DEVELOPMENT OF RACI MATRIX FOR COMPLETE MACHINE LIFECYCLE

Abstract - A RACI Matrix or Responsibility Assignment Matrix is a matrix of all activities or decision-making authorities undertakenfor any process. Ateachintersectionof activity and role it is possible to assign someone responsible, accountable, consulted or informed for that activity or decision. In this research, the process of capacitor manufacturing is observed and safety critical machines are identifiedfor the same. Then for those safety criticalmachines different stages of life cycle are identified. Once the identification of machine is completed with different stages, a list of safety related activities and list of stakeholders, associated with the task or activity, is created. To identify the stages, activities anddifferent stakeholders, a risk assessment study was carried out to find the safety critical equipment to define the criticality of the task andof the machine. Onfinding the risks, roles andresponsibilities were assignedfor thesame to ensure proper andsafeworkingoperationoftheequipment. The mainobjective of this research is to ensure accountability is placed with the person who really can be held accountable for specific work and safe work practices. It includes all routine and non-routine activities involved in capacitor manufacturing process.

Key Words: RACI,SafetyAccountability,Responsibility

1.INTRODUCTION

RACIMatrixorResponsibilityAssignmentMatrixisasafety management tool designed to assign tasks, activities, responsibilities,accountability,decisionmaking,supportto teammembersofaprocess/projectandclarifyexpectations on the level of their participation. This tool is used for identifyingrolesandresponsibilitiesandavoidingconfusion over those roles and responsibilities during project. To ensuecollaborationandprojectsuccess,itiscrucialforall stakeholderstounderstandtheirrolesandresponsibilities andthoseofotherprojectmembers.

It is an element of the safety assurance program which integratesvarioussafetymanagementtoolstoassuresafety oftheemployee.Therearefifteenelementsinthisprogram whichaddressthesafetyissuesinorganizationatdifferent levels.IthasfourlevelsinitnamelyPeopleCertification& Authentication, Engaging Hearts & Mind in Safety, Equipment Certification & Authentication and Safety AssuranceProgram.Allfourlevelstartsfromcreatingsafe environment, creating awareness among employees regardingsafetyatworkplace,creatingasystemtocheckif

***

the safety related issues have been addressed and maintainingalevelofsafetyfortheemployees.

RACIMatrixisoneofthekeysafetymanagementtoolsused inassuringsafetyofemployees.Itusesaworkbreakdown structureandorganizationalstructuretolinkdeliverablesor activitiestoresources

InResponsibilityAssignmentMatrix,aprocessoractivityis definedstepbystepandforeverysteportaskspecificroles areassignedaccordingtotheneeds.Itensureseachactivity haveaccountabilityfixedwiththerespectivepersonwhocan be held accountable for specific work and safe work practices.Itinvolvesrepresentativesfromalldepartments and information is being shared in between them. The purposeofaRACIMatrixistoeliminateconfusionbetween departments and individuals regarding their roles and responsibilities.

1.1 Elements

Stakeholders – Any individual or a group of individuals connectedtoagiventask,directlyorindirectly,andwhose involvementaffectstheoutcomeofthedesiredtaskwillbe calledasastakeholder.Otherthantheonesperformingthe task, there are many individuals and many departments whichworktogethertoformacommunicationmodeland helpsinperformingthetaskeffectively.

Operations–Forthisprojectthefocusistoidentifyvarious stagesofmachinelifecycleinwhichsafetyrelatedissuesare facedandareaddressed.Startingfrompre-commissioningto decommissioningofthemachinetherearesevenstagesin whichtheactivitiesareidentifiedandrolesaredefinedfor thesame.

-Pre-commissioningInspection

-Commissioning

-DailyStartupInspection

-StandardOperation

-MaintenanceOperation

-Modification

-Decommissioning

1.2 Assigning Roles and Responsibility

Responsible– Responsibleisonewhowill performthe defined task and will have required knowledge of the operation to perform the task. He should know the basic safetyawarenessabouttheoperationandPPEandstandard operating procedure knowledge. The role demands the individualtohaveunderstandingaboutwhattodoandwhom tocontactincaseofanemergency.

Accountable–Anindividualwhowillhavetotalauthority overtheoperationandwhocangivecommandtoperform the task. He should also have a total understanding of the workpermitsystemtoperformatask,ifrequired.Heisone who will have thorough knowledge of operations to be performed. He will decide by whom the task will be performed and how it is being performed. He should also have knowledge of operations safety training and will provide the same to the employees before starting the operation. He will have a thoroughknowledge of required rulesandregulationsandwillprovidethesametoemployees alongwithmanualsandchecklist.

practices, procedures and processes for risk prevention. Assumptionofresponsibilityincorporatestheprinciplesofa riskpreventionpolicy.

T.Kontogiannis,M.C.Leva,N.Balfa(2017):“TotalSafety Management: Principles, Processes and Methods” The integrationofsafetywithothermanagementsystems(e.g., quality,environmentandproductivity)hasbeenaddressed either at a strategic level or a standardization level. This articlelooksatthecoordinationbetweenbusinessprocesses thatarecommontothesemanagementsystemsandproposes several principles of Total Safety Management based on earlierstudiesandathree-yearexperiencewithaEuropean project. Four safety processes are proposed which are compatible with ISO 31000 & CCPS Standards 2008 and principles of TSM are discussed briefly. In general, a TSM approach should consider risk assessment within the frameworkofafunctionalsystemmodelthatdescribesboth the activities of operators and the business processes that supporthumanperformance(i.e.,supplies,tools,workplaces, training).Humanoperationsareanalyzedintermsoftasks, informationneeds,decisionsandcoordination.

Consulted

Anindividualwhoisanexpertinhisfieldand haveathoroughknowledgeandexperienceoftheworkbeing performed.Heshouldprovidesolutiontoanysafetyrelated problem.

Informed–Theonewhoisnotdirectlyconnectedtotask orwhohasnodirecteffectontaskcompletionbutisrequired togetanupdateaboutthetask.Theindividualwiththisrole isgenerallyahigherauthorityorseniordepartment.Heisthe headoftheteamconcernedwiththesectionofthetask.Heis onewhogivestheordertodothetaskandisinformedonce thetaskiscompleted.

Assigningrolesshouldprovidebothpositiveandnegative aspects of the tasks to be performed. Identifying and promotingindividualaccountabilitiescanraiseselffulfilment andcanleadtoenhancedperformance.Theactualpatternof responsibility assignment depends on the management body’s administrative structure and any legally defined accountability.

Too many responsibilities assigned wastes available expertise andlimit its further development in anylocal or fieldoffice

2. LITERATURE REVIEW

Jesús Álvarez-Santos, José-Á. Miguel-Dávila, Liliana Herrera,MarianoNieto(2018):“SafetyManagementSystem in TQM environments” The journal aimed at knowing the conditionsthatacceleratetheadoptionofsafetymanagement systemeitherunderprinciples,beliefsandvaluesofTQMor becauseoftheimplementationandapplicationofessential safetymanagementtechnique.Safetymanagementsystemis amanagementmodelthatgroupsfunctions,responsibilities,

Gudela Grote (2015): “Promoting safety by increasing uncertainty – Implications for risk management” In this research paper processes are proposed as a criterion for decisiononreducing,maintainingandincreasinguncertainty. Necessity tomanageuncertaintyanditsimpacton control and accountability. Reduced uncertainty results in stable systems and maximum control whereas increased uncertaintyleadstoflexiblesystemandself-organization

Sidney W.A. Dekker (2015): “The bureaucratization of safety” Bureaucratic accountability refers to the activities expectedoforganizationmemberstoaccountforthesafety performanceofthosetheyareresponsiblefor(e.g.unit,team, site). Bureaucratization of safety has brought benefits, includingareductionofharm,standardization,transparency and control. It has been driven by regulation, liability and insurance arrangements, outsourcingand contracting,and technologiesforsurveillanceanddatastorage.

OregonOSHA:SafetyandHealthManagement–theBasics Gives to basic understanding about safety management systemandbasicdefinitionofresponsibility,accountability and difference between the two. The research paper concludesthatproductionsupervisorsareheldaccountable forsafety,healthandergonomicsintheirdepartments.Top management is held accountable for facility safety performancethoughtheirownperformanceevaluations.

OverviewforManagementofChangebasedonBusiness ProcessModelofPlantLifecycle.Thisjournaltalksaboutthe accidentscausedbyuncontrolledchangeswhichcouldhave been monitored easily. Various plant lifecycle stages are discussed here and many activities are identified over the plantlifecyclesuchasprocesshazardanalysis,training,and soonarerequiredforthechanges.

2.1 Objective of the Project

Detailed study about the machine and process and to understandeverysingleactivityinvolvedintheprocess bybreakingdownitinsimplestages.

Identifyingactivitiesandtasksrelatedtotheprocessand themachineateverystage.

Assigningrolesandresponsibilitytoindividualsinvolved withtheprocessandtocreateapropercommunication model.

To eliminate and avoid confusions between different departmentsregardingtheirroles.

To know about every safety issue in every activity associated with the project and the steps taken to eliminateorreduceit.

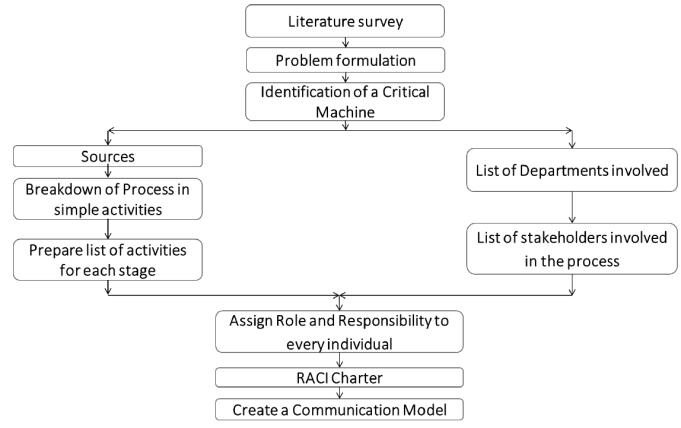

3. METHODOLOGY

Current research methodology to obtain the desired RACI Matrixisdemonstratedinfigurebelow:

Table 1: Probabilityofoccurrence

Probability Level Order of magnitude of Probability or Exposure duration

3-Probable Dailytomonthlyevent(largerexposure durations)

2-Improbable Monthlytoannualevent(exposureremaining limitedinduration)

1-Very improbable Eventsoccurringannuallyoreveryfewyears (shortandrareexposure)

The severity of injuries or damage to health can be estimated by considering reversible injuries, irreversible injuriesordeath.Therecommendedclassificationisshownin thetable2.Probabilityofoccurrenceisestimatedusingthe leastfavorablecase.Itisrecommendedtoensurethatthree factors namely Frequency of exposure, occurrence of hazardouseventsandpossibilitiesofavoidingtheharmare consideredasmentionedintable1.

Riskmatrixisusedtodeterminethelevelofriskbasedon theprobabilityofoccurrenceofthehazardandtheseverityof theharm.Onthebasesofriskassessmentcarriedoutforthe capacitor manufacturing process, following points are observed:

Table 2:Severityofoccurrence

Severity level Type of bodily harm considered

3-Veryserious Amputation major fractures; poisoning multiple fractures; fatal injury, occupational cancer; other illnesses reducing life expectancy; fatal acute illnesses.Partialpermanentincapacitytowork.

2-Quiteserious Lacerations and wounds; burns; concussion; serious sprains; minor fractures; deafness; dermatitis;asthma.Poorhealthleadingtoaminor butpermanentdisability;ortemporaryincapacity towork.

4. RESULTS

Figure 1 Methodologyofproject

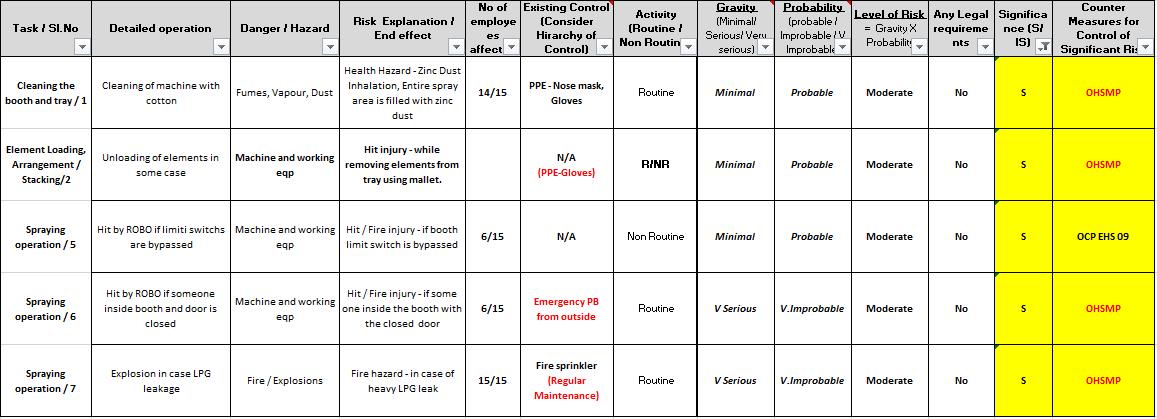

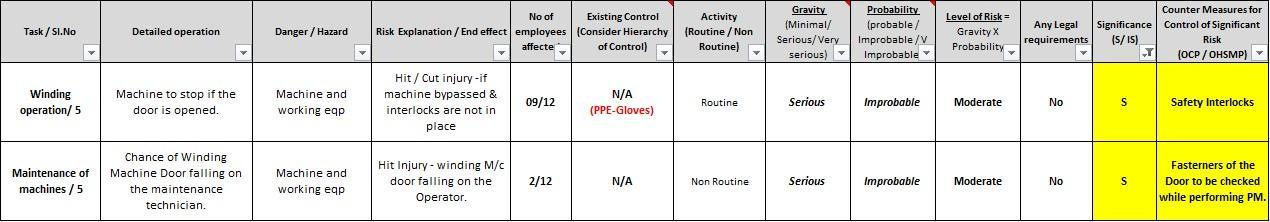

4.1 Identification of Safety Critical Machines

Thefirststepoftheprojectwastoidentifysafetycritical machines for which RACI Matrix was to be created. To complete this task, Occupational Risk Assessment of the capacitor manufacturing process was carried out. The purposeoftheriskassessmentwastofindoutthehigh-risk activitiesandcriticaloperationmachinesandtofindinvolved dangersinit.Mitigationplanforthesamewaspreparedand responsibilitieswereassigned.

1-Minimal Incidentsnearlywithoutinjuryorwithsuperficial injuries;smallcutsandbruises;irritationofeyesby dust; discomfort or problem with temporary discomfortofoneorseveralpeople.Benignevents oraccidentsthatarerecorded.

On the bases of risk assessment carried out for the capacitor manufacturing process, following points are observed:

Winding area consisted of activities categorized in five groups. Total 31 risks were identified for winding operationsoutofwhich2risksaresignificant.Thehighest riskratingobtainedbywindingmachineis3.

Sprayingareaconsistedofactivitiescategorizedinseven groups. Total 3 risks were identified for winding operationsoutofwhich5risksaresignificant.Thehighest riskratingobtainedbywindingmachineis3.

ElementTestingareaconsistedofactivitiescategorizedin threegroups.Total17riskswereidentifiedforwinding operationsoutofwhich1riskissignificant.Thehighest riskratingobtainedbywindingmachineis3.

Supportassemblylineconsistedofactivitiescategorized in 9 groups. Total 25 risks were identified for winding operationsoutofwhich0risksaresignificant.Thehighest riskratingobtainedbywindingmachineis2.

ResinFillingareaconsistedofactivitiescategorizedinsix groups. Total 21 risks were identified for winding operationsoutofwhich0risksaresignificant.Thehighest riskratingobtainedbywindingmachineis2.

Seamingoperationconsistedofactivitiescategorizedin ten groups. Total 19 risks were identified for winding operationsoutofwhich1riskissignificant.Thehighest riskratingobtainedbywindingmachineis3.

Capacitor testing area (Infinity and Koti) consisted of activities categorized in eleven groups. Total 63 risks wereidentifiedforwindingoperationsoutofwhich1risk issignificant.Thehighestriskratingobtainedbywinding machineis3.

The various risksidentifiedfor safetycritical machines during standard operations are identified. During winding operations two safety risks were identified and control measuresorcountermeasuresaredefinedforthesame.In the same manner for spraying area the five risks were identified with moderate risk level. Similarly, for testing operation, seaming operation and capacitor testing operations one risk is identified for each operation as moderatelevelriskandcontrolmeasuresareplaced.

4.2 List of Activities and Stakeholders

After finding the all safety critical equipment used in capacitormanufacturingprocess,thenextsteprequiresthe identification of all activities associated with the machine duringwholelifecycleandtofinddifferentstakeholdersfor differentstagesofmachinelifecycle.

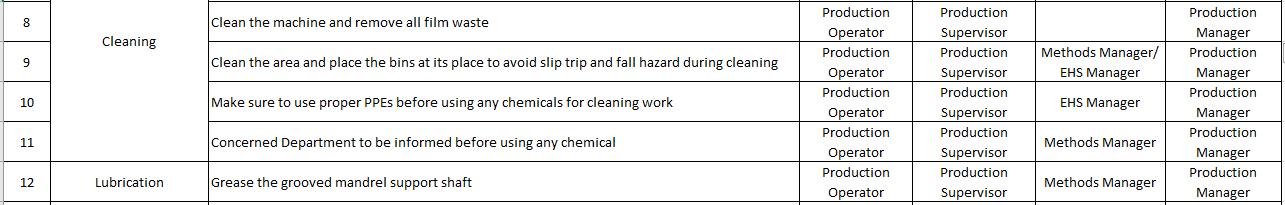

Table

Department Stakeholders

ProductionOperator

IFM

FacilityManager

HousekeepingPersonnel

HRDepartment HRManager

PlantHead

Tofindthelistofactivitiesvariousdocumentswerestudied andobservationsweremade.

Thedocumentsrequiredforfindingthelistofactivitiesare:

OperationsWorkStandards

Production

ProductionSupervisor/Shiftincharge

ProductionManager

CS&Q QualityManager

MaintenanceManager

StandardOperatingProcedure

MachineManualfromOriginalEquipmentManufacturer

JobBreakdownSheets

OccupationalRiskAssessmentSheets

Maintenance

MaintenanceTechnician

MethodsDepartment MethodsHead

SPS&CI

EHS

Supplychain Management

SchneiderPerformanceSystem&CI Head

EHSManager

EHSExecutive

WarehouseManager

SupplychainManager

OCPandOHSMP

A stakeholder is one who’s involvement, directly or indirectly, affects the outcome of the process. There are various departments and individuals from where the stakeholdersarefind.Toensurecollaborationandproject success, it is crucial for all project stakeholders to understand their roles and responsibilities and those of otherproject members. Thisisespeciallyimportant when project teams are more complex due to their large size, involvement of distributed team members or reliance on stafffrommultipledepartments.

Avoidingmultiplelevelsofoversightandworkingonone level.

Maintainingchartfluidity-makingchangesasneededand lettingpeopleknowwhenthingschange.

Assigning only one accountable per task. There shall neverbetwopersonsaccountableforasingletask

Ensuringaccountableassigneeshaveauthoritytoensure thetaskiscomplete.

Avoidtoomanyconsultantsastheymaytaketoomuch timewhiletoofewcandamagetheperformance

Informeveryonewithroleoftheirassignment

Iftoomanypeoplemustbeassignedconsulted,evaluate whetheronepersoncanbeassignedwhotalkwithother involved.

4.3 Assigning Roles and Responsibilities

4.3.1 Winding Area

IFM Housekeeping Staff Housekeeping Supervisor IFM Manager

Warehouse Operator Supervisor Manager

Similarly,theno.ofactivitiesandinvolvementofdepartment wereidentifiedforsprayingmachine,ECACtestingmachine, riveting machine, HV Lid testing, resin filling machine, seamingmachine,capacitortestingmachine.

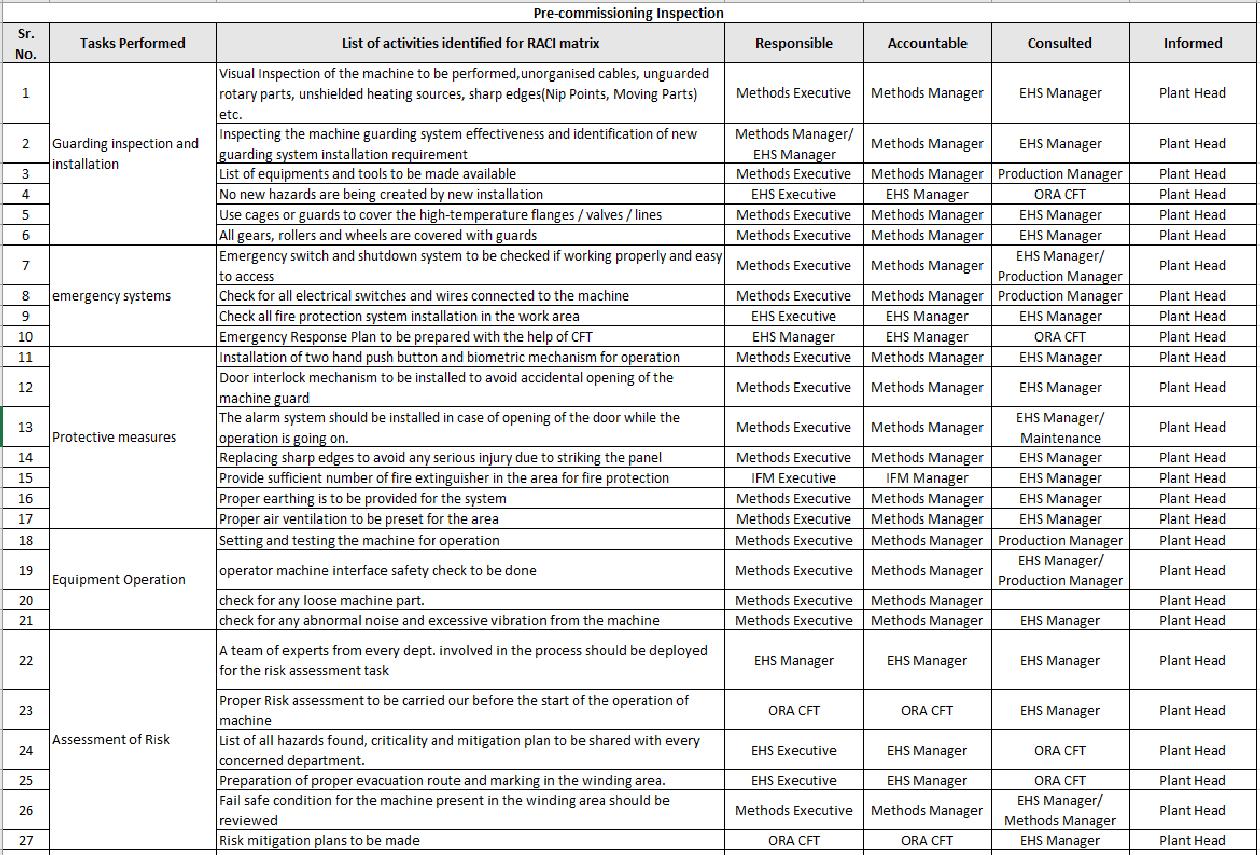

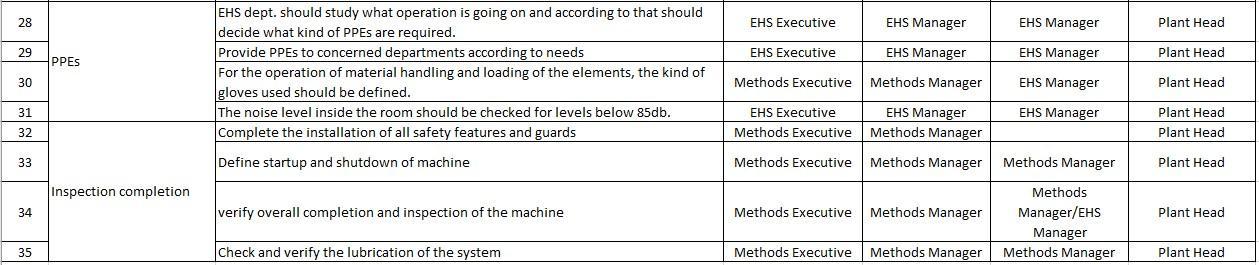

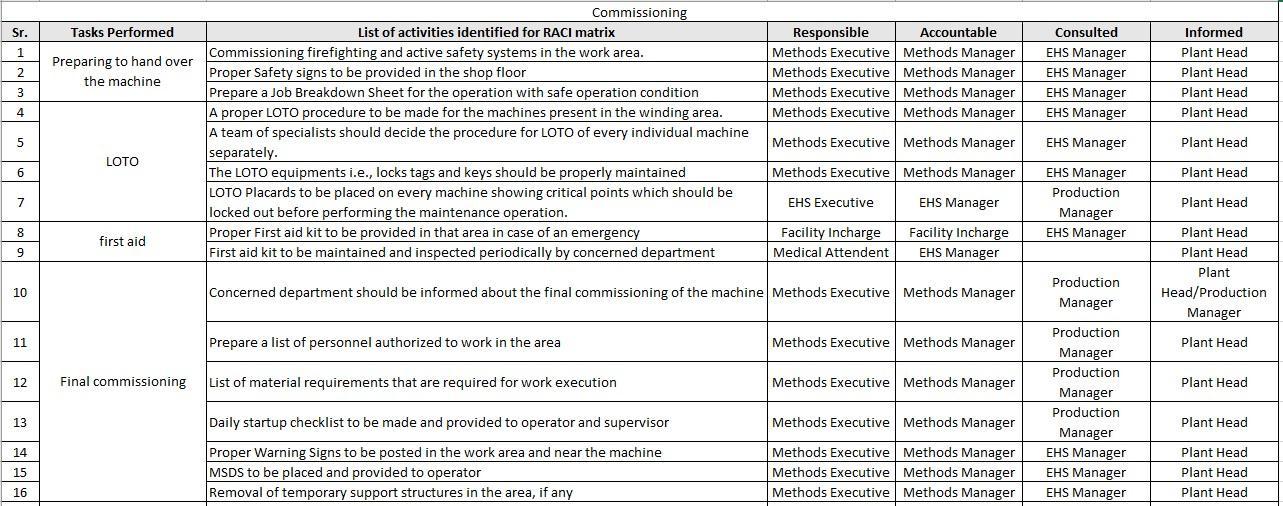

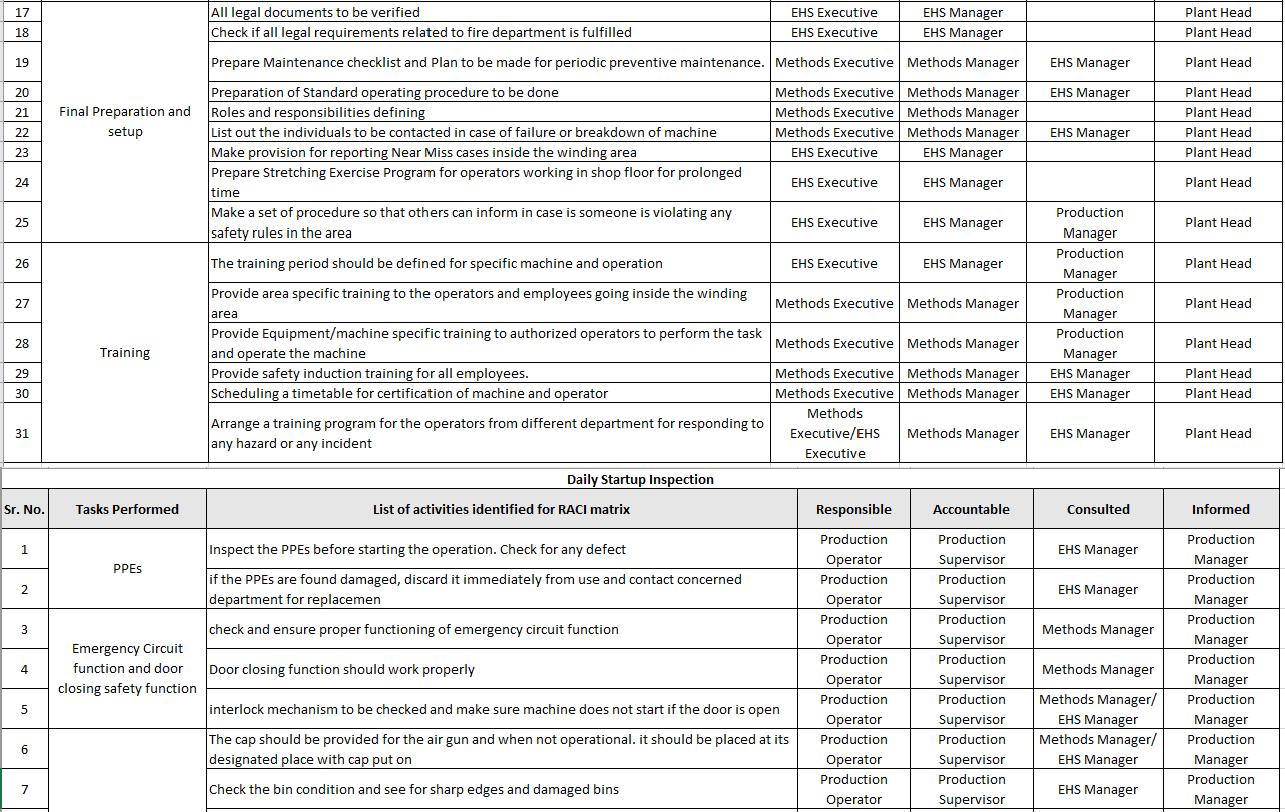

RACIMatrixasasampleforPre-commissioninginspection, commissioningandDailyStartupinspectionisattachedin theAnnexureIandAnnexureII.

5. CONCLUSIONS

RiskAssessmenthasbeencarriedoutforallthemachines involved in capacitor manufacturing process to identify criticalmachines.Theprocessinvolvedthedetailedstudyof everymachineandactivityandfindingrelatedactivitiesand stakeholders involved in the task. Assigning roles and responsibilities is done for all safety critical machines at differentstagesoflifecycle.Stepsundertakentocreatethe RACIchartare:

Identifiedtheprojecttasks–meetingthestakeholders todeveloptheactivitiesinvolved.MaintenanceofRACI matrixasataskistobedone.

Identified the roles – roles identified and allocated to stakeholdersassociatedwiththetasksandclarifyingthe resource allocation. This step helps in eliminating the confusion over the roles and responsibilities of employees.

Criticalmachinesfoundduringthestudyareasfollows

WindingMachine–forwindingMPPfilmoncore

SprayingMachine-Sprayingzinccoatingonsidesof theelements

ECAC Testing machine- Testing the quality of elements

Riveting machine – Preparation of capacitor lid usinghydraulicenergy

HVLidtesting–Checkingthequalityanddurability oflidsunderhighvoltage

Resinfillingmachine–Fillingtheresinincapacitor containers

Seaming machine – Sealing and seaming the capacitorcan

Capacitor testing machine – Final checking of the capacitorsbeforepacking

Thestudyoffollowingmachineswasdoneandtotal 1240 safetyrelatedactivitiesareobservedandrolesareassigned forthesame Theresultsofriskassessmentshowsthatmost of the risks observed were of risk rating 2 and were tolerable. Control measures were identified to further minimizethoserisksandtobringitdowntoariskratingof1

Table 12 RiskAssessmentSheet

6. KazuhiroTakeda,HideoSaito,YukiyasuShiamad,Teiji Kitajima, Tetsuo Fuchino, Yuji Naka; “Overview for ManagementofChangebasedonBusinessProcessModel of Plant Lifecycle” Journal of Process Safety, Volume 23(2013)

7. Safety and Health Management – the Basics, OSHA, OregonOSHA.

8. Project Management in Product Development, George Ellis.

9. ISO 12100-2010 - Safety of Machinery- General Principles for Design- Risk assessment and risk reduction.www.iso.org

REFERENCES

1. T. Kontogiannis, M. C. Leva, N. Balfa; “Total Safety Management: Principles, Processes and Methods” JournalofSafetyScience,volume100,PartB(December 2017),pageno128-142.

2. Gudela Grote; “Promoting safety by increasing uncertainty–Implicationsforriskmanagement”Journal of Safety Science, Volume 71, Part B (January 2015), Pageno71-79.

3. Jesús Álvarez-Santos, José-Á. Miguel-Dávila, Liliana Herrera,MarianoNieto;“SafetyManagementSystemin TQMenvironments” Journal ofSafetyScience,volume 101(2018),pageno135-143.

4. Marko Gerbec; “Safety change management – A new method for integrated management of organizational andtechnicalchanges”Journalofsafetyscience,Volume 100(December2017),Pageno.225-234

5. YulingLia,FrankW.Guldenmund,“Safetymanagement systems:Abroadoverviewoftheliterature”;Journalof SafetyScience,Volume103(2018),Pageno.95-123.