International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 02 | Feb 2023 www.irjet.net p-ISSN:2395-0072

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 02 | Feb 2023 www.irjet.net p-ISSN:2395-0072

bAssistant Professor in the Department of Civil Engineering, , Rayat-Bahra University, Chandigarh,140103***

Abstract

Due to the poor economic outlook faced by transportation authorities, the demand for maximising preservation and rehabilitation procedures employed to maintain highway concrete and asphalt pavements has never been stronger. Many of the techniques for using conventional bonded and unbonded concrete overlays to protect and restore concrete andasphaltpavementshavealonghistoryofsuccess.Techniquesthatemploythinnerconcretecoveringswithcloserjoint spacing, however, are more recent. Both bonded and unbonded (directly applied) overlays are applied using these methods.Thesethinnerbondedandunbondedconcreteoverlays havebeenusedintheUSAformorethan15years,and field testing has shown their usefulness as a cost-effective way to prolong the life of concrete. life of damaged concrete, asphalt, and composite pavements. Typically, thin concrete overlays range in thickness from 4 to 7 in (100 to 175 mm). The overlay panels generally measure 6 by 6 feet (1.8 by 1.8 metres) or less. In order to give extended performance lifetimes of 15 to 20 years and to satisfy individual objectives, thin concrete overlays can be developed for a variety of trafficloads.Thinconcreteoverlaysthatarewell-designedandbuiltcanrequirelittlemaintenanceandhavelowlife-cycle costs. This essay offers an analysis of thin concrete overlay usage and experience in the US. Additionally, a number of recentcasestudiesareprovidedtoshowthebroadrangeofusesforthinconcreteoverlays.

Keywords: - Bonded concrete overlays, concrete, concrete inlays, concrete overlays, concrete pavements, pavement rehabilitation,unbondedconcreteoverlays

Concrete is a very common material used in construction. It has been in use for over a century now and there is no shortage of structures that have been built using concrete. The biggest challenge with concrete rehabilitation is the fact thatitrequiresstrengtheningandrepair,whichoftenrequiresalotofeffortandmoney.Amongdifferentapproachesthat can be considered for concrete rehabilitation, overlays are often the most economical alternative. Overlays are used to extend the life of a concrete structure by restoring a smooth sound surface and/or its original load-carrying capacity. In somecases,theycanalsohelptoimprovetheload-carryingcapacityofaconcretestructurebyincreasingitsthickness.

Overlays are particularly suitable in the case of structures with large surface areas, where it can be either poured or sprayed, example pavements, bridge decks, walls and tunnels. Overlaying slabs is a common method for restoring worn out concrete. Overlaying a slab or pavement can be done to match the level of an adjacent slab, replace deteriorated or contaminated concrete, improve the frictional characteristics of the surface for pavements or bridge decks, and restore architecturalfeaturessuchascolourortexture.

Applicationsofconcreteoverlaysincludethefollowing:

Overexistingasphaltpavements

Bondedoverlayofasphaltpavements

Unbonded(directlyplaced)overlayofasphaltpavements

Overexistingconcretepavements

Bondedoverlayofconcretepavements

Unbonded(separated)overlayofconcretepavements

Overexistingcompositepavements

Bondedoverlayofcompositepavements

Unbonded(directlyplaced)overlayofcompositepavements

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

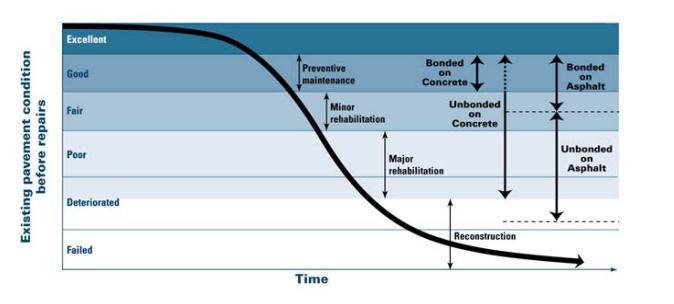

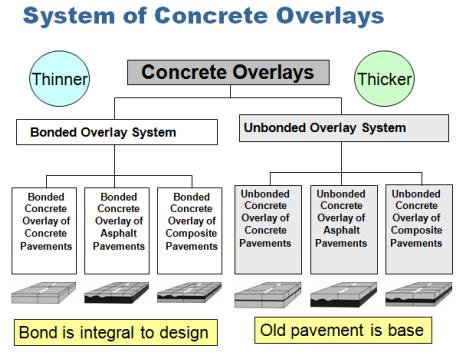

Figure 1 depicts the family of concrete overlays. Figure 2 provides a summary of the concrete overlays' application. As seen in Figure 2, existing pavements that are not substantially damaged can be effectively covered with thin concrete overlays.Unbondedconcreteoverlaysareincreasinglyacceptablewhenthequalityoftheoldpavementdeterioratessince theyrequirerelativelyminimalpre-overlayrehabilitation.Unbondedconcreteoverlaysarenormallythickerthanabout6 in.while bondedoverlays aretypically4to7in.(100to175mm)thick (150mm). However,asdiscussedinmoredetail below, good experience is being gained with the use of thinner, unbonded overlays that are 5 to 7 in. (125 to 175 mm) thick.

Thenormalthicknessofbondedoverlaysis4to6in(100to150mm).Theoverlaypanelsaregenerally6by6ft(1.8by 1.8 m) or smaller when bonded to a milled asphalt surface. Thin bonded AC pavement overlays are a more recent development. Even though several early test installations were built in the 1990s, it wasn't until the late 1990s that the method started to gain wider acceptance. The average in-service time for thin bonded overlays on AC pavement is thereforelessthan15years.However,theperformanceoftheseveralmilesofthinbondedoverlaysinnumerousUSStates suggeststhattheymayhaveaservicelifeofatleasttenyearsifdesignedandinstalledappropriately.

A composite pavement's use of thin bonded overlays must be carefully considered. Original concrete pavements with an asphaltconcrete(AC)overlayarereferredtoascompositepavements.Overtime,theoriginalconcretepavement'sseams andcrackstendtobecoveredbyreflectioncrackingintheACoverlay.Therefore,if thereisseverereflectioncrackingin thecompositepavementandthereisasignificantvolumeoftrucktraffic,thereisastrongpossibilityforthedevelopment of reflection cracking in the concrete overlay of the composite pavement. A bonded overlay may still be an option if the reflectioncrackinginthecompositepavementisnotseverebyemployingbentsteelbarstocoverthecracks.

The results of thin bonded overlays applied to existing concrete pavements have been inconsistent. These overlays are intended to cover any surface flaws in an existing concrete pavement, boost structural strength, and enhance surface friction,noise,andrideabilityforhighwayapplications.Theirthicknessrangesfrom2to4in.(50to100mm).Thebonded concrete overlay's joint spacing is the same as the overlay's joint spacing. When existing concrete pavements are still in good structural condition with just little surface deterioration, bonded overlays are typically employed to improve the structural capacity of those pavements. When properly built, these overlays last 15 to 20 years and offer good service. These overlays can, however, display early failures, often joint corner delamination leading to cracking in the overlay, sincetheyaresosensitivetoexistingpavementsurfacepreparation,curing,andjointsawingprocedures.The stateofthe existingpavementwasrestoredinoneofthecasestudiesinthisstudybyapplyinganovelthinbondedconcreteoverlay inlaystyleoveradeterioratedconcretepavement.

Unbondedoverlays,referredtoalsoasdirectlyplacedoverlays,areoftwotypes:

Conventionallythickoverlays,6in.(150mm)orthicker,arefull-widthandhavetransversejointspacingof12to15 ft.(3.7to4.6m).

Thinneroverlaysare4to6in.Theoverlaypanelsaregenerally6by6foot(1.8by1.8m)insizeand(100to150mm) thick. This use is a modification of AC pavements' thin bonded concrete overlays. The use of an unbonded overlay overacompositepavementinMichiganisdescribedinoneofthecasestudiesinthisstudy.

Unbonded overlays are often installed over an asphalt concrete surface, either over an existing asphalt pavement, over an asphalt interlayer installed over an existing concrete pavement, or over the AC surface of a composite pavement, depending on the kind and thickness of the existing pavement. An interlayer is necessary for effective utilisationwhenutilisedoverpre-existingconcreteorcompositepavements.

Theinterlayer'sfunctionistoisolateoverlayfromexistingpavement

Preventreflectioncracking

Preventbonding/mechanicalinterlocking

Providelevelsurfaceforoverlayconstruction

Provideasofterinterlayer–fewercurlingstresses

Typically, a 1 to 2 in. (25 to 50 mm) thick layer of densely graded hot mix asphalt concrete is utilised as the interlayer (HMAC). Studies are being conducted to assess the usage of thicker geotextile fabric as the interlayer material, as was addressedinthisstudy.ThisapplicationisbasedontheGermancustomofseparatinga cement-treatedfoundationfrom theconcreteslabfornewbuildingwitha0.2in.(5mm)thickgeo-fabric.ThisideaisbeingusedbyUSresearcherstostudy

International Research Journal of Engineering and Technology (IRJET) e-ISSN:2395-0056

Volume: 10 Issue: 02 | Feb 2023 www.irjet.net p-ISSN:2395-0072

thin, unbonded concrete coverings. A project that employed a thin geo-fabric as a separating layer for a thin unbonded overlaywasbuiltinMissouriin20085.Oneofthecaseexamplesinthisstudyisthisundertaking.

Thefollowingarekeydesignandconstructionconsiderationsforuseofthinconcreteoverlays:

Overlaytype:Plainconcrete

Jointing:

Exceptforbondedoverlaysofpre-existingconcretepavements,thesuggestedjointspacingis6by6ft(1.8by1.8 m)foroverlaythicknessesof4to6in(100to150mm).Theoverlayjointspacingforbondedoverlaysofjointed concrete pavements must match the joint spacing of the existing concrete pavement. The longitudinal joints in bonded overlays ofcontinuouslyreinforced concretepavement(CRCP)must matchthelongitudinal jointsinthe CRCP.However,bondedconcreteoverlaysofCRCPdonotoffertransversejoints.

To guarantee that the overlay concrete won't prevent the bonded overlay system from expanding during warm days, joint sawing for bonded overlays of jointed concrete pavement must be full depth of the as-constructed overlayplus12in.(12mm).

Foroverlaysthatarelessthan8in.(200mm)thick,dowelbarsarenotutilisedattransversejoints. Alongexternallongitudinaljoints,tie-barsareanoption.Thelongitudinaljointsmusthaveties-bars,accordingto theColoradoDOT.ThecustominMichiganisnottoemploytiebars.

Concretemixture

Concreteusedissimilartothatusedforconventionalconcretepaving. Useofsmallermaximumaggregatesizeforthinoverlays. Rapidsettingconcretemaybeusedifneeded.

Concreteplacement

Similartoconventionalconcretepaving-slipformorfixed-formconstructionmaybeused

Propercuringandjointsawingareverycriticalforthinoverlays

Surfacerequirements(rideandtexture):similartoconventionalconcretepavement.

Aswasmentioned,thinconcreteoverlaysthatwereproperlyplannedandbuilthaveworkedeffectivelyintheUS.Thisis basedonobservations madeoverthecourseof the past15yearsintheUS.Earlyimplementations ofthistechniquesaw certain difficulties, particularly when so-called ultra-thin concrete overlays were used, as the design and construction criteriawerenotclearlyspecifiedorunderstood.Thefollowingdistressesmaybepresentinthinconcreteoverlayfailure:

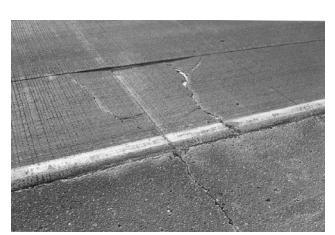

Panelcracking,asshowninFigure3.

Paneldelamination(andsubsequentcracking)forbondedoverlays

Panelrocking

ACstrippingandlossofsupportundertheoverlay

Panelsettlement,alsoshowninFigure3.

Roughness

Forconcreteoverlaysthatare4to6in.(100to150mm)thick,theexpectedservicelifeis15to20years.Itisanticipated thatthethinconcreteoverlayswillbemadetohavealongerservicelifeasmoreperformancedatabecomesavailable.

Inordertoincreasetheservicelifeofcurrentconcreteandasphaltpavements, thickerunbondedconcreteoverlayshave beenappliedoften.Althoughthinnerbondedconcreteoverlaysofconcretepavementshavealonghistory,thetechnology has traditionally been utilised to reinforce pavements that are in good condition. The design and construction processes are being improved upon and becoming more well-established, and the thin bonded overlays of AC pavements are establishingstrongservicerecords.Casestudiesofthefollowingcreativeprojectsareprovidedtodemonstrate howthin concreteoverlayscanbeusedinavarietyofsettings.

ThinbondedinlayofadeterioratedconcretepavementinKansas.

Missouri's deteriorating concrete pavement with a thin, unbonded overlay. Instead of a typical AC interlayer, a geotextileinterlayerwasemployedinthisproject.

ThinunbondedoverlayofadeterioratedcompositepavementinMichigan.

BondedOverlayon15thStreetinDelCity,Oklahoma

BondedOverlayonIowa3EastofHampton,Iowa

In2008,athinbondedinlaywasbuiltbesideI-35inJohnsonCounty,Kansas.Thecurrentconcretepavementwasbuiltin 1985 and is made up of a 4 in. (100 mm) thick cement treated foundation and a jointed reinforced concrete pavement (JRCP)thatis9in.(225mm)thick.JRCPjointswereseparatedby30feet(9.1m).JointdistresswasvisibleintheJRCPas surfacespallsthatwereseveralinchesbroadandabout2inches(20mm)deep.Thesand/cementmortarintheconcrete was failing due to a weak entrained air system, as can be seen visually from the spalls. Figure 4 depicts the state of the existing pavement. Only an infrequent limestone aggregate appeared to be impacted by "D-cracking," and the coarse limestoneaggregate wasdiscoveredtoremainintact. Wire meshwasusedto strengthen the JRCP, andit waspositioned 2.25to4.5inches(57to114mm)belowthesurface.Thepredictedconcreteflexuralstrengthwas680psi(4.7MPa).Fulldepthrepairofcertainseamswasdonebeforethesurfacewasmilledfor2inches,shot-blasted,andthenacementslurry (3partswaterto1partcement)wasusedbeforea2inch(50mm)thickplainconcreteinlaywasapplied.Figure5depicts the application of the slurry and the placing of the concrete. Over the already-existing joints, joints were sawed into the inlay. Full depth + 0.5 inches was the sawcut depth (12.5 mm). The entire job had to be finished in 10 weeks by the contractor. The inlay implantation was permitted across four weekends. The pavement may be opened to construction trafficat340 psi(2.3MPa) flexural strengthor 1800psi(12.4MPa)compressivestrength,accordingtothe construction standard. The inlay was ground with diamonds. The concrete inlay is functioning effectively about 18 months after construction.Therewerenofailuresatyoungages.AccordingtotheKansasDOT,theinlaywillatleastadd15yearstothe currentpavement'susefullife.

InMissouri in 2008,a geotextilecloth wasusedasan interlayerina thin,revolutionaryunbondedconcrete overlay.The 3.13-mile(5-kilometer)longprojectissituatedbetweenRoutes150and58alongastretchofRouteDinJacksonCounty. Thecurrentjointedconcretepavement,whichis30feet(9.1metres)apartand8inches(200mm)thick,wasbuiltin1986. Attransversejoints,one-inch(25mm)dowelbarswereemployed.TheMissouriDOT(MoDOT)anticipatedthatupto25% ofthepavementareawouldneedfull-depthrepairpriortoatypicalACoverlayasof2008sincethepavementsectionwas showingsevereD-crackingalongbothtransverseandlongitudinal joints.Figure6 depicts thestate ofthepavementasit standsrightnow.

TheMoDOTlookedatanumberofoptionsforrepairingtheRouteDpavement.Theseoptionsincludednewconstruction utilisingACand PCC,traditional unbonded overlaythat was8in. thick (200mm),andrubble witha 12 in.(300mm)AC overlay.Consideringanexperimentalthinunbondedconcreteoverlayusinganon-wovengeotextilefabricasaninterlayer in place of a typical AC interlayer was determined after negotiations between MoDOT and the industry. The concrete overlaydesignthatwascreatedcalledfortheusageof6ftby6ft(1.8by1.8m)panelswithanunbondedconcreteoverlay thatwas5in.(12.5mm)thick.Theshoulderswerechosentohavethesamedesign. TheGermanpractiseofemployinga geotextile cloth as an interlayer is expanded upon by this method of using one. The shoulders were chosen to have the same design. This method of employing a geotextile fabric as an interlayer is an expansion of the German practise of separating concrete from a foundation that has been treated with cement using a geotextile fabric that is 0.2 in. (5 mm) thick. Due to the cushioning effect of the 0.2 in. (5 mm) thick fabric, the Germans have successfully employed this applicationtominimisecurlingstrainsandremovebondingbetweentheconcreteandcementtreatedsubstrate.Forthis project,twononwovengeotextileswereused.ThesewereproducedbyPropexunderthenamesGeotex1201andGeotex 1601. These geotextiles were somewhat thinner than the 0.2 in. (5 mm) geotextile fabric used in Germany for new concreteconstruction.

Theoverlayconstructionstepsincludedthefollowing:

Pre-overlayrepairs–someoftheseverelydeterioratejointareaswerepatchedusingflowableconcrete. Fabricplacement-AsseeninFigure6,thegeotextilematerialwasdelivered totheprojectin300ft(90m)rolls. Theclothwas4.6metres(15feet)wide.Theclothwaspositionedusingatelescopingforklift,asseeninFigure7. Thepavementwascoveredwithtworollsofgeotextile.

Fabricfastening–aHiltigaspoweredfasteningsystemwasusedtofastenthefabricontotheunderlyingconcrete pavement.

Concreteplacement-Beforetheconcretewasplaced,thegeotextilematerialwasdamp.AsindicatedinFigure8, concrete was laid using a typical slipform paver that was supported by the cloth directly. During the laying of concrete,therewerenoissueswiththegeotextilenoted.

Concretecuring–Acuringcompoundwasusedandappliedatahigherratethattypicallyusedfornewconcrete pavementconstruction.

Concretejointsawing–Jointsweresawedinatimelymannerandnoearlyageproblemswereobserved.

TheMoDOTispleasedwiththeinitialprojectresultsandwillcontinuetoassesstheoverlay'seffectivenessinthecoming years.Afteraround16monthsofuse,thethinunbondedoverlayisstillfunctioningeffectively.

InthecityofDetroit,onM-3(GratiotAvenue)betweenI-75andI-94,theMichiganDepartmentofTransportation(MDOT) MetroRegionoptedtoundertakeathinconcreteoverlaydemonstrationproject.Theprojectwas3.17mileslongandused around 198,000 square yards (165,000 square metres) of pavement. The hot mix asphalt concrete had been applied multipletimesovertheoriginalconcretepavement,whichwasputdownintheearly1900s.Aparkinglane,threethrough lanes going in each direction, and a shared centre turn lane make up the pavement's nine lanes. The presence of underlyingbrickpaversalongtheoutsideparkinglanewasfoundafteracheckoftheavailableblueprints.Thecomposite pavement's surface quality had gotten worse. The composite pavement's surface condition has substantially declined, necessitatingtherenovationoftheroad.Visualexaminationofthecompositepavementrevealedafewisolatedlocations with suspect foundation support. An AC overlay will often conform to the contour of the foundation below, making it simpletospotweakspots. Themagnitudeofanypossiblesupportissueswasimmediatelyassessedwhenthe surfaceAC milling was finished. The state of the composite pavement is seen in Figure 9. It was agreed to build a thin unbonded concrete overlay over the composite pavement with smaller 6 by 6 ft (1.8 by 1.8 m) panels after negotiations between MDOT and the industry. Very few composite pavements nationwide have undergone this kind of restoration. A crossfunctional team held six working meetings from October 2003 to April 2004 to create plans and guidelines for the deploymentofthispavementtreatment.

InAugust2004theprojectwasputouttobid.Thelowestofferwas$7,17,000,000.Fulldepthpatcheswereusedtorepair places with the weakest foundation support, which are generally near inlets, whereas partial depth removal of concrete withhand-patchedasphaltorreplacementofconcretewasusedtorestoreregionswithlessseveredegradation.Inorder to preserve curb depth and cross-slope, an asphalt milling depth of 5 in. (12.5 mm) was developed. 350 manhole structures were present in the composite pavement, and they were separated from the pavement using a 5 ft (1.5 m) diametercoredrill.EachstepofthecoreholdingthemanholecastingwasremovedbeforemachiningtheACsurfacelayer. Beforeplacingtheconcrete,thecastingsweremodifiedtothenewpavementgrade.A4in.(100mm)concreteoverlayis applied after the AC surface layer has been cold milled. A 4 in. (100 mm) concrete overlay was put over a 1 in. (25 mm) asphalt separator layer after cold milling the AC top layer. This project also included the construction of experimental sections with two different asphalt separator mixtures and sealed vs unsealed seams. The slab panels had a maximum dimension of 6 by 6 ft (1.8 by 1.8 m) and were 6 in. (150 mm) thick. The majority of the work was started in 2005 and finished in the late fall or early part of that year. Full-depth repair and median strengthening are shown in Figure 10 as pre-overlayactions.Figure11illustrateshowtolayanACinterlayertoprovidealevelandconsistentsurfaceforpouring concrete. As seen in Figure 11, concrete was poured using slipform paving. The MDOT Metro Region has planned future demonstration projects since it is pleased with the results of the inaugural initiative. After more than three years of operation,theunbondedoverlayisstilloperatingwell.

4.4

InFelton,Delaware,aportionofUS13wasbuiltusingathin,bondedinlayofanexistingACpavementinNovember2009. Thejobentailedputtinga6in.(150mm)thickbondedinlayaftermachininga6in.(150mm)sectionoftheouterlane.A small number of pre-overlay tasks were completed to patch up holes and fill fractures in the existing AC pavement. The overlay concrete had to reach compressive strength of 2,000 psi (13.8 MPa) in 12 hours to allow opening to traffic the following day. The panel measurements for the inlay were 6 by 6 foot (1.8 by 1.8 m). Figure 13 depicts the milled AC pavementpriortotheapplicationofanoverlay.thelocationoftheconcreteinlayandtheinlayjointsawingareshownin Figure14.

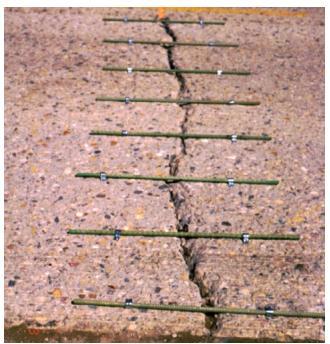

As a result of the opening of a liquid fertiliser factory near the western edge of Hampton, the Iowa Department of Transportation (Iowa DOT) built a 3 in. thick, 1.8 mi. long COC-B overlay on Iowa 3, a state major route, in September 1994.IowaDOT-sponsoredresearchwiththegoalsofmeasuringtherateofbondstrengthdevelopmentbetweenconcrete overlays and existing pavements and evaluating non-destructive testing techniques for estimating concrete strength includesdocumentationofthisproject(Cable1995).Theoriginal10in.thickconcretepavementwith10ftwidegranular shouldershadbeenbuiltin1969.Beforeapplyingtheoverlay,therewassomemildspallingatthecentrelinejoint(Figure 15). In1994,theoverlaywasbuiltonelaneatatimewhilebeingdrivenonbypilotvehicles.Utilizing36-inch-long,epoxycoated, deformed No. 5 reinforcing bars to delay reflection cracking of mid-slab nonworking transverse fractures was a novel element of the overlay. Prior to the installation of the overlay, the bars were fastened to 42 crack areas in the existingpavementsurface,asillustratedinFigure16.Eventhoughreflectivecrackingdidhappen,thesefissureswerejust hair-thin. Figure 17 shows that as of 2021, the COC-B overlay is in good shape after 27 years of operation, with the exceptionofa0.25miportionFigure18.Themildspallingthatwasfirstseeninthecentrelinejointoftheoldpavement in 1994hasnowbeenmirroredintotheoverlayandhasbecomemoresevereatthewestendoftheoverlay.

DelCity,Oklahomabuilta3in.thickbondedasphaltoverlayoveranexisting7in.thickconcretepavementthatwasbuilt inthe1970sinthefallof1994.Theprojectwaslocatedona1.25milongsectionofcommuterroute15thStreet. The3in. thickasphaltoverlaywascold-milledandreplacedwitha3in.thickCOC-Boverlaybythecityin2003.Atthattime,15th Streetsawabout7,500dailyvehicles,with5%ofthembeingtrucks.Figure19 depictstheexistingasphaltsurfacebefore milling,andFigure20 depictstheexistingconcretepavementfollowingthemillingoftheasphaltsurface.Asphaltwasalso milled in the curb and gutter portions to match the slope of the existing gutters Figure 20 Any residual asphalt was manuallyremovedafterthecold-millingoftheasphalt,andnon-stablepanelswereremovedbydoingfull-depthconcrete patchrepairsatcertainspots.Shotblastingwasusedtoconsiderablyroughenthesurfaceofthemilledconcreteinorder to remove any microcracking that may have resulted from the milling process and to improve bonding. As illustrated in Figure 21, many No. 5 reinforcing bars with U-shaped bends were secured over nonworking longitudinal fissures in the pre-existingconcrete.After15years,thefractureareaswereexamined,andtightcracksintheoverlaywerenoted.Figure 22depictstheCOC-Boverlay'sstatein2020.

Conclusion

The restoration of old asphalt, concrete, and composite pavements can be accomplished cost-effectively by using thin concrete overlays, as was detailed in this work. The case studies that are provided show the wide range of uses for thin concreteoverlays.Theseapplicationsaretheresultofwiseengineeringchoicesandadrivetokeeplookingfornewways to develop and enhance current technology. The success of these cutting-edge applications will provide pavement engineers additional resources they can rely on to efficiently and affordably renovate old pavements. Thin concrete overlayshavethemajorbenefitofpreservingtheexistingpavement,whichdrasticallycutsdownonconstructiontimefor therestorationactivityandencouragessustainablerehabilitationmethods.

Reference

1. McGhee,K.M.1994.SynthesisofHighwayPractice204:PortlandCementConcreteResurfacing.NationalCooperative HighwayResearchProgram,Washington,DC.

2. Chen,D.H.,M.Won,X.Chen,andW.Zhou.2016.DesignimprovementstoenhancetheperformanceofthinandultrathinconcreteoverlaysinTexas.ConstructionandBuildingMaterials,Vol.116,pp.1–14.

3. Barman, M., and B. Hansen. 2018. Comparison of Performances of Structural Fibers and Development of a SpecificationforUsingTheminThinConcreteOverlays.MinnesotaDepartmentofTransportation,St.Paul,MN.

4. Bhattacharya, B., A. Gotlif, and M. Darter. 2017. Implementation of the Thin Bonded Concrete Overlay of Existing AsphaltPavementDesignProcedureintheAASHTOWarePavementMEDesignSoftware.96thAnnualMeetingofthe TransportationResearchBoard,January8–12,2018,Washington,DC

5. Burnham,T.2012.ImpactofSealedJointsonPerformanceofThinWhitetoppingatMnROAD.91stAnnualMeetingof theTransportationResearchBoard,January22–26,2012,Washington,DC.

6. Chen,D.H.,M.Won,X.Chen,andW.Zhou.2016.DesignimprovementstoenhancetheperformanceofthinandultrathinconcreteoverlaysinTexas.ConstructionandBuildingMaterials,Vol.116,pp.1–14.

7. Kannemeyer, L., B. Perrie, P. Strauss, and L. du Plessis. 2008. Ultra-Thin CRCP Development in South Africa. Ninth InternationalConferenceonConcretePavements,August17–21,2008,SanFrancisco,CA.pp.995–1018.

8. King, D., and J. Roesler. 2014. Structural Performance of Ultra-Thin Whitetopping on Illinois Roadways and Parking Lots.ResearchReportNo.FHWA-ICT-14-018.IllinoisCenterforTransportation,Urbana,IL.

9. Ryu,S.,M.Park,J.Nam,Z.An,J.Bae,Y.Cho,andS.Lee.2009.InitialBehaviorofThin-BondedContinuouslyReinforced ConcreteOverlay(CRCO)onAgedJointedConcretePavement.NewTechnologiesinConstructionandRehabilitationof PortlandCementConcretePavementandBridgeDeckPavement.American SocietyofCivilEngineers,Reston,VA.pp. 101–106.

10. Strauss,P.J.,B.D.Perrie,andD.Rossmann.2005.PerformanceofaThinCRCPInlayDesignedforaFiveYearLife:A CaseStudy.8thInternationalConferenceonConcretePavements,August14–18,2005,ColoradoSprings,CO.

11. Tayabji, S., A. Gisi, J. Blomberg, and D. DeGraaf. 2009. New Applications for Thin Concrete Overlays: Three Case Studies. Proceedings: National Conference on Preservation, Repair, and Rehabilitation of Concrete Pavements; St. Louis, Missouri, April 22–24, 2009. Concrete Pavement Technology Program, Federal Highway Administration, WashingtonDC.

12. Verhoeven,K.1989.ThinOverlayofSteelFiberReinforcedConcreteandContinuouslyReinforcedConcrete:State oftheArtinBelgium.FourthInternationalConferenceonConcretePavements,April18–20,1989,WestLafayette, IN.pp.205–219.

13. J.L. Granju Thin Bonded Overlays About the Role of Fiber Reinforcement on the Limitation of Their Debonding, AdvnCemBasMat1996;4:21-27.

14. K. H. MCGHEE AND CELIK 0ZYILDIRIM, Construction of a Thin-Bonded Portland Cement Concrete Overlay Using Accelerated Paving Techniques, Virginia Transportation Research Council, Box 3817 University Station, Charlottesville,Va.22903-0817.

15. WILLIAM H. TEMPLE, STEVEN L. CUMBAA, AND WILLIAM M. KING, JR., Design and construction of bonded fiber concreteoverlayofcontinuouslyreinforcedconcretepavement,transportationresearchrecord1335.

16. Emad Alshammari, Ahmed Alsabbagh, Nakin Suksawang and Salam Wtaife Improving Bond Strength of Bonded ConcreteOverlaybyAddingSyntheticDiscreteFibersInternationalJournalofTechnologyandEngineeringStudies volume8issue1pp.1-8.

17. ManikBarman,JulieM.VandenbosscheandZichangLi3,InfluenceofInterfaceBondonthePerformanceofBonded ConcreteOverlaysonAsphaltPavements,J.Transp.Eng.,PartB:Pavements,2017,143(3).

18. David W. Mokarem, Khaled A. Galal, and Michael M. Sprinke, Performance Evaluation of Bonded Concrete Pavement Overlays After 11 Years, Journal of the Transportation Research Board, No. 2005, Transportation ResearchBoardoftheNationalAcademies,Washington,D.C.,2007,pp.3

10.