangalore University, Bengaluru ***

Abstract - Project management is main stream which overall makes a civil industry worth into existence in accordance with the control on constraints such as time and cost. This paper will mainly help out to differentiate actual and crashed schedule and their behavioral improvements in time according to the relative cost. Microsoft project software is used to enhance the scheduling adding Crashing, Slack time and alternative building material to the work planning activity. Crashing makes a proper inventory behavioral time benefits from the overtime of huge workforce and improvement in the duration of an activity using slack time in software. An alteration with the cost is maintained which helpful in retrogression of overall costs of the project.

The main aim is to reduce the improved development period from new time and to meet a specific deadline. The main motivation behind this project is to reduce time using crashing and slack (Time Optimization).For cost optimization alternative building material is used to reduce the cost and making project more well-organized and inexpensive.

Key Words: scheduling and crashing, crashing trials, alternative material and techniques, crash ability, cost slope.

1. INTRODUCTION

• Everyonewantstobemoreconservativewhenitcomesintotimeconstraint.

• Shorterdurationworkshouldbedonegivingmoreprofitableresults.

• Manyprojectshavesomeriskanduncertaintieswhichwenotconsideritorallybutitcomesintoaccountwhenwe executeitpracticallywhichmakesincreaseintime,costandoverallocationofresources.

• ToOvercome,PlanningandSchedulingaredoneandtohavecrashedscheduleFollowingMethodsareused

CrashingOfanActivity.

CrashingUsingMicrosoftProject.

SlackTime.

Iftimeisofsecondaryconcern,eachactivitycouldbeperformedatitslowestpossiblenormalcost.Ifcostisofsecondary importance,eachactivitycouldbespeededuptobecompletedintheleastcrashtime.Betweenthesetwolimitsliesthebestor optimalsolution.However,tofindsuchsolution,itrequirestheconsiderationofcomplexcollectionofconcurrent,interrelated, andoverlappingactivities.

Inordertocountertheunforeseendelays,Projectmanagementistheapplicationofknowledge,skill,toolsandtechniquesto project activities to meet the project requirements. The primary focus of this research is to compare actual and crashed schedulebyenhancingtheschedulethroughCrashing,SlacktimeandalternativeTechniquestotheworkplanningactivity usingMSP.

2. METHODOLOGY

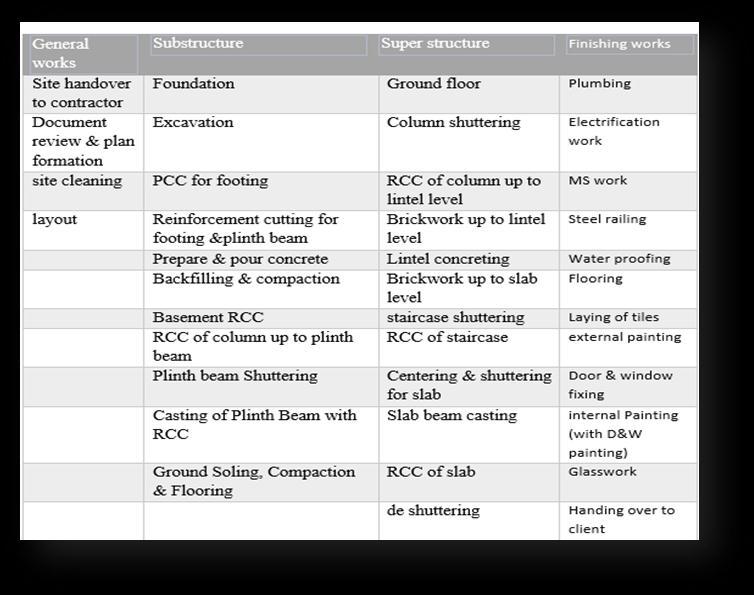

1. DataCollection.

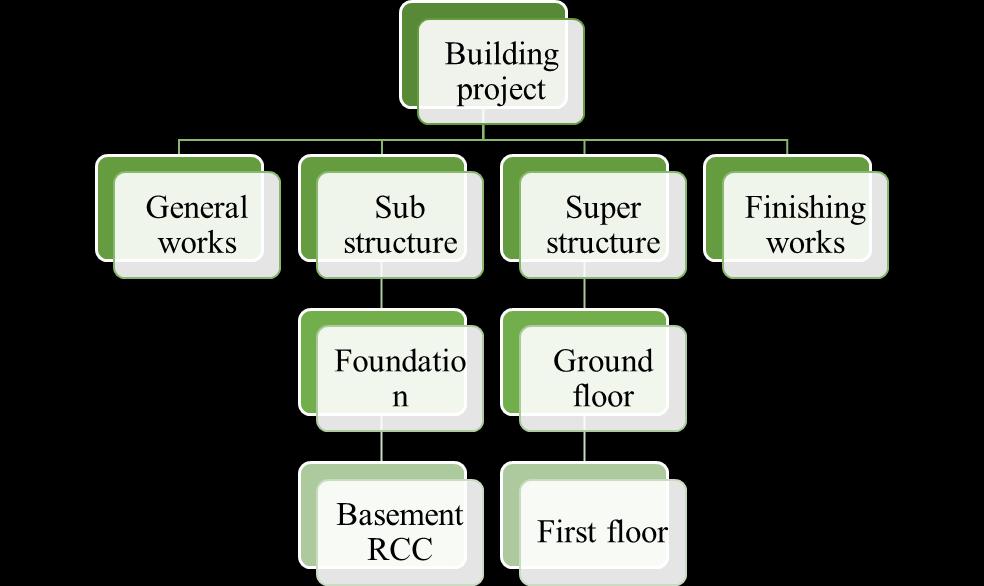

2. Workbreakdownstructure.

3. Maximumdurationisapplied.

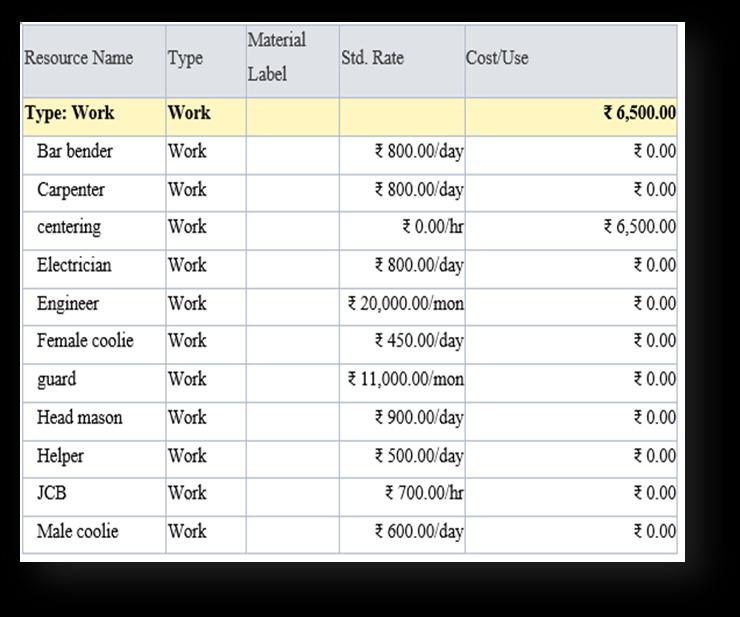

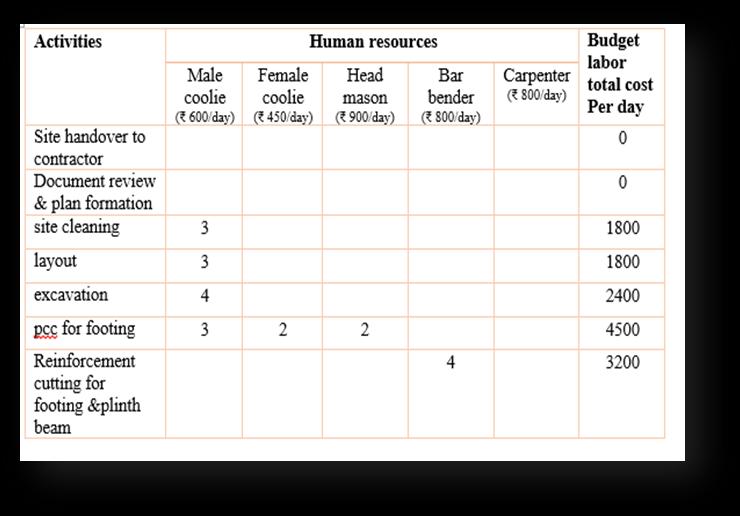

4. AddingResources.

5. AssigningResources.

Crashingusingovertime.

Slacktimeforoptimization.

Time&CostoptimizationusingAlternativeBuildingMaterialandTechniques.

6. ResultshowingTimeandCostOptimization.

7. Comparingactualandcrashedscheduleoftheproject.

3. PROJECT CASE STUDY

• Theresidentialprojectoftwofloors(G+1)signedbythecompanyfor8monthsiscompleted.Clientwantedhisproject tobecompletedinshorttime,accordinglyconstructionwasdonebythecompany.

• Inmyopinionthetimescheduleoftheprojecttoreachclientsatisfactioncanbereducedfurthermoreandcanobtain thebiggestprofitfromthisproject.SoIreplannedtheprojectandtriedtomakeadifferencetoshowhowtogetthe maximumprofitbycrashing.

• TheprojectlocatedinHulimangala,Bangaloresouth,andit’sabout1200sqft.

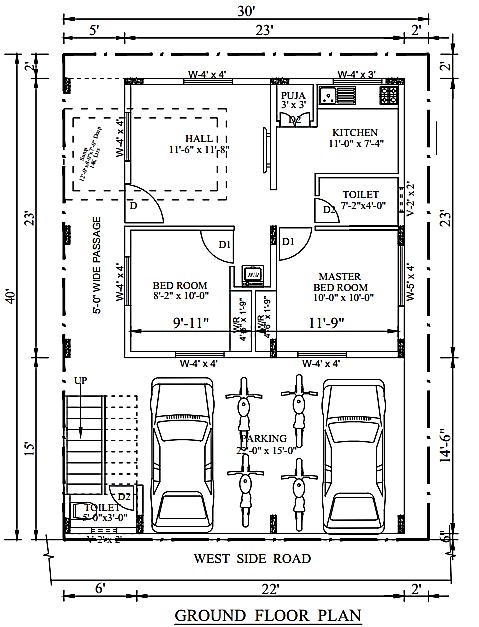

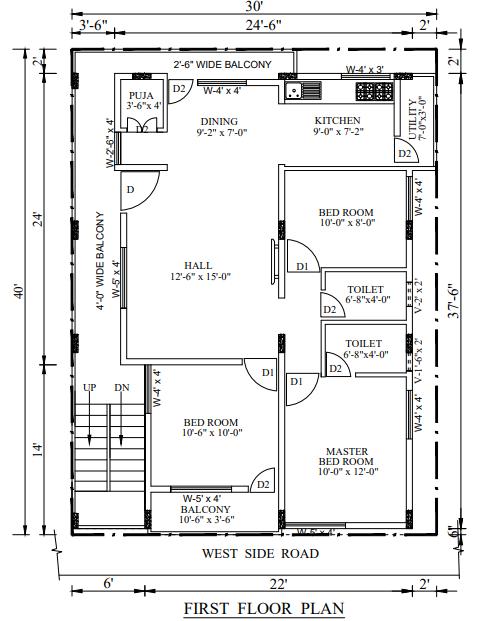

• Structure Builtuparea

Groundfloor 772.00sqft

Parkingarea 330.00sqft

Firstfloor 1102.00sqft

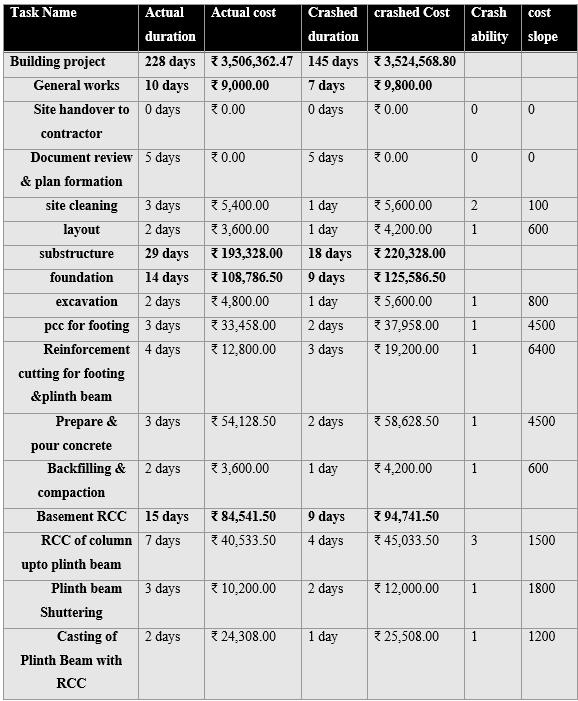

Theratebeforecrashing₹3,506,362/-,innumbers(Thirtyfivelakhsixtythreethousandsixtytworupeesonly).

4. PROJECT PLANNING

• ProjectPlanningisageneralandmostcommonterminconstructionmanagementwhichreferstoattaintheexpected goalsanddestinations.Planningisthekeytobringtheexpectedprojectsintorealityorinexistence

5. SCHEDULING AND CRASHING OF PROJECT

Thescheduleisatooloratechnicofeveryprojectmanagementteamwhichisusedandpracticedtopredictmost probableprojectcompletiontimeandthusenablingthein/ontimeresourcesconceptionwhicharebudgetedonthe particularwork.

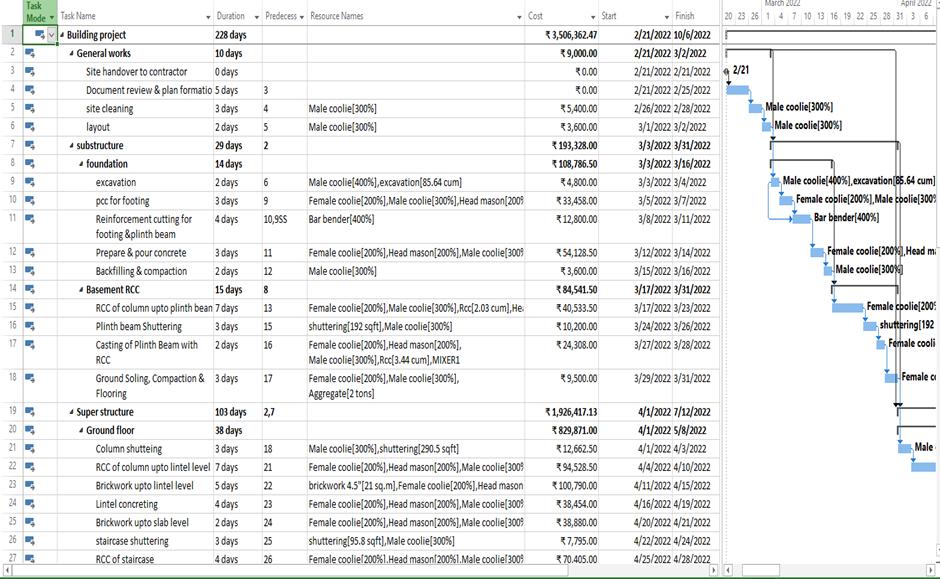

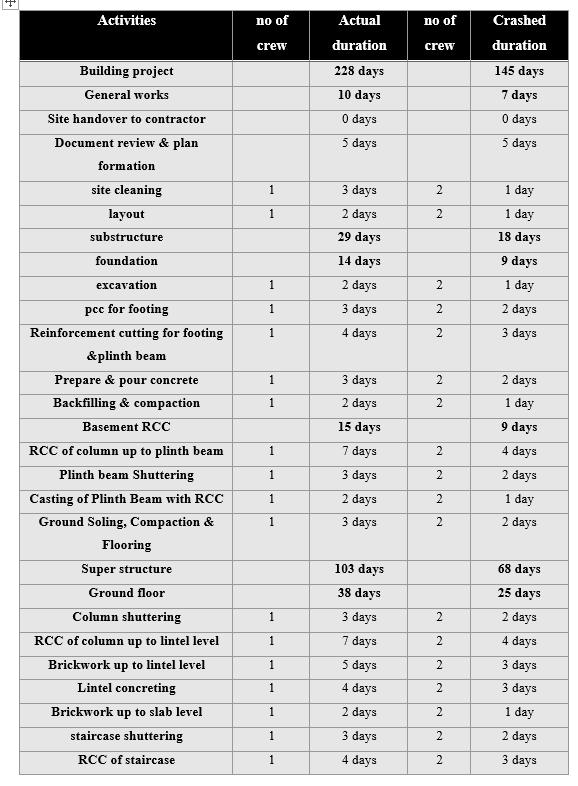

Thenormaldurationoftheproject is228days

5.1 DURATION CRASHING

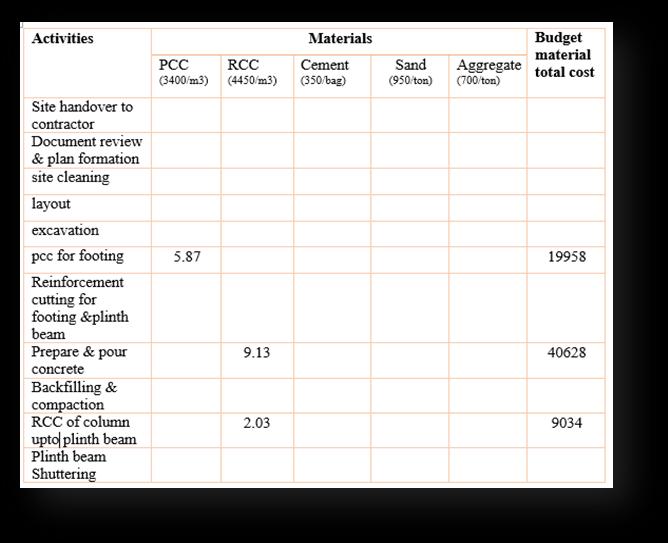

Tofinishthisactivity,thecrewshouldbeformedfrom7Labors,PCC&mixer.So,weassumedtohave1crewwith budgettotalcost/day=4500rupees Wefoundthatthiscrewwith100%productivitywillfinishtherequiredamount ofworkin3days.

Totallaborcost=4500x3=13500rupees

Materialcost(PCC&mixer)=19958rupees

Thereforetotalamountrequiredforthisactivityis 33458 rupees.

Crashing; nowweassumedwehave2crewsbutwefoundthatiftheonecrewgiveproductivityof100%,thetwo crews won’t get a completion rate by 200% due to crowdedness and the lack of supervisors and other considerations.Soweassumedthatifwehave2crewtheproductivitywillincreaseby160%to170% Sothisactivitywillbefinishedin2dayswithatotalcostof 37958 rupees

ThemainapproachesforcrashingofanactivityinMicrosoftprojectis:

1.Apportioningadditionalresourcestotheprojectwhichmakeseasywayforcrashingofanactivity.

2.Overtimeallocatedtotheresourcesmainlyhumanresource.

3.Hiringadditionalresources.

4.ForEarlycompletionextrapayments.

5.2 ALTERNATIVE BUILDING MATERIAL AND TECHNIQUE

• Alternatematerialandtechniquenotonlycrashthetimebutalsocutsdowntheoverallcost

Rat trap bond

Rattrapbondisacavitywallconstructionandleadstoreductioninthequantityofbricksrequiredformasonrywork

ByadoptingthismethodofbondingofbrickmasonrycomparedtotraditionalEnglish/Flemishbondmasonry,itis possibletoreduceinthematerialcostofbricksby25%and10%to15%inthemasonrycost.

Thecavityinredtrapbondprovideseffectivethermalandsoundinsulation.

Plank & Joist Roofing System

PrecastRCCPlankandJoistisasystemwhichconsistsoftwotypesofprecaststructuralelementsPlank(whichislike asmallcomponentofabiggerroofslab)andJoist.Afterplacingprecastelements,in-situconcreteisplacedtogiveflat surface

Thetechnologycanproveeconomicalifthenumberofplanksandjoistsaremore- suchasinthecaseofa2or3 storiedbuildings.

Cost - Overall cost reduction by 15-20% because of reduction in steel consumption and because of faster roof constructiononcethewallsarecomplete.Itdoesn’trequireanymaterialforshutteringduringconstruction

Time- Saves construction time – the slab can be ready in 2-3 days as compared to at least 14-21 days for a conventionalRCCslab

Quality-Centralizedproductionprovidesabetter,durableandconsistentqualityroofascomparedtothequalityof conventionalRCCroofsinmountainregions

Polycarbonate glass

Polycarbonateisamaterialwhichcontainsagroupofcarbonatesintheirchemicallybuildstructure.Polycarbonateis mainlyassimilartoaconventionaltransparentglassbutinflexibleasplastic.Polycarbonateglassiseasilyinstalled, cutandeasilyavailableinribbedsinglesheetorflattwin-wallthicknesses.

Useofpolycarbonatesheetismuchlesserthanthecostoftoughenedglass.Polycarbonatesheetislightweight,good fireresistant,provideUVprotectionandhashighimpactresistance.

5.2 PROJECT CRASHING METHOD

TheProjectCrashingmethodwasusedtofindtheoptimumdurationandminimumcostoftheproject.Theprocedure forshorteningprojectdurationcanbesummarizedinthefollowingsteps:

Drawtheprojectnetworkdiagram.

CPMcalculationsandidentifythecriticalpath,usenormaldurationsandcostsforallactivities.

Computethecostslopeforeachactivityfromthefollowingequation: cost slope = crash cost – normal cost / normal duration – crash duration

Startbyshorteningtheactivitydurationonthecriticalpathwhichhastheleastcostslopeandnotbeenshortenedto itscrashduration.

Reducethedurationofthecriticalactivitieswithleastcostslopeuntilitscrashdurationisreachedoruntilthecritical pathchanges..

The cost increase due to activity shortening is calculated as the cost slope multiplied by the time of time units shortened.

Continueuntilnofurthershorteningispossible,andthenthecrashpointisreached.

Thisistheprojectdirect-cost/timerelationship.Byaddingtheprojectindirectcosttothiscurvetoobtaintheproject time/costcurve.Thiscurvegivestheoptimumdurationandminimumcost.

Crash ability & cost slope

5.3.1 DIRECT AND INDIRECT COST

Directcost:Normalcostwhichwillbeassignedontoaselectedworkpackageorprojectactivity

Directcost=3506362rupees

Indirectcost:Cost thatcan’tberelatedtoanyparticularworkpackageorprojectactivity

Engineer=20000/month

Supervisor=18000/month

Guard=11000/month

SoifweestimatethetotalsupervisorysalariesinMonthwillbe=49000rupees.

Indirectcostperday=1633.33rupees

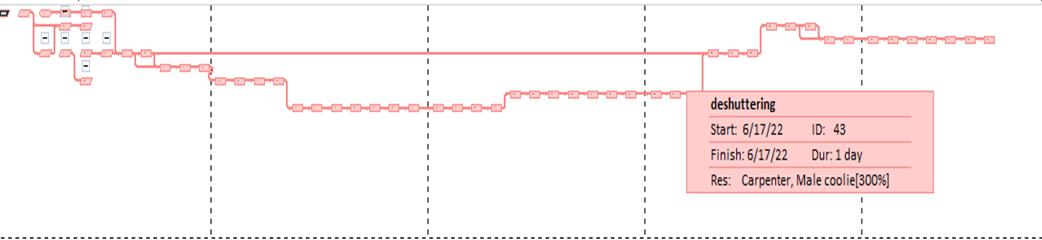

5.3.2 CRASHING TRIALS

Indirectcostoftheproject=228*1633.33=372400rupees

6. RESULT AND DISCUSSION

Result for Time Optimization

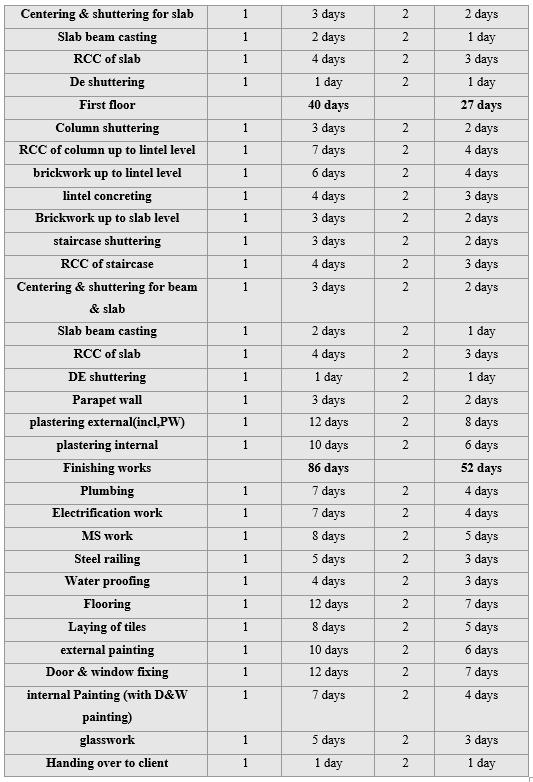

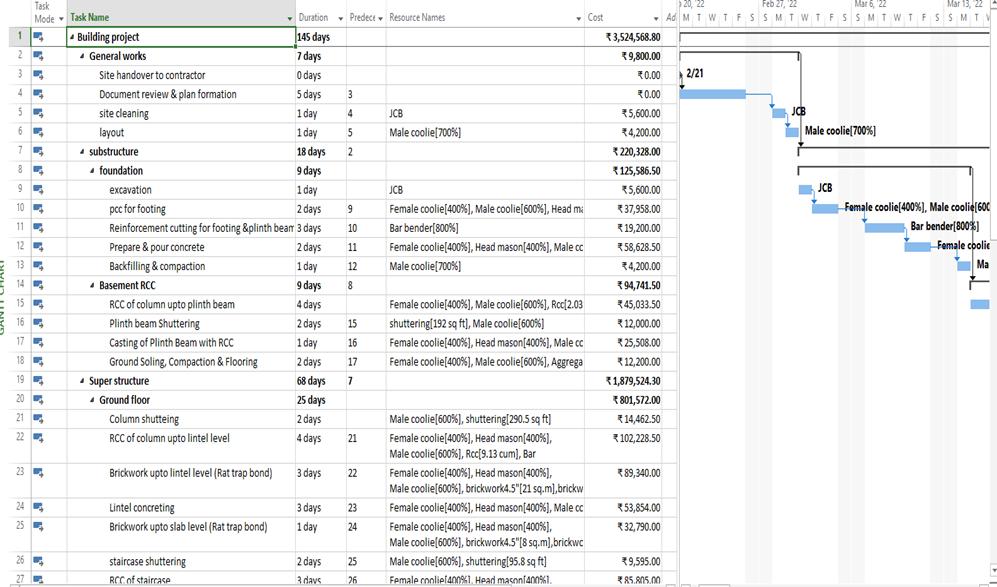

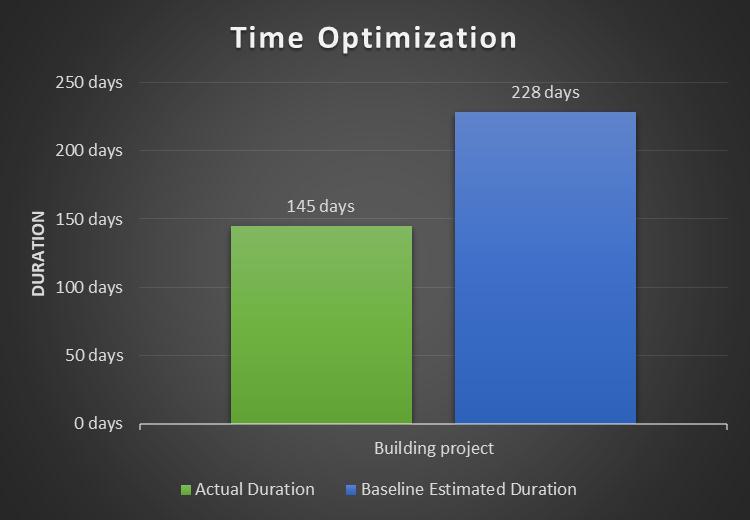

Thedurationwhichisconventionallyobservedis228dayswhichisbeingdecreasedbycrashingandwiththehelpof slacktime.Theapproximatelyreduceddurationis145days.

Majorlyforoptimizingtimethemethodologyextrahumanresourcesareusedandworkeasilywithoutanyhectic situations.

The time optimization is also depending on how well a contractor organizes his work schedule with a proper utilizationofmaterial,machineriesandhumanresource

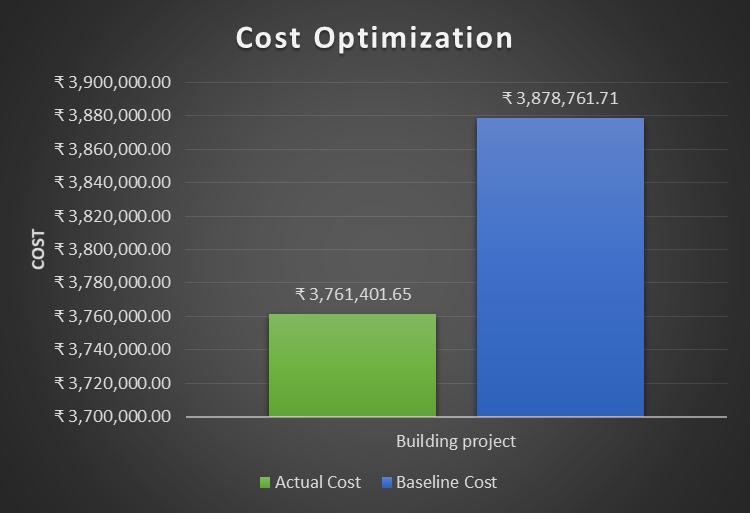

Result For Cost Optimization

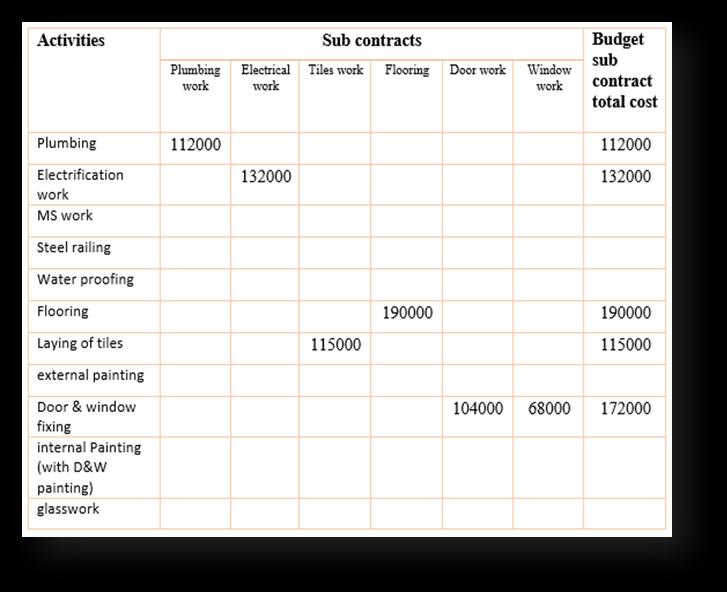

Projectcostoptimizationisdonebyusingthealternativebuildingorientedmaterialswhichreadilycutdownthecost oftheprojectbutalsosatisfiesownerwithaneconomicalresult.

Soforalternativebuildingmaterialaninsulatedstructuraltoughenedglassisreplacedbypolycarbonateglass,regular brickmasonryisreplacedbyRattrapbondtechniqueandregularRCCofslabisreplacedbyPlankandjoistroofing system,whichcutsthecostoftheproject.

Thecostofpolycarbonatesheetis₹650/sqmwhichisconsiderablyverymuchlesscomparedtotoughenedglass whichis₹2400/sqmandbyrattrapbondandplankjoistroofingsystemcostreducedupto30%foreachreplaced activity.

Thecostoftheprojectis ₹3878761,byapplyingcrashingand byapplyingthealternativematerialcosttheoverall costofthebuildingisreducedby₹3761401

7. CONCLUSION

Fromtheresultswecanmaketwocomparativeconclusions:

1)Comparisonofactualtimeandcrashedtimeoftheproject.

2)Comparisonofactualcostandcrashedcostoftheproject.

Fromprojectcrashingwecanconcludethat

1) Projectcrashingcostandindirectcosthaveinverserelationship.

2) Indirectcostincreasesasprojectdurationincreases.

3)Crashing cost are highest when the project is shortened, to overcome this we have used alternate materials and techniques.

ThisprojectconcludesthatanyrelativeconstructionprojectmainlydependsontheTimeandCostconstraintswhich givesapropereconomicalweightagetoanyproject.

A proper planning and scheduling will also make a huge differenceinconstruction projectconsidering the labor management

Propermanagement,interpersonalmanagement,technicalmanagement,andtheuseoftechnologyinbuildingprojects mayallhelptoreducedelays.

Clientwantedhisprojecttobecompletedfaster,companycanstillreducethetimetoreachclientsatisfactionandhe didn’t obtain the biggest profit from this project. So, after completion of the project, crashing is done to make a differenceandshowhowtogetthemaximumprofitfromit.

Additionofhumanresourcesandalternativebuildingmaterialsliketoughenedglassisreplacedbypolycarbonate glass,regularbrickmasonryisreplacedbyRattrapbondtechniqueandregularRCCofslabisreplacedbyPlankand joistroofingsystem,whichcutsthetimeaswellascostoftheproject.

Asaresult,thetotaldurationofprojectwas228daysanditwasreducedto145daysusingcrashingandalsocostof ₹117360wasdecreasedfromtheactualcost.

REFERENCES

1. KomeshSahuandMeenaSahu(2014),Costandtimeandalsominimumprojectdurationusingalternativemethod, Internationalreviewofappliedengineeringresearch,vol-4,no5,pp,403-412

2. Bhushan V.Tatar and Prof.Rahul S.patil (2016),Time and cost optimization techniques in construction project management,

3. Shifat Ahmed et.al (2016), Minimize time and cost for Successful completion of a Large scale project . Planning, schedulinganddelayanalysiscasestudyRathodRajshekharGopal (2016)

4. AkashLankeandD.Venkateswarlu(2016),DesignCost&TimeAnalysisofPrecast&RCCBuilding.ComparativeStudy OfTime-costOptimizationDileepkumarreddyandVenkatavaraPrasad(2018)

5. FloatTimeReductionPotentialInConstructionProjectAndItsImpactShubhendraKumarMishraandSarthakSingh Rajput.(2020)

6. ToStudyAdvancedProjectPlanningAndScheduling-caseStudyMr.GunjalKartikeyanandMr.RohitGholap(2021)

BIOGRAPHIES

Sanjay jagadeshwara E

ReceivedB.E(civilengineering)

From Acharya institute of technology&pursuingM-tech (constructiontechnology)in Universityvisvesvarayacollegeof engineering,Bangaloreuniversity

Dr. Nagaraj P S

Professor,CivilEngineeringDept. UniversityVisvesvarayaCollege ofEngineering,Bangalore University