Enrichment of the properties of Concrete mixes containing Reclaimed Asphalt Pavement (RAP) aggregates & Silica Fume – A Laboratory Investigation.

Ranjeet T. Bhosale1 , B. Manjula Devi21Post Graduate Student, Dept. of Civil Engineering Datta Meghe College of Engineering Airoli, Navi Mumbai-400708, India

2Assistant Professor, Dept. of Civil Engineering Datta Meghe College of Engineering Airoli, Navi Mumbai-400708, India ***

Abstract - During the recycling of flexible pavement, an enormous amount of Reclaimed Asphalt Pavement (RAP) aggregate accumulates, which is dumped legally and illegally in the surrounding communities, posing severalchallenges for agencies Utilization of these aggregates in cement concrete pavements seems to be a novelistic approach and could facilitate with many socio-economic-environmental benefits. In this study, conventional concrete is made using recycled aggregates with additional of micro silica as admixture in concrete. The concrete mix is designed for target strength of M40 MPa. Coarse aggregate were partially with RAP aggregate at 30 %, 45 % and 75%. The relative parameters influencing the strength of concrete were studied in terms of RAP aggregate and silica content respectively. Insomestudies the test results reveled concrete produced with 45% of RAP aggregate tend to reduce the strength by 15% whereas addition of silica fume up to (4-10%) enhances the strength comparable to control mix (M40). The addition of micro silica improves the physical and mechanical properties of concrete by micro filling the unreacted core. The significant reduction in compressive strength is noticed, when the RAP aggregate is increased beyond 30%

Key Words: Road construction, Reclaimed asphalt pavement, Cement concrete, Compressive strength, Silica fume,Review,Performance,Durabilityetc.

1. INTRODUCTION

As we know that Urbanization is growing in the present days,wherepeoplearelookingfor acomfortablelifewith safeshelterandwell-connectedroadsfortransportation.To meetthesebasicneedspeopleareheavilydependentonthe naturalresources.Mostofthereclaimedasphaltpavementis thrown or stored in landfills, destroying a bit more of the environmentbyincreasingpollution.Hence,RAPconcretes mixtures can be considered as the most economic and ecologicalmaterialsinasustainabledevelopmentcontext. Thus,standardisedtestsforconventionalconcretescanbe carried out to assess the mechanical properties of RAP concretes.Itshouldbenotedthattheexperimentalresults showed that RAP concretes are similar to conventional

concretesintermsofshearstressandshearratebehaviour. In order to improve the properties of concretes, many admixtures can be used. Reusing reclaimed asphalt pavementincementconcretesisstillanuncommonpractice, butitisaproceduretobeencouraged.Inthiscurrentproject weare goingtouseM40Gradeof concrete.M40Grade of Concreteispreparedbyusingdesignmix.MixdesignofM40 grade of concrete is as per IS Code 10262:2009. So, M40 signifies that the structure erectedwith thisgradeof concrete willhavea minimalstrengthof 40 N/mm2 after 28days.Thehigherthenumber,thestrongerthematerial. The fifth ingredient must be added to the concrete mix to improve certain properties both in plastic and hardened states.AddingSF(SilicaFume)modifiesthecharacteristics and the behaviour of fresh concretes and hardened concretes.Onceestablished,itenablesthepredictionofthe compressivestrengthofconcretewithdifferentRAPandSF contents,intheexploredfields.

ThereforeuseofSFinconcretestotallyorpartiallybyadding RAP aggregates in a concrete mix, experimental results reported that shown a significant increase in the compressive strength; even if the compressive strength decreaseswhenrecycledaggregatecontentincreasesinmix, byaddingsilicafumeisagoodwaytoimproveit.However, there may be need to produce concrete with a particular resultbyusingadmixtureandRAPaggregatescouldbemost convenientway.

1.1 Problem Statement

Thehugedevelopmentofurbanhighwaysandroadshasleft behind a great amount of wasted materials which is been replaced with new materials. One of these left behind materialsisasphaltpavement.ThemainusageofRAPisto befilledassub-basematerialatthereconstructionprocess orusethemasembankmentfillmaterial.Thedisintegration ofRAPbeneaththegroundtouchesaseriousenvironmental issue.TherecomestheapplicationofusingRAPaspartial replacementofnaturalcourseaggregateinconcretemix.

1.2 Project Objectives

1.To identifythe workabilityoffresh concretecontaining RecycledAsphaltPavement(RAP).

2. To determine the optimum replacement percentage of Recycled Asphalt Pavement (RAP) as coarse aggregate in concretemix.

3.Toinvestigatethecompressivestrengthofconcretemix containingRecycledAsphaltPavement(RAP)andcompareit with concrete mix containing 100% of natural coarse aggregate(thecontrol).

4. To investigate the effect of replacement of cement by Micro-SilicaonRAPaggregateconcrete.

5. To investigate the effect of replacement of cement by Micro-silica on fresh properties of Recycled Asphalt Pavementaggregateconcrete

6. To investigate the effect of Micro-silica on compressive strengthofconcrete.

1.3 Scope of Work

This study concentrated on the performance of a single gradation of RAP. The asphalt pavement samples were collectedfromThane-BelapurRoadnearGhansoliRailway Station and manually crushed into pieces in J.kumar LaboratoriesnearBKC toachieveauniformsizeof5mm-20 mm,whichisthemaximumaggregatesizeinthemixdesign. All the RAP samples are chosen in Laboratory of J. kumar infraprojects,toavoidanyinconsistentpropertiesthatmay arise by mixing materials from different sources. The propertiesofRAPfromotheroutsidewerenotincludedin this study. The selection of the aggregate and cube sizes weredeterminedaccordingtothecodesofpracticefromIS Code 10262:2009. The study was conducted on concrete samplescontainingRAPincorporatedintoPortlandcement. TheinfluenceofusingRAPinhighstrengthconcretewasnot coveredinthepresentstudy.Thepercentagereplacements arelimitedtothreelevels:30,45and70%replacementof naturalcoarseaggregate.Thedifferenteffects,whichcanbe observedatdifferentpercentagesofreplacements,willbe comparedinthepresentstudy.Sothescopeofstudycanbe followas;

1. Design of RAP Concrete mix with 7, 14 & 28 days characteristicstrengthofconcreteof40N/mm2

2. Use different percentages of RAP as coarse aggregate replacement: 30%,45%and75%

3.FreshconcretetestusingSlumptesttoidentifyconcrete workability.

4. Hardened concrete test using Compressive test to determineconcretecompressivestrength.

2. LITERATURE SURVEY

SolomonDebbarma,M.Selvam,SurenderSingh–Canflexible pavements’ waste (Rap) be utilized in cement concrete pavements? A critical review – This paper focuses on Reclaimed Asphalt Pavement (Rap) aggregates prediction using flexible pavements in concrete mixes with a specific implementationofthePerformance&DurabilityApproach. Asaresult,thispaperpresentsacomprehensiveandcritical analysisofthesuitabilityofRAPforconcretemixproduction. In addition, it identifies the various gaps that need to be addressedtomakepavementsmoresustainable.[1]

M.N. Balakrishna, Fouad Mohamad, Robert Evans, M.M. Rahman–DurabilityofConcretewithdifferentialConcrete MixDesign–Theaimofthepresentresearchwastoexamine theinfluenceofuni-directionalexposureofconcretecubesto waterabsorptiontoevaluatedifferentmixturesproportion. Seventy-twoconcretecubeswithdifferentgradesofconcrete were prepared and evaluate the rate of absorption characteristicsinconcretemixturesdesign.[2]

M.T.Tiza1,O.N.Mogbo,E.C.Duweni3J.I.Asawa –Recycled Asphalt Pavement: A systematic Literature Review – This review paper aims to build an insight into the interaction betweennewandagedasphaltbindersinReclaimedAsphalt Pavement(RAP).Thisresearchexaminesthedifferencesin asphaltpropertieswhenReclaimedAsphaltPavement(RAP) is used as aggregate, and compares the result to natural aggregate.[3]

Rim Larbi, El Hadi Benyoussef, Meriem Morsli, Mahmoud Bensaibi, Abderrahim Bali1 –Improving the Compressive Strength of Reclaimed Asphalt Pavement Concretes with SilicaFume–Usingsilicafume(SF)asamineraladmixturein RAP concrete is the main objective of the present study.Experimental results show that SF increases the compressivestrengthofRAPconcreteaswellasconventional concretes.[4]

AnuragJain,Student,GHRCE,Nagpu,P.Y.Pawade,PhDHOD Dept.ofCivilEngineeringGHRCE,Nagpur–Characteristicsof Silica Fume Concrete – The paper describes the results of compressivestrengthtestsperformedonfourandsixyearold concrete cores obtained from well-documented field experiments using both silica-fume and non-silica fume concrete mixtures. An optimal silica-fume content was identifiedatwhichconcretestrengthincreasedsignificantly.. ThispaperdealswithaliteraturereviewonCharacteristicsof SilicaFumeConcrete.[5]

K. E. Hassan, J. J. Brooks and M. Erdman – The use of reclaimedasphaltpavement(RAP)aggregatesinconcrete–Thepaperpresentstheresultsofalaboratorytestofordinary Portland cement concrete made from reclaimed asphalt pavement(RAP)inplaceofnatural aggregates.Toachieve optimumperformance,RAPaggregateswerecombinedwith

concretebasedonmaximumpackingtoensureminimalvoids inthemixture.[6]

3. MATERIAL USED

3.1

Cement

In this study, Ordinary Portland Cement (OPC) 53 grade conforming IS 12269-2004 obtained from J. Kumar Laboratory(BKC).Physicalpropertiesofcementusedinthis studyaregiveninTable-1

Table -1: PhysicalpropertiesofOPC-53grade

Test Results

Consistency 32% (30-35%)

Soundness 2mm not more than 10mm

Initialsettingtime 40min – not less than 30min

Finalsettingtime 460min – 600min (max)asperIScode4031 part-5

Specificgravity

Fineness

3.12 ≤ 3.15

7% Sieveteston90μSieve as per {IS 4031 Part-1) < 10%

Compressive strength (28 days) 53N/mm2

3.2 Fine Sand (Crushed Sand)

Fineaggregateismadefromcrushedsand.AccordingtoIS 383-2004,thesandusedherebelongstozone-II.Physical propertiesoffineaggregateusedinthisstudyaregivenin Table-2

Table -2: PhysicalpropertiesofCrushedsand

3.3 Coarse Aggregate

Crushedstonepiecesofmaximumnominalsizeof20mm& 10mmdownwereusedascoarseaggregatesconfirmingtoIS 383-2004.Physicalpropertiesofcoarseaggregateusedin thisstudyaregiveninTable-3

Table -3: Physicalpropertiesofcoarseaggregate

Sr.No

3 Abrasion Value

shall not exceed 45% non-wearing surfaces, 30 percent for wearing surfaces

Foraggregates to be used in concrete for wearing surfaces not exceed30

4 Impact Value 27.0% shall not exceed 30 percent by weight for concrete for wearing surfaces

5 Water Absorption 20mm & 10mm

6 Combined Elongation and Flakiness Indices

3.4

(10mm)

PartIV

IS-2386 PartIV

IS-2386 PartIV

- IS-2386 PartIII

Not to exceed 30% % IS2386 PartI

Silica fume (Micro-silica) used in this study was procured from local chemical dealers confirming to IS 153882013.Physical and chemical properties of Micro-silica are giveninTable-4andTable-5respectively.

3.5 GGBS

Ground Granulated Blast-furnace Slag (GGBS) used in this work is the mixed slag from JSW Granulated Slag used forJSWSteelLtd.,GBSconformsto IS 12089:1987

3.6

3.6.1 Physical Properties of

Some of the physical and mechanical properties of aggregates usually include Specific gravity, Water absorption, Bulk density, Abrasion Resistance, crushing strength and Impact resistance etc., these are the major properties which help in assessing the quality of the aggregateswhicharebeingusedintheconcretemix.

Thedata providedin Table-8wastakenasanaverage by considering various available research data provided by differentresearchers.Thisdatahelpsustoassessthequality of the RAP aggregates in comparison with the available naturalaggregates.

An X-Ray Fluorescence Machine was used to test the chemical properties of cement and GGBS at the J.Kumar LaboratoryinBKC.

3.6.2 Chemical Properties OF RAP

RAPcontainsmineralaggregatesof93%to97%byweight and3%to7%ofhardenedasphaltcement.Incomparisonto thechemicalcompositionofnaturalaggregates,RAPhasa similarcomposition.

Table -9 ChemicalcompositionsofRAPaggregates

4.1 Methods of Testing

Aftercastingandcompaction,theconcretespecimens,itwas keptinthelaboratoryfor24hour.Afterthat,theyweredemouldedandcuredina fog room maintainedat20~ and 99% and placed in a curing tank, filled with water until testing for 7, 14 & 28 days. Then the specimens were removed from curing tank and tested immediately under CompressionTestingMachine/FlexuralTestingMachine.

4.1.1 Curing

Immediatelyaftermouldingthespecimens,thecubeswere storedinaplacewhereitisfreeofanyvibrationandinan environment which prevents loss of moisture. The cubes werestoredfor24hoursinroomtemperaturetoensurea relative humidity of higher than 90%. After that, the specimens were released from moulds and were cured in water in a curing tank before testing. This curing process ensured the continuous hydration of the specimen by maintaining the temperature and moisture. The curing process followed the method of normal curing of test specimens(20ºCmethods).Concretepropertiesimprove withageaslongasconditionswerefavourabletoobtainthe designedconcretestrength

4. RESEARCH METHODOLOGY

Here,wewilldiscussthemethodologyusedtoachievethe mainobjectivesofthestudy,aswellasthematerialsused (Water, Cement, Natural fine & coarse aggregate, Microsilica, GGBS, Admixture and RAP aggregates) used to be mixedintermtoformtheRecycledAsphaltPavement(RAP) concrete to bring out the scopes and aims of this study. Concrete testing (Slump test, Compression strength test, SplitTensilestrengthtest,FlexuralstrengthConcretetest, Water Permeability test, Rapid Chloride Permeability Testing of concrete of Recycled Asphalt Pavement (RAP) were accomplished, and applied at Concrete Testing Laboratory (RMC Plant) in J. Kumar Infra projects Ltd (Mumbai).ThematerialswereusedinthisstudyareOPC–53GradeCement,fine,andcoarseaggregate,water,Microsilica, GGBS, Admixtures and some % of Recycled Asphalt Pavement(RAP)ascomponentsofRAPconcrete.Therehas beennostandardmixdesignforRecycledAsphaltPavement (RAP)concretesincethismethodisanewbornmethod.The mixdesignwasbasedonsometrialmixingthatwascarried out 150 x 150 x 150mm cube test was used for determinationofcompressivestrength

4.1.2 Slump test

Themainpurposeofslumptestistodeterminethedegreeof workabilityforconcretemix.Thestrengthdependsonhow theconcreteisbeingpoured.Therefore,theconcretethatis to be used must be easily poured and compacted. Factors that affect the workability are the water content, size and shapeofaggregatesandthewatercementratio.Theconefor theslumptestasspecifiedIS:1199-1959hasaheightof12 in,abottomdiameterof8inchandatopdiameterof4inch. TheslumptesthasbeenperformedaccordingtoIS:11991959

4.1.3 Compressive Strength Test

Dependingonthesizeoftheaggregate,eithercubesof15cm x15cmx15cmor10cmx10cmx10cmareusedforcube

tests.Itiscommontousecubicalmoldsof15cmx15cmx 15cmformostoftheworks.Thesespecimensaretestedby compressiontestingmachineafter7,14dayscuringor28 daysofcuring.

4.1.4 Flexural Strength Test

N/mm2 or MPa is the unit of measurement for concrete's flexural strength The flexural strength of the concrete determinedaspertheIS516-1959standards.Thecastingof thebeamsaremadewiththeshapeofprism.Ingeneral,the beamsare150mmx150mmx700mminsize.

4.1.5 Split Tensile Test

Splitting tensile test isgenerally carried out to obtain the tensilestrengthofconcrete,andthestressfieldinthetestsis actuallyabiaxialstressfieldwithcompressivestressthree timesgreaterthanthetensilestress.Splittensilestrength testswereperformedaccordingtoIS5816-2004.

4.1.6 Rapid Chloride Permeability Test

RapidChloridePermeabilityTestEquipment(RCPT)isused to evaluate the resistance of concrete samples to the penetrationofchlorideions.Inthesamplecellscontaining 3.0%saltsolutionand0.3Nsodiumhydroxidesolutions,a 100 mm diameter concrete cylinder is placed. Across the endsofthesample,avoltageof60VDCismaintained.

4.1.7 Water Permeability Test

It is particularly important to check the permeability of cementmortarorconcreteinstructuresintendedtoretain or come into contact with water. Besides functional considerations,permeabilityisalsointimatelyconnectedto the durability of concrete, especially its resistance to progressivedeteriorationinsevereclimates.Itsresistanceto leachingcausedbyprolongedseepageofwater,particularly inthepresenceofaggressivegasesorminerals.

4.2. Mix Design

MixdesignforM40gradeofconcretewascarriedasperIS 456-2000.Allthematerialswereproportionedbyvolume batching method With proper dosage of Micro-silica, conventional concrete and concrete with recycled RAP aggregatecontentof30%,45%,&75%werecast.Aslump conetestwasconductedonthehomogenousconcretemix.

Based on these material properties, the Mix Design is preparedforMix1(75%RAP),Mix2(45%RAP)andMix3 (30% RAP). The proportions and details of the mix are calculatedusingtheIRC:44-2008method

Thecubespecimenswerecastusing150mmx150mmx 150mmmouldsfordeterminingthecompressivestrength andwaterpermeabilitytest.Cylindricalspecimens,150mm diameter x 300 mm height, were casted for split tensile strengthtest.Similarlyprismspecimens,700mmx150mm x 150 mm moulds for determining the Concrete flexural Beamstrengthtest.Theentirespecimenwerede-moulded after24hrsandthensubjectedtowatercuringunderroom temperature Enough specimens were cast to facilitate compressivestrengthtestsat7-days,14-days,and28-days asshowninTable-12.

5. RESULTS AND DISCUSSION

The following are the results of various tests such as the slump test, compression test, split tension test, flexural strength test, permeability test of concrete, and water penetrationtestofconventionalconcreteandconcretewith recycledRAPaggregatecontentof30%,45%,and75%were castwithappropriateMicro-silicadosages..Thecubeswere tested for7,14and28daysforeachtest.

Testsadoptedforthemeasurementoftheworkabilityofthe concretemixinthepresentinvestigationare,

1. Slump Test

2. Compacting Factor Test.

TheresultsofworkabilitytestsaretabulatedinTable-13

Table -13: MeasurementofWorkability

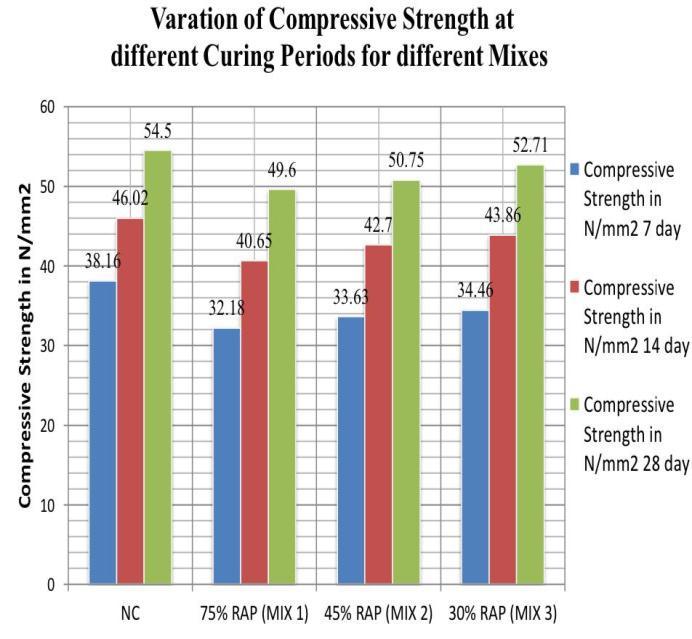

5.1.1 Discussion on Compressive Strength Results

Mix3isgivingmaximumstrengthof96.71%ofNCstrength, 52.71N/mm2whichisverynearertoNormalConcreteMix Strength for 28 days curing period. And also Mix 3 is showing good early strength of 34.46 N/mm2 for 7 day curing period, which is of 90.30% of strength gain with respecttoNCMix.

5.1 Compressive Strength Test

The cube specimens were tested in Compression Testing Machine(CTM)afterspecifiedcuringperiodfordifferent% ofRAPreplacement30%,45%and75%.Table-14showthe compressivestrengthsaftertherespectivecuringperiods

Table -14: CompressiveStrengthTestResultfor ReplacementofRAPAggregates%

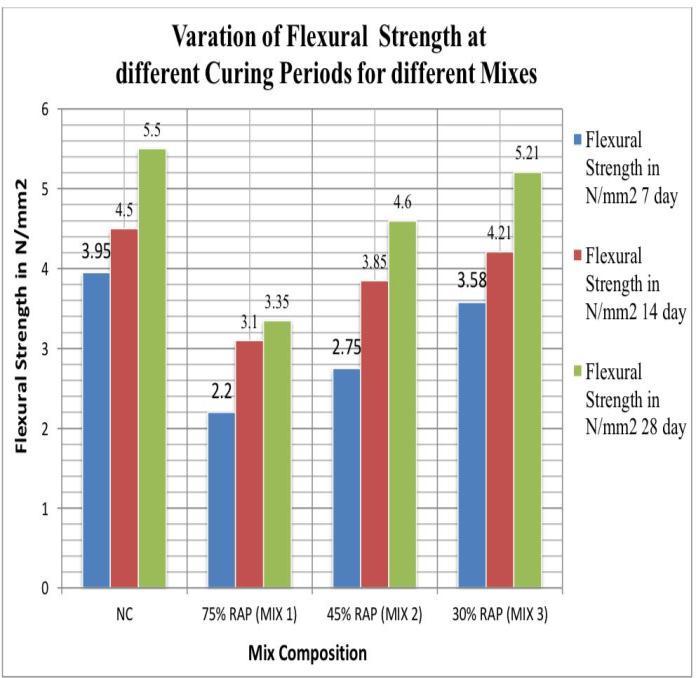

5.2 Flexural

Test

Testspecimenswereplacedinaflexuraltestingmachineand theflexuralstrengthwascalculatedbasedonthefailureplane position. Values obtained for concrete with different RAP replacement levels as note in Table -15 Concrete prisms (150X150X700mm) were used for the measurements of flexure strength in accordance with As per IS Code 516. A symmetricaltwo-pointloadwasappliedtotheprisms(atthe third point of the loaded span) the load was increased gradually with continuous monitoring of the mid-span deflectionuntilfailure.

5.2.1 Discussion on Flexural Strength Results

The results of flexural strength tests indicate that NC has higherflexuralstrengththandifferentreplacementlevelsof RAP.Mix3showshigherflexuralstrengthof5.21N/mm2for 28dayscuringperiod,whichisverynearer(94.72%ofNC Strength)tostrengthofNormalConcrete(5.50N/mm2)

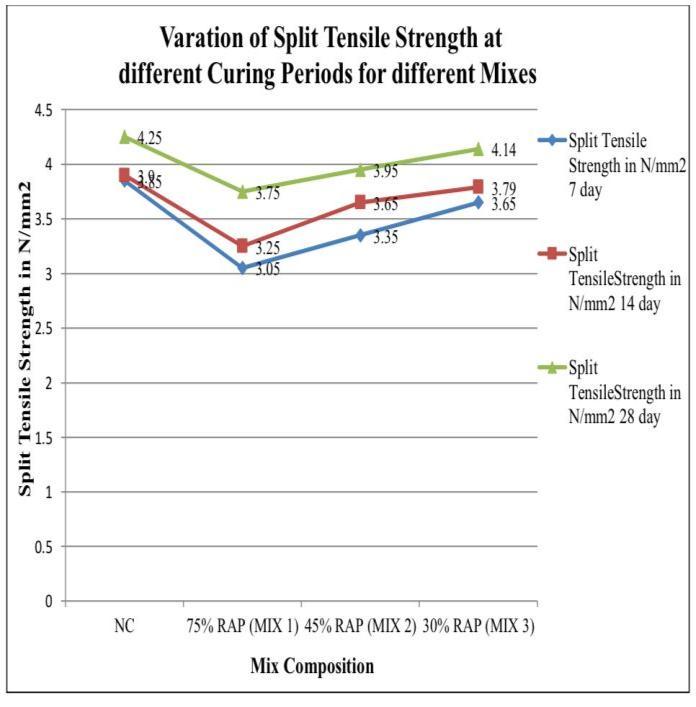

5.3 Split Tensile Strength Test

Table-16presentstheresultsofsplittensilestrengthtests conductedaccordingtoIS5816-2004forthevariousmixes after7-days,14-days,and28-daysofcuring.

5.3.1 Discussion on Split Tensile Strength Results

Not much has been studied on the effect of RAP on split tensilestrengthRAPdifferentmixes;itisnotedinthereport that split tensile strength decreases as RAP content increases.IncorporatingRAPreducessplittensilestrength regardless of curing age. For instance, replacing 100% natural aggregates with combined RAP reduced the split tensile strength by about 38%, whereas incorporation of 45%combinedRAPdecreasedthesplittensilestrengthby about 14.57% only, which is why 45% combined RAP (20MM & 10MM) is recommended. Meanwhile, it was noticedonlya4.77%decreaseinthesplittensilestrength, but only 30% of coarse RAP was utilized in this study.

FromthetestresultsofSplitTensilestrength,itisobserved thatNCshowssplittensilestrengthnearertodifferentRAP replacementlevels.Mix3showshigherflexuralstrengthof 4.41N/mm2for28dayscuringperiod,whichisverynearer (97.411% of NC Strength) to strength of Normal Concrete (4.25N/mm2).

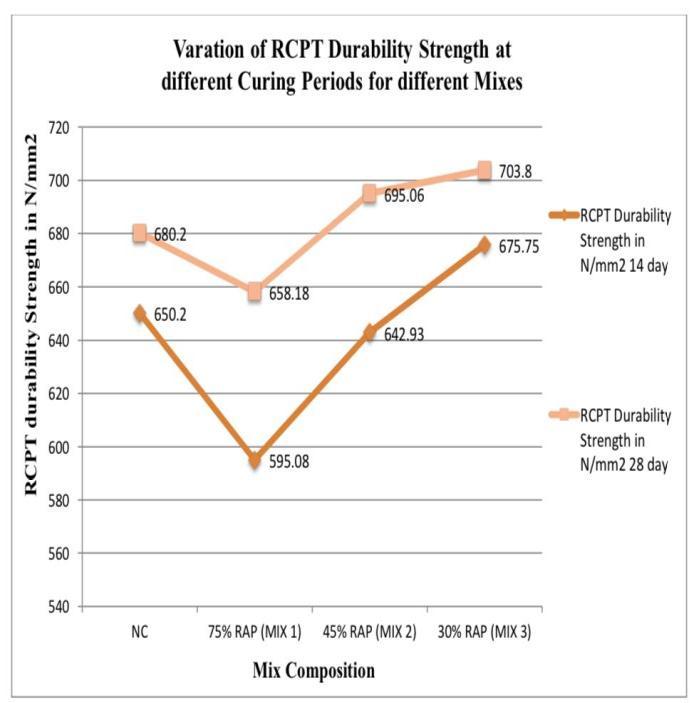

5.4 Rapid Chloride Permeability Test (RCPT)

The Rapid Chloride Permeability Test (RCPT) determines how easily chloride ions can penetrate. Rapid chloride permeabilitytestsRCPT-ASTMC-1202arecommonlyused toassessconcrete'sresistancetochlorideioningresssince theyaresimpleandquick.

5.4.1 Discussion on RCPT (Durability) Strength Results

The results of RCPT tests of all three mixes at different curingperiodsarepresentedin Graph -4. itisseenthatthe RCPTvalueincreasesfor30%RAPmixesascomparedtoNC duetoriseinMicro-silicacontentsupto3.46%forallthe curingperiods.AthigherlevelsofMicro-silicaabove3.46% asareplacementforOPC-53Grade,thevaluesarefoundto increase.Theinitialimprovementinresistancetochloride ion penetration is credited to the mix’s densification as a resultoftheadditionoffinerSilicafumeparticlesthanOPC particles to fill in voids. Further, with an increased curing periodtheRCPTvaluesarefoundtoincreaseinRAPmixes for28daysascomparedtonormalmix.

6. CONCLUSION AND RECOMMENDATIONS

6.1 Conclusion

From the experiments, and based on the results, and the analysisofthisstudy,thefollowingconclusionsweremade:

• Workability of concrete containing RAP aggregate is significantly decreased because of high porosity and low densityofRAPaggregaterequiresalargeamountofwaterto achievetherequiredslump.

• Irrespective of the curing period of RAP aggregate concrete, an increase in the percentage of RAP aggregate diminishes compressive, tensile and flexural strength. However,additionofsilicafumeenhancestheperformance ofRAPaggregateconcrete.

• When compressive strength analysis of RAP inclusive concretehasbeenmade,itwasdeterminedthatthestrength of the specimens decreases with an increment in the RAP aggregates this was due to the weak bond between the asphaltfilmaroundtheRAPaggregateandthecementpaste. Butasasolutiontothis,treatedRAPaggregateswhichare freefromdirthasabetterperformance.Replacementof30% RAP (Mix-3) gives maximum compressive strength comparativelythanotherreplacementpercentages(About 96.71%ofNCStrength).

•The flexure and split tensile strengths of the concrete specimensusingRAPaggregatesfollowedthesamepattern as the compressive strength, and they both increased in accordance with it. But it was assessed that due to the presenceoftheasphaltfilmaroundtheRAPaggregates,the load absorption of the concrete specimens increased in comparisonwiththeconcretemadeofnaturalaggregates. This resulted from the concrete's elastic modulus being decreased while its RAP content was increased. In comparison to the RAP-replaced mixes, the reference mix exhibitsgreatermaximumflexuralstrength.ButtheMix-3, i.e.StrengthiscomingextremelyclosetothatofNCwitha 30%RAPreplacement.

Because RAP has a higher permeability than regular concrete,usingitincreasestheriskofreinforcingcorrosion. Thiswasbroughtonbythegradationandfinenessmodulus of the RAP aggregates. When using RAP aggregates, this issue can be resolved by using silica fume to increase the permeabilityoftheconcrete.

• When recycled aggregate is used in place of natural aggregatewith3.50%silicafume,theresultsarecomparable tocontrolmix.

•Thefollowingargumentsaremadeinfavouroftheusageof RAPMix:

A. Flexible pavement that is simple to remove; use of its material in the construction of concrete pavement. As a result,thepriceoftransportationandnaturalaggregatesis decreased.

B. Using RAP aggregate also lessens the need for natural courseaggregate,whichisincreasingduetotheconstruction ofnewroads.

C.Removingnaturalmaterialfromaquarrycontributesto reducingpollutionandenvironmentalimbalances.

6.2 Recommendations

Recycled Asphalt Pavement (RAP) concrete is sustainable technology, and it is helpful and useful to be used in construction sites, that regarding to it is advantages and benefits,asitislesscostly,andreducetheusageofnatural

aggregate recourses. Some of the recommendations have beenrecordedinthefollowinglines:

1. Propertechniquesshouldbeusedforobtaining, stockpiling,andprocessingRAPtomaintainits quality. In the case of high RAP mixtures, fractionation of the RAP material may be necessary

2. To try different lower partial replacement percentages of RAP as coarse aggregate in concretetocompareitsresultswiththeresults ofthisstudy.

3. To try partial replacement of RAP as fine aggregateinconcrete.

4. It is also recommended not to use concrete containingRAPaggregateinconstructionsite, thatbecausetheloweststrengththathavebeen recorded. And use it for non-structural applications.Suchaswalkwaysorplaygrounds.

REFERENCES

[1]. G. Nataraj, ‘‘Union Budget 2017’s impetus to infrastructuremaynotbeenoughtorevivesector,”Financ. Express,2017.

[2]. A. Copeland, ‘‘Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice,” vol. Technical, no. No. FHWA-HRT-11-021,2011.

[3]. X. Shi, A. Mukhopadhyay, K.-W. Liu, Mix design formulation and evaluation of portland cement concrete paving mixtures containing reclaimed asphalt pavement, Constr.Build.Mater.152(2017)756–768.

[4]. S.K.Shafi,M.A.M.M.,Shakeel,M.A.A.,andPai,‘‘Lifecycle cost analysis of road pavements in rural area,” Int. J. Sci. Technol.Manag.,vol.5,no.8,pp.260–267,2016.

[5]. S. Singh, G. D. R. N. Ransinchung, and P. Kumar, ‘‘Feasibility study of RAP aggregates in cement concrete pavements,”RoadMater.PavementDes.,vol.20,no.1,pp. 151–170,2019.

[6]. I.K. Pateriya, Strength Performance of Pond Ash Concrete,Int.J.EarthSci.Eng.5(1)(2012)180–185.

[7]. Shiran Jayakody, Chaminda Gallage, Arun Kumar, Assessmentofrecycledconcreteaggregatesasapavement material,Geomech.Eng.6(3)(2014)235–248.

[8].G.D.Ransinchung,R.N.BrindKumar,Investigationson PastesandMortarsofOrdinaryPortlandCementAdmixed

withWollastoniteandMicrosilica,J.Mater.Civ.Eng.22(4) (2010)305–313.

[9]. X. Shi, A. Mukhopadhyay, D. Zollinger, Long-Term PerformanceEvaluationofConcretePavementsContaining RecycledConcreteAggregateinOklahoma,Transp.Res.Rec. J.Transp.Res.Board(2019)0361.

[10].SolomonDebbarma,G.D.RansinchungR.N.,Surender Singh, Feasibility of roller compacted concrete pavement containingdifferentfractionsofreclaimedasphaltpavement, Constr.Build.Mater.199(2019)508–525.

[11]. Xijun Shi, Anol Mukhopadhyay, Dan Zollinger, Sustainability assessment for portland cement concrete pavement containing reclaimed asphalt pavement aggregates,J.CleanerProd.192(2018)569–581.

[12].K.E.Hassan,J.J.BrooksandM.Erdman.―Theuseof reclaimedasphaltpavement(RAP)aggregatesinconcrete.‖ WasteManagementSeriesVolume1,2000,Pages121-128.

[13].NabilHossiney,MangTia,MichaelJBergin.―Concrete Containing RAP for Use in Concrete Pavement.‖ InternationalJournalofPavementResearchandTechnology, Volume3,IssueNumber5.

[14]. B. Huang, X. Shu and E. G. Burdette ―Mechanical properties of concrete containing recycled asphalt pavements.‖MagazineofConcreteResearch,2006,58,No.5, June,313–32.

BIOGRAPHIES

Ranjeet T. Bhosale (MECivilStructural Engineering, B-Tech Civil Engineering, DiplomaCivilEngineering)

B. Manjula Devi (Ph.D Civil, M.E. Civil Engineering,B.ECivilEngineering)