Response Surface Optimization of Chemical Additives and Engine Parameters on Performance Efficiency of Diesel Engine

Deepak Chouhan1, Purushottam Sahu2, Ghanshyam Dhanera 31First Author Research Scholar, BM College of Technology, Indore

2Professor and HEAD, BM College of Technology, Indore

3Example: 2 Assistant Professor, BM College of Technology, Indore, MP ***

Abstract:

The findings revealed that, with the exception of ignition time, the impact of engine conditions on engine performance followed a similar behavioral pattern. 25 percent engine load, 20 percent hydrogen, 50 ppm MWCNTs, 220 bar ignition pressure,and21ofTDCignitiontimingwerefoundtobethebestsettingsforimprovedengineperformance.Interestingly, theanticipatedoptimalengineperformancewaswithin95%ofthediscoveredoptimal,howeveritdidnotfallwithinthe testing runs that were taken into consideration. To clarify the effectiveness of the confirmation analysis, experimental workbasedonthediscoveredoptimalsettingsisadvised.

Keywords: Compression ignition, direct injection, Brake thermal efficiency, Brake specific fuel consumption, Hydrocarbons,Carbonmonoxide,RSM,TaguchiMethod,Optimizationapproach

ThisstudyusedcashewshelloilandDIPEtopresentabrand-newGreyrelationalanalysiswithTaguchitechniquemodel. The engine operating conditions for various injection pressures and timings can be improved and predicted using this model in the future [153–160]. For better combustion, 150 ppm of oxygenated DIPE was added to the same biodiesel blend as before. However, the braking thermal efficiency rises to 32.5% and the SFC value falls to 0.679 when the percentageofDIPEforvariousloadsincreases.(YessianandVarthanan2020)

In the study, when three input parameters were changed at once, an effort was made to optimize the engine reactions madeupofeightseparateparameters.Sincetheinquiryunmistakablysuggestedthatalargenumberoftestcombinations were possible,theexperimentwasdesignedusingtheTaguchimethod toreducethenumber ofexperimentsby creating an orthogonal array, but without losing important data. The responses were not unidirectional, which demonstrated the complexityoftheoptimizationchallenge.Theweightingelementsofgreyrelationalanalysiswerethenappliedtothemulti response problem to make it into a single problem, and the best solution was found using the test data.(Pohit and Misra 2013)

RESPONSE SURFACE METHODOLOGY OF EXPERIMENT

It's commonly used in the industry because it's the most effective technique for meeting welding requirements. This research looked at how to prepare low-cost goods and how to improve welding defects so that they work properly. This type of technique is commonly used to minimise costs and increase product quality, and it logs as functions of desired performance. Via rigorous design of experiments, the approach and variance in a process are minimised to aid in data interpretation and prediction of optimal outcomes. RSM is an effective modeling tool to establish a relationship between controllable input and their dependent output response. The studies concentrated on the modeling and optimization of combustion and thermal performance of the biodiesel in the dual-fuel engine through RSM are even rarer The following arethekeyRSMobjectivesandmeasuresfortheparameterdesignphase:

Choosing an experiment design and optimizing Based on literature survey, it has observed that Taguchi method is most easy and robust method. Also it is cost effective as it identifies the minimum number of experimental trials needed by suggestingcorrectcombinationofdifferentdesignparameterneededforanalysisoftestresultsavoidingunnecessarydata collection and their analysis. So Taguchi DoE has been used to identify the correct combination of selected design factor and their levels in present study. For the present study, factors and levels were selected based on literature review are mentionedinTable4

Optimization and Validation

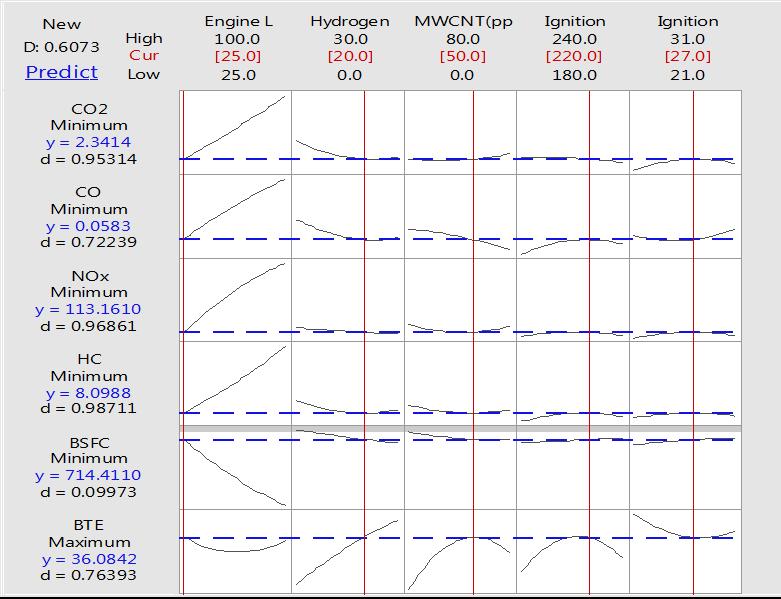

Response optimizer is used to define a single response or combination of input variable settings that optimize a set of responses. In this study, the main purpose of optimization is to maximize BTE while simultaneously minimizing brake specific fuel consumption (BSFC), hydrocarbons (HC), nitrogen oxide (NOx), carbon monoxide (CO), and carbon dioxide (CO2).

Optimization criteria are shown in Table 5.5. The optimum engine operating parameters obtained from the optimization and the optimum BTE, brake specific fuel consumption (BSFC), hydrocarbons (HC), nitrogen oxide (NOx), carbon monoxide(CO),andcarbondioxide(CO2).valuesbasedontheseparametersareshowninFig.5.13.Ontheleftsideofeach responserowintheoptimizationgraph,thereistheoptimizedresponse(y)andtheindividualdesirabilityscore(d)atthe currentvariablesettings.Intheupperleftcorneristhecompounddesirability(D).

5.13Optimizationresults

These findings indicate that RSM models were found to be suitable to model and predict input parameters and performance and emissions of engine. RSM models developed for brake specific fuel consumption (BSFC), hydrocarbons (HC),nitrogenoxide(NOx),carbonmonoxide(CO),andcarbondioxide(CO2). Emissionsareexperimentallyverified,and theresultswerefoundtobewithinthetolerableerrorrange.Thesemethodologiescanalsobeappliedforothervariables andamoreholisticmodelcanbedeveloped.(ShunmugeshandPanneerselvam2017)

Table: 9. Optimization criteria

Validation of RSM output response at 25% Engine load (%), 20% hydrogen, Nanoparticles 50 (ppm).220 (bar) ignition pressureand31Ignitiontiming(0bTDC),

TheoptimumvaluesforBTE,BSFC,hydrocarbons(HC),nitrogenoxide(NOx),carbonmonoxide(CO),andcarbondioxide (CO2)are36.0842,714.4110,8.09,113.16,0.0583and2.3414respectively.

CONCLUSION AND FUTURE SCOPE

Hydrogenwilllikelyplayasignificantpartinthefutureofthe transportationindustryasasustainablerenewableenergy source. This study was designed to look at how hydrogen and Nanoparticles affect the diesel engine's combustion and emissions. With a complete factorial design and 16 runs, the experiments are carried out by altering the engine load, hydrogenfraction,Nanoparticlesratio,ignitiontiming,andignitionpressure.

1. The Taguchi approach includes predicting the ideal variables for increasing BTE, decreasing BSFC, and reducing emissions.

2. Verification of optimization findings is needed. Utilizing the ideal engine settings determined during the optimization study, an experimental study was carried out to confirm. The optimization's results are compared withexperimentresults.

3. The optimum values for Engine load (%), hydrogen, multi-walled carbon nano tubes (MWCNTs), ignition pressure,andtimingas25%Engineload(%),20%hydrogen,Nanoparticles50(ppm).220(bar)ignitionpressure and31Ignitiontiming(0bTDC),respectively..

4. RSM models developed for brake specific fuel consumption (BSFC), hydrocarbons (HC), nitrogen oxide (NOx), carbon monoxide (CO), and carbon dioxide (CO2). Emissions are experimentally verified, and the results were found to be within the tolerable error range. These methodologies can also be applied for other variables and a moreholisticmodelcanbedeveloped.

REFERENCES:

1. Bademlioglu, A. H., A. S. Canbolat, N. Yamankaradeniz, and O. Kaynakli. 2018. “Investigation of Parameters AffectingOrganicRankineCycleEfficiencybyUsingTaguchiandANOVAMethods.” Applied Thermal Engineering doi:10.1016/j.applthermaleng.2018.09.032.

2. Belhocine,Ali,andOdayIbraheemAbdullah.2020.“ThermomechanicalModelfortheAnalysisofDiscBrakeUsing the Finite Element Method in Frictional Contact.” Multiscale Science and Engineering 2(1):27–41. doi: 10.1007/s42493-020-00033-6.

3. Ganesan,S.,M.Mohanraj,N.Kiranpradeep,andR.S.GowsikSaran.2021a.“MaterialsToday :ProceedingsImpact of Diisopropyl Ether on VCR Diesel Engine Performance and Emission with Cashew Shell Oil Using GRA Approach.” Materials Today: Proceedings (xxxx).doi:10.1016/j.matpr.2021.03.628.

4. Ganesan,S.,M.Mohanraj,N.Kiranpradeep,andR.S.GowsikSaran.2021b.“MaterialsToday :ProceedingsImpact of Diisopropyl Ether on VCR Diesel Engine Performance and Emission with Cashew Shell Oil Using GRA Approach.”(xxxx).

5. Manigandan,S.,A.E.Atabani,VinothKumar,ArivalaganPugazhendhi,P.Gunasekar,andS.Prakash.2020.“EFfEct ofHydrogenandMultiwallCarbonNanotubesBlendsonCombustionPerformanceandEmissionofDieselEngine UsingTaguchiApproach.” Fuel 276(May):118120.doi:10.1016/j.fuel.2020.118120.

6. Patil, Amit R., and A. D. Desai. 2019. “Application of Taguchi and Response Surface Methodology Approach to a Sustainable Model Developed for a Compression-Ignition Engine Using Polanga Biodiesel/Diesel Blends.” SN Applied Sciences 1(2):1–11.doi:10.1007/s42452-019-0163-7.

7. Pohit, Goutam, and Dipten Misra. 2013. “Optimization of Performance and Emission Characteristics of Diesel EnginewithBiodieselUsingGrey-TaguchiMethod.”2013.

8. Prajapati, Parth P., and Vivek K. Patel. 2019. “Thermo-Economic Optimization of a Nanofluid Based Organic Rankine Cycle : A Multi-Objective Study and Analysis Abstract :” Thermal Science and Engineering Progress 100381.doi:10.1016/j.tsep.2019.100381.

9. Prasad, T. Siva, T. Krishnaiah, J. Iliyas, and M. Jayapal Reddy. 2014. “A Review on Modeling and Analysis of Car WheelRimUsingCATIA&ANSYS.” International Journal ofInnovative Science andModern Engineering 2(6):1–5.

10. Saravanamuthu, Murugapoopathi. 2022. “Optimization of Engine Parameters Using NSGA II for the ComprehensiveReductionofEmissionsfromVCREngineFuelledwithROMEBiodiesel.”

11. Science, Thermal. 2017. “MULTI-RESPONSE OPTIMIZATION OF DIESEL ENGINE OPERATING PARAMETERS RUNNINGWITHWATER-IN-DIESELEMULSIONFUEL.”21(1):427–39.doi:10.2298/TSCI160404220V.

12. Sharma, Abhishek, Yashvir Singh, and Avdhesh Tyagi. 2020. “Application of Taguchi and Response Surface Methodology Approach to a Sustainable Model Developed for a Compression-Ignition Engine Using Polanga Biodiesel/DieselBlends.”doi:10.1177/0959651820965301.

13. Shunmugesh,K.,andK.Panneerselvam.2017.“GreyRelationalAnalysisBasedOptimizationofMultipleResponses in Drilling of Carbon Fiber-Epoxy Composites.” Materials Today: Proceedings 4(2):2861–70. doi: 10.1016/j.matpr.2017.02.166.

14. Simsek, Suleyman, Samet Uslu, Hatice Simsek, and Gonca Uslu. 2021. “Multi-Objective-Optimization of Process Parameters of Diesel Engine Fueled with Biodiesel / 2-Ethylhexyl Nitrate by Using Taguchi Method.” Energy 231:120866.doi:10.1016/j.energy.2021.120866.

15. Tadkal,Sagar.2020.“ApplicationofRSMtoOptimizePerformanceandEmissionCharacteristicsofaDieselEngine FuelledwithKaranjaMethylEsterandItsBlendswithConventionalDieselOil.”6(2):725–33.

16. Uslu,Samet.2020.“LEtherDopedDieselEnginebyTaguchiMethodMulti-ObjectiveOptimizationofBiodieseland Diethy.”4:171–79.doi:10.30939/ijastech..770068.