Effect of steel fiber and poly propylene fiber on the strength properties of fly ash based Geopolymer concrete

Gururaj M H 1 , Naresh Kumar B G 21 Assistant Professor, Department of Civil Engineering, Maharaja Institute of Technology Mysore, Mandya, Karnataka, India.

2 Professor, Department of Civil Engineering, Maharaja Institute of Technology Mysore, Mandya, Karnataka, India.

Abstract – In order to improve the tensile strength and durability properties of Geopolymer concrete addition of fibre particles play a vital role in the field of modern concrete technology. In this research, combined effects of steel fibre and polypropylene fibre were studied with different aspect ratios. The crimped steel fiber with aspect ratio 60 and polymeric synthetic fibers of aspect ratio 240 were used. Alkaline liquids (Sodium Hydroxide and Sodium, Silicate solution) together mixed with proper ratio (Ratio of Na2SiO3 to NaOH is 2.50). Sodium hydroxide solution was made by dissolving NaOH solid in water. Sodium hydroxide solutions were prepared for 12 molar mass of solid depends on the concentration of solution. For 12 molar solution 480gm of NaOH pellet were mixed in 1000 ml of water.

Key Words: Steel fiber,polypropylene fiber,geopolymer concrete,flyash,alkalineliquid.

1. INTRODUCTION

Concreteisthesecondhighestconsumablematerialinthe world nextto water.Asconstruction increasesdemand of concreteincreasessothedemandofPortlandcementalso increases. Around65%ofglobalwarmingiscontributedby carbon dioxide among all greenhouse gasses due to the productionofcement.Thecementindustriesisalsooneof theresponsiblefortheemissionofcarbondioxidethatisone toneofcarbondioxideisemittedinproductionofonetone Portland cement to the atmosphere The utilization of the other cementing materials such as fly ash, silica fume, granulatedblastfurnaceslag,ricehusketc.aredevelopedas the alternative binders to the Portland cement. In the meantime the Geopolymer technology was introduced. These new binders which are alternative materials to blendedcementandconcreteareobtainedbythealkaline activation or geopolymerization of different industrial products. To improve the mechanical performance of Geopolymerconcretetheefficientmethodistoaddthefibers inconcrete.Addingofthesefiberswillarrestthecrack,also it is well known for the increase in facture toughness providedbyfiberbridgingonthemaincrackplanepriorto crackextension.Thesteelfiberandpolypropylenefibersare usedinthisexperimentandstudythemechanicalproperties andbehaviorofGeopolymerconcrete.

Thisdocumentistemplate.Weaskthatauthorsfollowsome simpleguidelines.Inessence,weaskyoutomakeyourpaper lookexactlylikethisdocument.Theeasiestwaytodothisis simplytodownloadthetemplate,andreplace(copy-paste) thecontentwithyourownmaterial.Numberthereference itemsconsecutivelyinsquarebrackets(e.g.[1]). However the authors name can be used along with the reference number in the running text. The order of reference in the runningtextshouldmatchwiththelistofreferencesatthe endofthepaper.

1.1 Scope of the work

The experimental work was conducted to obtain the strengthofflyashbasedGPCattemperatureof60ºC.

In this experimental work only one source of dry low calciumflyash(classF)fromtheRaichurThermalPower Station(RTPS)wasused.

Sodium silicate solution and Sodium hydroxide pellets wereprocuredcommerciallyfromlocalvender.

Fiberadmixturelikesteelfiberandpolypropylenefiber areintroducedintheconcrete.

To prepare the concrete that exhibits environmental friendlyandminimizetheglobalwarming.

Manufacture and test of compressive strength, split tensile strength and flexural strength of geopolymer concretebeamswithfiberreinforcedandwithoutfiber reinforcedbychangingthevolumefractionofthefiber.

2. MATERIALS & METHODS

2.1 Fly ash

Flyashusedinthisstudywaslowcalcium(classF)dryfly ash from Raichur Termal Power Station, Shakthinagar, Karntaka.Flyashisthealuminosilicatesourcematerialused forthesynthesisofgeopolymericbinder.

Specificgravity:2.36

2.2

Locally available aggregates were used comprising of 20mm,12mmand6mmandfineaggregatepassingthrough 4.75 mm all aggregates were in saturated surface dry condition.Thecourseaggregateswerecrushedgranitetype andthefineaggregateusedinthisstudywasmanufactured sand.

2.3 Alkali Activator

InthealkalineactivatorsubstancesofSilicaaredissolvedin strong alkaline conditions with high PH. During the dissolutionofthesilicaandaluminumthealkalinesolutionis active and plays a main role in the condensation process (Lindgård et al. 2012). Sodium hydroxide, potassium hydroxide, sodium silicate and potassium silicate are the commonactivatorsusedforgeopolymer.Alkalineliquidwas framed by mixing sodium hydroxide (NaOH) solution and sodium silicate (Na2SiO3) solution. Sodium hydroxide solutionwasmadebydissolvingNaOHsolidinwater.Sodium hydroxidesolutionswerepreparedfor12molarmassofsolid depends on the concentration of solution. For 12 molar solution 480gm of NaOH pellet were mixed in 1000 ml of water. Where1M=40gmofsolidin1000mlwater,during theprocessofmixinglotofheatgetliberatedwhendissolving NaOHpelletinwater.Thereforesolutioniskeptforcoolfor 24hour;thisdurationisrequiredforpolymerizationprocess ofalkalineliquids

2.3.1 Sodium Hydroxide (NaOH)

Caustic soda is the other name to Sodium hydroxide, whichismanufacturedbytheelectrolysisofsodiumchloride brine in a membrane or diaphragm electrolytic cell (OccidentalChemicalCorporation2000).Paperindustryand manufacturersthatneedanalkalinebasedmaterialarethe largestusersandbuyersofcausticsoda.Sodiumhydroxide (NaOH) is accessible in four varieties: beads, flakes, compoundersandsolidcastings.Alltheformshavethesame chemicalcomposition.

2.3.2 Sodium Silicate Solution (Na2SiO3)

Alkali silicates Solutions are also termed as “water glass”.Na2SiO3Solutioncanbeproducedintwowaysoneby dissolvingalkalisilicatepelletsinhotwaterorsecondwayis hydrothermally dissolving a reactive silica source, mainly silicasand,intotherespectivealkalihydroxidesolution(PQ Europe2004).

2.4 Super plasticizer

To improve the workability of fresh concrete super plasticizerareaddedwhicharehighrangewaterreducing naphthalenebasedsuperplasticizerConplastSP430.

ConplastSP-430isbasedonsulphonatednaphthalene polymer.

Itisbrownincolorandinstantlydispersesinwater.

ConplastSP-430hasaminimum12monthofdurability whenstoredinnormaltemperature.

2.6 Poly propylene fiber

Thefibersarepolymericsyntheticfibersusedtoincreasethe tensilestrengthandtoarrestthecrack.

Effectivediameter:0.05mm

Length:12mm

Specificgravitymorethan: 1.0

Meltingpoint:160oC

Aspectratio:240

Densityofpolypropylenefiber:900to920Kg/m3

Steelfiberswereusedtoincreasethetensilestrengthofthe Geopolymer concrete. It also act has a crack arresting materialinconcrete.Thecrimpedsteelfiberwithaspectratio 60isused.

Effectivediameter:0.5mm

Length:30mm

Specificgravitymorethan: 7.86

Meltingpoint:11210C

Aspectratio:60

Densityofsteelfiber:7850Kg/m3

2.7 Ratio of Steel fiber to polypropylene fiber

Asthedensityofsteelfiberishigherthanthedensityofpoly propylenefiber,(i.e.1partofpolypropylenefiberequalto 8.72timesofsteelfiber).Theamountadditionoffiberinthis study is combination of steel and polypropylene fiber of 0.3%, 0.6% and 0.90%. So add 88.50% of steel fiber and 11.5%ofpolypropylenefibertotheamountofcementitious material (Fly ash). Following Table.3 gives the details of amount of fiber (steel fiber and poly propylene fiber separately) to beaddedto the geopolymerconcrete atthe timeofpreparation.

3. GEOPOLYMER CONCRETE MIX PROPORTION

3.1 Mixing

Flyashandaggregateswerefirstmixedtogetherdryin80 liters capacity pan mixer for around 2 to 3 minutes. Aggregates used in this mix are saturated surface dry condition. Get ready with alkaline liquid and super plasticizer, and the extra water if required to be added dependsupontheworkabilityoreaseoftheconcrete.The liquidcomponentalkalineliquidslowlyaddedtothepanwith continuousmixwiththedrymaterial,thismixingshouldbe againcontinuedupto2minutes.Thenthesteelfibersand polypropylenefiberswereaddedaftertheadditionofliquid inthepanmixerandmixedfor1to2moreminutesthesame procedure were repeated for different volume fraction of fibers 0.3%, 0.6% and 0.9%. Then the prepared fresh concreteispouredintheworkabilitymouldandcheckthe consistency of the concrete. If the Geopolymer concrete doesn’t achieve required slump (80 to 100), discard the sampleandpreparethefreshmixonceagainbyrepeatingthe sameprocedure with different mix proportions,then pour theconcretetothemouldspreparedwhicharealreadyoiled orgreasedandtampedassameastheconventionalconcrete.

Table -4: QuantityofmaterialsaspertheMixdesign

3.2 Curing of geopolymer concrete

Afterthepreparationoffreshconcretetheconcreteisfilledin themouldsandleavethem24hoursintheroomtemperature andthenitisdemouldedandkeptinovenforcuringatthe temperatureof600Cfor24hours.Thecuringtemperature will also influence the strength of concrete. The chemical reaction occurs in the geopolymer concrete and the polymerizationprocesstakesplaceinthecuringprocesses. Thespecimenswerethenallowedtoambientcuring.Some researchesnoticedthatevencuringthesespecimensinoven for extended duration with constant temperature may increasethestrengthpropertiesofthegeopolymerconcrete.

4. TEST RESULTS AND DISCUSSIONS

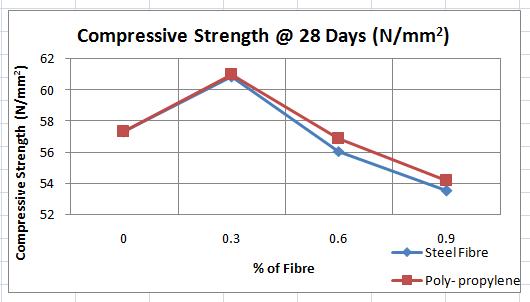

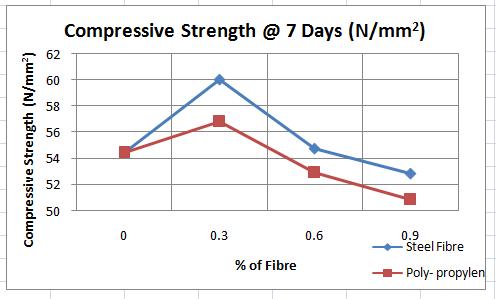

4.1 Compressive Strength on GPC

Concrete is used mostly for structural purposes such as foundations,columns,beamsandfloorsandthereforemust becapableintakingtheloadsthatwillbeapplied.Oneofthe methods of checking its fit for purpose is to carry out a concrete cube test which measures the compressible cube strengthoftheconcreteandrelatesdirectlytotherequired design strength specified. Compressive strength is in turn relatedwithdurability,highercompressivestrengthbetteris thedurability.

RelevantIndianStandards: As per IS: 516-1959

Compressivestrength=[P/A]N/mm2

Crosssectionalareaofcube=0.0225m2 ,

Paceratio=5.2

Table -5:

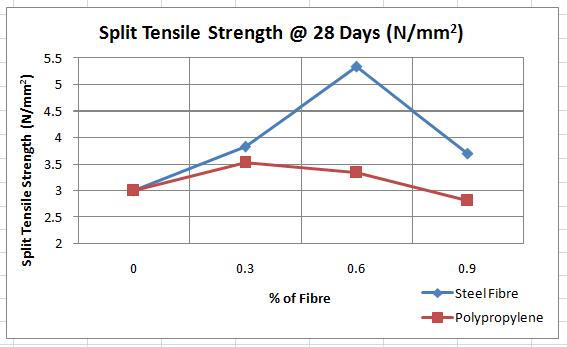

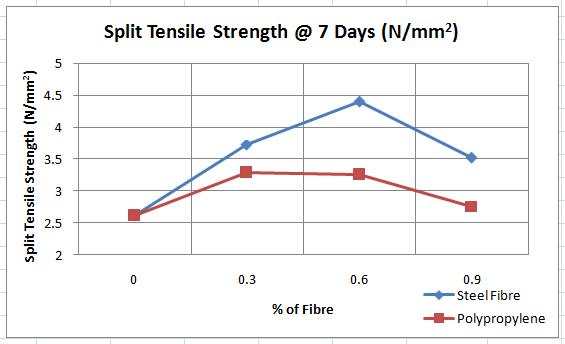

4.2 Split

Tensilestrengthisoneofthebasicandimportantproperties ofconcrete.Theconcreteisnotusuallyexpectedtoresistthe directtensionbecauseofitslowtensilestrengthandbrittle nature. However determination of tensile strength of concrete is necessary to determine the load at which the concretemaycrack.Thecrackisaformoftensionorflexure failure.

crosssectionalareaofcylinder= [(2xP)/(πxdxL)]N/mm2

Paceratio=4.8

SplitTensilestrength(MPa)

%of fibre 7Days 28Days

Steel Fibre Poly propylene Steel Fibre Poly propylene

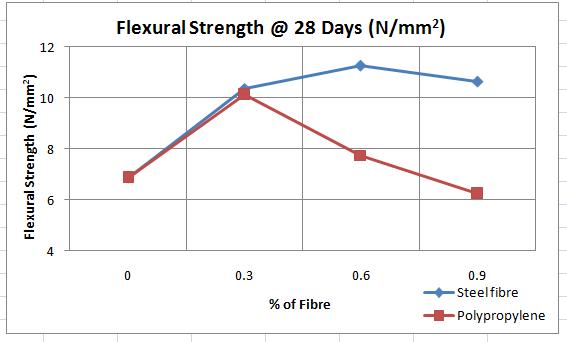

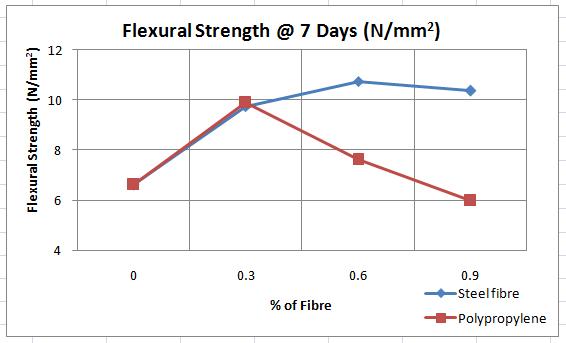

4.3 Flexural Strength on GPC

Theflexuralstrengthisexpressedas“ModulusofRupture” (MR). Flexural MR is about 12% to 20% of compressive strength.However,thebestcorrelationforspecificmaterials isobtainedbylaboratorytests.Flexuraltestsareextremely sensitive to specimen preparation, handling, and curing procedure.Ashortperiodofdryingcanproduceasharpdrop in flexural strength. The beam is of a rectangular cross sectionof100mmx100mmandlengthof500mm.Thesize of test specimen was selected to suit the capacity of the testing machine in the laboratory. All beams were simply supportedovera spanof500mm.Fig.4.19,4.20and4.21 showtheloadingconfigurationandatypicaltestset-upfor eachtestspecimen.Flexuralstrengthistheabilityofabeam orslabtoresistfailureinbending.

Flexuralstrength=[(PxL)/(BxD2)] N/mm2

5.0

The geopolymer concrete is having good compressive strengthasthe%ofsteelfibresandpolypropolynefibre increaseduptovolumefractionof0.3%andthestrength decreaseshencetheoptimumdosageoffibreis0.3%.

The geopolymer concrete with steel fibre increase the splittensilestrengthupto0.6%ofvolumefractionand decreases as the fibre increased from 0.6% to 0.9% therefore the optimum dosage of steel fibre admixture was0.6%.

The geopolymer concrete with steel fibre increase the flexural strength up to 0.6% of volume fraction and decreases as the fibre increased from 0.6% to 0.9% therefore the optimum dosage of steel fibre admixture was0.6%.

The geopolymer concrete with polypropylene fibres increasethesplittensilestrengthupto0.3%ofvolume fractionanddecreasesasthefibreincreasedfrom0.3%to 0.9% therefore the optimum dosage of steel fibre admixturewas0.3%.

The geopolymer concrete with polypropylene fibre increase the flexural strength up to 0.3% of volume fractionanddecreasesasthefibreincreasedfrom0.3%to 0.9% therefore the optimum dosage of steel fibre admixturewas0.3%.

REFERENCES

[1] Davidovits,J.Supriya,“ExperimentalStudyonBagasse AshinConcretebyPartiallyReplacementwithCement”, International Journal of Computer Engineering In ResearchTrends,Volume2,Issue12,December-1994, PP.995-1001.

[2] D.Hardjito,B.V.Rangan,“Developmentandproperties of Low-calcium fly ash based geopolymer concret”, Austria,2005,pp.1-94, https://hdl.handle.net/20.500.11937/5594.

[3] MIAbdulAleem,PDArumairaij,“Optimummixforthe geopolymer concrete”, Indian Journal of Science and Technology,Vol.5,pp.2299-2301,2012.

[4] Nabil M. and Al-Akhras, „Durability of metakaolin concrete to sulphate attack‟, Cement and Concrete Research,Vol.36,Issue.9,2006.

[5] AbhishekC.Ayachit,PranavB.Nikam,SiddharthN.Pise, AkashD.Shah,Vinayak,H. Pawar“MixDesignofFlyAshBasedGeopolymerConcrete”,InternationalJournal ofScientificandResearchPublications,Vol6,Issue2,pp. 381-385,2016.

[6] AliA.Aliabdo,AbdElmoatyM.AbdElmoaty,HazemA. Salem,“EffectofCementAddition,SolutionRestingTime andCuringCharacteristicsonFlyAshBasedGeopolymer Concrete Performance”, Construction and building materials,Vol.23,pp.581-593,2016.

[7] AminN,“Useofbagasseashinconcreteanditsimpact on the strength and chloride resistivity”, Journal of Materialsincivilengineering(ASCE)23(5),pp.717-720, 2011.

[8] Lavanya M R, Sugumaran B, Pradeep T, “An experimental study on the compressive strength of concrete by partial replacement of cement with sugarcane bagasse ash”, International Journal of EngineeringInnovations,1,pp.01-04,2012.

[9] Bahurudeen A, Kanraj D, Dev V G, Santhanam M, “Performance evaluation of sugarcane bagasse ash blended cement in concrete”, Cement and concrete Composites,2015.

[10] Castaldelli V N, Akasaki J L, Melges J T, Tashima M M, SorianoL,BorracheroMV,MonzoJ,PayaJ,“Useofslag /sugarcane bagasse ash blends in thr production of alkali–activatedmaterials”,Materials,6(8),p.p.31083127,2013.

[11] AkramT,MemonSA,ObaidH,“Productionoflowcost self compacting concrete using bagasse ash”, ConstructionandbuildingMaterials,23(2),pp.703-712, 2009.