EXPERIMENTAL INVESTIGATION ON CONCRETE USING RECYCLED COARSE AGGREGATE

Sabunam Chettri1 , Aaqib Firdous2

Sabunam Chettri1 , Aaqib Firdous2

Abstract - This project deals with the excremental investigation on the properties of concrete using recycled coarse aggregate. In this project the M30 concrete mix is selected and the compression and tensile tests are carried out for the hard concrete. Due to the rapid population growthand rapid urbanization the natural resources are depleting day by day. So the natural aggregates are very hard to obtain. So many people are opting to use recycled aggregates in construction. The cost of good quality crushed aggregates as compared to recycled aggregate is also very high due to the high demand of it in construction works.

Recycling of stone, aggregate, will reduce the quarrying and mining of stones thereby reducing the use of natural resources excessively. The land surface can be prevented from any unwanted dumping of wastes and hence ecological disturbances will be reduced. To conserve the conventional natural aggregates for other important construction works. The slump test is carried out in the project to investigate the workability of fresh concrete. The slump of the concrete mix is recorded as 130mm.The preliminary tests are also carriedout for this project such as, Water absorption test, fineness modulus test, bulk density test etc. Methodologyofproject, test results and discussion are enclosed in this report.

Key Words: Concrete, Compression test, Tensile tests, Aggregate, Recycling of stone

1. INTRODUCTION

Concrete is the most widely used construction material today. Concrete is a manufactured product, essentially consisting of cement, aggregates, water and admixture. Traditionally aggregates have been readily available at economicprice.However,inrecentyearsthewisdomofour continuedwholesaleextractionanduseofaggregatesfrom natural resourceshasbeen questionedataninternational level. This is mainly because of the depletion of quality primaryaggregatesandgreaterawarenessofenvironmental protection.

Global warming has emerged as the most serious environmentalissueofourtimeandsincesustainabilityis becoming an important issue of economic and political debates,manygovernmentsthroughouttheworldhavenow introducedvariousmeasuresaimedatreducingtheuseof primary aggregates and increasing reuse and recycling,

where it is technically, economically, or environmentally acceptable.Recycledaggregatesaretheaggregatesproduced from the processing of previously used construction materialssuchasconcreteormasonry.Itconsistsofhard, graduated fragments of inert mineral materials including sand,gravel,crushedstone,slag,rockdust,orpowder.

1.1 Scope of using recycled coarse aggregate

a.Recycling of stone, aggregate, will reduce the quarryingandminingofstonestherebyreducing theuseofnaturalresourcesexcessively.

b. The land surface can be prevented from any unwanted dumping of wastes and hence ecologicaldisturbanceswillbereduced.

c. Theavailabilityoflandforwastedisposalwillbe increased.

d. Toconservetheconventionalnaturalaggregates forotherimportantconstructionworks.

e.Toreducethecostofconstructionmaterials.

1.2 Objective of the experimental investigation

a. Investigating the behavior, strength and durabilityofconcretewhilereplacingthenatural aggregates by recycled aggregates in various proportions.

b. Toreducethedemandofnaturalaggregate.

c. Toemphasisonthe3Rconcept(Reduce,Recycle andReuse)intheconstructionfield.

d. Foreffectivesolidwastemanagement.

2. METHODOLOGY

Thischapterdealsaboutthemethodologyoftheuse ofcoarseaggregateinconcreteandisasdiscussed below.

The used concrete cubes and cylinders were collected from laboratory of excel engineering collegekomarapalayam.Thiswasofmorethantwo yearsold.

Thespecimenswerecrushedtoobtainthedesired sizeoftheaggregateandthentherecycledcoarse aggregatewasextracted.

Therecycledcoarseaggregates(RCA)werescreened toremoveanyunwantedmaterials.

The RCA was then washed with clear water to removeanymortarattachedtotheaggregate.

Thenitwasheatedinaheatingoventoremovethe moisturecontentpresentinit.

The % of replacement of coarse aggregates by recycled aggregates was 30%, 50% and 70% of coarseaggregateandthespecimenswerecast.

Thecastspecimensarecubesandcylinders.Thecast specimenswerecuredfor3,7and28days.

Thecastspecimensaftercuringweresubjectedto compressiontestingandsplittensiletesting.

Test results are obtained and discussed with the helpofgraphsunder‘ResultandDiscussions’.

3. PRELIMINARY TESTS

3.1

Specific gravity of cement

Thespecificgravityofcementisdeterminedwiththehelp ofLeChatelier’sFlask.IS4031PartIIisusedforthetestingof specificgravityofcement.

Sp.Gravityofcement=(Wt.ofcement)/(increseinvolume inLechatelier^'sflask)

Valuesofspecificgravityfordifferentkindsofcementare asfollows:

OPC = 3.1to3.18

PPC = 2.9to2.95

Slag = 2.8to2.9

3.2 Specific gravity test of aggregate

IS2386PartIIIisusedfordeterminingspecificgravityof aggregates.Pycnometerisusedforthetest.

A -sample+water+pycnometer

B -water+pycnometer

C -sampletakenafterwetcondition(24hrs)

D -weightofsampleafterdriedinovenafter24hrs.

SepcificGravity=D/(C-(A-B))

3.3 Bulk density test

IS2386PartIIIisusedfordeterminingbulkdensityof aggregates.

Thebulkdensityforriversandisgivenby

Bulkdensity=weight/volume

Wherevolume=π/4×D^2×h

D=diameterofcylinder

h=heightofcylinder

3.4 Water absorption test

IS2386PartIIIisusedfordeterminingwaterabsorptionof aggregates.

Waterabsorption=C-D/D*10

4. EXPERIMENTAL INVESTIGATION

4.1 Preparation of materials

Sample ofaggregate for eachbatchofconcrete shell be of desired grading and in air-dried condition. In general, the aggregate shall be separated into fine and coarse fraction andrecombinedforeachconcretebatchinsuchamannerso astoproducethedesiredgrading.

Collectionofaggregates

4.2 Proportioning

The proportioning of the materials including water in concretemixesfordeterminingthesuitabilityofthematerial available shall be similar in all aspects to those to be employedinwork.Wheretheproportionsoftheingredient ofconcreteusedonthesitearetospecifiedbyvolume,they shallbecalculatedfromtheproportionalbyweightusedin thetestcubesandtheunitweightofthematerials.

4.3 Weighing

The quantities of cement, each size of aggregate and water for each batch shall be determined by weight to an accuracyof0.1percentofthetotalweightofthebatch.

4.4 Mixing of concrete

The concrete shall be mixed by hand or perfectly in laboratorybatchmixerinsuchamannersoastoavoidloss ofwaterorothermaterials.Eachbatchofconcreteshallbe ofsuchasizesoastoleaveabout10percentexcessafter mouldingthedesirednumberoftestspecimen.

4.5 Compaction

Mixingofconcrete

Whencompactionbyhand,thestandardtampingrodshall beusedand thestokesoftherodshall bedistributedin a uniform manner over the cross section of the mould. The number of stokes per layer required to produce specified condition will vary according to the type of concrete. For cubical specimen, the concrete shall be subjected to 35 stokesperlayerfor15cmcubes.Thestokesshalltouchthe surfaceofunderlyinglayer.Wherevoidsareleftbytamping rod,thesidesofthemouldshallbetappedtoclosethevoids.

4.6 Curing of test specimens

Thetestspecimensshallbestoredonthesiteataplace free from vibration, under damp matting, sacks or other similarmaterialsfor24hours+halfhourfromthetimeof addingthewatertotheotherincidents.Thetemperatureof theplaceofstorageshallbewithintherange22-32Celsius Aftertheperiodof24hours,thespecimenshallbemarked for the later identification removed from the mould and unless required for testing within 24 hours store in clean water at temperature of 24 – 30 Celsius until they are transportedtothetestinglaboratory.Theyshallbesentto the testing laboratory well packed in a damp sand, damp sack or other suitable materials so as to arrive there in a dampconditionnotlessthan24hoursbeforethe time of test

5. Test on fresh concrete

5.1

Slump test:

The slump test is used to determine the workability of concretemixpreparedatthelaboratoryorconstructionsite. Theslumpvaluewasdeterminedforthevariousmixtobe preparedintheproject.Generallyconcreteslumpvalueis usedtofindouttheworkabilityofconcretewhichindicates water–cementratio.

Procedure:

• Cleantheinternal surfaceof themouldandapply oil.

• Placethemouldonsmoothhorizontalnon–porous baseplate.

• Fill the mould with the prepared concrete mix in fourapproximateequallayers.

• Tampeachlayerwith25stokesoftheroundedend of the tamping rod in a uniform manner over the cross-section of the mould. For the subsequent layers the tamping should penetrate into the underlyinglayer.

• Remove the excess concrete and level the surface withatrowel.

• Cleanawaythemortarorwaterleakedoutbetween themouldandthebaseplate.

• Raisethemouldfromtheconcreteimmediatelyand slowlyinverticaldirection.

• Measuretheslumpasdifferencebetweentheheight ofthemouldandthatofhighestpointofspecimen beingtested

Slumptest

6. Tests on hardened concrete

6.1

Compressive strength test

• Oneofthemostimportantanduseful propertyof concrete.

• Primarily meant to withstand compressive stress and can be used as an approximate qualitative measureforotherpropertiesofhardenedconcrete.

• Compressivestrength testiscarriedoutoncubes forvariousmixesM1,M2,M3andM4.

• Thecompressivestrengthofcubeswastestedon3, 7and28days.

• Formulaforcompressivestrengthofconcrete: =Loadapplied(P)/Crosssectionalarea(A)=N/mm2

Compressivestrengthtest

6.2 Split tensile strength test

Thetensilestrengthofconcreteisoneofthebasicand important properties. Splitting tensile strength test on concrete cylinder is a method to determine the tensile strengthofconcrete.

Need: The concrete is weak in tension due to its brittle nature and is not expect to resist the direct tension. The concretedevelopscrackswhensubjectedtotensileforces. Thus it is necessary to determine the tensile strength of concrete to determine the load at which the concrete membermaycrack.

Procedure:

• Drawdiametriclinesoneachendofthespecimen usingasuitabledevicethatwillensurethattheyare inthesameaxialplane.

• Determine the diameter of the test specimen by averagingthethreediametersandthelengthofthe specimen by averaging at least two length measurements taken in the plane containing the linesmarkedonthetwoends.

• Placethespecimenontheplywoodstripandalign so that the lines marked on the ends of the specimen are vertical and centered over the plywood strip. Place a second plywood strip lengthwise on the cylinder, centered on the lines markedontheendsofthecylinder.

• Applytheloadcontinuouslyandwithoutshockata constantratewithintherange100to200psi/min [0.7 to 1.4 MPa/min] splitting tensile stress until failure of the specimen. Record the maximum applied load indicated by the testing machine at failure.Notethetypeoffailureandtheappearance oftheconcrete.

Calculation:

The splitting tensile strength of the specimen are given below:

Where,

T = 2P/πld

T = splittensilestrengthin MPa

P = maximum applied load indicated by the testingmachineinN

l= lengthinmm

d= diameterinmm

Splittensilestrengthtest

7. TEST RESULTS

7.1 Compression test results for cube

7.1.1 M1 (Control mix)

3DaysCompressiontestresult(controlmix)

7.1.2

7Dayscompressiontestresult

7.1.3 M3 (50% replacement of coarse aggregate by recycled aggregate)

7Dayscompressiontestresult

28Dayscompressiontestresult

28Dayscompressiontestresult

7.1.4 M4 (70% replacement of coarse aggregate by recycled aggregate)

3Dayscompressiontestresult

7Dayscompressiontestresult

28Dayscompressiontestresult

7.2 Split tensile test results for cylinder

8.1 Compressive strength test results

SplittensileresultforM2(30%replacementofCAbyRA)

Compressivestrengthtestresults

SplittensileresultforM3(50%replacementofCAbyRA)

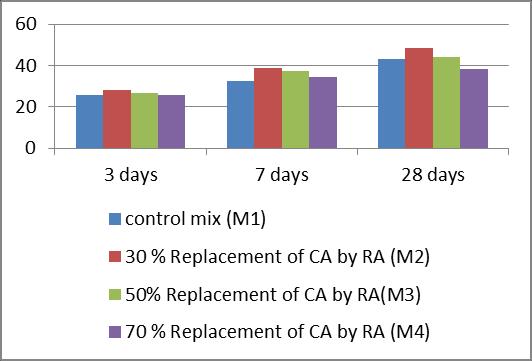

Chartshowingthecomparativecompressivestrengthof variousmixesat3,7and28days

Theabovetestresultshowsthatthecompressivestrength at3,7and28daysishighestforM2(i.e.when30%ofcoarse aggregateisreplacedbyrecycledaggregate)followedbyM1, M3 and M4 except for the 7 day strength where the compressivestrengthofM3andM4isgreaterthanM1.

8.2 Split tensile strength test results

SplittensileresultforM4(70%replacementofCAbyRA)

8. DISCUSSION

This chapter deals with the discussion of results and conclusionoftheproject.

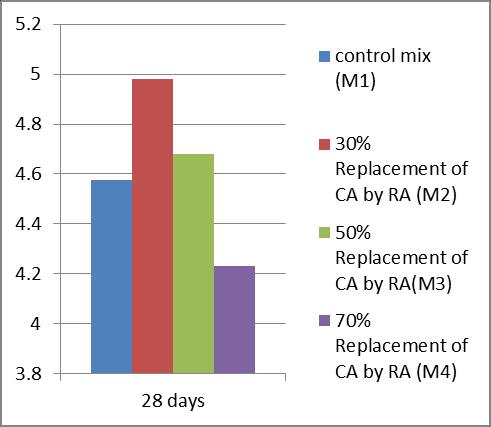

Splittensilestrengthtestresults

Chartshowingthecomparativesplittensilestrengthof variousmixesat28days

Incaseofthistest,thehighestsplittensilestrengthafter28 days isobservedin M2whereasthelowestisobserved in M4.Consideringthestrengthfactor,theaboveexperimental investigationshowsthatitisveryadvisabletoadoptM2as the strength for M2 is relatively higher than other mixes. Unsurprisingly,M4performsthepoorestintermsofallthe strengthsmentionedaboveanditisnotadvisabletouse.

9. CONCLUSION

The results indicated that the compressive strength of recycle aggregate is found to be less than the natural aggregate. With the judicious analysis done, the following conclusionswerearrived:

The compressive strength test showed that the compressivestrengthat3,7and28daysishighest for M2 (i.e. when 30% of coarse aggregate is replaced by recycled aggregate) followed by M1(control mix), M3(50% replacement of coarse aggregate by recycled aggregate) and M4(70% replacement of coarse aggregate by recycled aggregate)exceptforthe7daystrengthwherethe compressivestrengthofM3andM4isgreaterthan M1.

Thesplittensiletestshowedthatthehighestsplit tensile strength after 28 days is observed in M2 whereasthelowestisobservedinM4.

Considering the strength factor, the above experimental investigation shows that it is very advisable to adopt M2 as the strength for M2 is relativelyhigherthanothermixes.

Unsurprisingly,M4performsthepoorestintermsof all the strengths mentioned above and it is not advisabletouse.

Theoptimummixpercentageisfoundtobe30%.

Thematerialcanbeusedforalltypesofstructures wherenormalconcreteisused.

REFERENCES

a) Indian standards method of physical test for hydrauliccementIS4031Part2.

b) Indian standards methods of tests for aggregates for concrete, IS 2386(Part 2) of IndianstandardNewDelhi.

c) Standardtestmethodforelectricalindicationof concrete’s ability to resist chloride ion penetration,ASTMC1202.

d) Standardtestmethodoftestforsamplingand testingforchlorideioninconcreteandconcrete rawmaterials,AASHTOT259.

e) Standard test method for measurement of water by hydraulic- cement concretes, ASTM C1585-13.

f) Hand book on concrete mix design, sp: 231982,BureauofIndianstandards,NewDelhi.

g) Indianstandardcodeforplainandreinforced concrete, IS 456:2000, Bureau of Indian standardsNewDelhi.

h) Indian standards methods of tests for aggregates for concrete, IS 2386(Part 3) of IndianstandardNewDelhi.

i) Indianstandardsmethodoftestsforstrengthof concrete, IS 516:1959, Bureau of Indian standardNewDelhi.

j) Indianstandardsonrecommendedguidelines forconcretemixdesign,IS10262:2009,Bureau ofIndianstandardsNewDelhi.

k) Mohan Raj.R, Vasantha Prabhu.R, Rajnith.N, Suresh.P, experimental study of partial replacement of fine aggregate by bore sand.(2015)

BIOGRAPHIES

SABUNAM CHETTRI is a Civil EngineerfromtheAnnaUniversity. Her academic record is very impressive and good. She is very hardworkingandintelligent.

AAQIB FORDOUS is a Civil EngineerfromtheAnnaUniversity. His latest paper was “Design and analysisof4in1schoolcomplex” publishedinIRJET.