Abstract – The present works were done by Partially replace fine aggregate by bottom ash in certain varying percentage. The bottom ash which is a waste material of coal firing thermal power plant were used it was taken from BML (Brahmaputra Metallic Limited), Gola of Ramgarh district in Jharkhand India To find the optimumpercentage of bottom ash, and to find the strength behaviour of different composition of mix. 36-nos concrete cubes were tested for 7 and 28 days of curing. The results obtained were found that in certain amount of replacement the strength were first increased after 15% replacement of bottom ash with fine aggregate the results were showing reduction in strength like compressive, split tensile&flexurestrengthwerecalculate and was found negative strength when mix was increased.

Key Words: Bottom ash, cement, fine aggregate, Compressive strength, flexural.

1.INTRODUCTION

Concrete has been used as a major construction material eversinceitsinception.Thepossibilityofusingsolidwastes inconcretehasreceivedincreasingattentioninrecentyears as a promising solution to the rising solid waste problem. Production of concrete and utilization of concrete has rapidlyincreased,whichresultsinincreasedconsumptionof natural aggregate and sand. Aggregate is one of the main ingredientsinproducingconcretewhichcovers75%ofthe totalforanyconcretemix.Strengthofconcreteproducedis dependent on the properties of aggregates used Conventionally concrete is mixture of cement, sand and aggregate.TheuseofBottomashcanbethesubstitutefor fineaggregateincertainpercentageofreplacementinmix design.

1.1 Methodology

In this study locally available sand, cement and coarse aggregateareusedforpreparationofconcrete.Hereused bottom ash and replace it with a fine aggregate in some different percentage. Concrete cubes were made using mixtureof20mmand10mmofcoarseaggregateandpartial replacement of sand by 0%. 10%, 20%, 30%, 40% ,50%,60%,70%,80%,90%,and100%ofbottomash.

1.2 Materials

Bottom ash is a by-product of burning coal at thermal powerplants.Bottomashparticlesaremuchcloserthanthe fly ash.It is a coarse, angular material of porous surface texturepredominantlysandsized.Thismaterialiscomposed ofsilica,alumina,andsulfategrainsizestypicallyrangefrom finesandtogravelinsize.Chemicalcompositionofbottom ashissimilartoflyashbuttypicallycontaingreaterquantity ofcarbon Sandstonerawbottomashisagranularmaterial thatconsistsofamixofinertmaterialssuchassand,stone, glass, porcelain metals and ash from burnt materials. OrdinarySandfromTatisilwai(dist.Ranchi)hasbeenused. Thepropertiesofthesandhavebeenobtainedfromthetests carriedoutinthestructurelaboratoryofC.I.TRanchiasper specificationlaiddowninIS-383:1970.Thesandretainedon 4.75mmsievewas4.8andon10mmitwasfoundwas0%.

1.3 Literature review

R.G.DSouza(2017)HadconcludedthatBottomashisused asconcreteaggregateorforseveralothercivilengineering applicationswheresand,gravelandcrushedstoneareused. In his work M20, M 30 and M30 grade of concrete is considered for the experimental investigation. Fine aggregateisfullyreplacedtill100%percentageofbottom ash. Comparative result of workability and compressive strength of conventional concrete cube and bottom ash added concrete cube are reported. From the results it is concludedthatbottom-ashcanbeusedasareplacementfor fineaggregate.Theresultsprovedthatthereplacementof 100% of fine aggregate by bottom-ash achieved higher compressivestrength.

Shambalid Ahadyet.all(2016):Inhisworkshefoundthat the Bottom ash can be replacement of fine aggregates in concreteandtheinvestigationontheuseofbottomashhas been very limited. It gives an overview of the various literatureandexperimentalinvestigationsbeencarriedout by many researchers to study the use of bottom ash as aggregatesinconcrete.

JawaharS.et.all,(2017):Theengineeringandconstruction industry has faced many challenge for consuming, “Sustainablegreenandrecycledproducts”inmanufactureof concrete.CoalBottomAsh(CBA)hasthepotentialtobeused

‘‘Experimental Study on Partial Replacement of Fine Aggregate by Bottom Ash in M30 Concrete’’Shahil Khan1 , Vikram Choudhary 2 , Ankit Kumar3, V.K.Badal4 1M.Tech Scholar, Civil Engineering Department, CIT, Ranchi, Jharkhand, India 2,3,4 Assistant professor, Civil Engineering Department, CIT, Ranchi, Jharkhand, India

asconcretematerialsinplaceoffineaggregate.Bottomash isthedominantsolidresiduegeneratedinpowerstations.In thisstudy,experimentalinvestigationhasbeenconductedto assesstheperformanceofbottomashasfineaggregatewith variouspercentages(20%,40%,60%&100%)incement concrete subjected to chemical curing. The concrete specimenswerecastedandtestedforcompressivestrength and tensile strength at 7, 28 and 90 days. The functional properties like Sorptivity, Water Permeability, Rapid Chloride Penetration, Sulphate and Acid Resistance were testedon28,56and90daysoldspecimens.Itisobserved thatbottomashreplacementupto40%asfineaggregatein cementconcreteisdurable.

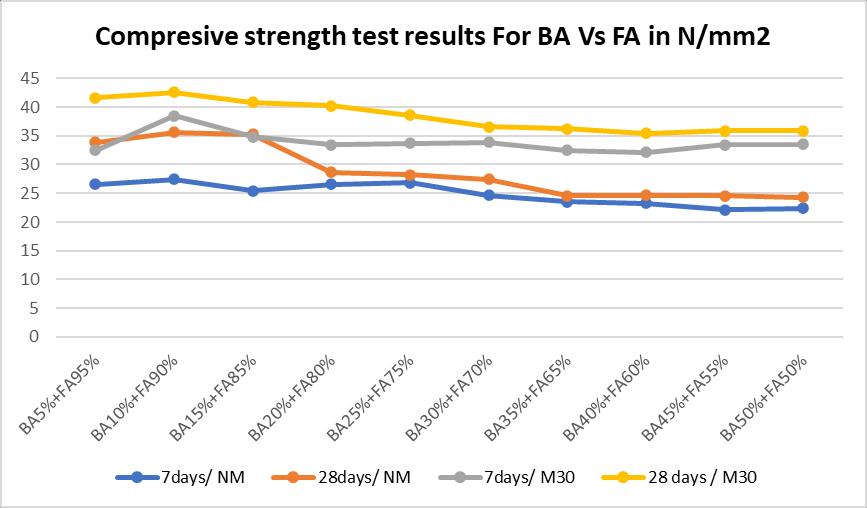

2. Compressive strength

The compressive strength is finding using 2000kN compression testing machine in accordance with IS: 5161959. The compressive strength test is conducted on 150 mm size of cube at 3, 7 and 28 days adopting wet curing process.Threecubespecimensweretestedforeachcuring periodfor 7and28dayscuringperiod.Atotalof36cube specimens were tested for compressive strength for each mixinthelabofCITRanchi.

Table -1: Compressive strength test results

forM30grade

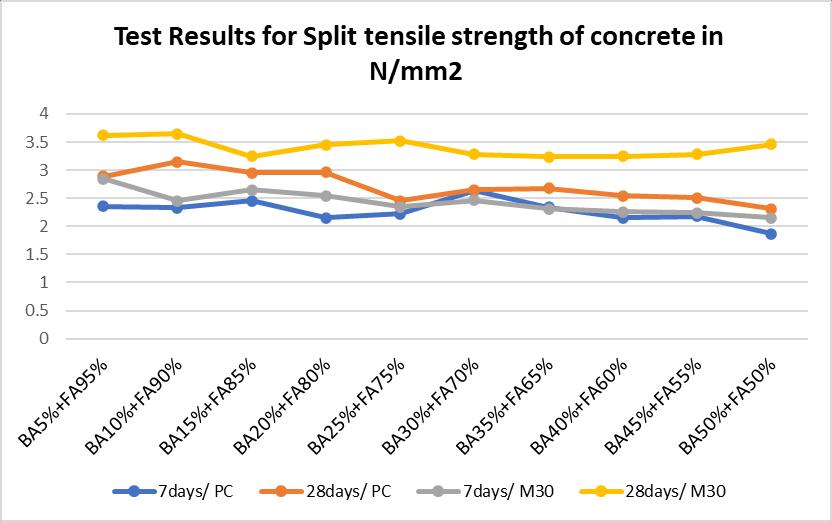

3. Split tensile strength

Thesplittensilestrengthofconcretewasdeterminedafter7 and28daysofcuringoncylindricalspecimensof150mm diameter x 300 mm height using 1000kN compression testingmachineaspertheproceduregiveninIS:5816-1999.

Table -2: TestResultsforSplittensilestrengthofconcrete

TestResultsforSplittensilestrengthofconcrete

S. NO % Replacement Splittensilestrengthofconcrete for Normal mix

Table -3: TestResultsforFlexurestrengthofconcrete

TestResultsforFlexurestrengthofconcrete

S. NO %Replacement TestResultsforFlexurestrength ofconcrete for

(PC) forM30grade

Chart-2. TestResultsforSplittensilestrengthofconcrete

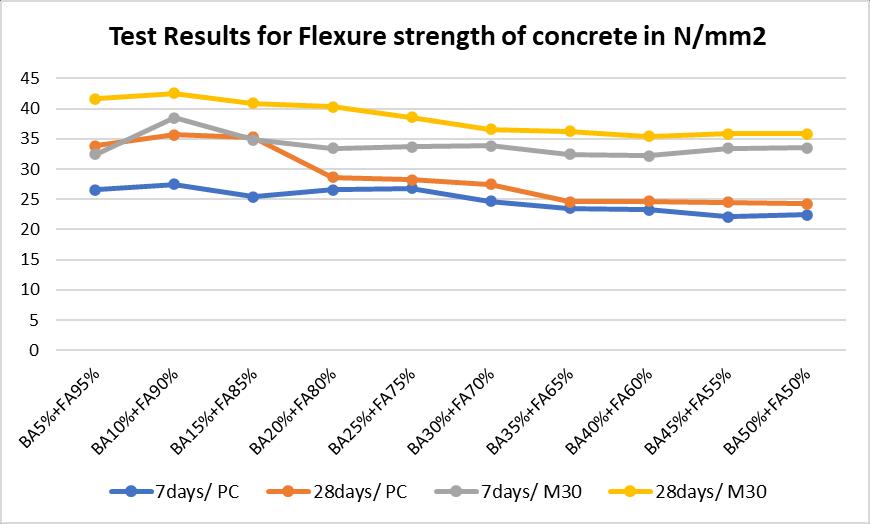

4. Flexural strength

ThistestwasperformedinaccordancewithIS:516-1959on prismsofsize100x100x500mmafter28daysofwater curingusing200KNuniversaltestingmachine

Chart-3. TestResultsforFlexurestrengthofconcrete

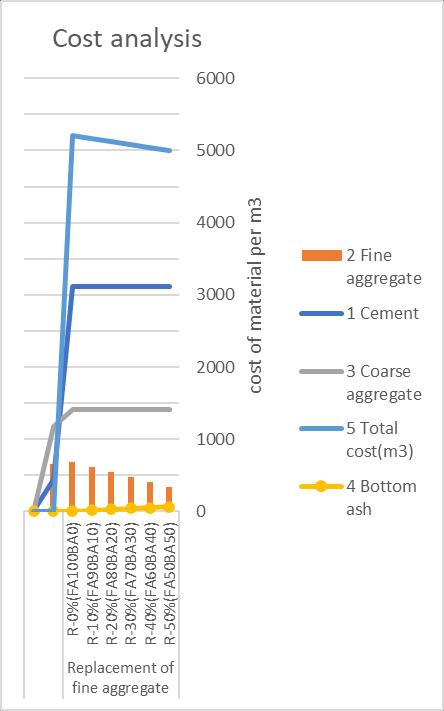

5. COST ANALYSIS

Thecomparisonofcostsregardingprojectbeforeandafter replacementoffineaggregatebybottomash.

Table -4: CostanalysisofReplacement-0%(FA100BA0)mix concretepercubicmeter

27.45N/mm2andfor28daysits35.65N/mm2.Similarly,for splittensilestrengthitsmaximumvalueis2.45N/mm2 for M30gradeat15%BAreplacementfor7daysalsoitisfound maximum value of 2.96 N/mm2 for 28 days. Similarly, FlexurestrengthforM30gradeat50%BAreplacementfor 7daysitisfoundmaximumvalueof2.85N/mm2 andfor28 daysits3.65N/mm2.Weseethatat10%replacementthe valuesismaximumvaluethatis3.65N/mm2

5. The challenge in making a lightweight concrete is decreasing the density while maintaining strength and withoutadverselyaffectingcost.

6. The bottom ash as aggregate and clay as cement in concrete can reduce the material cost in construction becauseofthelowcostanditsavailabilityisabundance.

7. Afterreplacementof50%offineaggregatebybottom ashinmixconcretethecostreduce5.3%permetercube

7. Scope

Thisprojectwasmainlyfocusedonthepartialreplacement of Fine aggregate with BA at different percentage in concrete. Researchmay be conductedonother properties and uses of BA in the near future to make this product a preciousbuildingmaterialtoimprovethequalityofbuilding construction industry. Other types of study that can be includedwithBAmaybelistedbelow;

o BAconcreteasanacousticbuildingstructure.

o ThechemicalattackonBAconcretestructure.

o The durability of BA concrete as an underwater structure.

o EarthquakeeffectonBAconcretestructureforlowcost building.

o BA concrete with plasticizer for higher grade of concrete. Mass utilization of waste' material in construction by using stone dust as a partial replacementmaterialforfineaggregatesinconcrete.

6. CONCLUSIONS

1. Specificgravityandbulkdensityofbottomashislessas comparedtothenaturalcoarseaggregate

2. Thepercentageabsorptionofwaterinbottomash(BA) ismoreascomparedtothenaturalandfineaggregate

3. The slump value of concrete as we increase the percentage of bottom ash firstly increases up to 10% and thendecreasesupto70%ofreplacements.

4. The various properties of hardened concrete that is compressive strength test, flexural strength test and split tensilestrengthtestdecreasesasweincreasethepercentage ofbottomash.ThecompressivestrengthForM30gradeat 10%BAreplacementfor7daysitisfoundmaximumvalueof

8. References

1. IS465-2000Codeofpracticeforplainandreinforced concrete.IS10262-2019isacomprehensivecodefor standardandhigh-performanceconcretemixdesigns.

2. Abubakar,A.U.,&Baharudin,K.S.(2012).Properties of concrete using tanjung bin power plant coal bottom ash and fly ash. International Journal of Sustainable Construction Engineering and Technology,3(2),56–69.

3. Aggarwal, Y., & Siddique, R. (2014). Microstructure and properties of concrete using bottom ash and waste foundry sand as partial replacement of fine aggregates.ConstructionandBuildingMaterials,54, 210–223.

4. Baite, E., Messan, A., Hannawi, K., Tsobnang, F., & Prince,W.(2016).Physicalandtransferpropertiesof mortarcontainingcoalbottomashaggregatesfrom Tefereyre (Niger). Construction and Building Materials,125,919–926

5. Ustainable Construction Engineering & Technology (ISSN:2180-3242)Vol3,Issue2,2012.

6. Abdulhameed Umar Abubakar, Khairul Salleh Baharudin Propertiesofconcreteusingtanjungbin power plant coal bottom ash and fly ashî International Journal of Sustainable Construction Engineering&Technology(ISSN:2180-3242)Vol3, Issue2,2012.

7. K. Soman, Divya Sasi and K.A. Abubaker, “Strength properties of concrete with partial replacement of sand by bottom ash”, International Journal of Innovative Research in Advanced Engineering (IJIRAE),ISSN:2349-2163,Volume1,Issue7,August 2014,pp.223-227.

8. RemyaRaju,MathewsM.PaulandK.A.Aboobacker, “StrengthPerformanceofConcreteusingBottomAsh asFineAggregate”,InternationalJournalofResearch inEngineering&Technology(IJRET),ISSN(e):23218843,ISSN(p):234.